Patents

Literature

70results about How to "Realize fully automatic measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

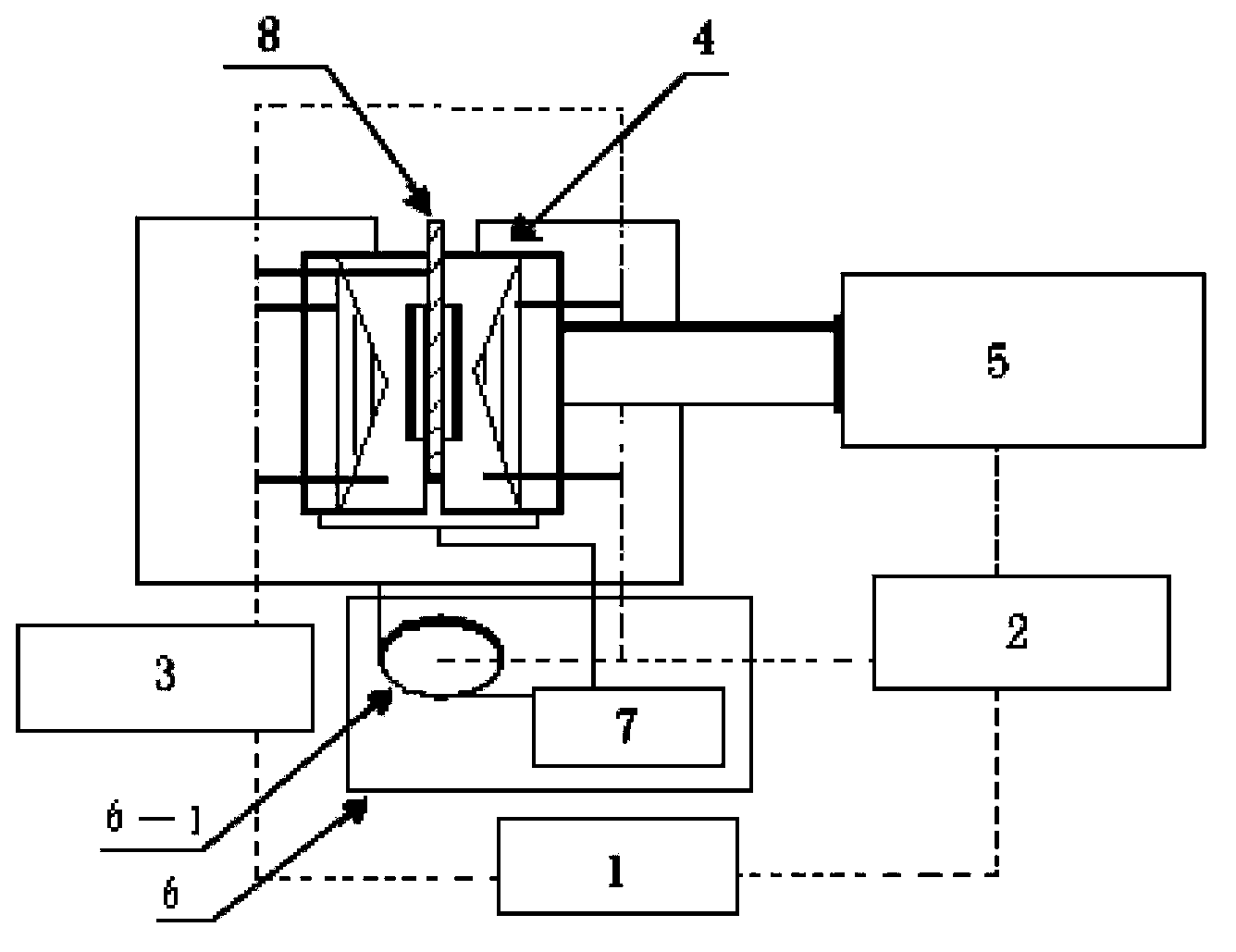

Photoelectric detector amplitude versus frequency character test method for optical fiber peg-top

InactiveCN101126784AAccurate Frequency CharacteristicsAccurately obtain frequency characteristicsSagnac effect gyrometersContactless testingGyroscopePhotodetector

The utility model discloses a method for testing the frequency properties of the photoelectric detector used for fiber optic gyroscopes. A signal generator produces sinusoidal signals and adds the signal to a light intensity modulator to carry out sinusoidal modulation on the optical power of the optical signal from the fiber source in order to produce an optical signal with sinusoidal components. The measured photodetector converts the modulated optical signal into an electrical signal and samples the electric signal by means of high-speed data acquisition card, then conducts narrowband filter and signal processing over the collected samples and calculates the corresponding frequency response. The frequency sequence pre-selected by a numerical control system changes the frequency at which the sine wave generator (NC) system sends out signals , tests a series of frequency point responses, which can be combined into an amplitude frequency response curve of the measured photodetector, and the curve is transmitted to the terminal computer for displaying and storage. By controlling all the test processes by numerical control system, the utility model has the advantages of automatic measurement, fast testing speed, high testing precision, and therefore is suitable for carefully weighing the photodetector frequency performance in the whole operating frequency range.

Owner:ZHEJIANG UNIV

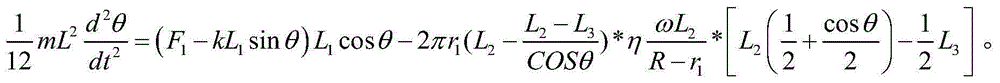

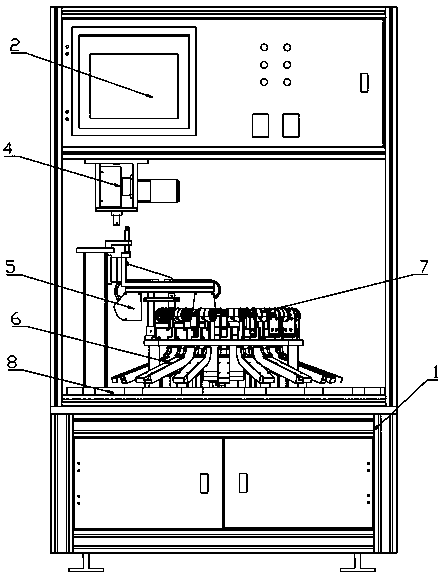

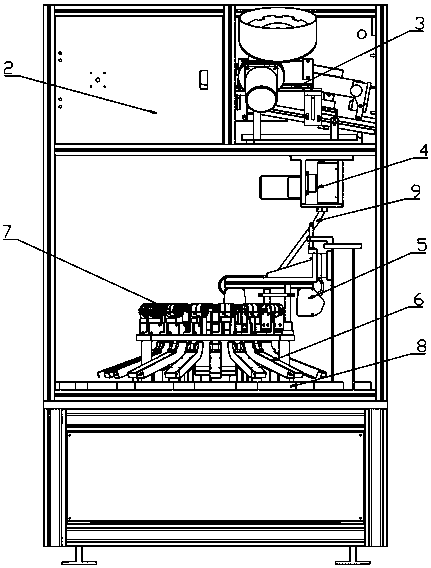

Comparative measurement method-based multi-parameter vision measurement system of inner ring of bearing

InactiveCN102735177AHigh measurement accuracyRealize high-precision measurementConveyorsUsing optical meansImage resolutionEngineering

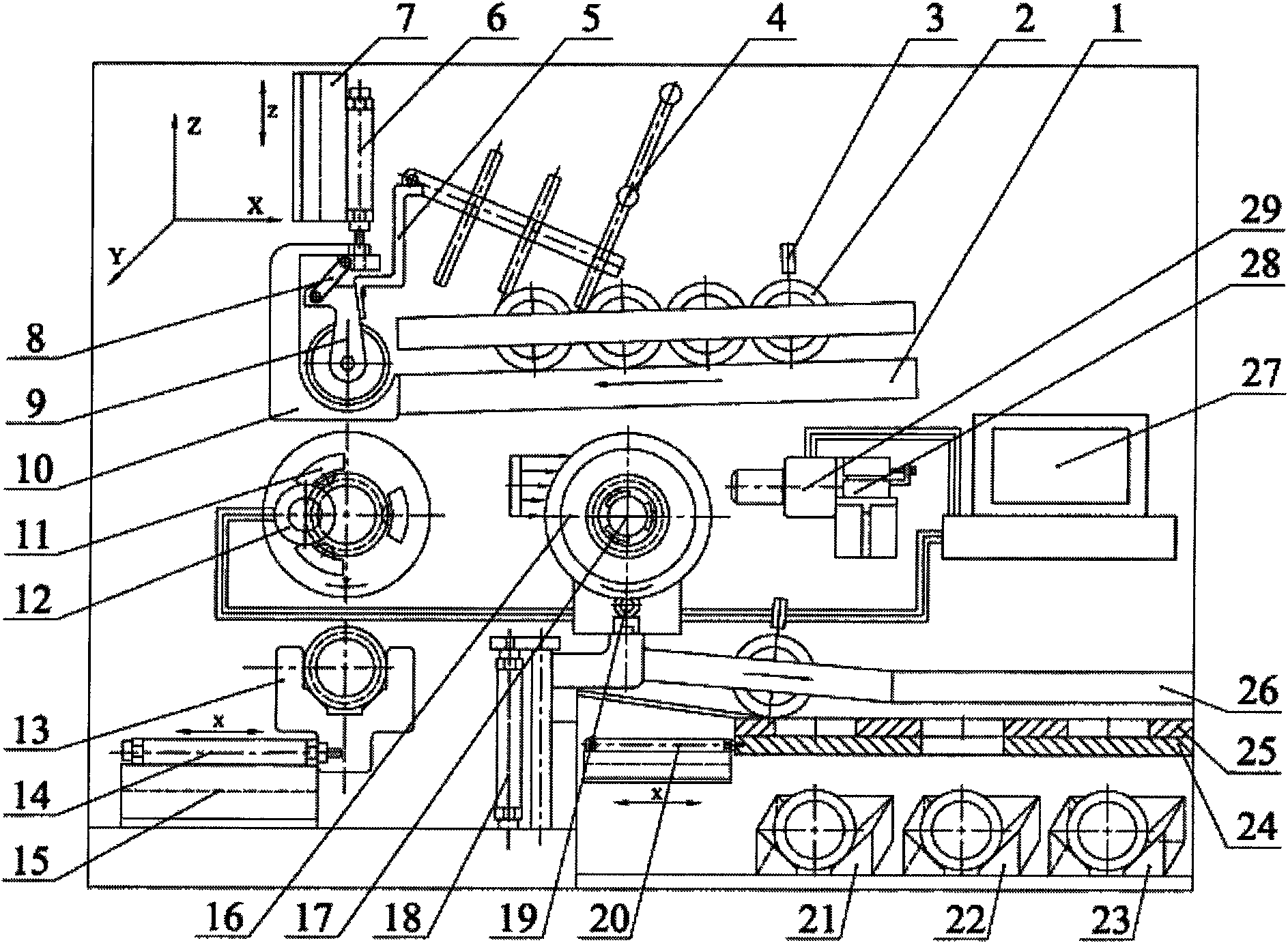

The invention discloses a comparative measurement method-based multi-parameter vision measurement system of an inner ring of a bearing. The multi-parameter vision measurement system comprises a swing-rod barrier feeding mechanism, an axial parameter measurement apparatus, a radial parameter measurement apparatus, a conveying mechanism, a separation mechanism, a PLC control module, an upper computer control module and a man-machine interaction module. According to the measurement system, with utilization of a standard and high-precision inner ring of a bearing as a reference component as well as a camera as a comparative measurement instrument, a measured outer ring of a bearing is compared with the reference component so as to carry out separation of a qualified product, a reprocessed product and a scraped product based on calculation of a localization error of the outer ring of the bearing. Therefore, not only can automatic comparative measurement of the inner hole diameter of the inner ring of the bearing, the outer diameter, the diameter of a groove, a curvature radius of the groove and the width be realized, but also a bottleneck problem that the system cost is too high due to a requirement of a high resolution ratio of a camera during the high precision detection and large-size detection of the inner ring of the bearing can be solved.

Owner:ZHEJIANG UNIV

Full automatic intelligent measuring apparatus for gelatineous layer of mixed coal and measuring method thereof

InactiveCN1963387AImprove the accuracy of measuring displacementReduce pressure measurement errorsFlow propertiesObservational errorMeasurement device

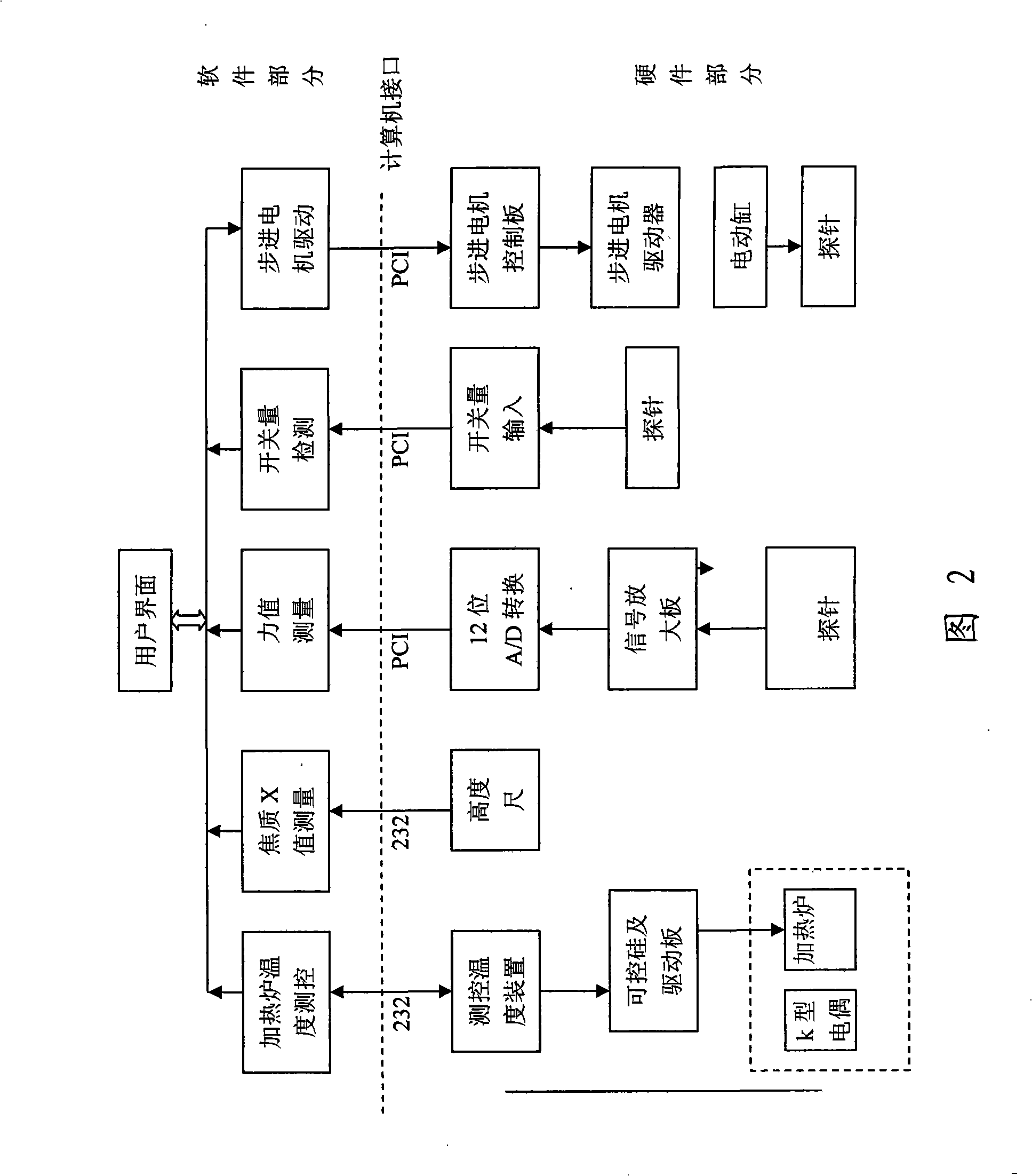

This invention relates to coal glue layer total automatic measurement device, which comprises computer, input and output data card, automatic heating temperature control part, smoke volume measurement, probe upper and down drive structures, probe rotation part and pressure automatic measurement, wherein, its uses volume measurement part to judge coal sample volume at peak or trough and to start probe drive structure for coal layer measurement through line step motor impulse sequence to determine coal layer upper and down layer position then uses OLS to match upper and down list layer change curve to get maximum thickness values.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Alternating current and direct current voltage true virtual value measurement method capable of automatically identifying type of signal

ActiveCN103743944AAvoid enteringVersatileMeasurement using digital techniquesConvertersHemt circuits

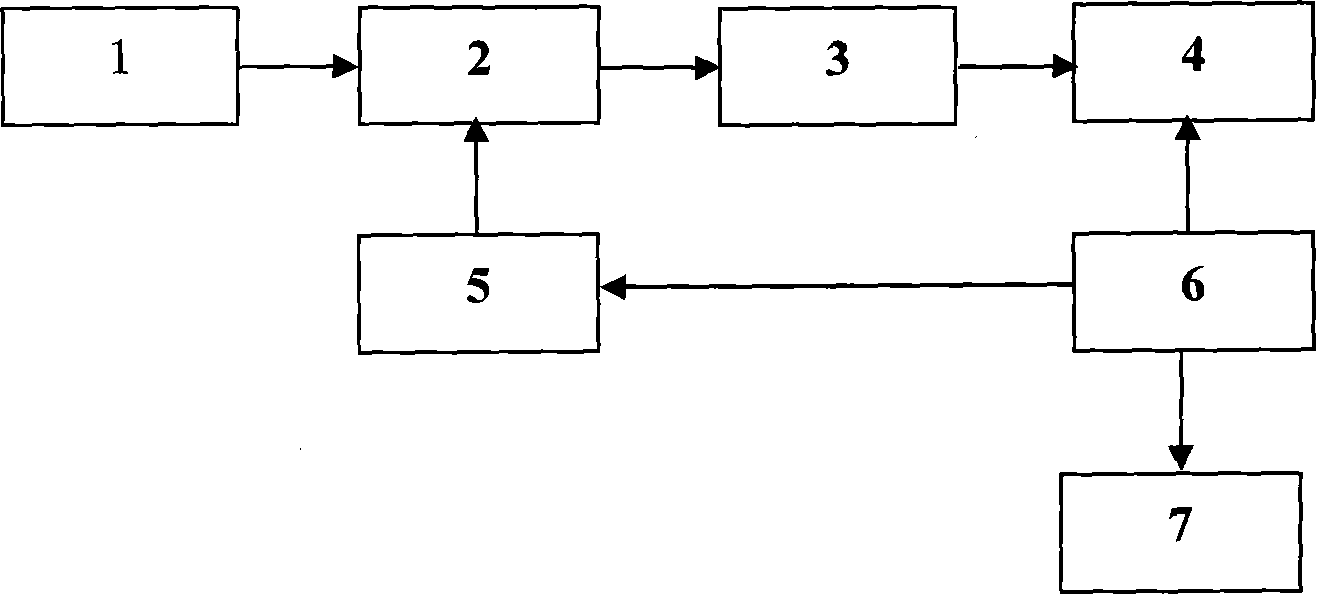

The invention discloses an alternating current and direct current voltage true virtual value measurement method capable of automatically identifying the type of a signal. The method comprises the following steps that a measured alternating current and direct current signal is input to the input end of a voltage dividing buffer (1), and a low-impedance signal is output to a level translation circuit (2) and a zero-crossing synchronization circuit (4) after impedance conversion; an analogue signal output by the level translation circuit (2) enters the analogue input end of an A / D (analogue / digital) converter (3), and a digital signal obtained by conversion is transmitted into a microprocessor (5); the reference voltage output of the A / D converter (5) is connected to the reference voltage input end of the level translation circuit (2) for the determination of a new reference level point after the rising of reference zero level; the microprocessor (5) detects a synchronization pulse output by the zero-crossing synchronization circuit (4) through built-in measurement control software; a measurement result is output through a display interface and a communication interface. According to the method, alternating current, direct current and hybrid alternating current and direct current types are automatically identified, and an alternating current voltage true virtual value, a direct current voltage value and a hybrid alternating current and direct current true virtual value are automatically measured.

