Cable force detecting method and cable force sensor using same

A technology of cable force sensor and detection method, which is applied to force/torque/power measuring instruments, instruments, measuring devices, etc., can solve the problems of complex sensor processing technology, low sensor measurement accuracy, slow sensor response speed, etc., and achieve test Fast speed, improve the signal-to-noise ratio, and eliminate the effect of mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

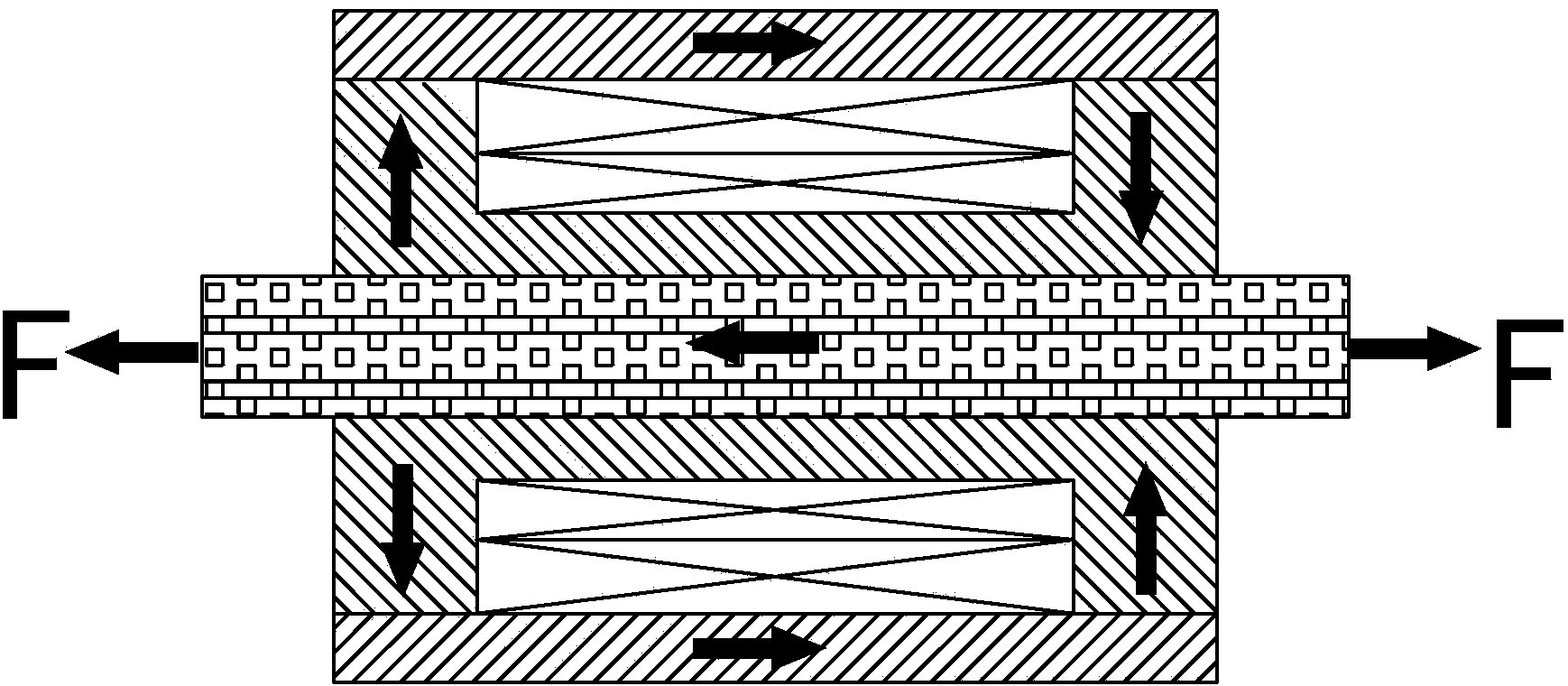

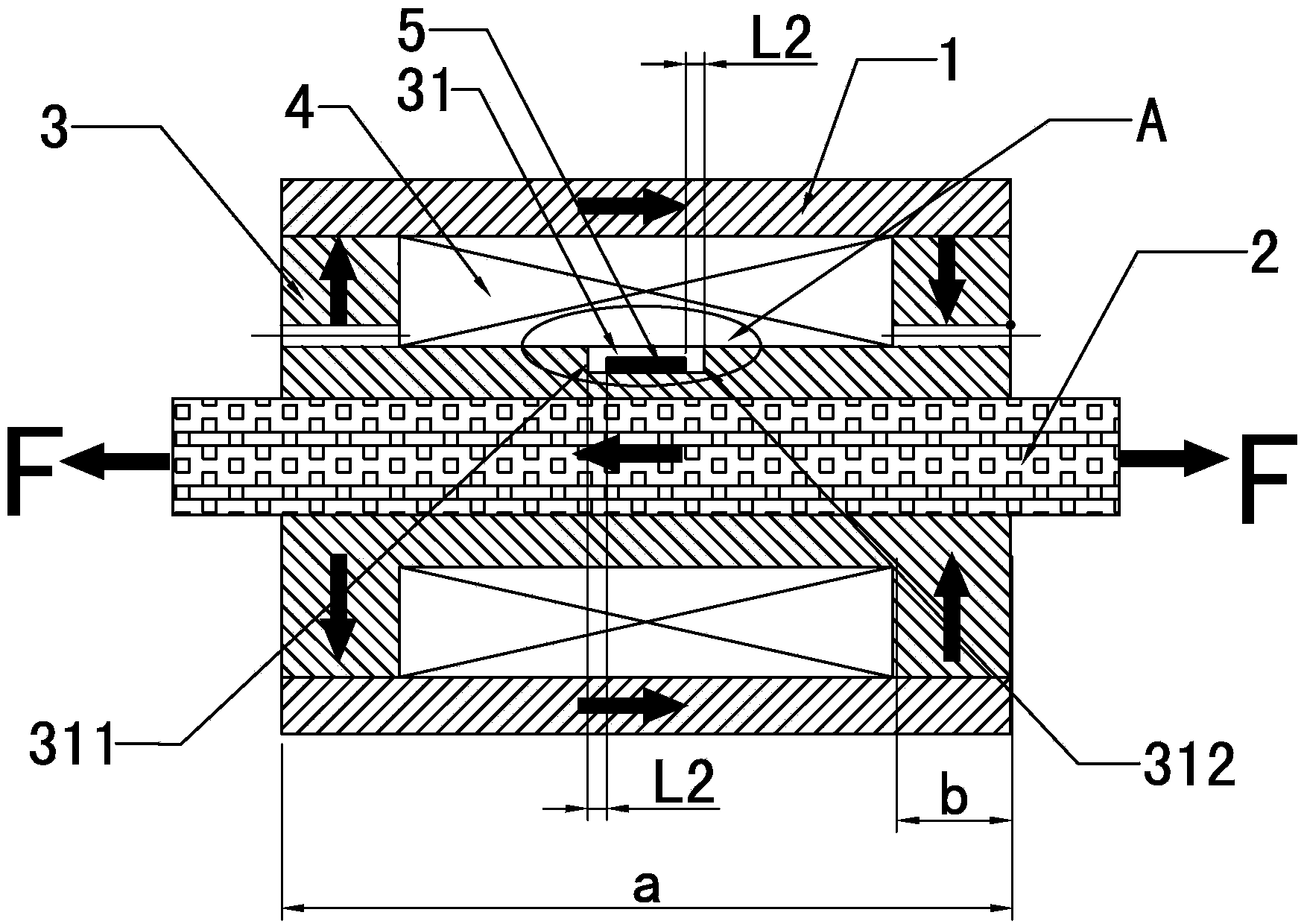

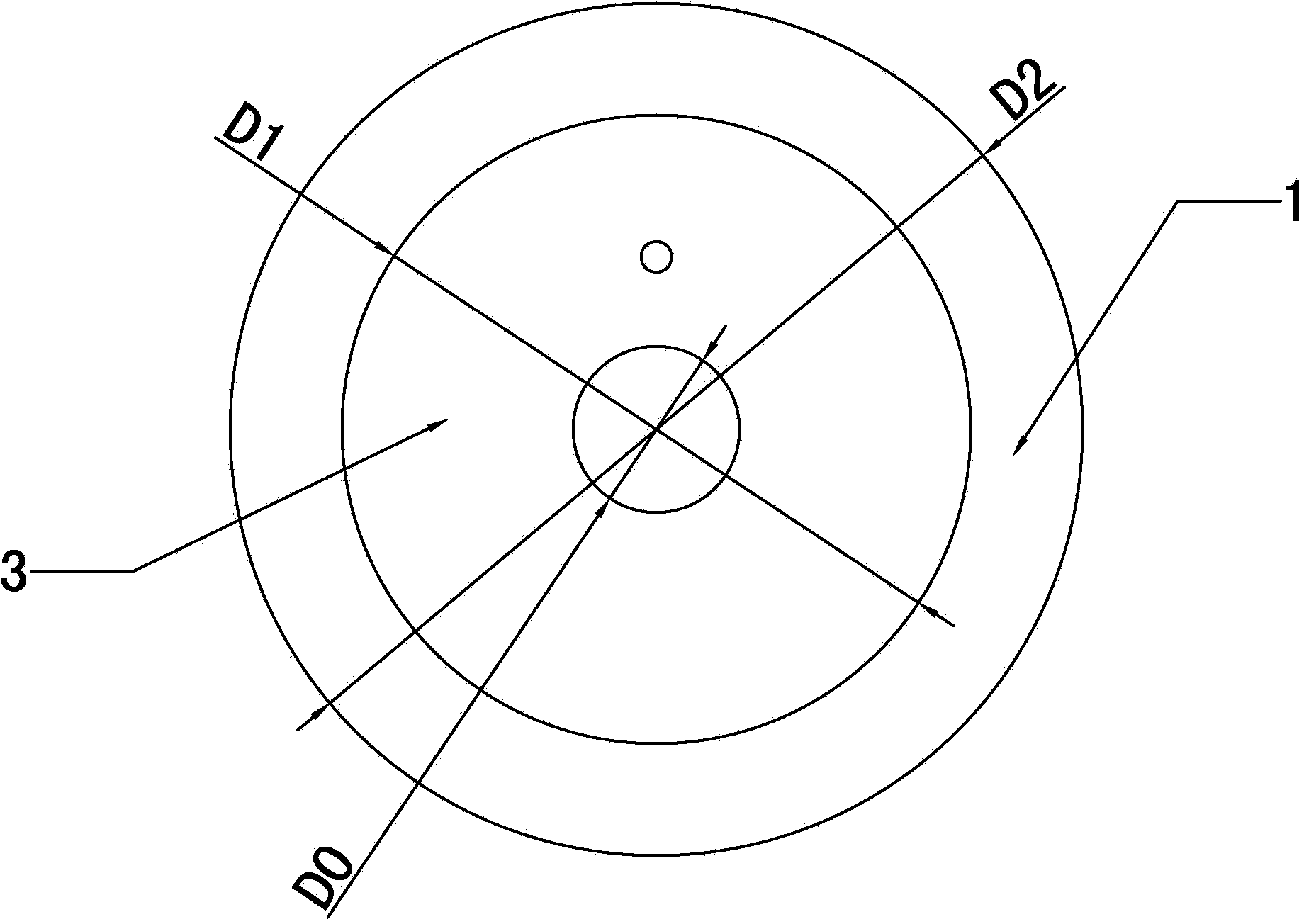

[0067] Embodiment one: if Figure 1~4 As shown, a cable force sensor includes a housing 1, a coil frame 3 sleeved on a steel cable 2, and an excitation coil 4. The excitation coil 4 is formed by winding a copper wire on the outer wall of the coil frame 3. The coil The outer wall of the skeleton 3 is provided with a rectangular groove 31, the rectangular groove 31 is located in the middle of the axial