Three-axis linkage-based complicated part accurate measurement central path planning realizing method and device

A technology for path planning and complex parts, applied in measuring devices, electrical devices, optical devices, etc., can solve problems such as wear, reduce detection accuracy, and difficulty in tooling processing, and achieve the effect of solving detection errors and simplifying the detection process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

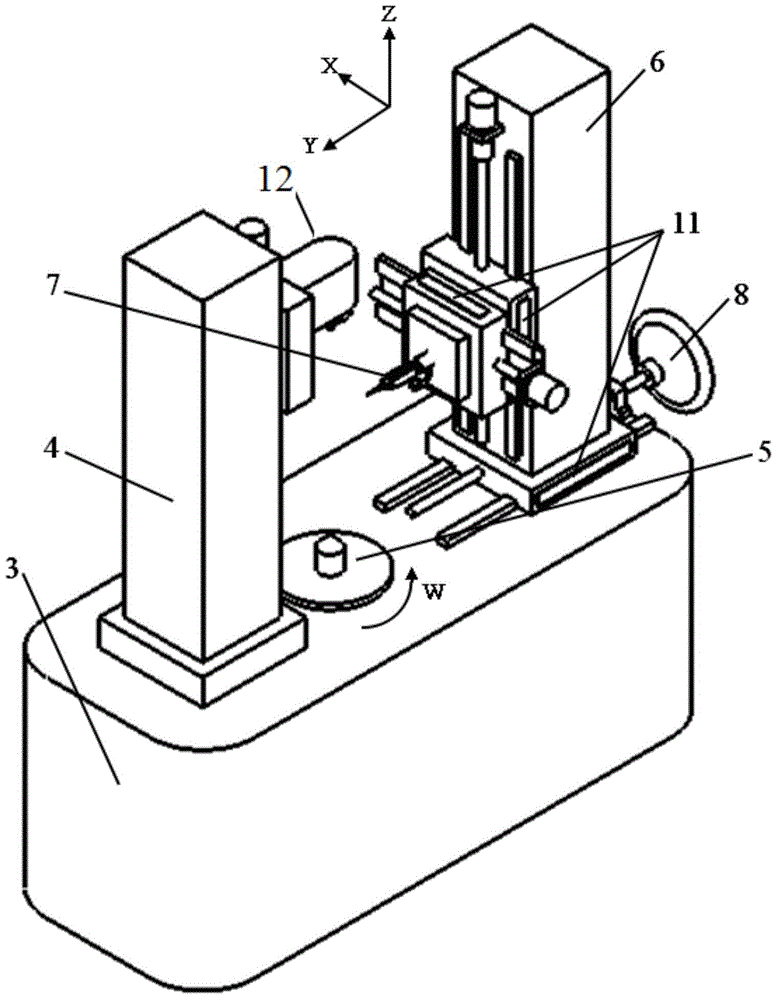

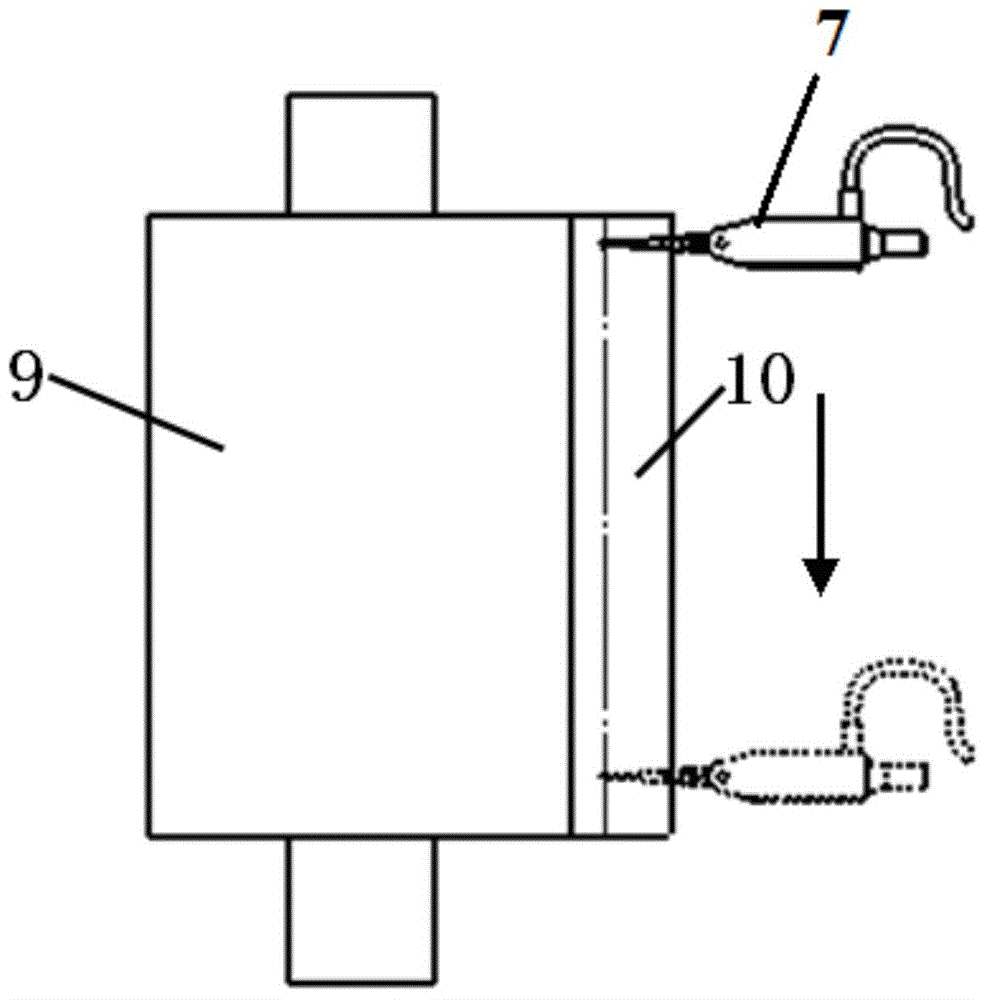

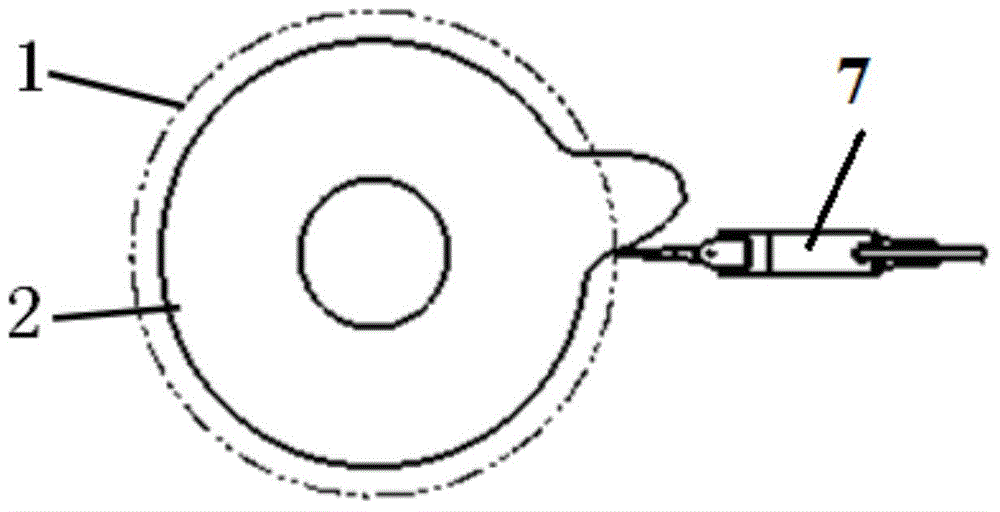

[0063] see figure 1 , a quasi-measurement center path planning implementation device for complex parts based on three-axis linkage, including a manually-controlled measuring column that can move along the Y-axis, and a measuring column that is controlled by a servo drive system and can move along the X, Z axis. The probe that moves in the axial direction also includes a spindle rotary shaft system that can rotate along the W-axis direction. The distance between the probe and the center of the spindle rotation axis system along the Y-axis can be displayed in real time through the computer.

[0064] The device also includes a base, a workpiece column for clamping the workpiece, and a drive control assembly (a computer and three grating rulers 11 corresponding to the X, Y, and Z axes).

[0065] The probe is a TESA inductive probe.

[0066] Taking the non-eccentric gear measurement process as an example, after inputting the parameters of the measured gear into the computer, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com