Owner:GUIZHOU METROLOGY & TESTING INST

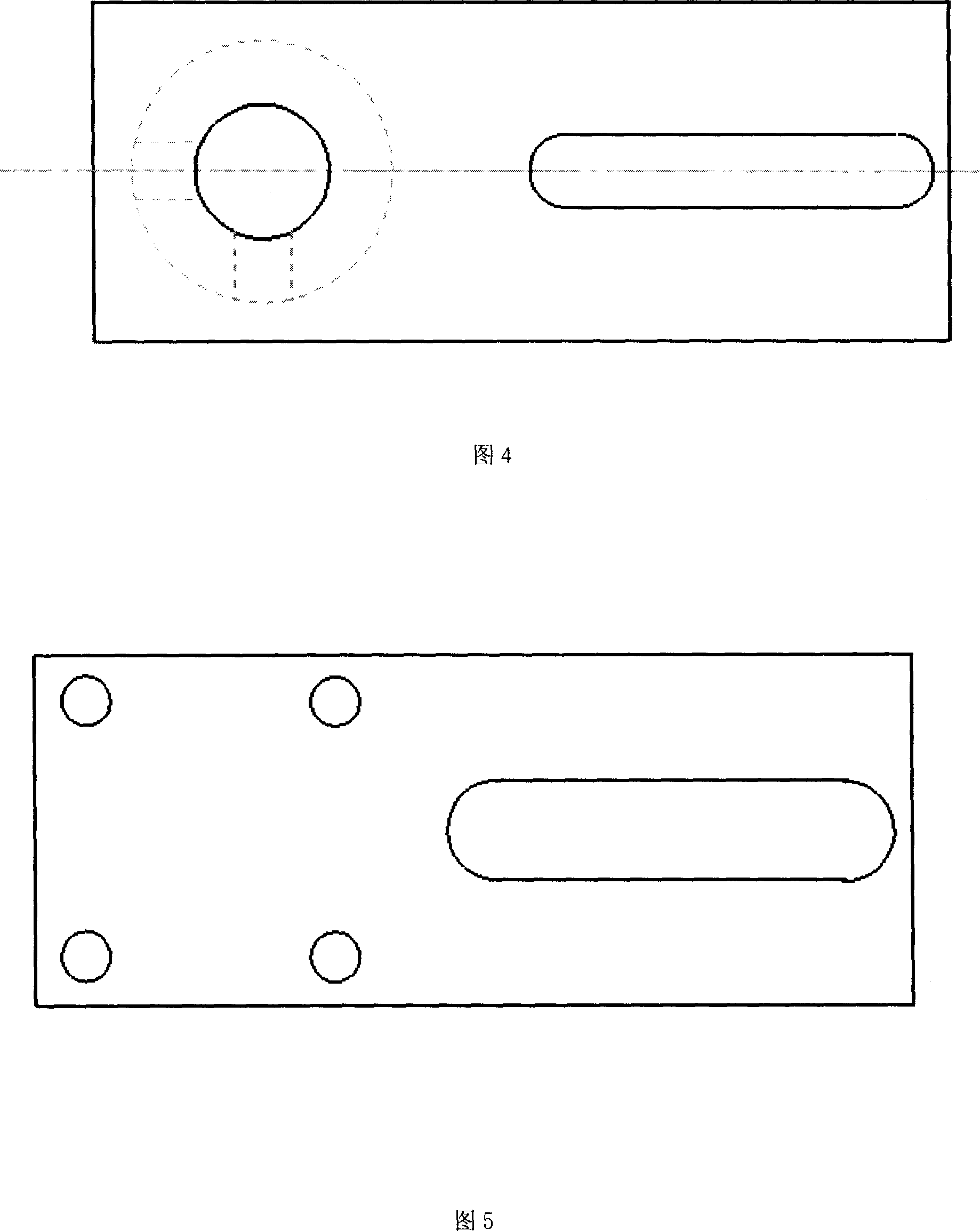

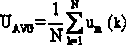

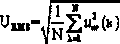

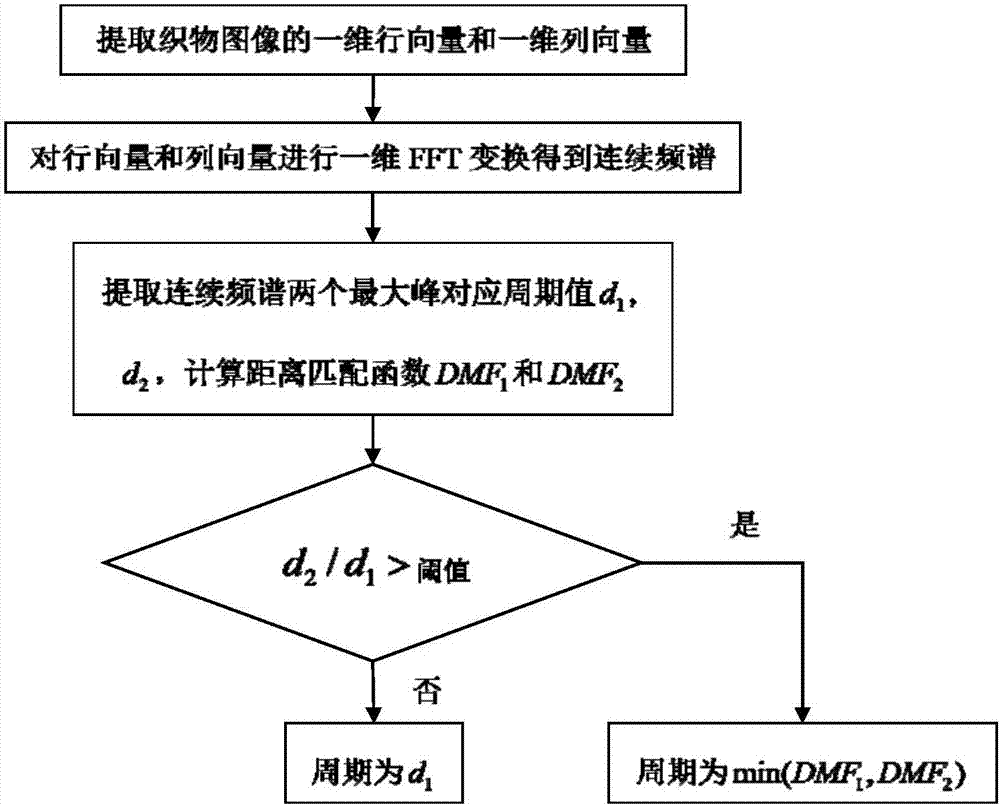

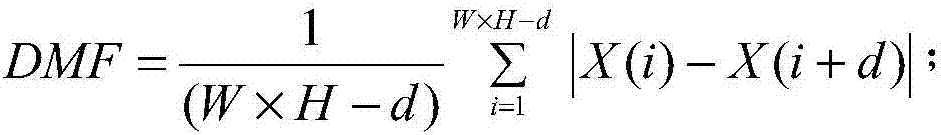

Automatic measuring method of fabric image texture cycle

ActiveCN107037050AIdentify texture cyclesHigh precisionImage enhancementImage analysisPattern recognitionFrequency spectrum

The invention relates to an automatic measuring method of a fabric image texture cycle. The method comprises the steps that a two-dimensional gray-level fabric image is expanded to one-dimensional row vectors and one-dimensional column vectors in the row mode and the column mode respectively, the one-dimensional row vectors and the one-dimensional column vectors are subjected to a rapid one-dimensional Fourier transformation to obtain a corresponding continuous spectrum, a principle period d1 and a secondary period d2, corresponding to the maximum peak point and the secondary peak point of the continuous spectrum respectively, are extracted, the distance matching function value DMF1 and DMF2 of the d1 and the d2 are calculated respectively, and making the peak point ratio K is equal to d2 / d1, when the value of K is lower than a threshold value, the ultimate period is d1, or the ultimate period is min (DMF1, DMF2). According to the method, on the basis of the Fourier transformation, the fabric texture period is automatically measured combining the distance matching function, and the method has better stability, higher calculation efficiency, and better measuring effect on a small period texture which is hard to be recognized by most measuring methods, and can be applied to the automatic measuring field of fabric longitude and latitude texture periods.

Owner:DONGHUA UNIV +1

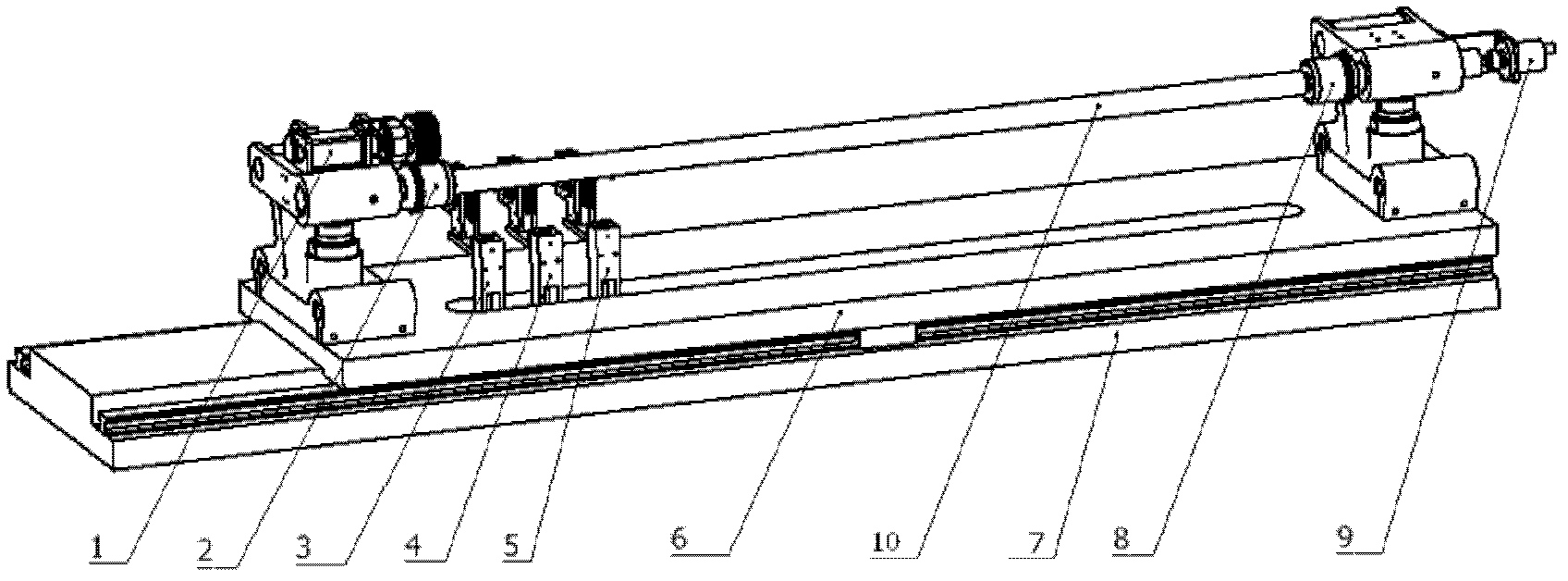

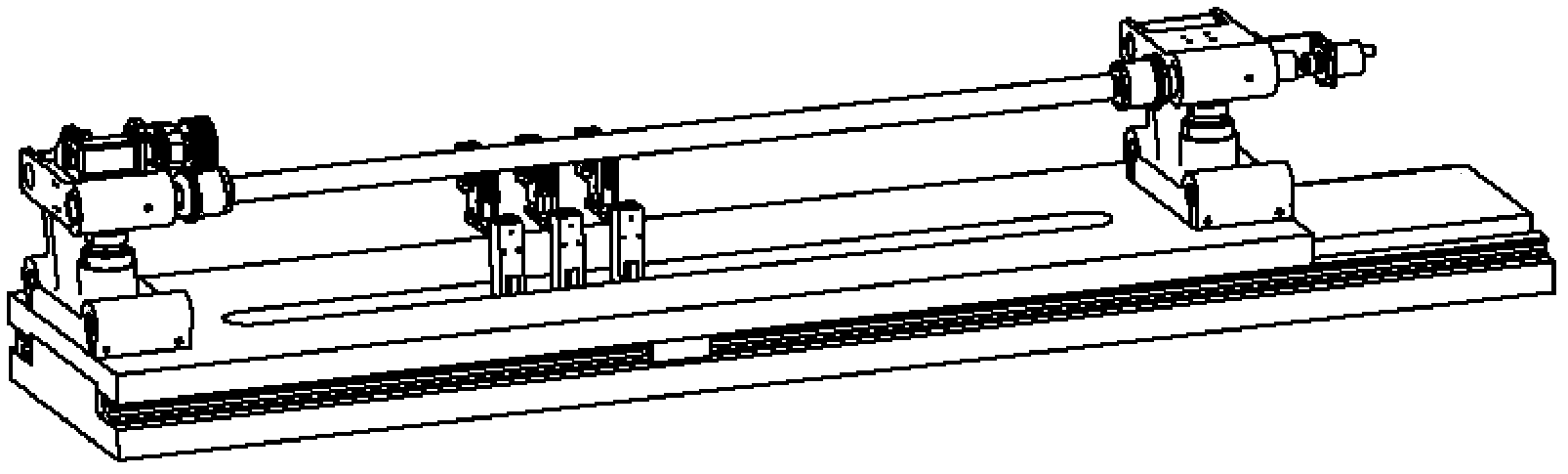

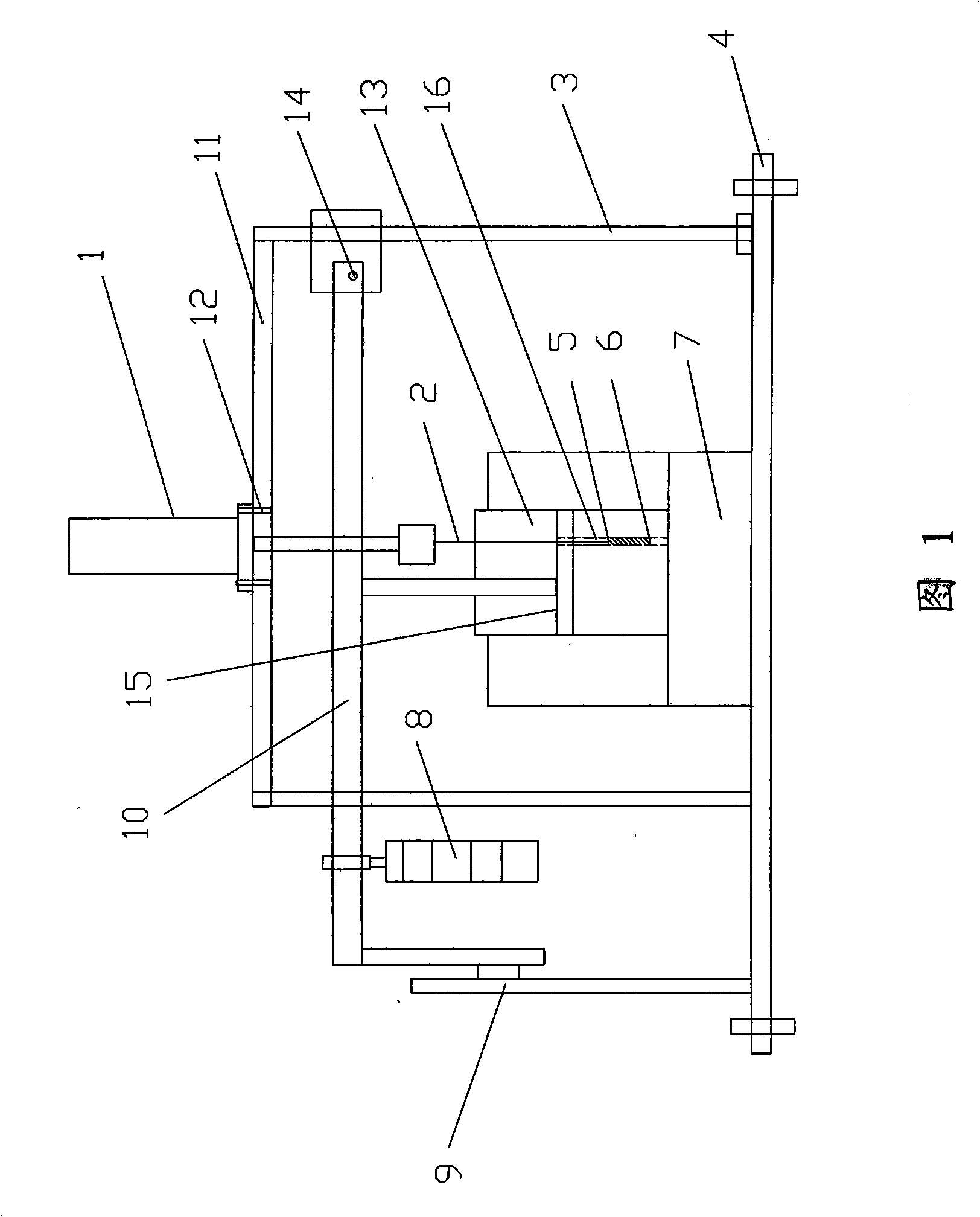

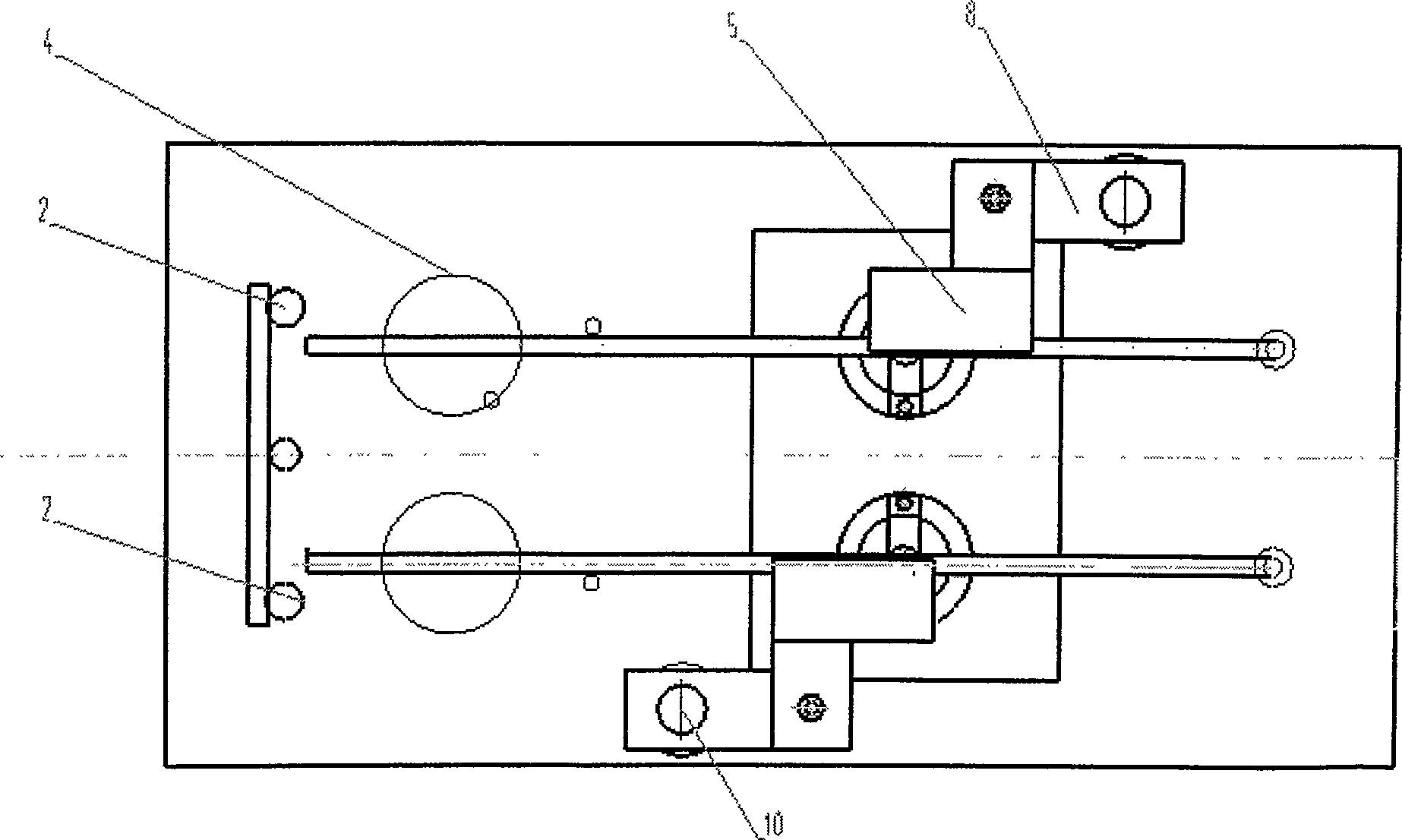

Radial runout measuring method for straightening machine long axis workpiece, and device thereof