direction F of the coil bobbin 3, and the magnetoelectric sensing unit 5 with magnetostrictive performance is installed in the rectangular groove 31. The sensing unit 5 is a cuboid structure, the magnetization direction of the magnetoelectric sensing unit 5 is parallel to the axial direction of the bobbin 3, the upper end surface of the magnetoelectric sensing unit 5 does not exceed the rectangular groove 31, and the long side of the magnetoelectric sensing unit 5 Parallel to the axial direction of the coil bobbin 3, the two ends 51 and 52 of the magnetoelectric sensing unit 5 alo...

Embodiment 2

[0072] Embodiment 2: This embodiment is basically the same as Embodiment 1, the only difference is that the sum of the volumes of the first magnetostrictive layer 53 and the second magnetostrictive layer 55 in this embodiment accounts for the volume of the first magnetostrictive layer 53, the pressure 76% of the volume sum of the transistor layer 54 and the second magnetostrictive layer 55 .

Embodiment 3

[0073] Embodiment three: as Figure 1~4 As shown, a cable force sensor includes a housing 1, a coil frame 3 and an excitation coil 4 sleeved on a steel cable 2, and the excitation coil 4 is formed by winding a copper wire on the outer wall of the coil frame 3. The coil The outer wall of the skeleton 3 is provided with a rectangular groove 31, the rectangular groove 31 is located in the axial F middle of the coil bobbin 3, and the magnetoelectric sensing unit 5 with magnetostrictive performance is installed in the rectangular groove 31, and the magnetoelectric sensor unit 5 is installed in the rectangular groove 31. The sensing unit 5 is a cuboid structure, the magnetization direction of the magnetoelectric sensing unit 5 is parallel to the axial direction of the bobbin 3, the upper end surface of the magnetoelectric sensing unit 5 does not exceed the rectangular groove 31, and the long side of the magnetoelectric sensing unit 5 Parallel to the axial direction of the coil bobbi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com