Piezoelectric intelligent torsional control lever

A control rod and piezoelectric technology, applied in the direction of rotation vibration suppression, electrical components, manufacturing tools, etc., can solve the problems of large volume, complex drive structure, general control characteristics, etc., and meet the requirements of fast response, high precision vibration suppression, structure simple compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

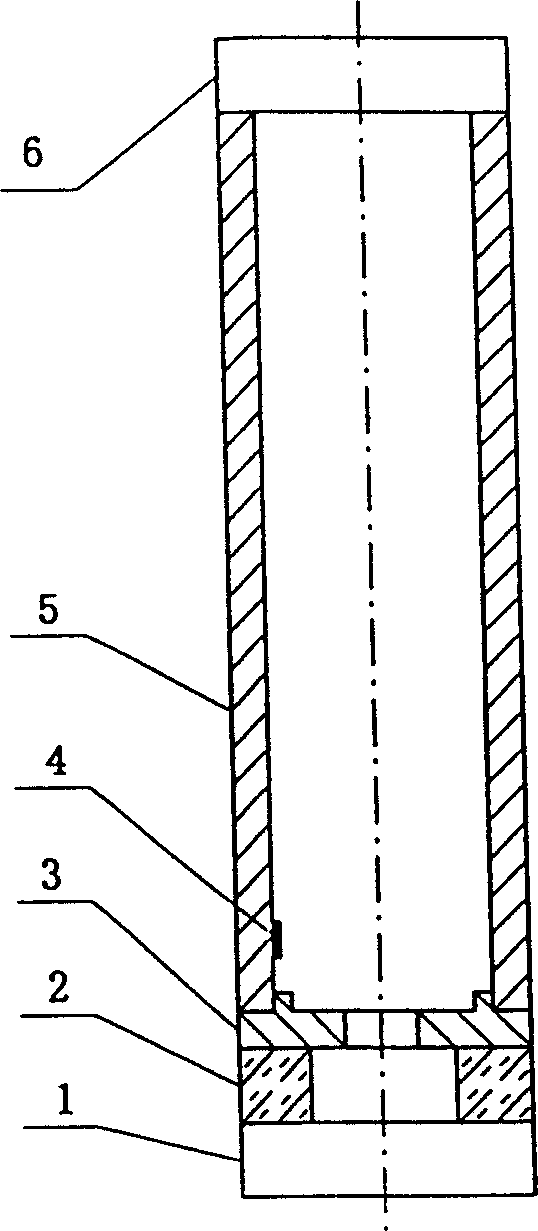

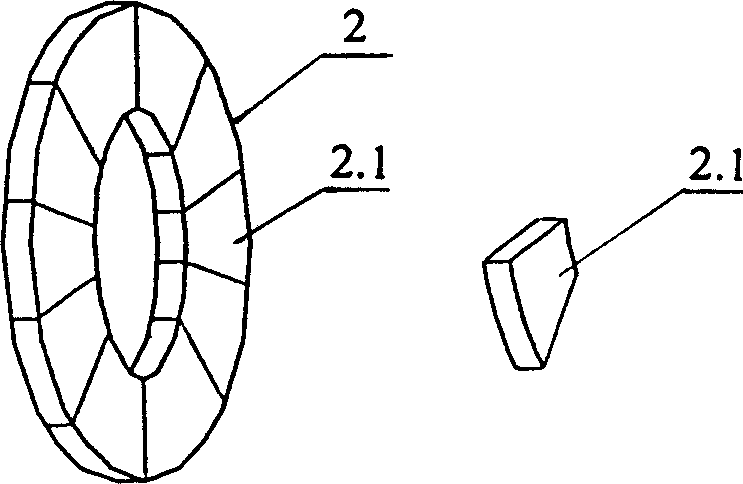

[0019] Such as figure 1 As shown, it includes: a hollow round rod 5, a sensor 4, three connecting blocks 3, 1, 6, and an annular piezoelectric torsion driver 2; the lower end of the hollow round rod 5 is sequentially equipped with the first connecting block 3, Annular piezoelectric torsion driver 2, second connection block 1, a third connection block 6 is installed on the upper end of the hollow round rod 5, and a third connection block 6 is installed on the inner or outer surface of the hollow round rod 5 at one end of the annular piezoelectric torsion driver 2. sensor4.

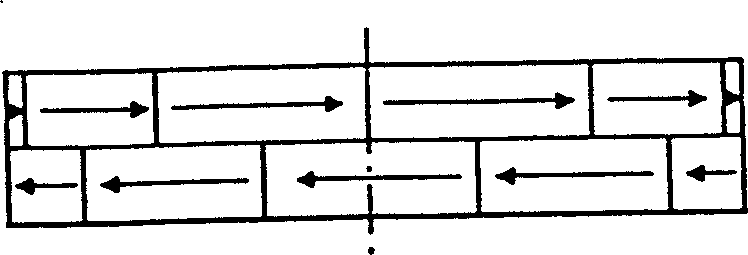

[0020] The present invention adopts the thickness shear vibration polarization mode, that is, the electromechanical coupling coefficient is K 15 (Piezoelectric constant d 15 ) piezoelectric material as a driver, a torsional vibration suppression smart rod with self-sensing and self-control is designed. Such as figure 1 As shown, the annular piezoelectric torsion driver 2 and the hollow round rod 5 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com