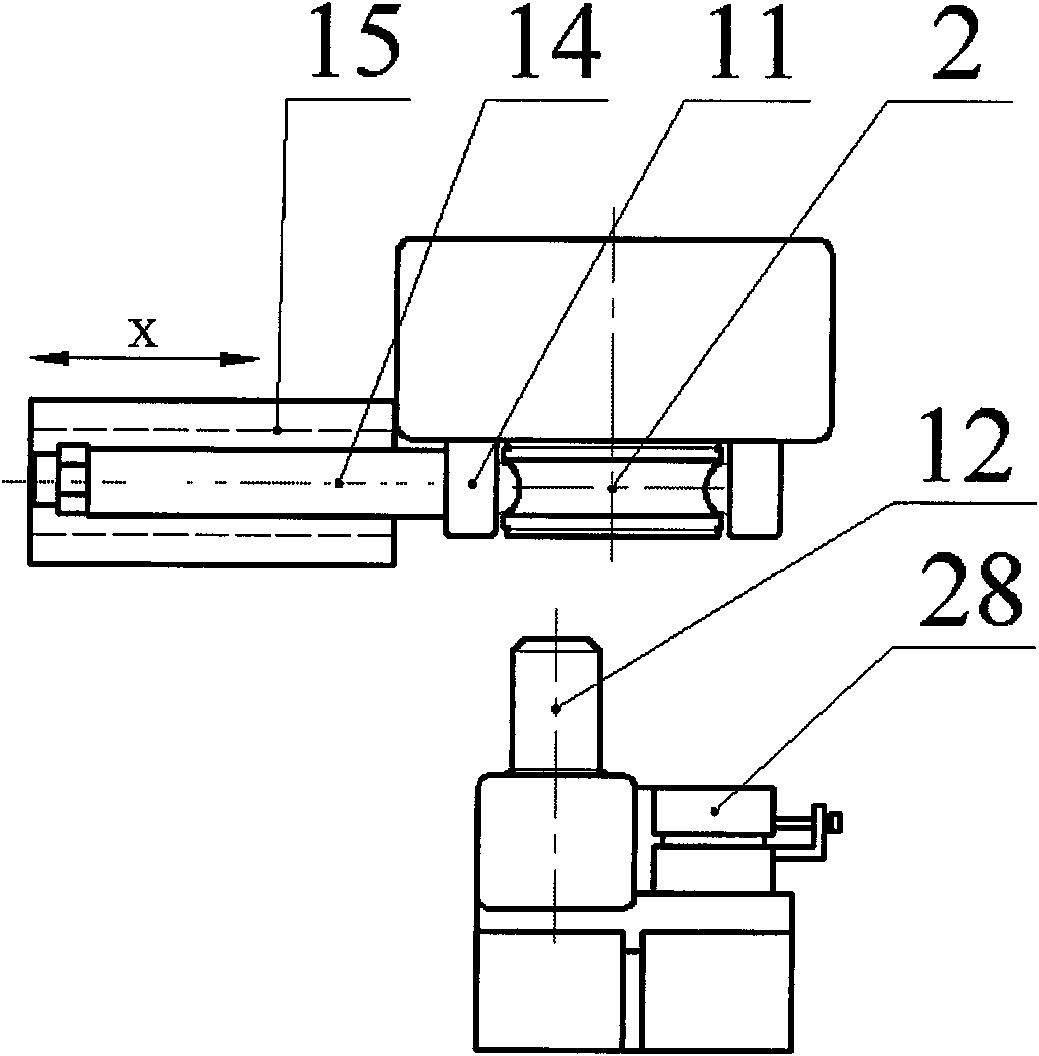

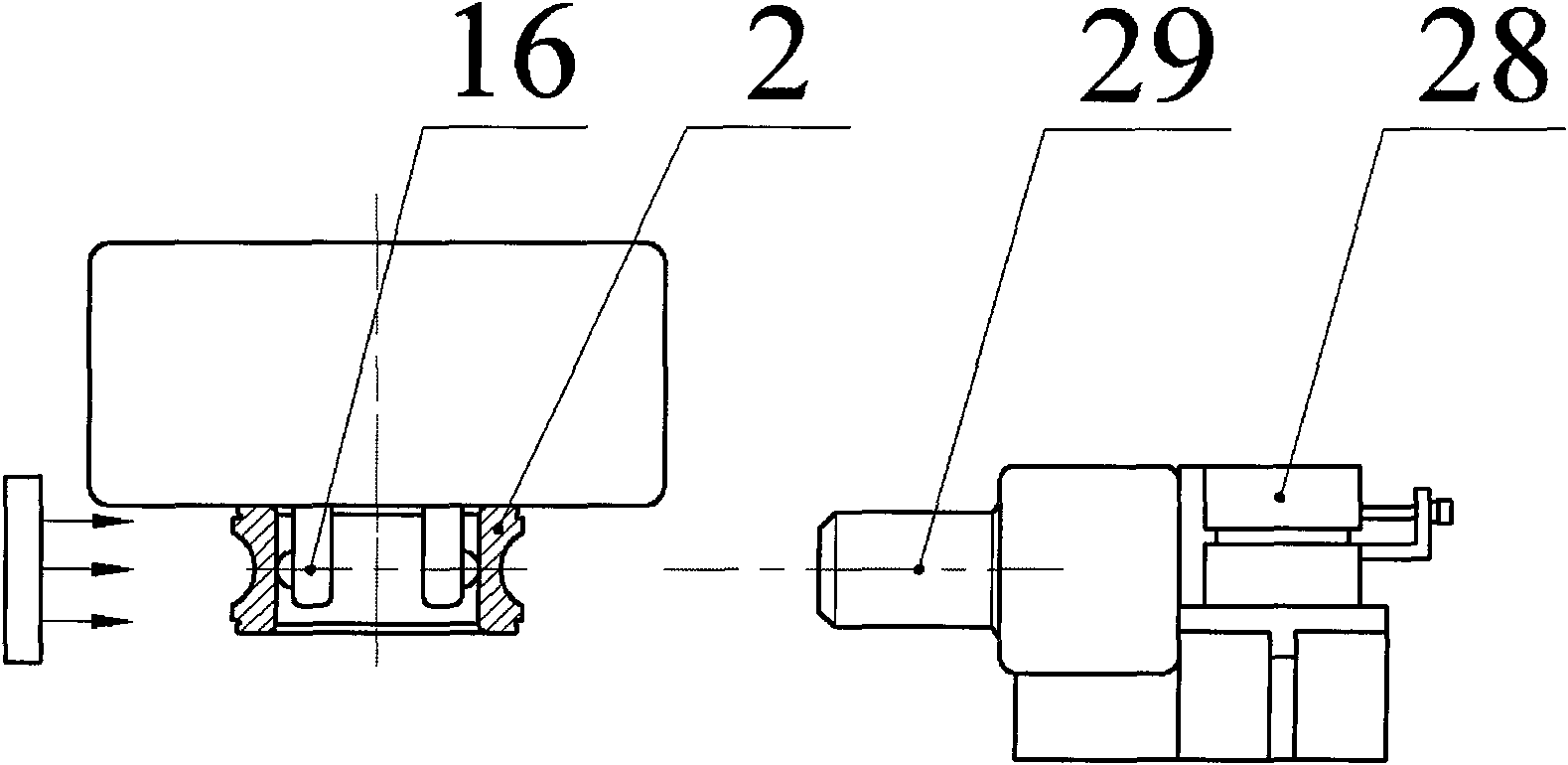

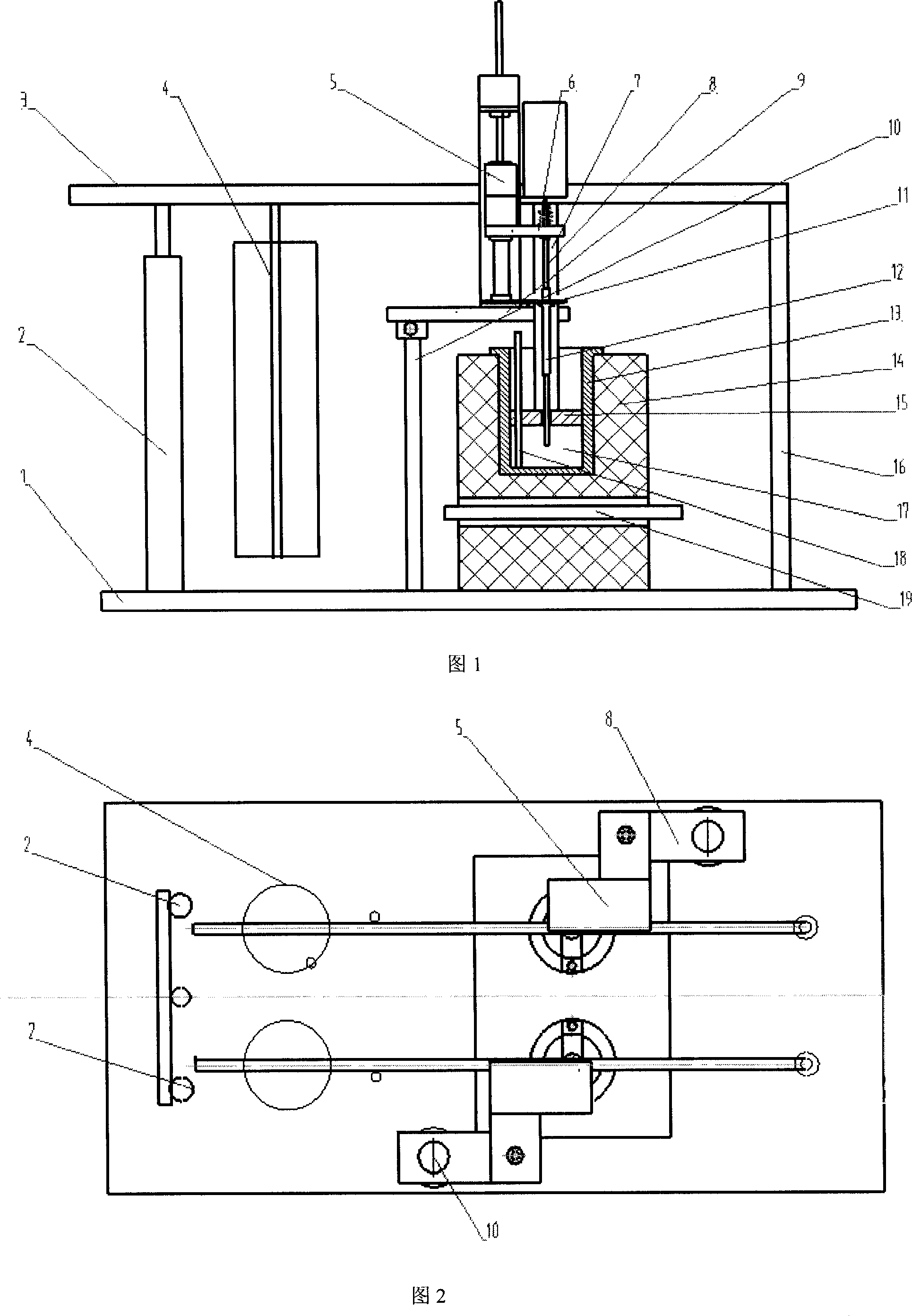

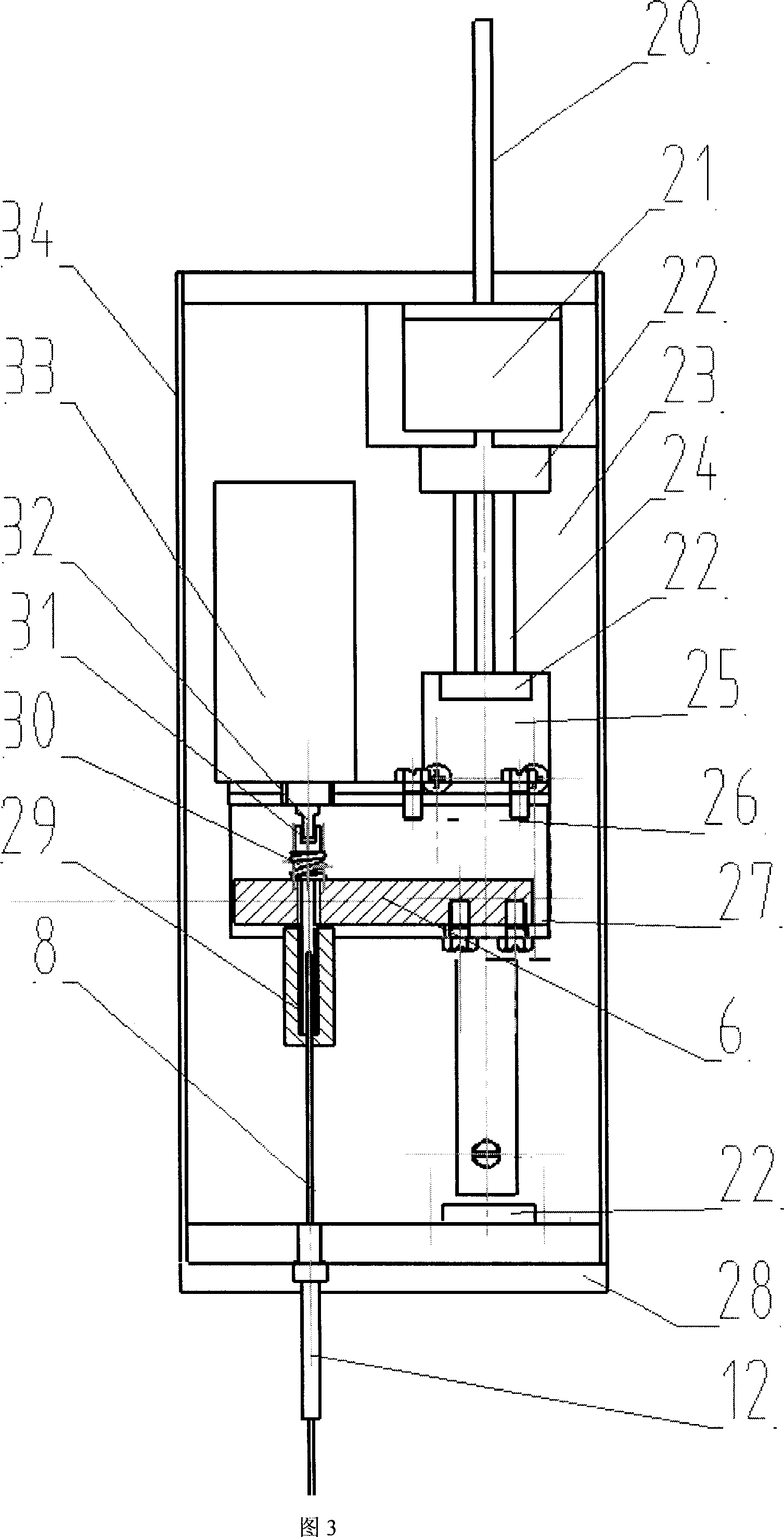

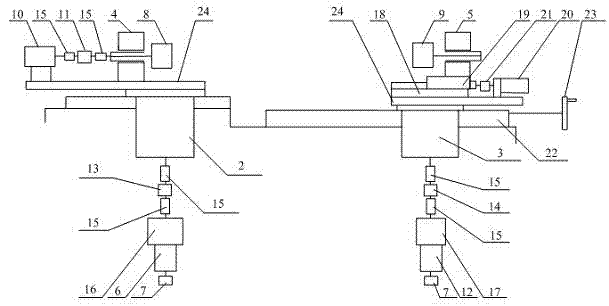

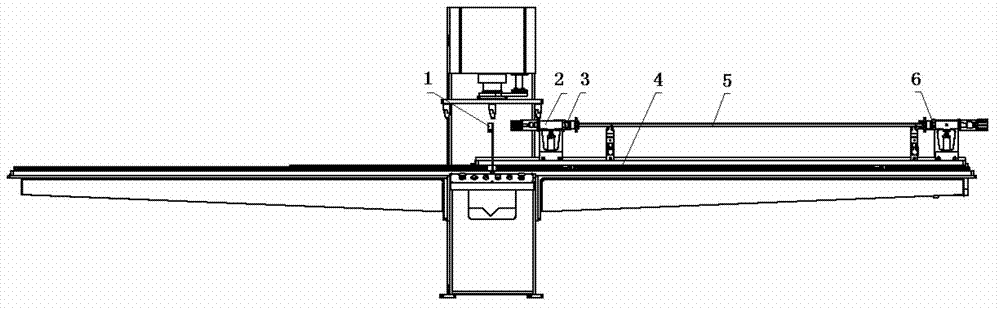

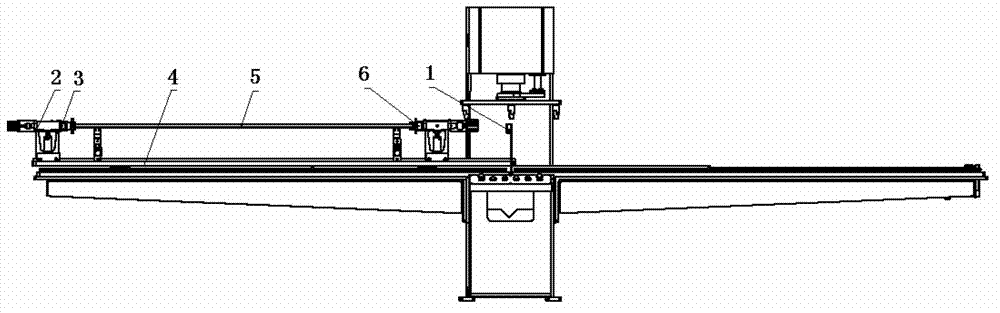

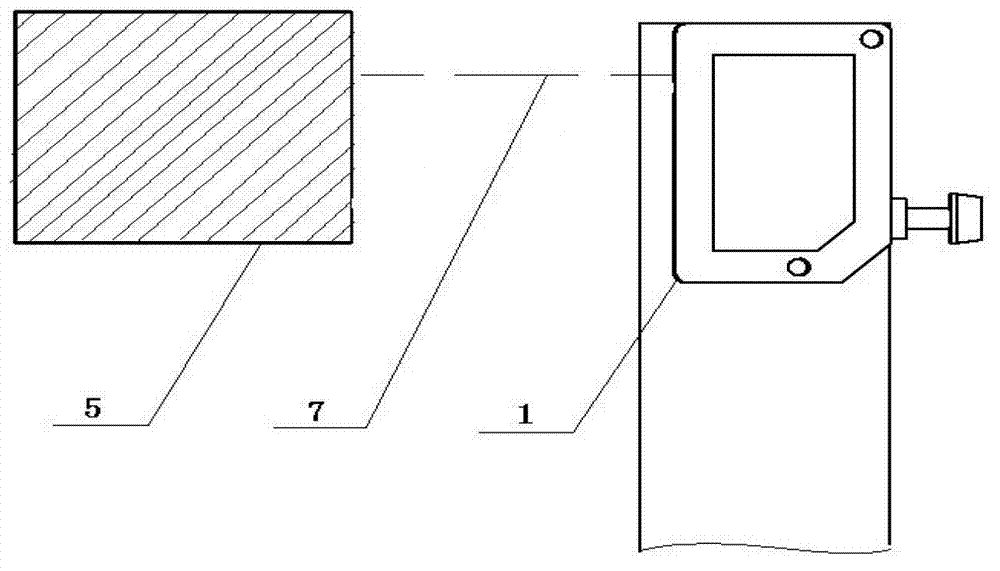

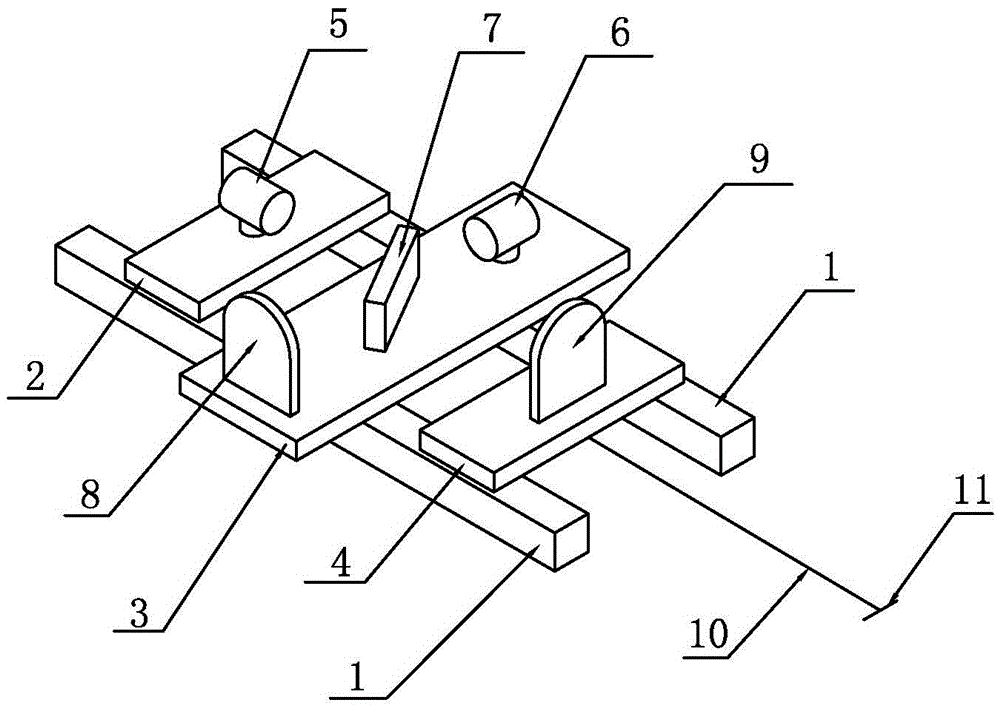

InactiveCN102513410ARealize fully automatic measurementRealize fully automatic measurement and calculationMetal working apparatusLong axisEngineering

The present invention relates to a radial runout measuring device for a straightening machine long axis workpiece, and belongs to the field of straightening machine manufacturing. According to the device, a left top tip and a right top tip are arranged on a work platform; the work platform forms a slidable connection with a work table; a motor forms a rotary connection with the left top tip; a photoelectric encoder and the right top tip are fixedly connected; and a tappet type displacement measuring device 1, a tappet type displacement measuring device 2 and a tappet type displacement measuring device 3 are respectively and fixedly connected with the work table. The method and the device of the present invention have the following advantages that: the full automatic measuring calculations of the whole radial runout and the local radial runout of the long axis workpiece on the straightening machine can be achieved, such that the total length radial runout measurement and the local radial runout measurement of the long axis workpiece can be achieved while the cost can be reduced; the method is simple and universal.

