Distortionless sound playback system for counter electromotive force signals

A back electromotive force, distortion-free technology, applied in the direction of electrical components, transducer circuits, sensors, etc., can solve problems such as blindness and failure to meet expectations, and achieve the effect of no distortion of sound, wide frequency response, and distortion elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

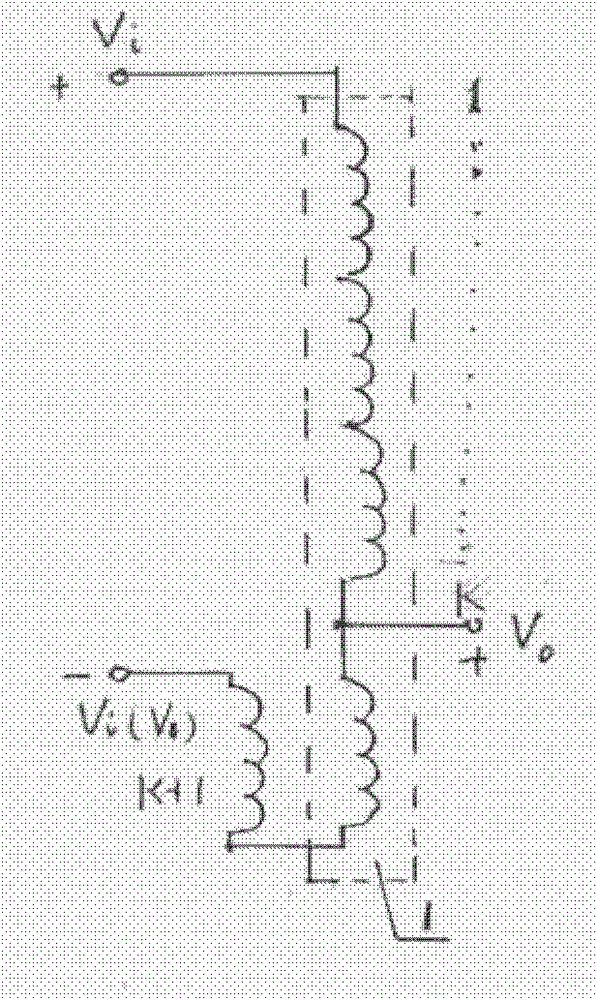

[0027] refer to figure 2 , regard the speaker voice coil as (K+1) segments with the same effective length, starting from the hot end of the voice coil (end with the same name) as the first segment, until K-1, K, K+1 segment and then to the cold end of the voice coil (not the end of the same name) ends. A tap is drawn between the K-1 section and the K section as the output terminal. For conventional loudspeakers, the output terminal (between the cold terminal of the voice coil) should get Uo=2E+2I(ZL+R), where E, ZL, R are the parameters of a coil, and I is the voice coil current.

[0028] The counter electromotive force signal speaker makes two changes: firstly, the K+1 section is separated from the moving voice coil, and placed in the magnetically conductive soft iron in the speaker, that is to say, the K+1 section does not participate in the movement of the voice coil. Uo=E+2I(Z L +R), minus one E. Then reverse it again, according to the self-inductance principle K, IZ ...

Embodiment 2

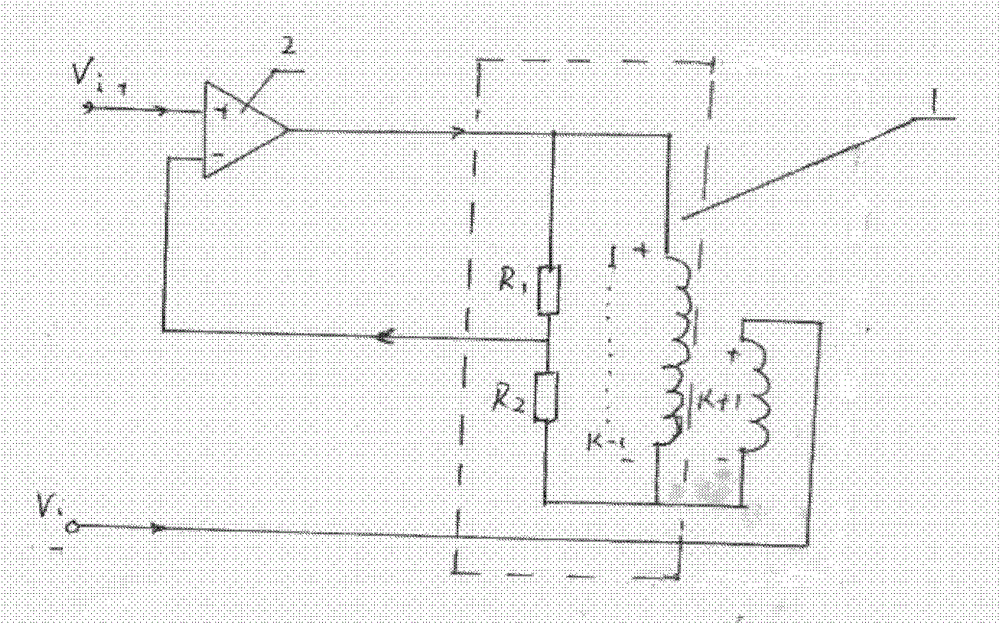

[0030] refer to image 3 , use two resistors R1, R2 to make the total Uo value as a partial pressure of K / 1 to replace the movable K section in the first embodiment to obtain Uo=E+I(Z L +R), and after canceling the K section in the voice coil, the K-1, K+1 sections are connected and the tap is taken out, and the negative I(Z L +R), and then E+I(Z L +R) mixed and added, just offset I(Z L +R) item, the remaining counter electromotive force E signal is output to the counter electromotive force signal amplifier. This method is simpler than the first embodiment, but the disadvantage is that the adjustment of the voltage dividing resistor needs to be precise.

Embodiment 3

[0032] refer to Figure 4, the speaker voice coil is divided into two groups in parallel (actual speaker voice coils are often double-wired in parallel), the two groups are from the first segment to the K segment, the two groups of winding directions are exactly the same, each group K-1 , the output lines are drawn between the two sections of K. For conventional speakers, the voltage values of the two output lines (between the cold end of the voice coil) are obtained: Uo=E+I(Z L +R).

[0033] Only one change is made to the back EMF signal speaker: the K segment of one group is changed to be fixed in the magnetically conductive soft iron inside the speaker, and does not participate in the movement of the voice coil. At this time, the voltages obtained on the two sets of output lines are respectively U1=E+I(Z L +R) and U2=I(Z L +R), at this time, U1 and U2 are sent to the back electromotive force signal amplifier to subtract them to obtain the back electromotive force E sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com