Counting and stamping device for metal plates

A punching device and sheet metal technology, applied in the field of mechanical processing equipment, can solve the problems of low equipment cost and low efficiency, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

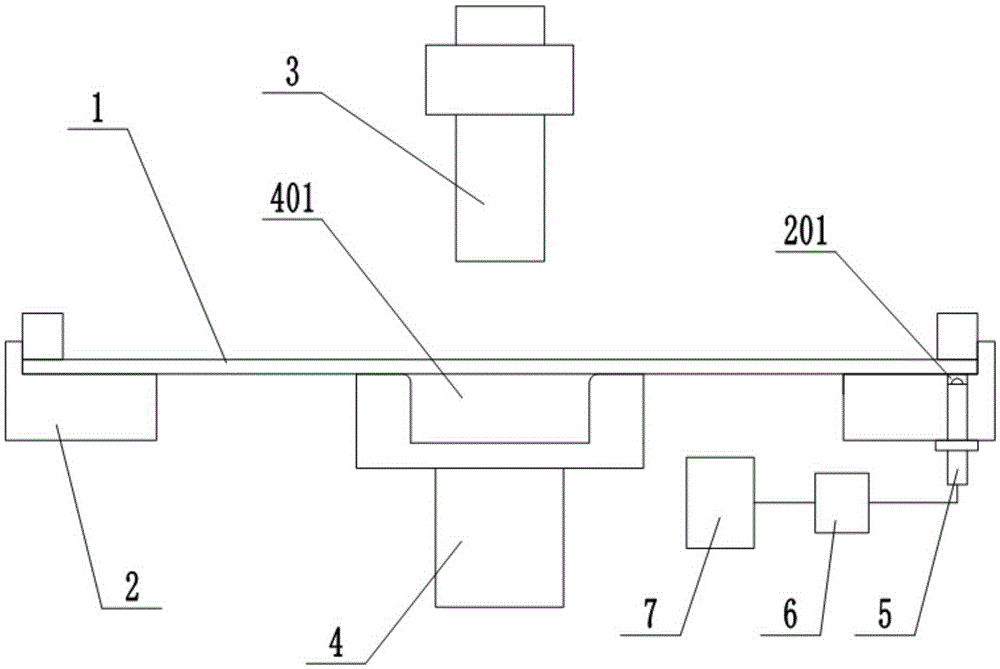

[0011] Such as figure 1 As shown, in the sheet metal counting stamping device of this embodiment, the sheet metal part 1 is installed horizontally on the stamping support base 2, the stamping head 3 is placed above it, and the stamping die 4 is installed below it. The stamping die 4 has a stamping cavity 401, the stamping support base 2 has a through installation hole 201, and a photoelectric sensor switch 5 is installed in the installation hole 201, and the photoelectric sensor switch 5 is connected with the counter 7 through the signal processor 6.

[0012] The present invention uses the photoelectric sensor switch 5 to detect the processed sheet metal parts 1, and the detection signal is processed by the signal processor 6 and then sent to the counter 7 for counting, without the need for manual counting in the later stage, thereby improvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com