Owner:CHANGCHUN HUIKAI TECH

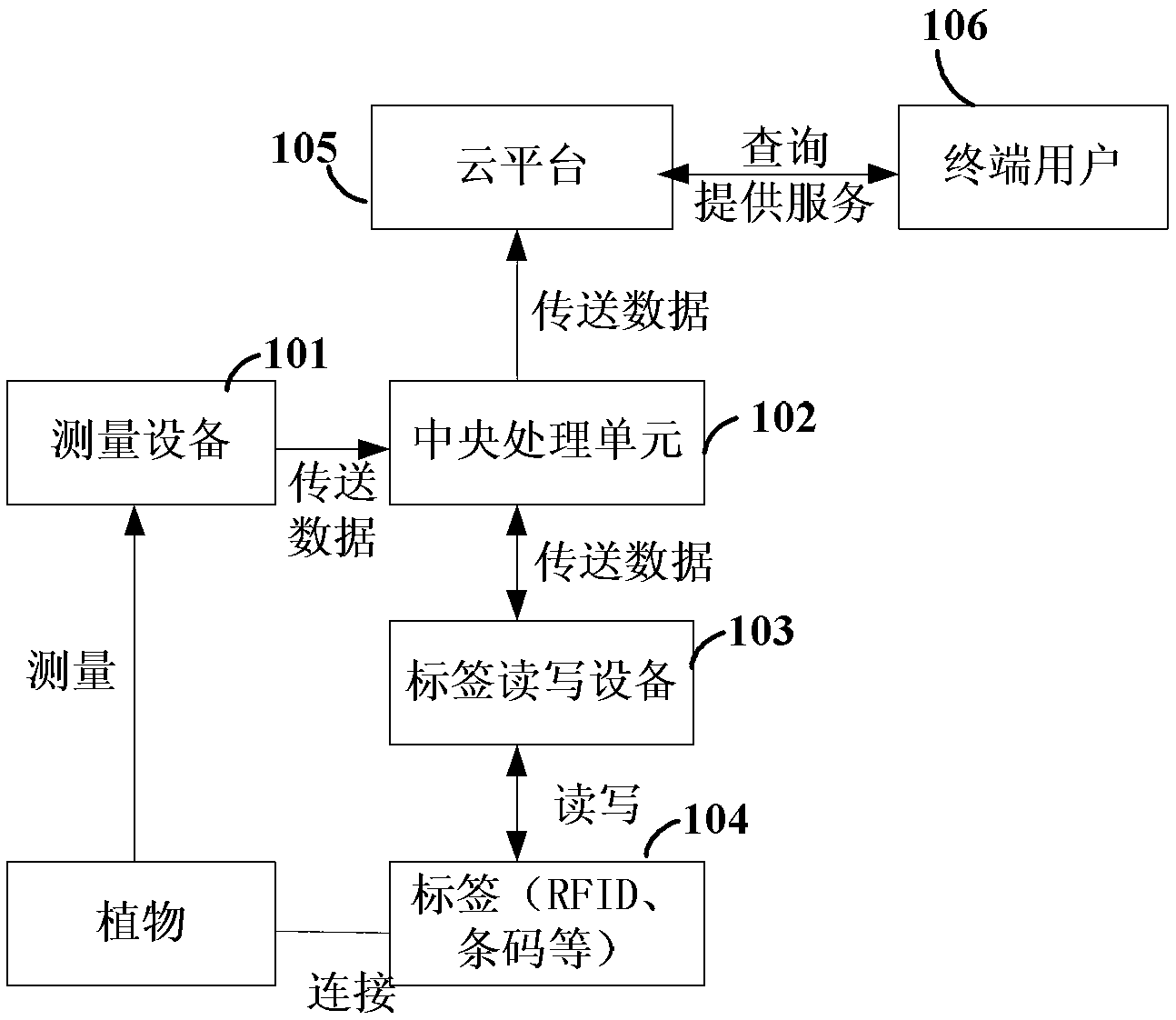

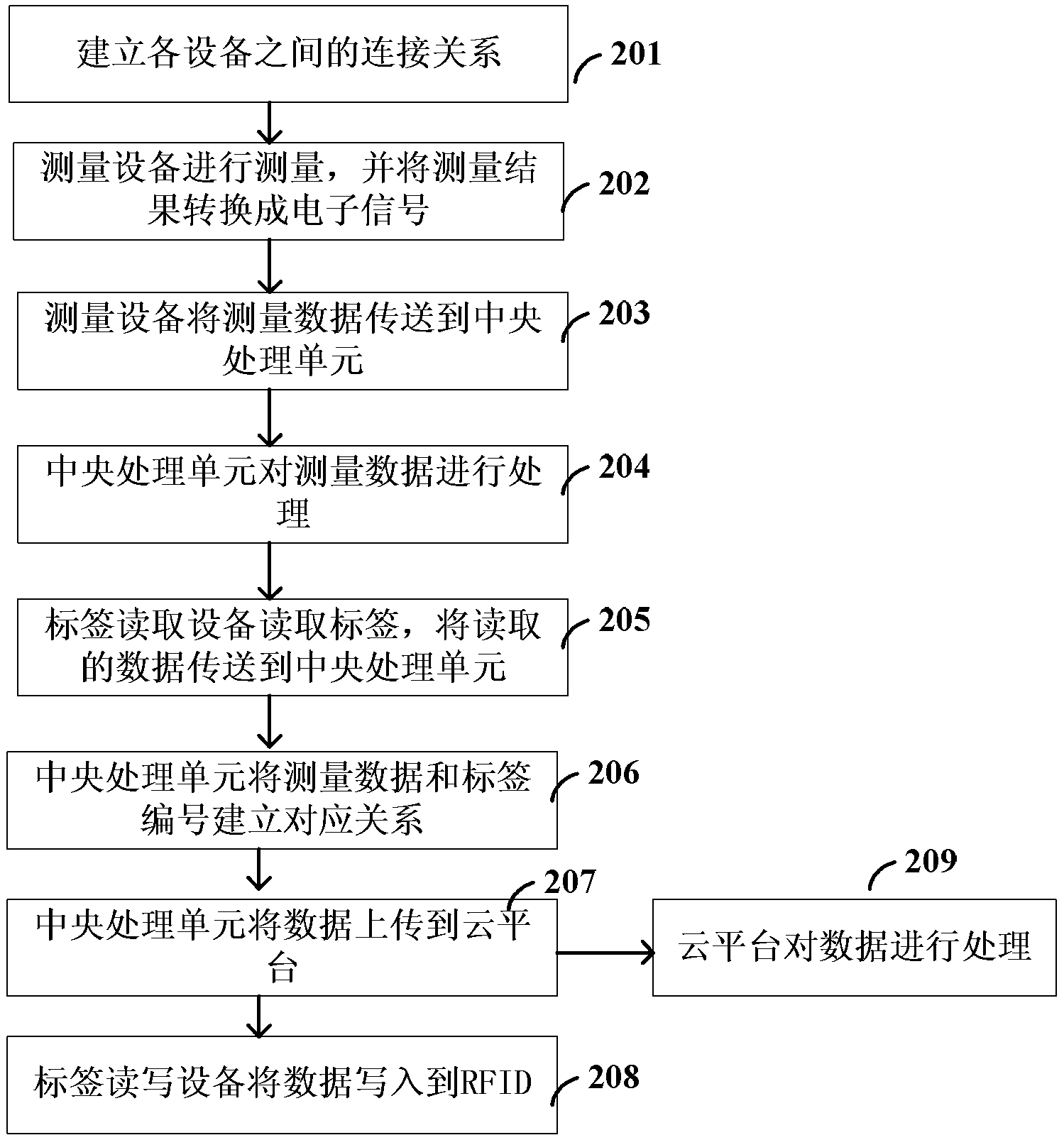

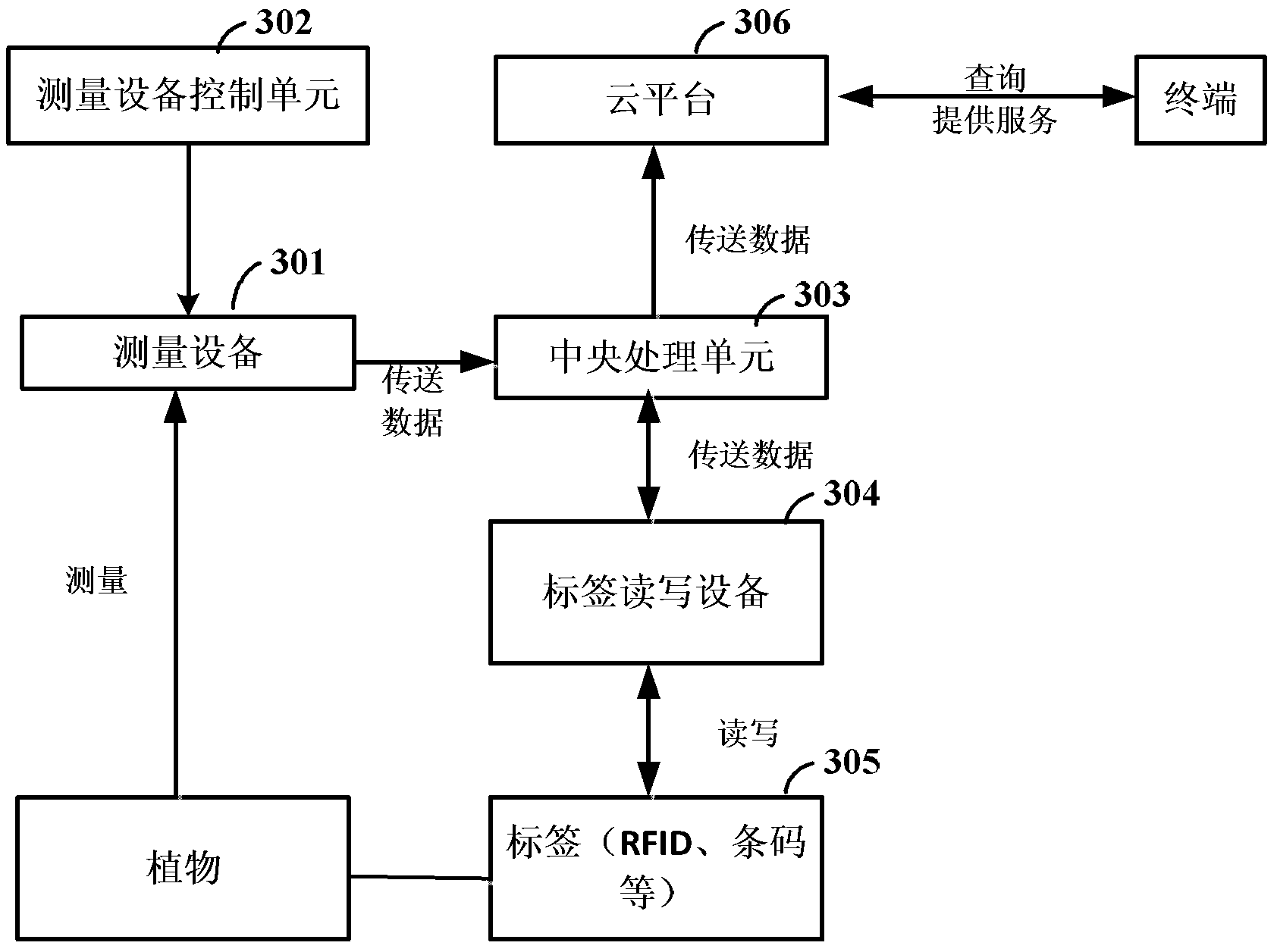

Plant characteristic data measuring and storing system based on Internet of Things and cloud platform

InactiveCN103218637ARealize automatic measurementRealize transmissionCo-operative working arrangementsProcess MeasuresThe Internet

The invention discloses a plant characteristic data measuring and storing system based on the Internet of Things and a cloud platform. The plant characteristic data measuring and storing system based on the Internet of Things and the cloud platform comprises a measuring device, a label read-write device and a central processing unit. The measuring device is used for measuring dimensionality information of plants, automatically converting measuring results into electronic signals and sending the converted electronic signals to the central processing unit. The label read-write device is used for reading labels on the plants and transmitting information about the labels which are read to the central processing unit. The central processing unit receives measuring data from the measuring device, processes the received measuring data, receives label numbers of the plants from the label read-write device, establishes a corresponding relation between the processed measuring data and the received label numbers and transmits the data after the correspondence to the cloud platform. According to the scheme of the plant characteristic data measuring and storing system based on the Internet of Things and the cloud platform, the measurement of each plant can be finished through manual operation, and after the measurement, linking between the data and the labels and storage at cloud ends can be realized automatically. The plant characteristic data measuring and storing system based on the Internet of Things and the cloud platform can also realize a full-automatic measurement and storage scheme and can realize automatic measurement, transmission and storage of the data.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

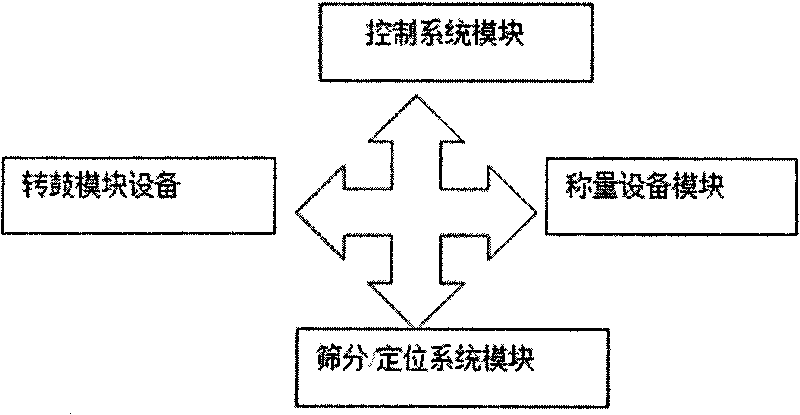

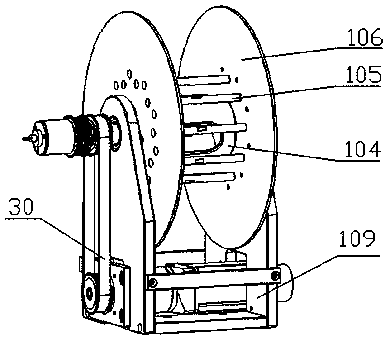

Automated test device of bituminous coal caking index

The invention provides a device for automatically measuring the caking index of bituminous coal, comprising the following steps: driving the double-drum to rotate by the main engine; driving the piston in the drum to go forward or backward by two step motors; driving the sieve to vibrate to sieve bituminous coal particles by two step motors and automatically weighing on a digital scale; and displaying the weighing results on the casing of the box body and the main engine of the computer simultaneously and giving corresponding caking index calculation results. Experimenters only need to place bituminous coal used for experiments in the drum, with no need of participating in the subsequent experiment process.

Owner:江苏靖隆合金钢机械制造有限公司

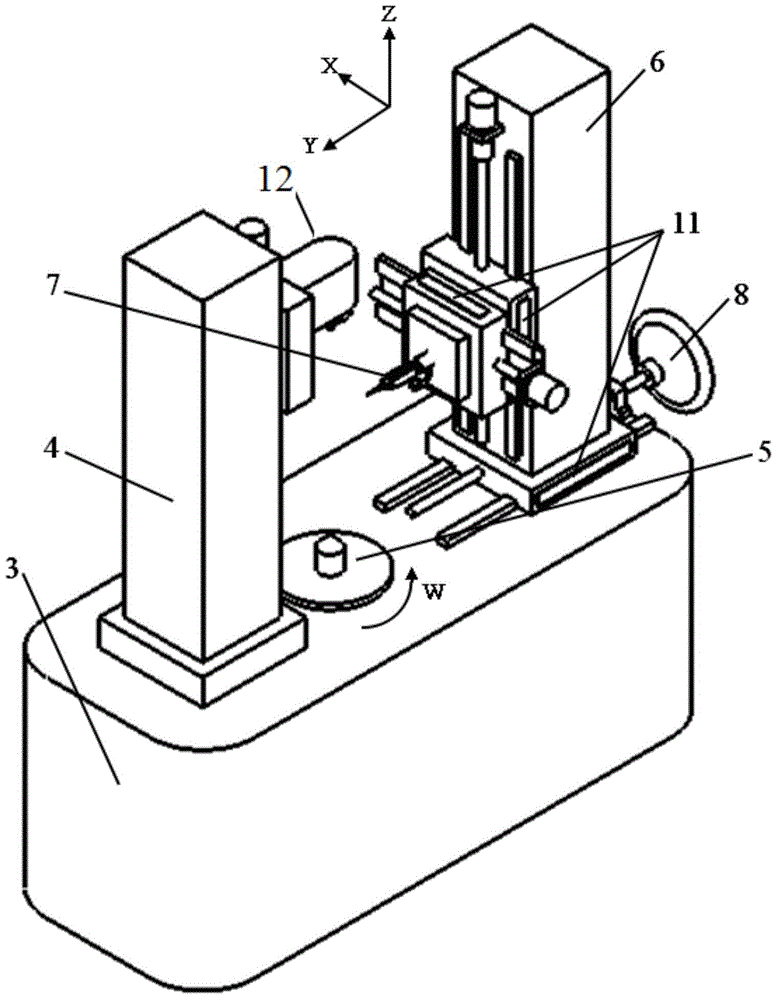

Three-axis linkage-based complicated part accurate measurement central path planning realizing method and device

ActiveCN104154849ARealize stepless adjustmentEasy to detectUsing electrical meansUsing optical meansCircular discElectric sense

The invention provides a three-axis linkage-based complicated part accurate measurement central path planning realizing method and a device. the device comprises a base, a workpiece vertical column, and a measurement vertical column, wherein the measurement vertical column is provided with an electric sensing head capable of moving vertically and horizontally. Horizontal movement of the measurement vertical column is used for contotrlling the distance between the measuring head and the center of a spindle rotating shaft system, stepless adjustment of a basic circle can be realized, a series of basic circle discs do not need to assist measurement of a gear, the detection process is simplified, and detection errors due to wear of the basic circle discs can be solved. Through controlling vertical movement, horizontal movement of the measuring head and linkage of the spindle rotating shaft system, control of the measuring trajectory of the measuring head can be realized respectively, and helix, tooth profile and pitch error of the gear with any base circle radius value within the measuring range can be fully automatically measured. In addition, path planning of an eccentric gear can be realized, and full-automatic measurement on helix, tooth profile and pitch error of the eccentric gear can be realized.

