Magnetic-electric sensing transducer

A transducer and sensing technology, applied in the field of piezoelectric devices, to achieve the effects of convenient fabrication, simple structure and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

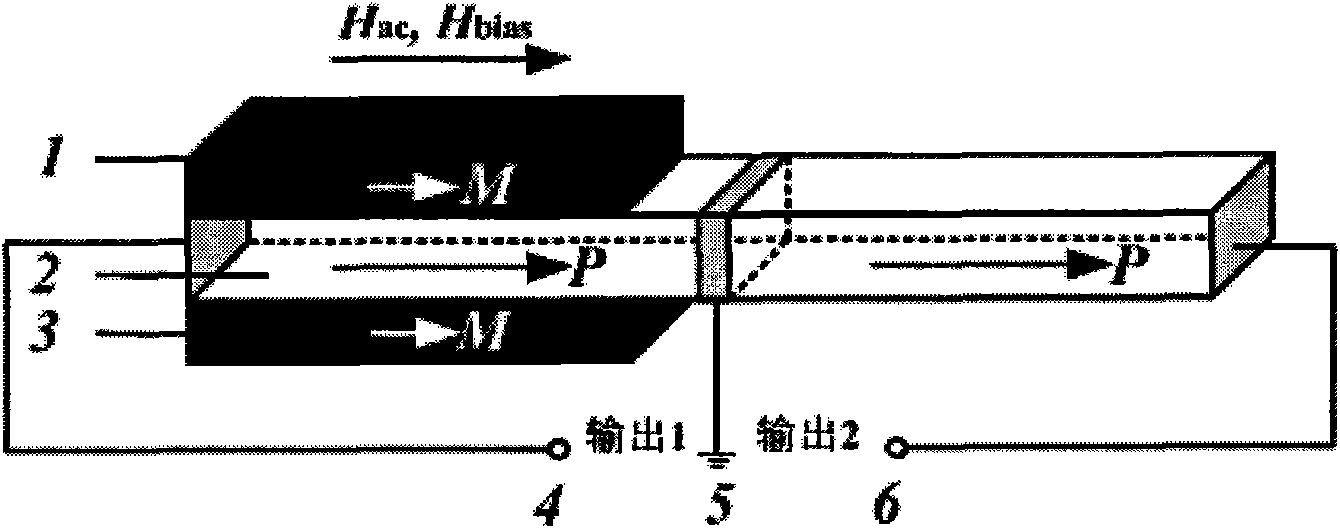

[0026] The structure of the magnetoelectric sensing transducer is as follows: figure 1 As shown, the improved Bridgman (Bridgeman) method is used to grow PMN-PT (lead magnesium niobate-lead titanate) single crystal with a composition of 0.28 direction. Electric material 2. Magnetostrictive material 1 and magnetostrictive material 3 are made of Terfenol-D (terbium dysprosium iron) alloy. The size of PMN-PT (lead magnesium niobate-lead titanate) is 16×2×2mm 3 , the size of Terfenol-D (terbium dysprosium iron) is 6×2×2mm 3 . Lead electrodes 4, 5 and 6 from 2. Non-conductive epoxy glue is used for bonding between 1, 2 and 3, so that the upper and lower layers of magnetostrictive materials and piezoelectric materials are well insulated and mechanically coupled.

