Friction electric sensing coupled mine shaft harmful gas passive detection apparatus

A harmful gas and passive detection technology, which is applied in the field of gas sensing, can solve problems such as inconvenience, safety, and hidden dangers, and achieve the effects of easy installation, energy and cost savings, and avoiding cable laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

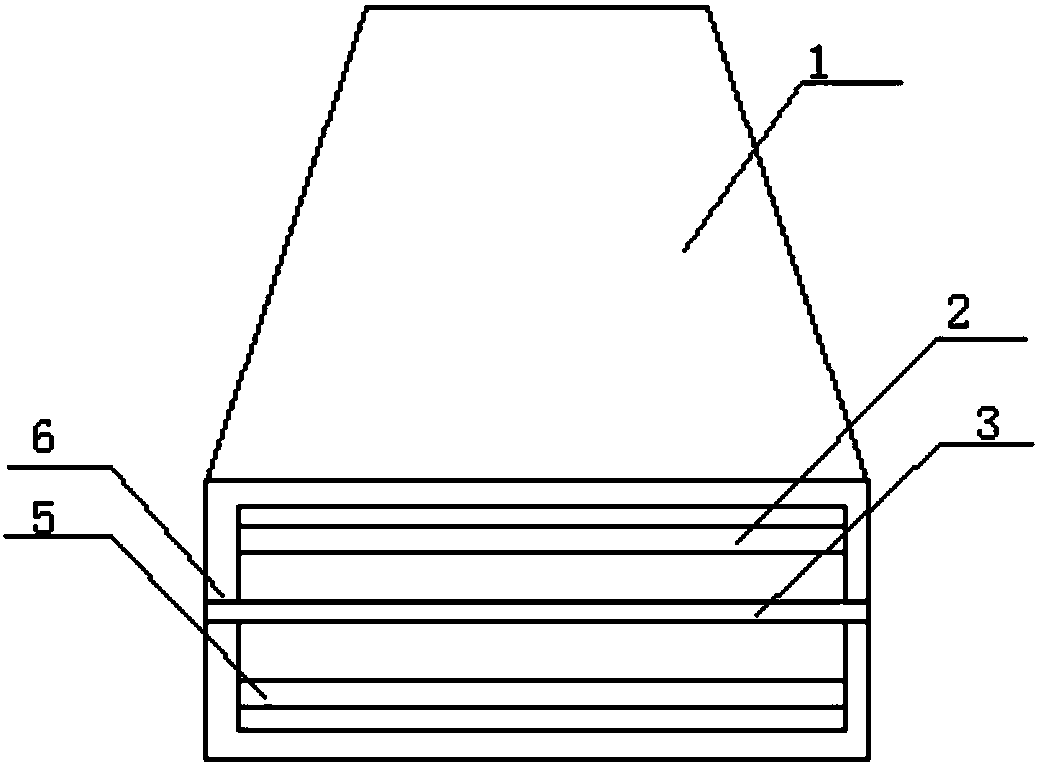

[0037] The material of the fixed plate is copper; the material of the vibrating film is polytetrafluoroethylene, and the thickness is 50 μm; the surface of the negative friction layer is nano-treated, and the treatment method is manual sanding; the conductive polymer can be polyaniline eigenstate; the shell adopts 3D printing technology or stamping injection molding technology.

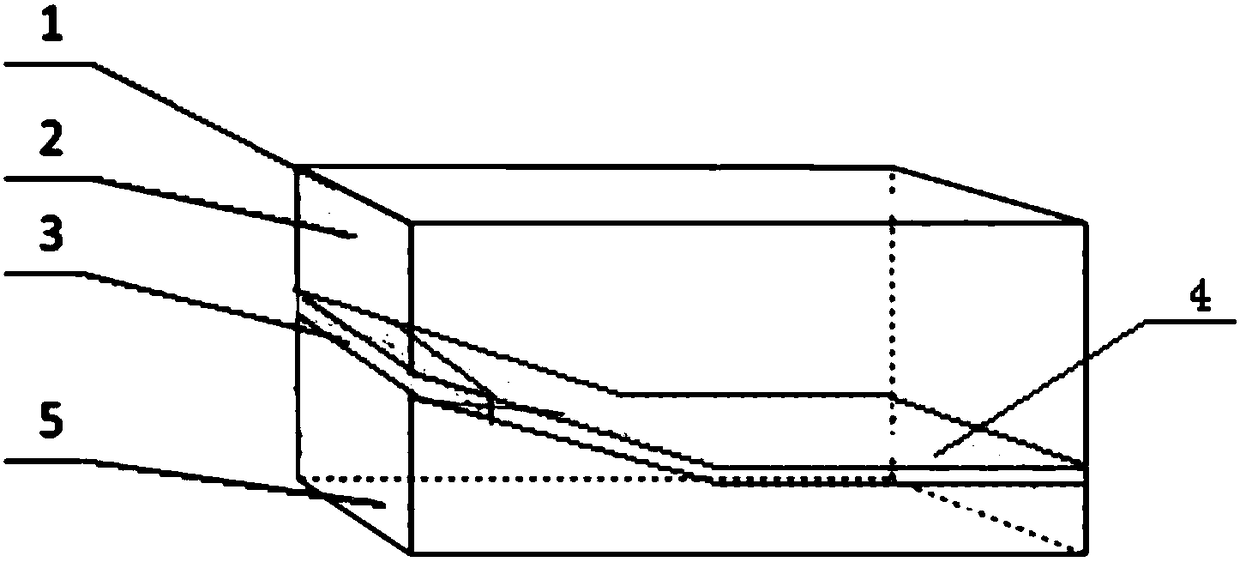

[0038] Figure 5 It is the working comparison diagram of the triboelectric sensor coupling type mine harmful gas passive detection device in the air flow and the harmful gas flow in the embodiment 1, as shown in the figure, the polyaniline film is a kind of high conductivity polyaniline, in which The polymer chain is doped with protonic acid, and when the harmful gas comes into contact with polyaniline, the -H bond or -OH bond in it will react with the N atom in the polyaniline chain to prevent the rearrangement of molecular conformation and prevent Charge transport and electron migration in the mole...

Embodiment 2

[0041] The material of the fixed plate is iron; the material of the vibrating film is polyethylene, and the thickness is 50 μm; the surface of the negative friction layer is nano-treated, and the treatment method is inductively coupled plasma etching; the conductive polymer can be polypyrrole, and the chemical state is oxidation state; the shell is made by 3D printing technology or stamping and injection molding technology.

Embodiment 3

[0043] The material of the fixed plate is nickel; the material of the vibrating film is polyvinyl chloride, the thickness is 50 μm; the surface of the negative friction layer is nano-treated, and the treatment method is manual sandpaper polishing; the conductive polymer can be polyacetylene, and the chemical state is the intrinsic state ;The shell is made by 3D printing technology or stamping injection molding technology.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com