Owner:西安秦川思源测量仪器有限公司

Device and method for measuring viscosity of petroleum

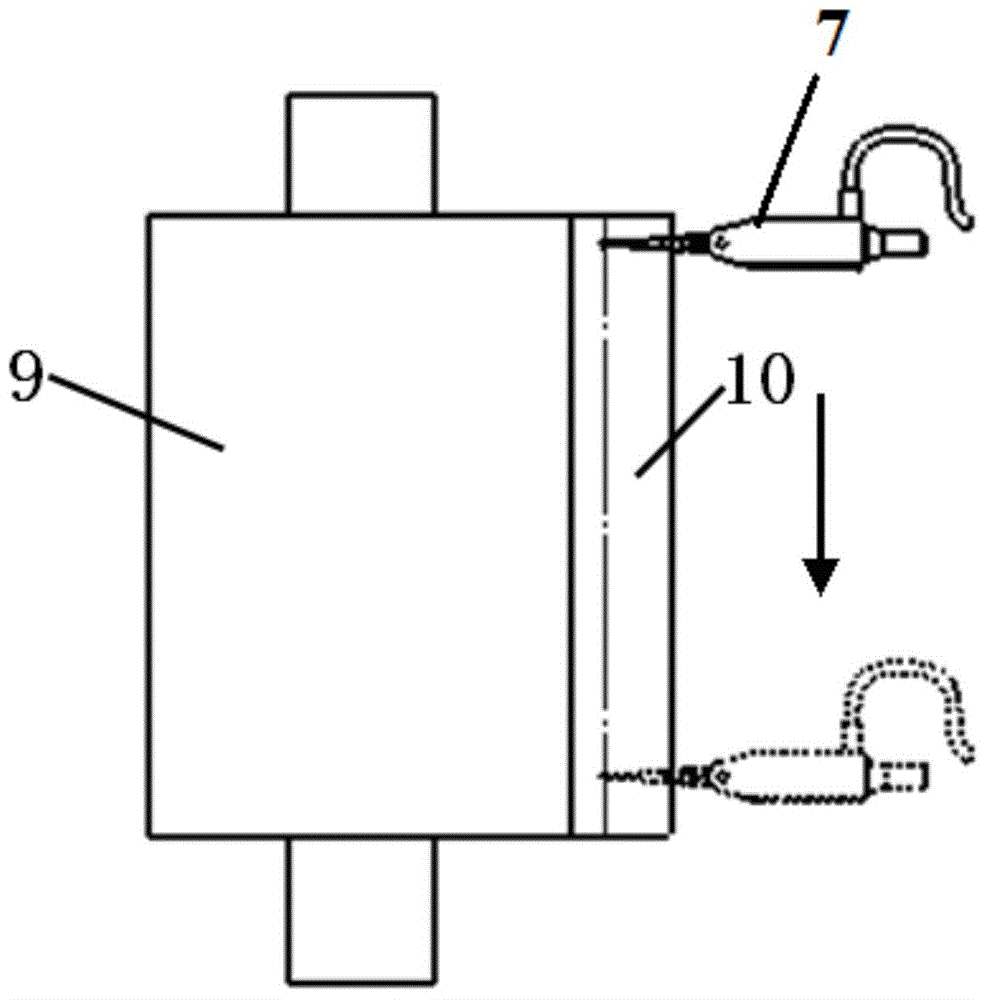

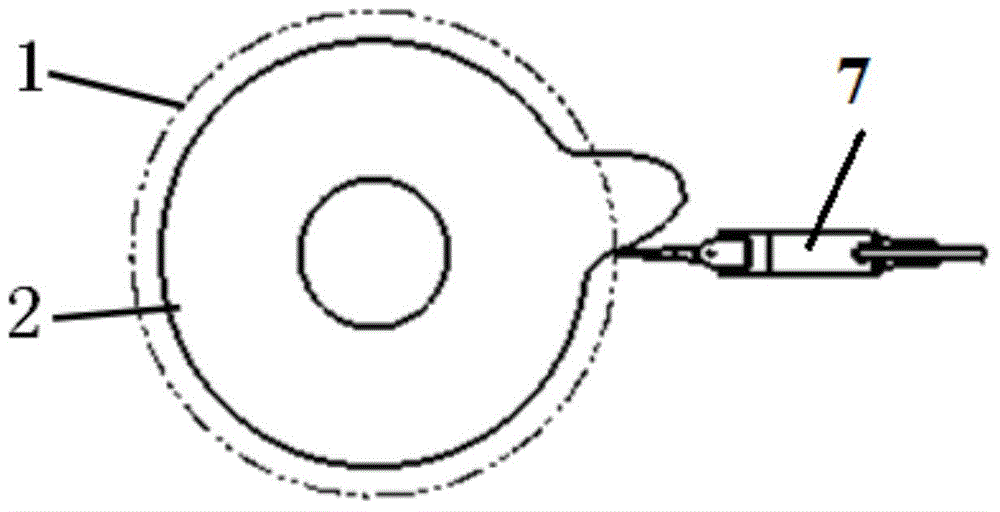

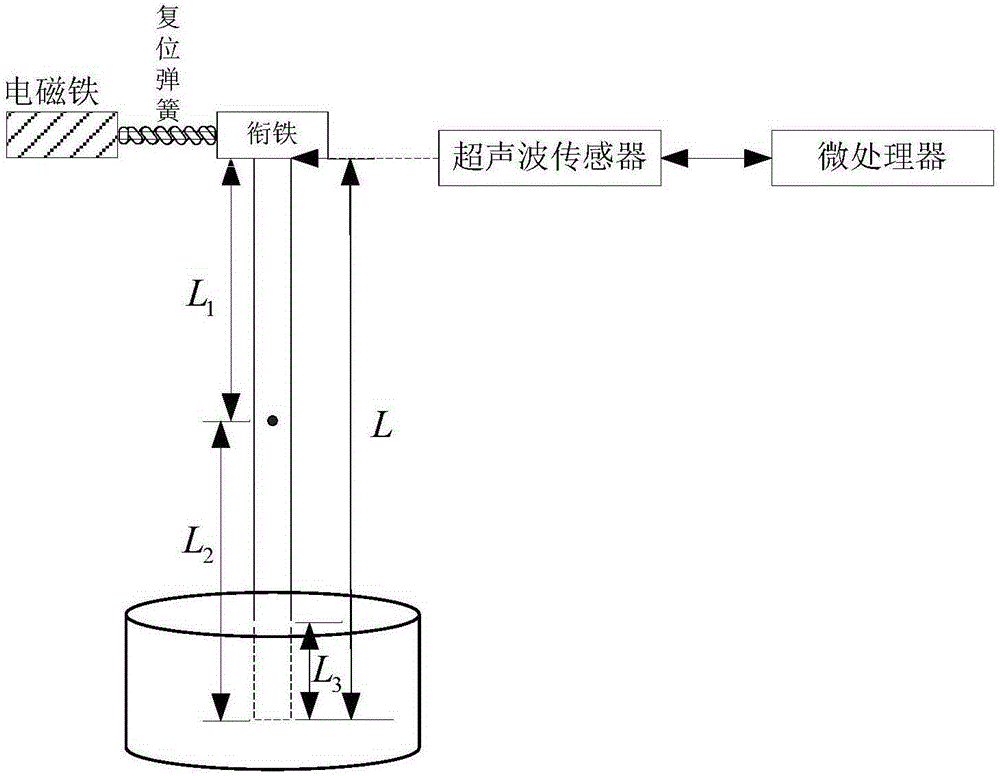

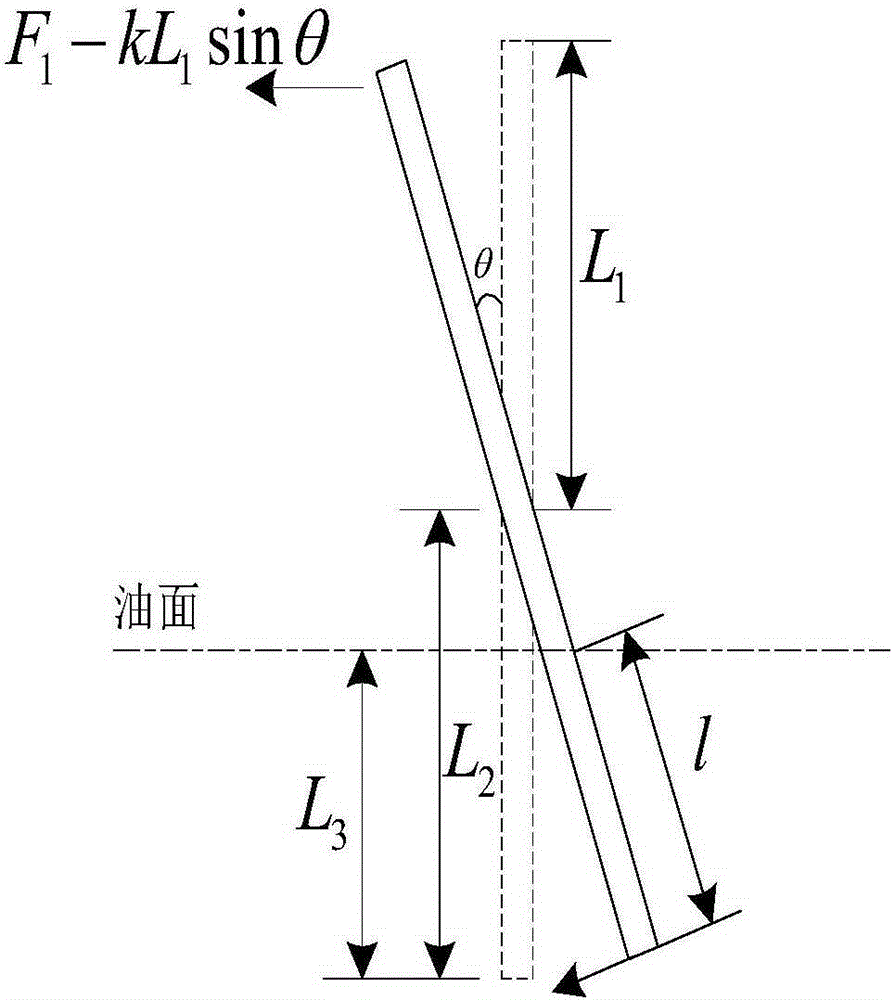

InactiveCN105223108ARealize fully automatic measurementHigh measurement accuracyFlow propertiesMeasurement deviceMeasurement precision

The invention provides a device and a method for measuring viscosity of petroleum. The device comprises a drawing mechanism, a rotating mechanism, a detection mechanism and a control mechanism; the drawing mechanism is an electromagnet; the electromagnet comprises an armature and a reset spring, and is started under the control of the control mechanism; the upper end of the rotating mechanism is connected with the armature; the lower end of the rotating mechanism is arranged in a to-be-measured petroleum body; the middle of the rotating mechanism is provided with a support shaft; the armature is capable of driving the rotating mechanism under the attraction drawing of the electromagnet to rotate along the support shaft; the detection mechanism is used for detecting the rotating angle or / and rotating displacement or / and rotating time of the rotating mechanism; the control mechanism is used for controlling the starting of the drawing mechanism, and calculating the viscosity of the to-be-measured petroleum body according to parameters detected by the detection mechanism. Full-automatic measurement is realized by the device and the method provided by the invention, so the device and the method are high in measurement precision, low in cost, and easy to popularize and apply.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

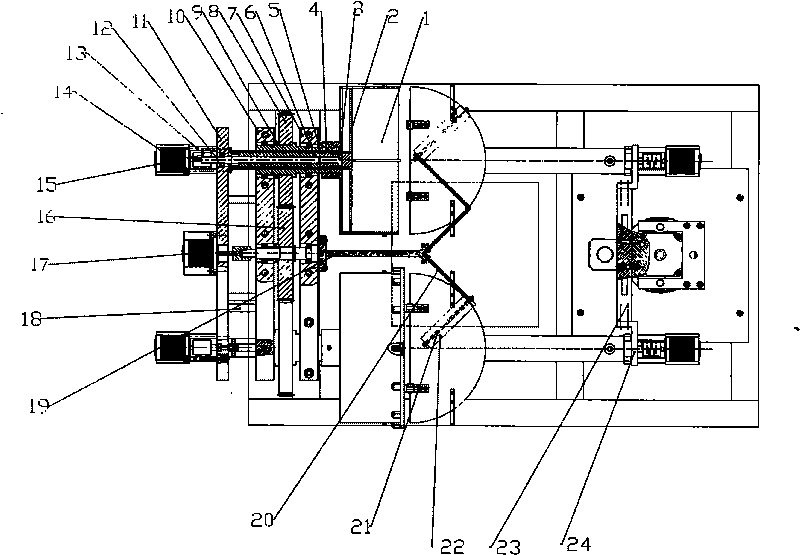

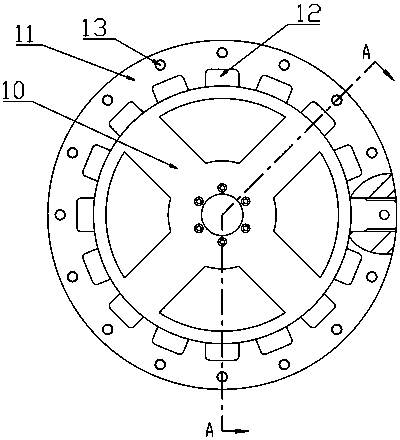

Fully-automatic roller sorting machine

ActiveCN108772307AGuaranteed accuracyRealize fully automatic measurementPlastic recyclingSortingEngineeringFully automatic

The invention especially relates to a fully-automatic roller sorting machine, belonging to the field of tapered roller detection technology. According to the invention, the upper end of a frame is provided with a roller feeding mechanism; a turning-around mechanism is arranged on the part, below the roller feeding mechanism, of the frame; a detection turntable is arranged on the part, below the turning-around mechanism, of the frame; a detection ring extending outwardly is arranged on the edge of the upper end of the detection turntable; a plurality of detection holes are evenly arranged in the detection ring at an equal interval; the middle position of each detection hole is vertically provided with a material hole which penetrates the whole detection ring; a baffle plate is attached ontothe lower end surface of the detection ring; two ends of one of the detection holes are provided with a group of measuring mechanisms; the parts, corresponding to the material holes, of the baffle plate are provided with gaps extending from exterior to interior; and the parts, out of the gaps, of the frame are provided with blanking plates driven by a rotary cylinder. The fully-automatic roller sorting machine in the invention realizes automatic orientation, turning-around, detection and sorting of rollers, and is high in automation degree and improved measurement precision and the like.