Embodiment 2

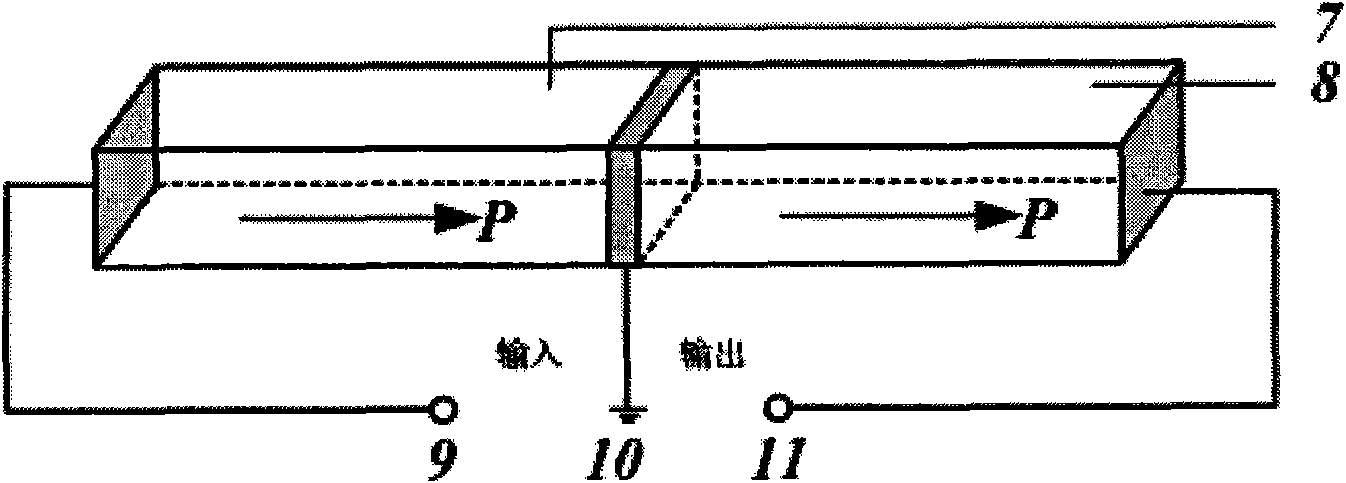

[0028] Make piezoelectric materials with amplification function, such as figure 2 As shown: the left half is the driving part 7, and the right half is the output part 8, both of which are polarized along the length direction, such as figure 2 As shown by the middle arrow, the electrode positions are shown in Figures 9, 10 and 11, the electrodes 9 and 11 are full electrodes, and the width of the electrode 10 is 1mm.

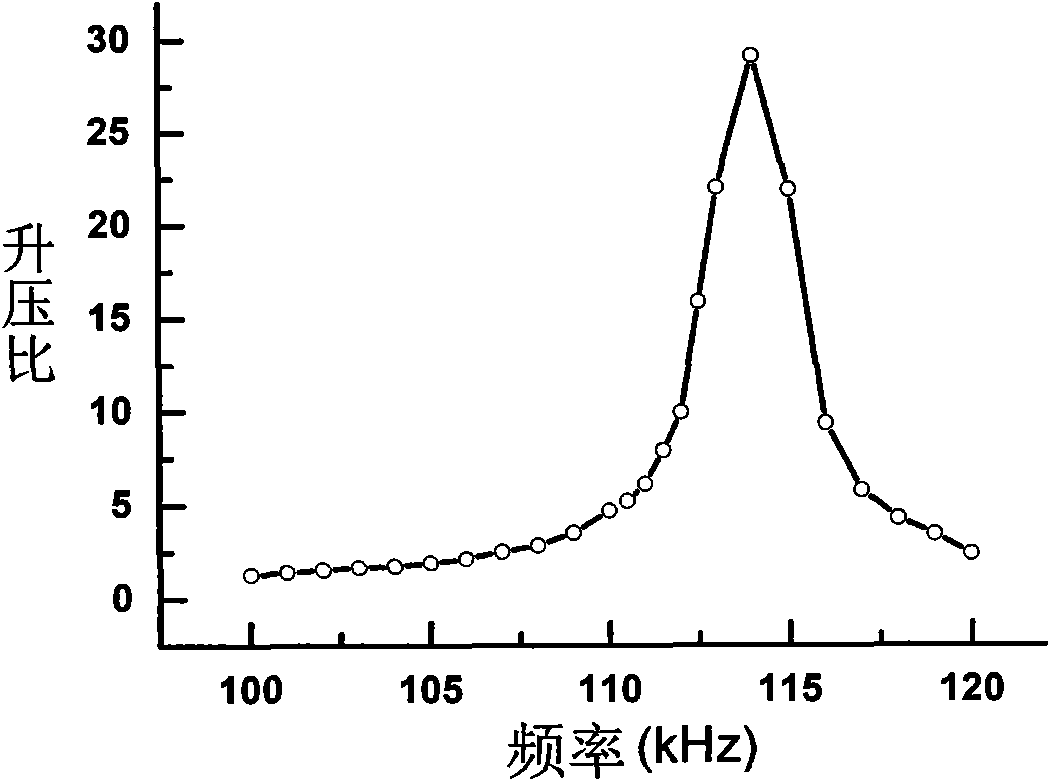

[0029] When testing the boost ratio curve of the piezoelectric material with amplification function, the signal generator is connected to the input terminal 9 and the ground terminal 10 , and the oscilloscope is connected to the output terminal 11 and the ground terminal 10 . Test results such as image 3 As shown, at about 115kHz, the step-up ratio can reach 30 times.

Embodiment 3

[0031] Test magnetoelectric coefficient:

[0032] In order to effectively transmit the strain energy of the magnetostrictive material to the piezoelectric material, Terfenol-D (terbium dysprosium iron) with a similar length is selected to stick to the piezoelectric material 2, and the size of Terfenol-D (terbium dysprosium iron) is 6 ×2×2mm 3 . After combining 1, 2 and 3 of Example 1, test its magnetoelectric coefficient, the input magnetic field amplitude is 1Oe, and the frequency range is 1-175kHz. The results show that under the best bias magnetic field of 800Oe, the input part , in the range of 1-50kHz, with stable voltage signal output, magnetoelectric coefficient α V Up to 315mV / Oe; in the resonant state, after the signal is amplified, the magnetoelectric coefficient α in the output part V Up to 7.86V / Oe.

[0033] The magnetoelectric sensing transducing device of the present invention can provide multi-terminal output. For the input end, it has a flat frequency respo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com