Owner:浙江晟禧精密机械科技有限公司

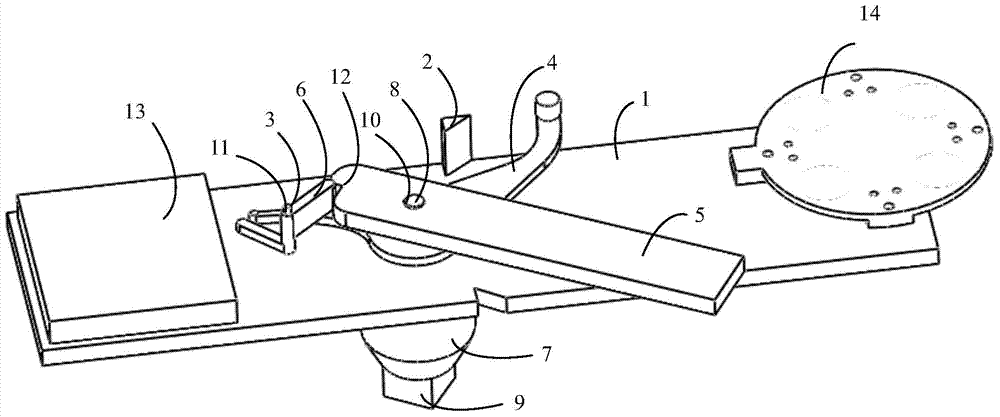

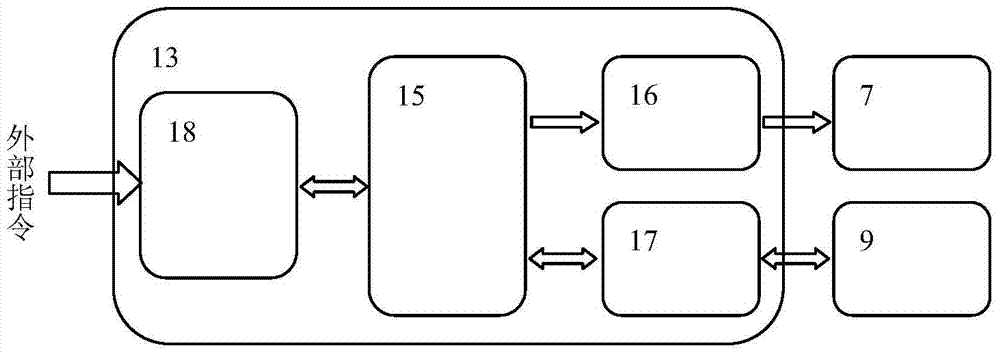

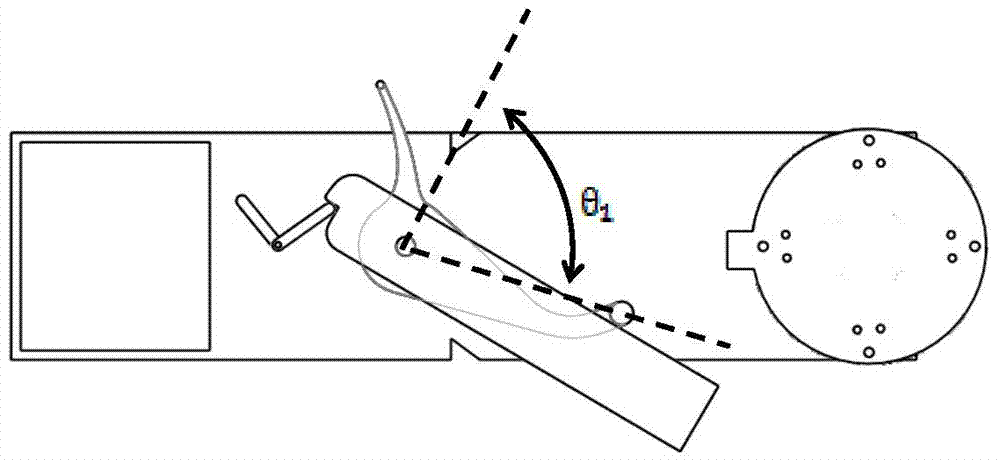

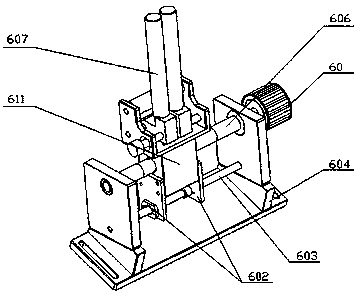

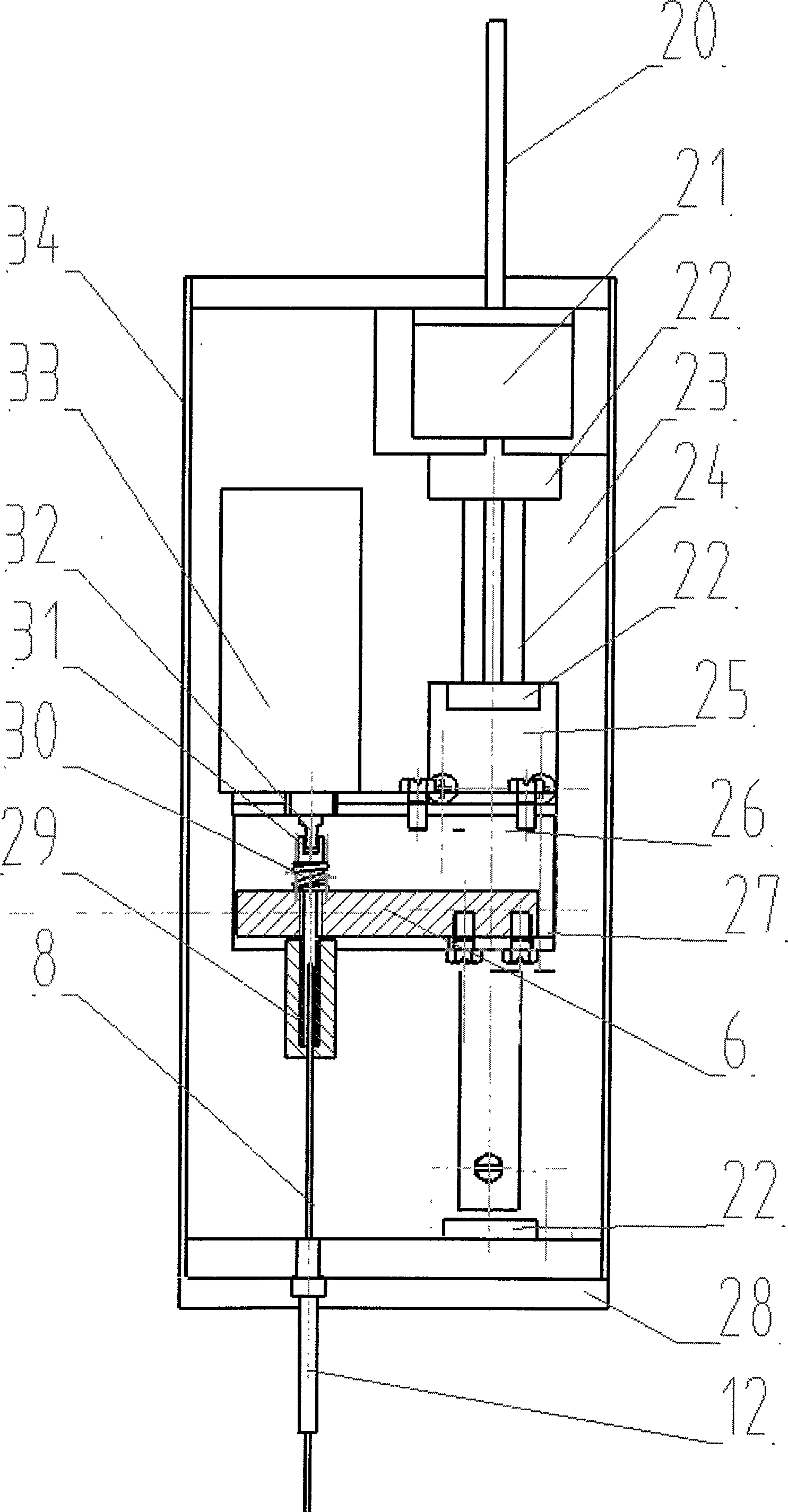

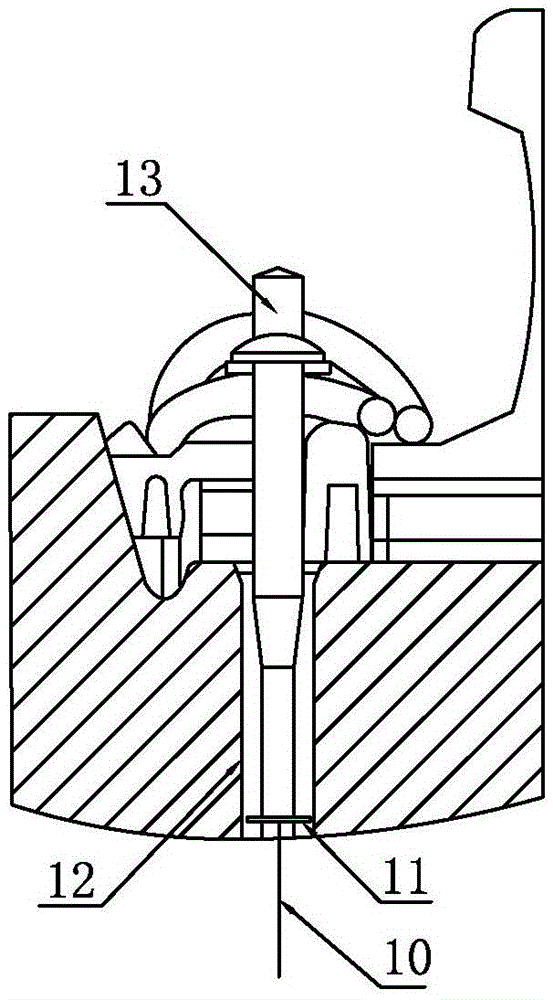

Program-controlled impact device for automatically measuring output delay time of fiber-optic gyroscope

InactiveCN103487065ARealize fully automatic measurementReduce manual interventionProgramme controlMeasurement devicesFiberGyroscope

The invention discloses a program-controlled impact device for automatically measuring the output delay time of a fiber-optic gyroscope. A motor is installed on the lower side of a base of the program-controlled impact device; a push rod, a torsional spring and an oscillating arm striker are installed on a motor shaft from the lower part to the upper part in sequence, so that the push rod can rotate with the motor shaft, and the oscillating arm striker can rotate around the motor shaft; an angle sensor is installed at the other end of the motor shaft; a limiting spring leaf is installed on the base through the torsional spring, so that the limiting spring leaf is closely attached to the tail end of the oscillating arm striker under the effect of the torsional spring; and a control unit is connected with the angle sensor and the motor respectively and controls the motor to rotate and to drive the push rod to rotate by monitoring a rotate angle in real time, and the striker is pushed further to be reset and to trigger the limiting spring leaf to release the striker. The program-controlled impact device adopts a feedback control technology, is accurate in control and stable to operate, does not need high current starting, and is free of electromagnetic interference. By adopting the device, the fully automatic measurement of the output delay time of the fiber-optic gyroscope can be realized.

Owner:ZHEJIANG UNIV

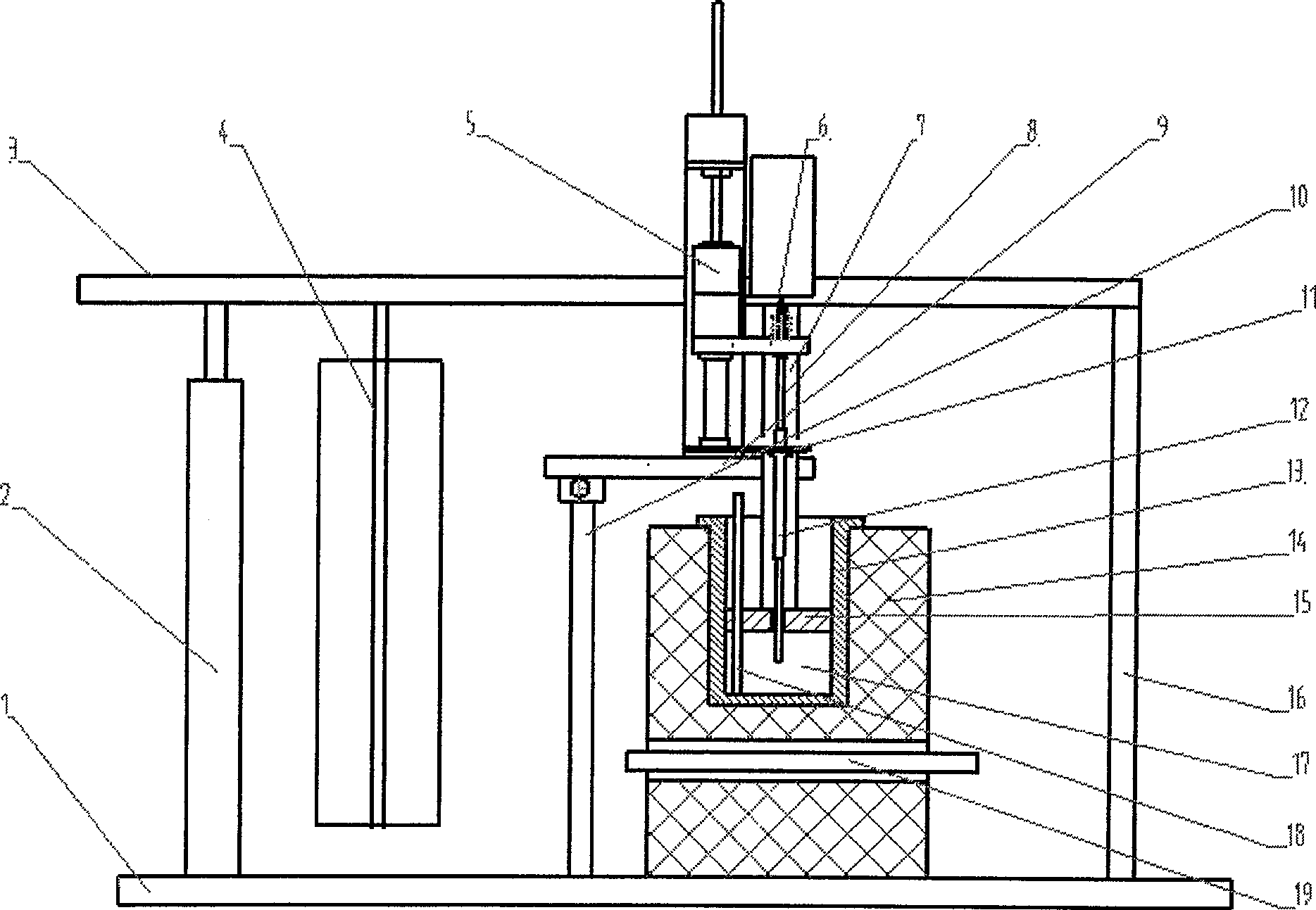

Full-automatic coal colloidal layer index measuring apparatus

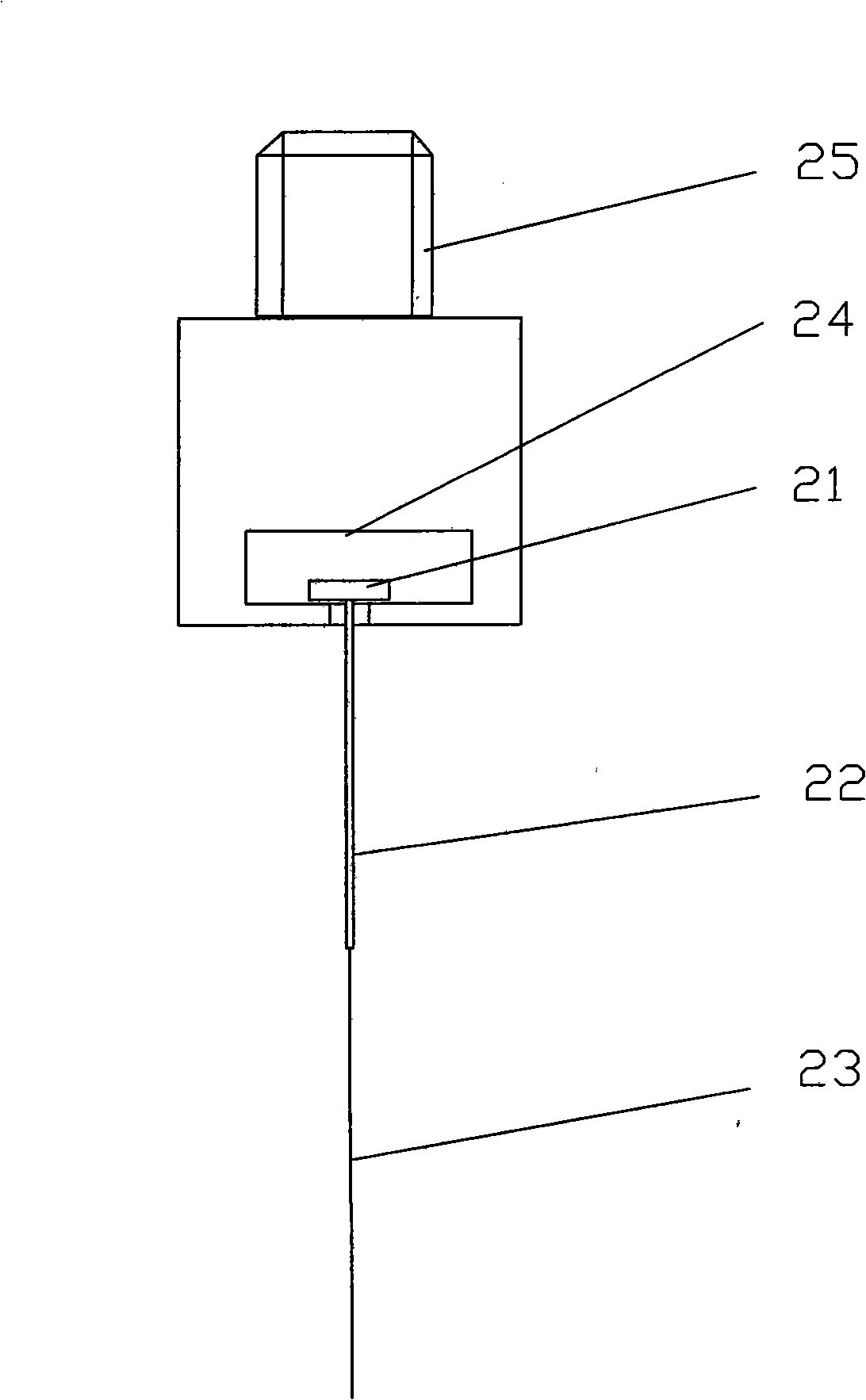

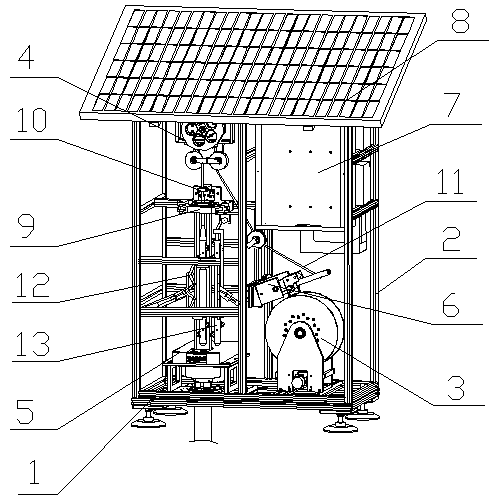

ActiveCN101334396AImprove work efficiencyImprove technical levelFuel testingChemical methods analysisMeasurement deviceCoal

The invention relates to a full automatic coal glial layer index measuring instrument and a detection process and a method of the measuring instrument. The structure of the measuring instrument mainly comprises: a drive device of a stepping motor, a probe of a force-measuring device, a frame, a heating furnace, a height automatic measurement device and a coal cup, etc.; the probe is deep arranged in the coal cup which can generate the glial layer, the coal cup is arranged in the heating furnace; a lever device is arranged at the upper part of the frame, and the height automatic measurement device is arranged outside the lever device; the invention simultaneously uses a set of software for carrying out the automatic measurement; the detection process and the method of the measuring instrument comprise the following steps: a measurement device is connected, meanwhile, the position of the probe is initiated; the heating procedure of the heating furnace is started, the temperature monitoring is simultaneously started and the timing is carried out, then the measurement is carried out according to the provisions of national standards; the full automatic coal glial layer index measuring instrument and the detection process and the method of the measuring instrument can realize the full automatic measurement of the glial layer index, improve the precision and reduce the labor intensity and the human error, thereby being more practicable and having the industrial utilization value.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Intelligent inclination measuring system and monitoring method thereof

ActiveCN110359440AImprove human-computer interactionRegression is accurateIn situ soil foundationData acquisitionDeformation monitoring

The invention provides an intelligent inclination measuring system and a monitoring thereof method. The intelligent inclination measuring system comprises an automatic inclination measuring machine, adata acquisition terminal, a cloud monitoring management system and a power supply system. The automatic inclination measuring machine comprises a machine frame, an unwinding device, a cable arranging device, a meter counting device, a reversing device, a correcting device, an in-place detecting device, an electric control system, a gripping device and a trial winding device; the intelligent inclination measuring system is simple in structure and convenient to maintain, assemble and disassemble, and does not have a safety hazard; an inclination measuring pipe is detected by simulating automatic trial winding of an inclination measuring device; the damage of an inclination measuring sensor, inaccurate data and the like are avoided; the operating state of equipment can be monitored in realtime by arranging a tension sensor; automatic measurement is realized in the overall process; measuring point data are automatically acquired through the data acquisition terminal and are transmittedto the cloud monitoring management system in real time; event information in the operating process of the equipment is displayed through the cloud monitoring management system; the intelligent inclination measuring system processes and gives an alarm when an abnormity appears; the measurement precision is high; and the equipment is stable and reliable, and can be applied to deformation monitoringon a sliding surface in a soil body of a landslide mass, dangerous rock, high side slope and the like.

Owner:广州日昇岩土科技有限公司

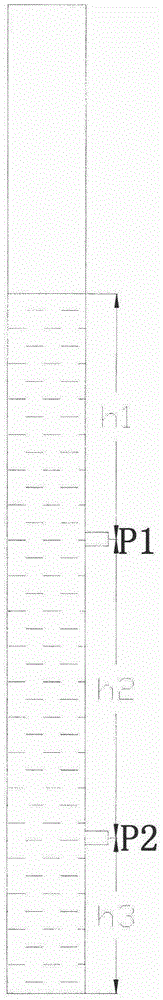

Method for measuring liquid level of liquid in container

InactiveCN105466521AHigh measurement accuracyReduce mistakesLevel indicators by pressure measurementObservational errorPhysics

The invention relates to the field of intelligent measurement and provides a method for measuring the liquid level of liquid in a container. The method includes the following steps that A, two points are selected from the side wall of the container and are the upper measuring point and the lower measuring point respectively, the upper measuring point is higher than the lower measuring point, and pressure intensity sensors are installed to measure the pressure intensity value of the upper measuring point and the pressure intensity value of the lower measuring point respectively ; B, the height between the liquid level and the upper measuring point is calculated through the pressure intensity value of the upper measuring point, the pressure intensity value of the lower measuring point and the vertical distance between the upper measuring point and the lower measuring point, and the calculation formula is shown as h1=P1h2 / (P2-P1), wherein P1 is the pressure intensity value of the upper measuring point, P2 is the pressure intensity value of the lower measuring point, h1 is the height between the upper measuring point and the liquid level, and h2 is the vertical distance between the upper measuring point and the lower measuring point. According to the method, the accurate liquid level height can be obtained through calculation by measuring the pressure intensity values of two different heights of liquid in the container, measuring precision is high, errors are small, and measuring errors caused by factors such as temperature and density are effectively avoided.

Owner:SUZHOU XINRUI ELECTRIC CO LTD

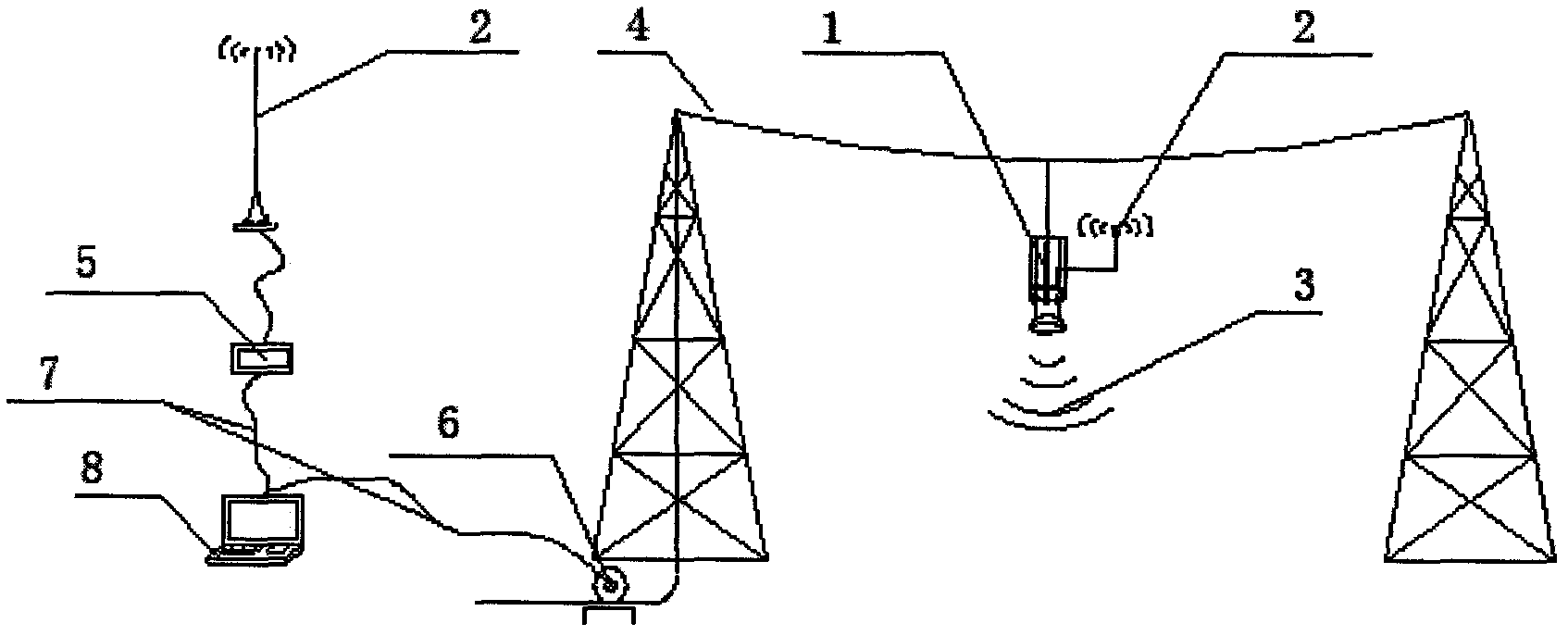

High water flow testing mode of non-contact microwave flow meter capable of replacing traditional buoy

InactiveCN103033643AShort timeReduce workloadOpen water surveyFluid speed measurementMicrowaveMeasuring instrument

The invention provides a high water flow testing mode of a non-contact microwave flow meter capable of replacing a traditional buoy. The high water flow testing mode comprises a microwave flow meter, the microwave flow meter transmits a beam of microwave to the water surface through a microwave antenna, the microwave is divided into two parts; one part of electromagnetic wave energy is refracted into water, other small part energy is reflected back by the water surface to be received by the microwave antenna, and Doppler frequency information corresponding to flow velocity is generated through a circular polarization mixer; and depression angle information of a tilt angle sensor measuring instrument is combined, and the flow velocity can be obtained.

Owner:HENAN ANHONG INFORMATION TECH

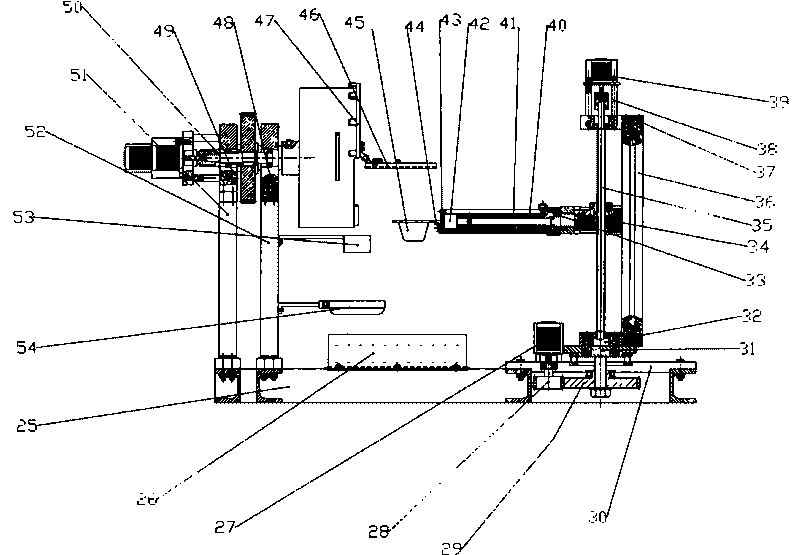

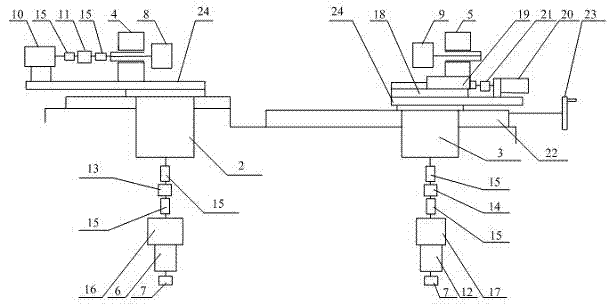

Instrument for measuring startup torque, swing torque and slippage force of constant-velocity universal joint assembly

InactiveCN102175375ARealize fully automatic measurementHigh measurement accuracyApparatus for force/torque/work measurementUniversal jointEngineering

The invention discloses an instrument for measuring a startup torque, a swing torque and a slippage force of a constant-velocity universal joint assembly. The instrument comprises an outer spherical-cage swinging shafting, an inner spherical-cage swinging shafting, and an outer spherical-cage rotating shafting and an inner spherical-cage rotating shafting which are arranged on the upper ends of the outer spherical-cage swinging shafting and the inner spherical-cage swinging shafting respectively, wherein an outer spherical-cage swinging motor for driving the outer spherical-cage swinging shafting to rotate is arranged at the lower end of the outer spherical-cage swinging shafting; an angle sensor is arranged on the outer spherical-cage swinging motor; an outer spherical-cage fixing device and an inner spherical-cage fixing device are arranged on the outer spherical-cage rotating shafting and the inner spherical-cage rotating shafting respectively; an assembly rotating motor for driving the outer spherical-cage rotating shafting to rotate is arranged at the other end of the outer spherical-cage rotating shafting; and an assembly torque sensor is arranged between the assembly rotating motor and the outer spherical-cage rotating shafting. By the instrument, the startup torque, swing torque, and slippage force, at a slippage end, of a constant-velocity universal joint assembly can be detected at the same time, the measurement precision is high, the measuring method is advanced and the operation is simple and convenient; and thus, the automatic measurement is achieved and current gap in the field is filled.

Owner:成都斯瑞工具科技有限公司

Device for automatically measuring surface chromium content on tin plate by using electrolytic process and determination terminal point judgment method

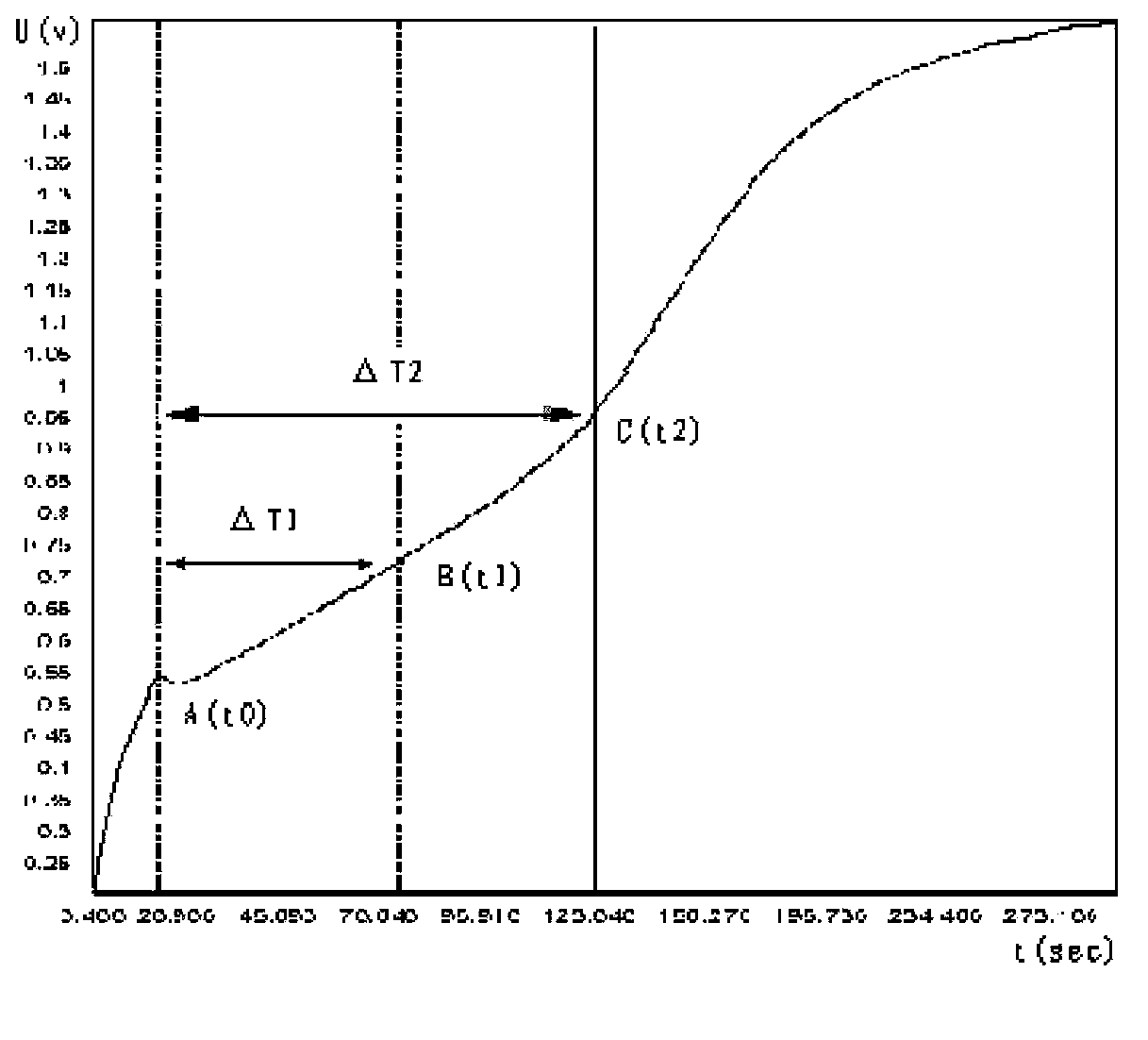

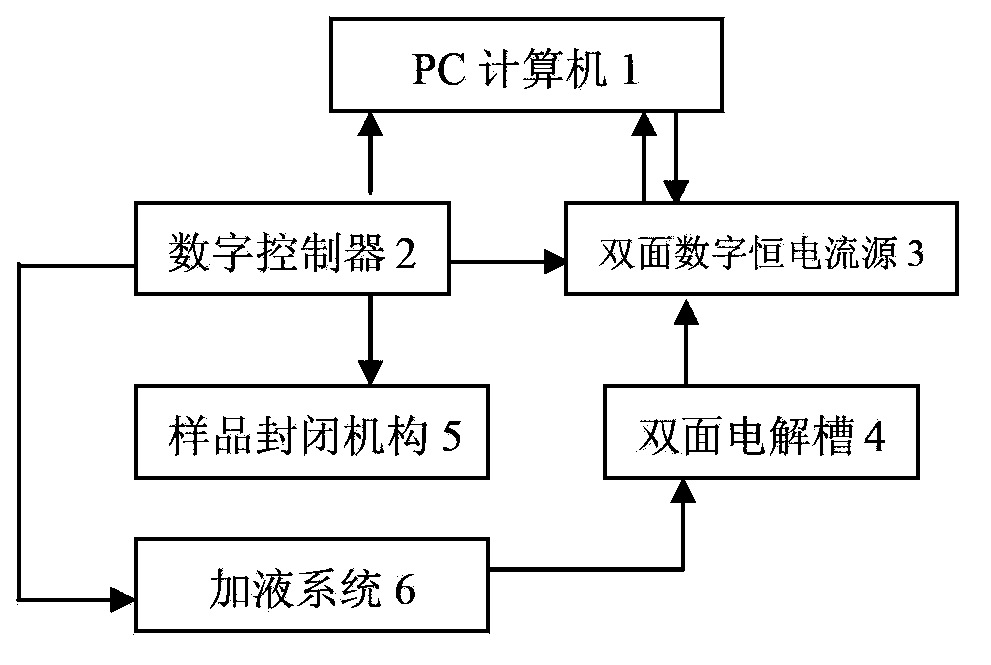

ActiveCN103901082ARealize fully automatic measurementSimple and fast operationMaterial electrochemical variablesMeasurement deviceEngineering

The invention discloses a device for automatically measuring the surface chromium content on a tin plate by using an electrolytic process and a determination terminal point judgment method, and belongs to the field of analysis. The device comprises a computer, a digital controller, double paths of constant current sources, a dual-sided electrolytic cell, a sample sealing mechanism and a charging system, wherein an I / O port of the computer is connected with the control ends of the digital controller and the double paths of constant current sources; the output end of the digital controller is respectively connected with the control ends of the sample sealing mechanism and the charging system correspondingly; the output ends of the double paths of constant current sources are respectively connected with electrodes in the dual-sided electrolytic cell correspondingly; and the charging system is respectively connected with electrolyte pipelines of the dual-sided electrolytic cell correspondingly. The invention also provides a terminal point judgment method of the electrolytic process by using the automatic measurement device for measuring the surface chromium content. A dual-electrolytic cell structure is adopted, so that full-automatic determination on the front side and the back side of the sample is achieved, the measurement accuracy of the surface chromium content on the tin plate by using the electrolytic process is improved, and the device and the method can be widely applied to the field of detection of surface chromium content of the tin plate product.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Device and method for automatic workpiece inspection

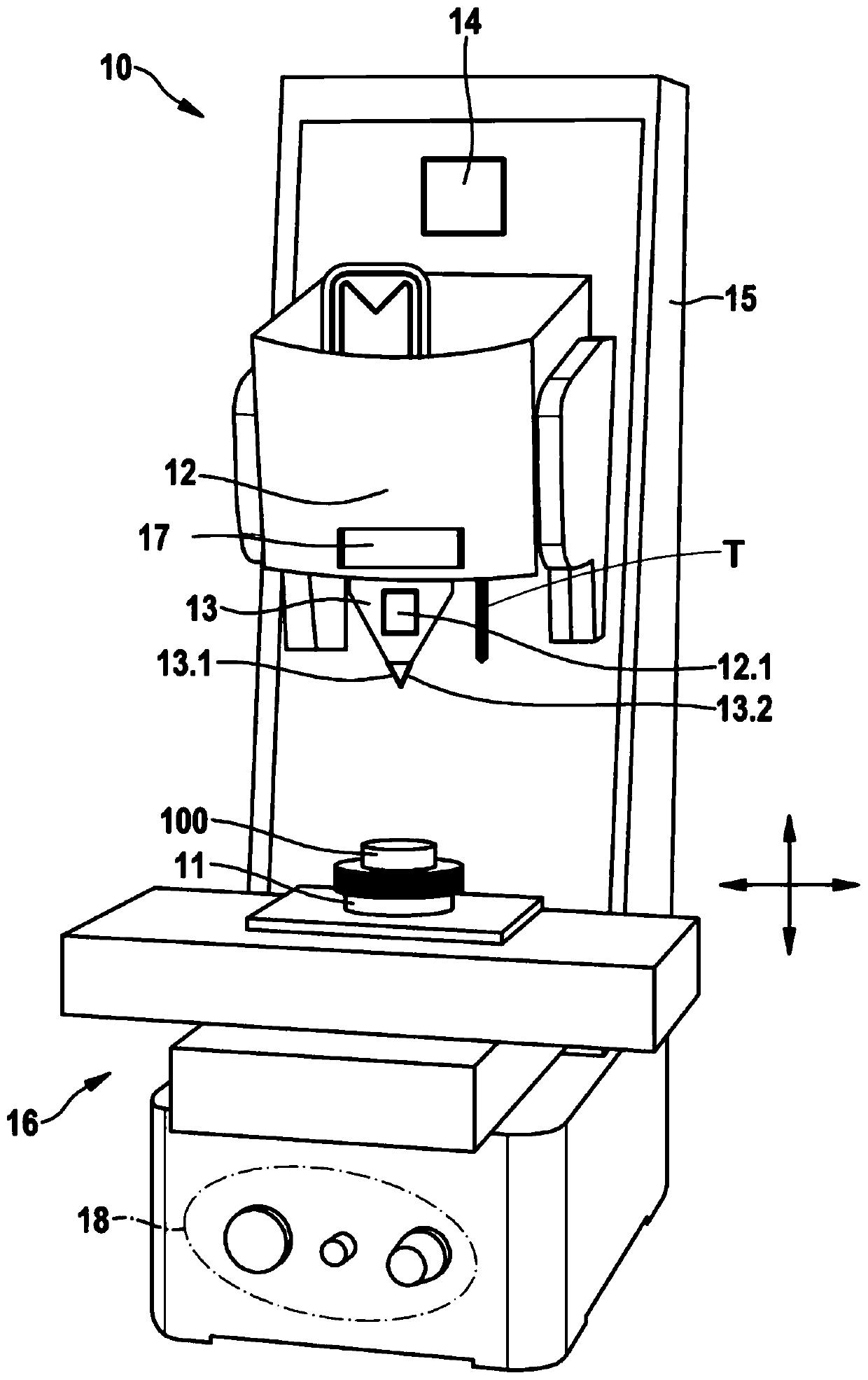

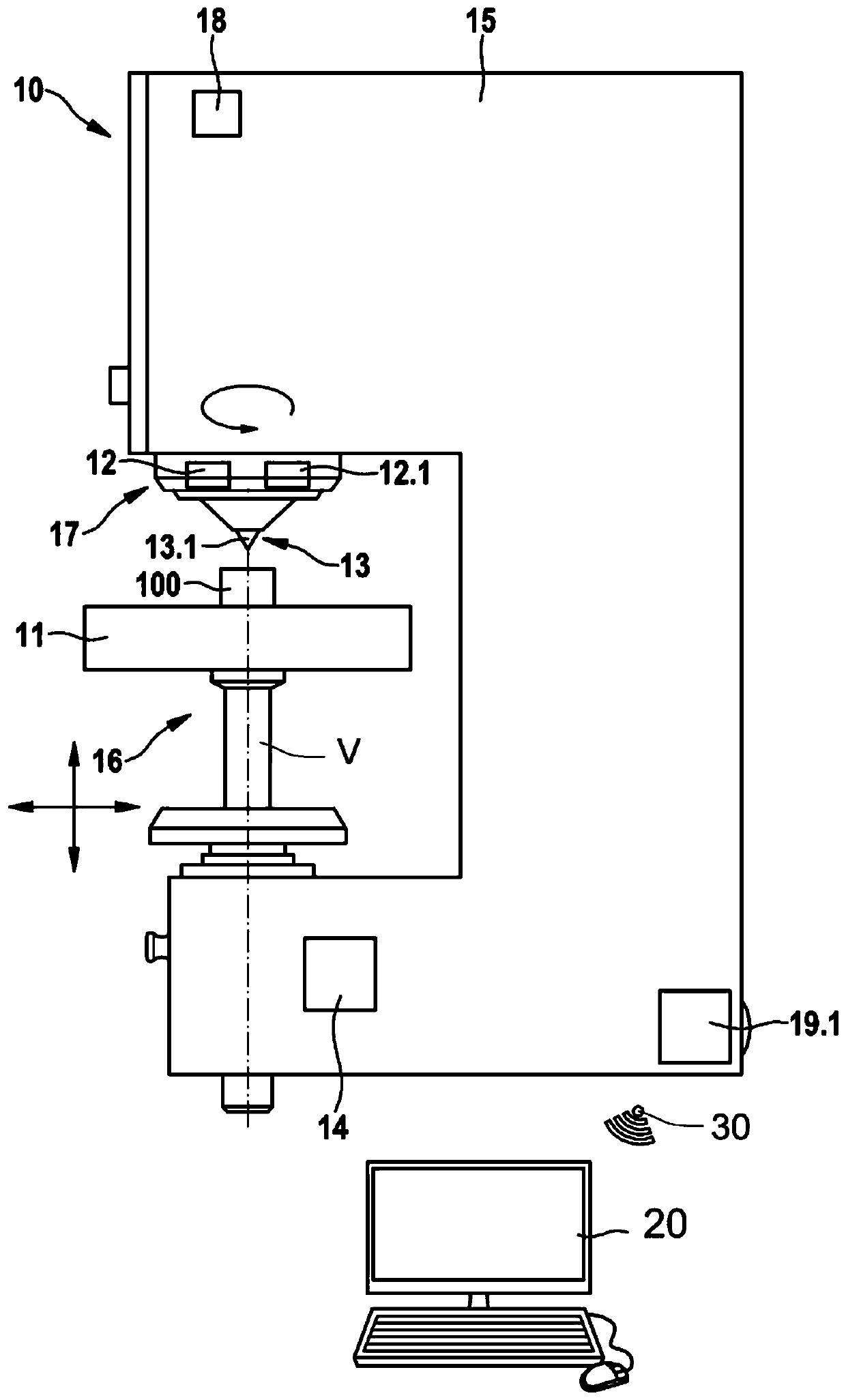

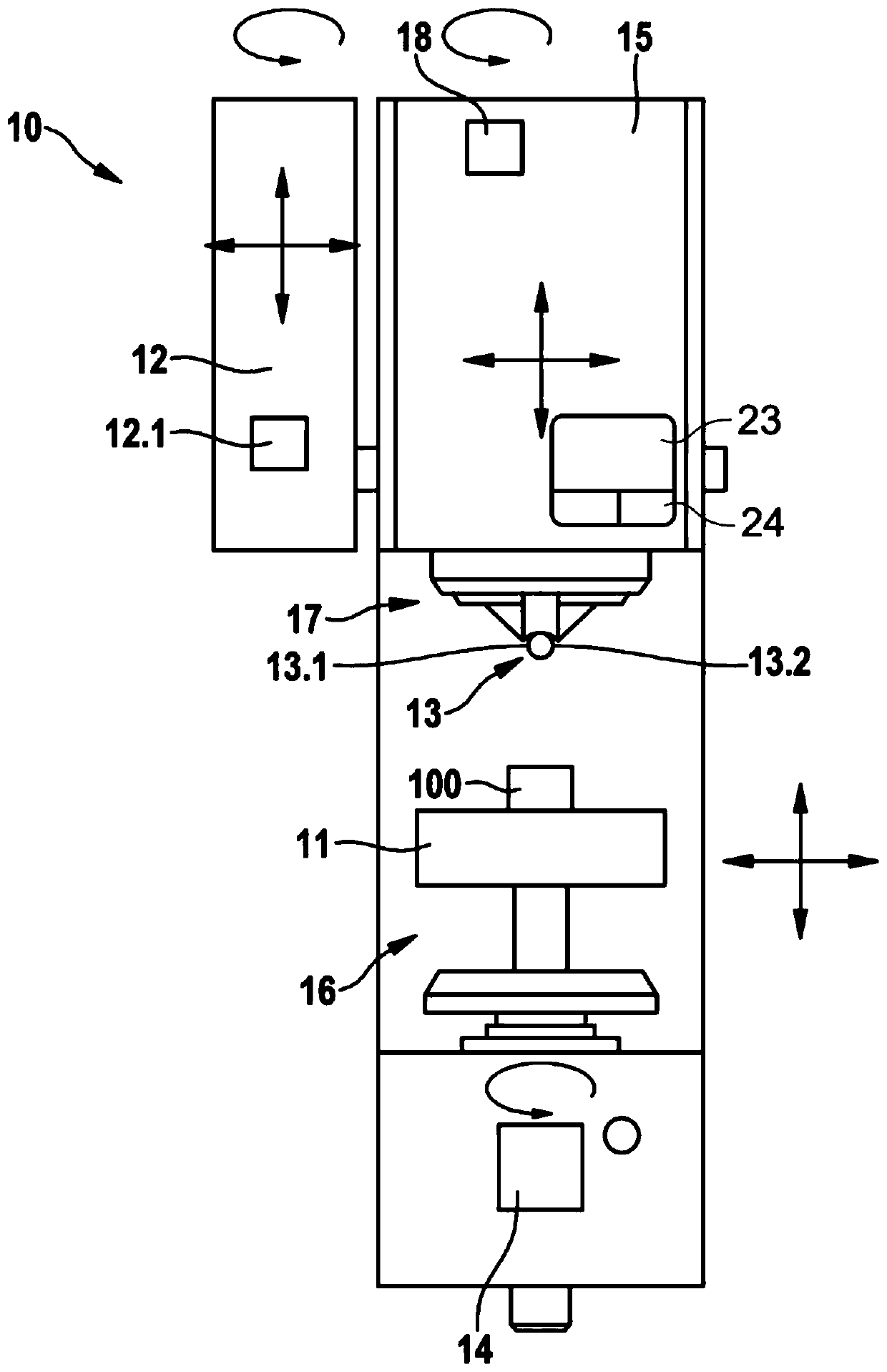

PendingCN111226106ARealize fully automatic measurementImprove the possibility of applicationInvestigating material hardnessEngineeringMechanical engineering

The invention relates to a measuring device (10) for determining at least one mechanical property of a workpiece sample (100), which comprises at least one image capturing unit (12) for optically determining a workpiece geometry of the workpiece sample (100), and at least one mechanical inspection head (13) for making an indentation (101) in the workpiece sample (100). According to the invention,at least the image capturing unit (12) and the mechanical inspection head (13) form a structural unit (B) together.

Owner:IMPRINTEC GMBH

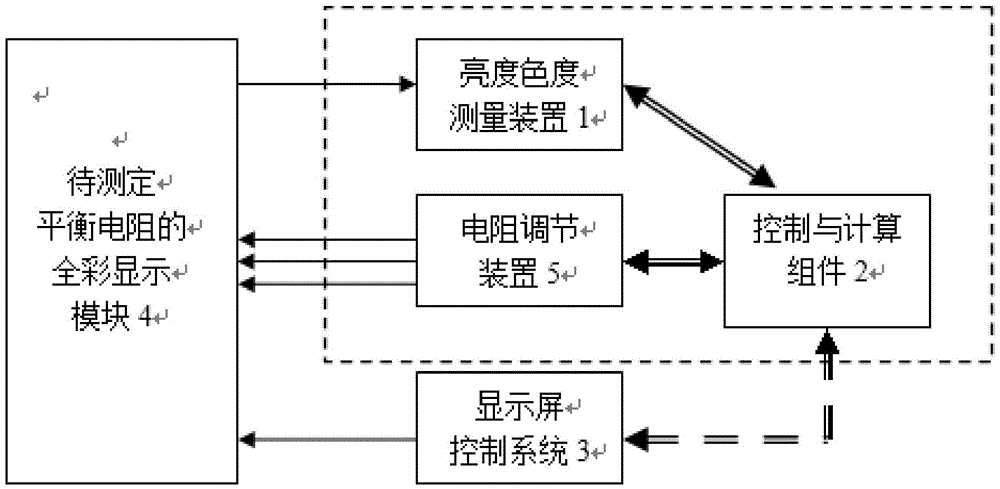

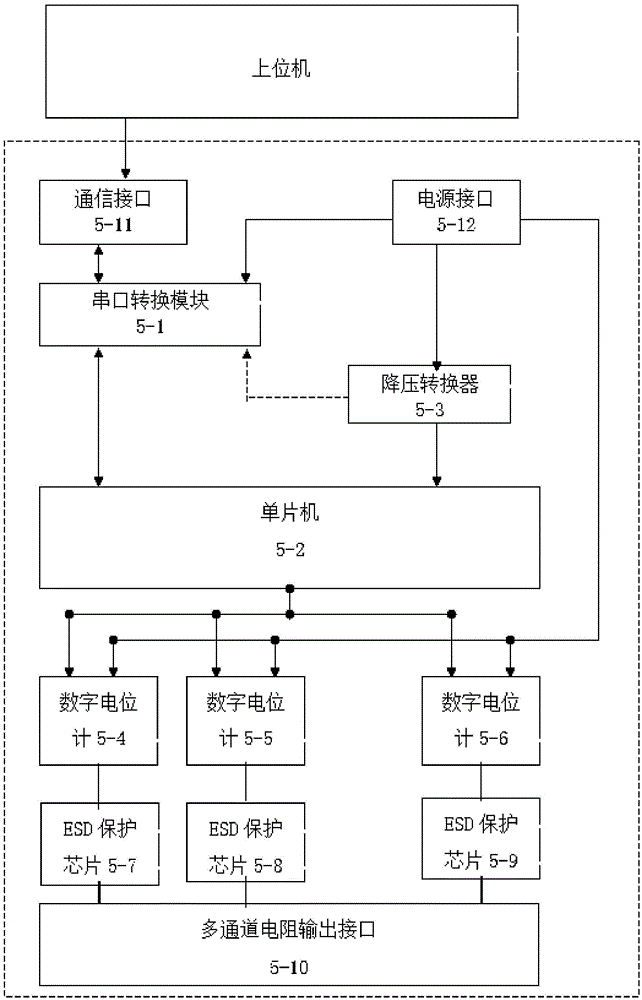

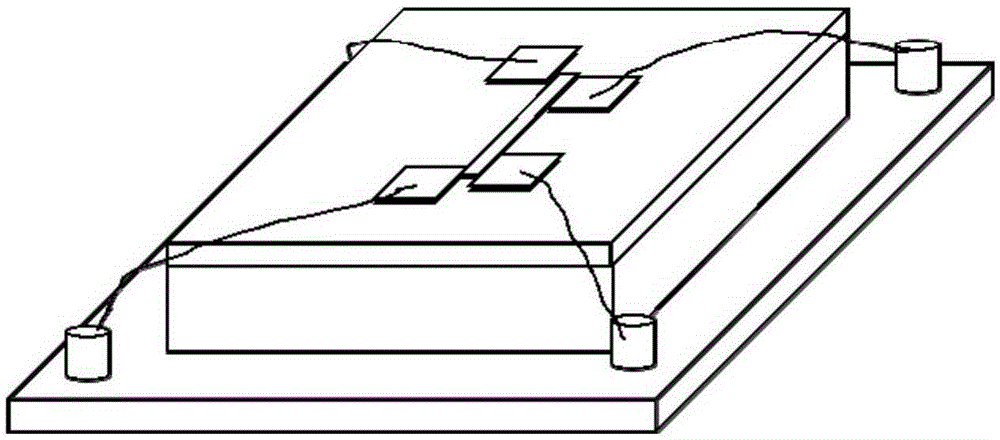

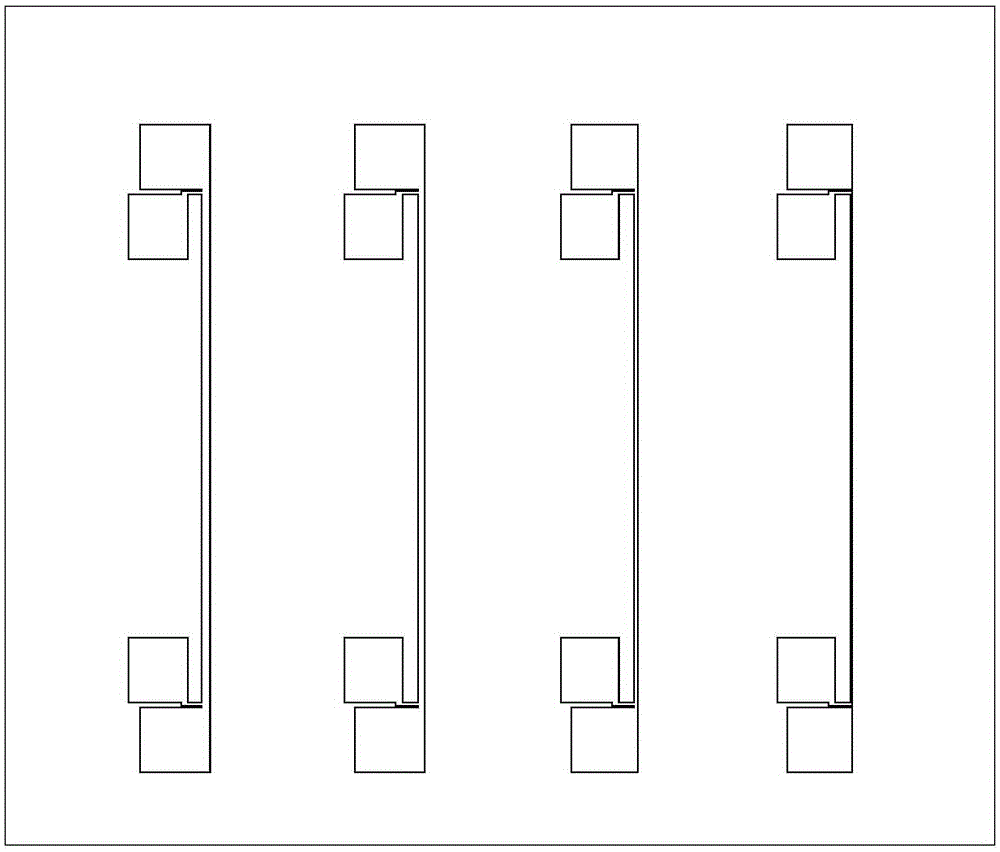

Device and method for automatic determination of white balance adjustment resistor of LED display screen

ActiveCN105551410ARealize fully automatic measurementGuaranteed accuracyStatic indicating devicesMeasurement deviceColor measurement

The present invention provides a device and method for automatic determination of a white balance adjustment resistor of a LED display screen. The device provided by the invention comprises a brightness and color measurement device, a control and calculation assembly, and a resistance regulation device arranged between a full-color display module and the control and calculation assembly; the brightness and color measurement device is a programmable general luminosity and color measurement instrument which is a brightness and color measurement module being capable of communicating with the control and calculation assembly, and the programmable general luminosity and color measurement instrument is connected with the illumination photometer, the brightness colorimeter and the spectrometer of a communication module being capable of communicating with the control and calculation assembly and is connected with one of communication modules, through employing a luminosity sensor and a set of XYZ spectrum response coupling optical filters, capable of communicating with an electrical parameter measurement module and the control and calculation assembly; and the control and calculation assembly and the upper computer software of a display screen control system communicate through a protocol instruction. The device and method for automatic determination of a white balance adjustment resistor of a LED display screen is able to realize the automatic measurement of a white balance resistance value, is simple, fast, reliable and visual; and moreover, the resistance value of the resistance regulation device may be regularly calibrated and automatically corrected so as to guarantee the accuracy.

Owner:深圳中科维优科技有限公司

Low temperature thermal conductivity measurement method

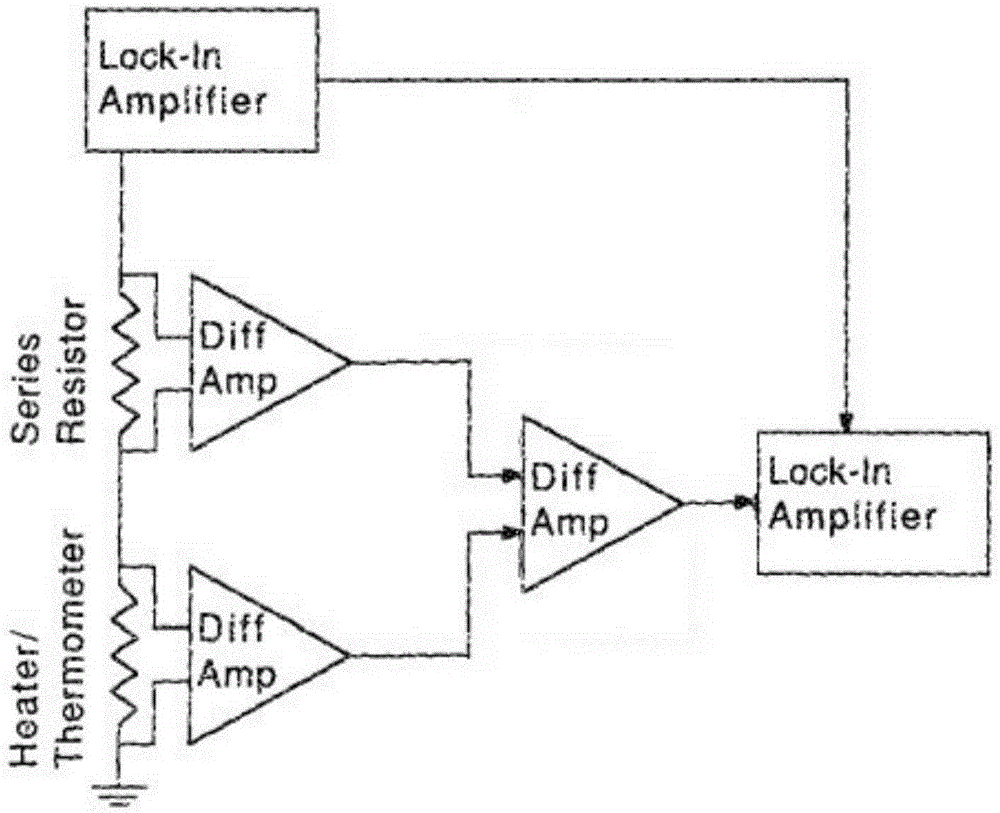

InactiveCN105241918AEliminate measurement biasHigh measurement accuracyMaterial heat developmentMicrocontrollerPermalloy

The invention relates to a low temperature thermal conductivity measurement method. The method can be used for measuring the thermal conductivity of a solid substrate or a film at normal temperature or a low temperature. The method is a 3omega method based on solid material thermal conductivity measurement, and is improved from the following aspects: the thickness of a film on a substrate is changed, measurement is carried out multiple times, and the vertical thermal conductivity of the film is obtained through a difference technology, so the measured value deviation caused by boundary thermal resistance on a film and substrate interface is effectively avoided; a preamplifier with extremely low linear deflection is arranged in front a lock-in amplifier for measurement, and amplifies a signal 10 times, so the measurement precision is effectively improved; the amplification factor of the preamplifier is adjusted through a one-chip microcomputer control digital potentiometer, so fully-automatic measurement is realized; and a measurement warm area is expanded to extremely low temperature by adopting magnetic material permalloy.

Owner:PEKING UNIV

Efficient projection enlarged image detection method

ActiveCN103954215AHigh degree of automationRealize fully automatic measurementUsing optical meansData processingAutomation

The invention belongs to the field of detection, and relates to improvement of a projection enlarged image detection method. An efficient projection enlarged image detection method can be used for detecting a projection enlarged image, quick measuring of the projection enlarged image is achieved, a visualization detection data processing mode is formed, efficiency, the automation degree and the intelligence degree of a detection device are improved, complexity and mistakes during measuring and calculation processes in the prior art are reduced, data accuracy is improved, detection efficiency and detection accuracy are improved, and the first-class level of the industry is reached.

Owner:AECC AVIATION POWER CO LTD

Full automatic intelligent measuring apparatus for gelatineous layer of mixed coal and measuring method thereof

InactiveCN100473946CImprove the accuracy of measuring displacementReduce pressure measurement errorsFlow propertiesObservational errorMeasurement device

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

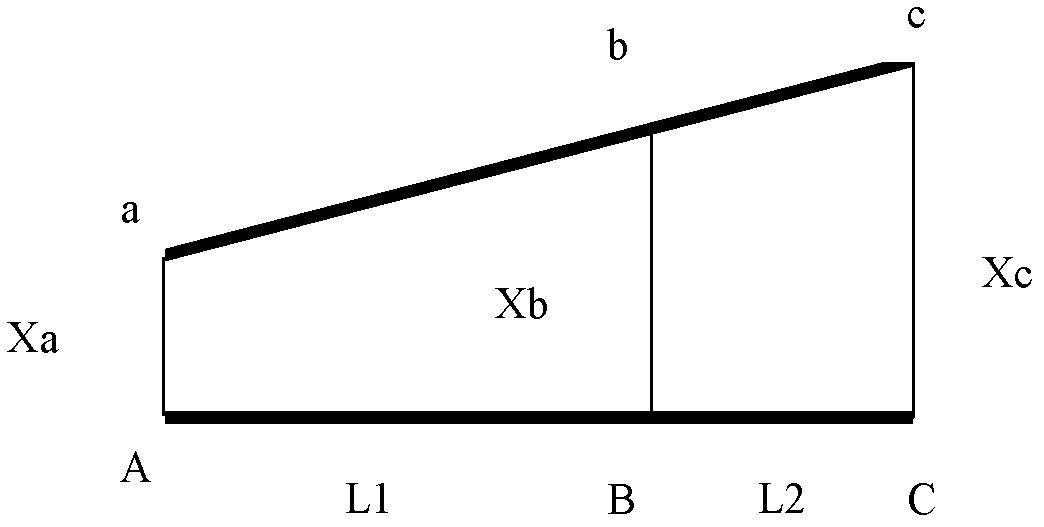

Non-contact straightening point confirming method for straightness of rectangular-section long-rail work piece

InactiveCN103394550ARealize fully automatic measurementRealize measurementMetal working apparatusSinuosityComputer science

The invention relates to a non-contact straightening point confirming method for the straightness of a rectangular-section long-rail work piece and belongs to a curvature measuring and straightening point confirming method. A point laser is used for measuring data of the straightness of the surface of the long-rail work piece, and then the collected data are processed and calculated in a sagitta mode to form the required compression point position and the supporting point position. The non-contact straightening point confirming method has the advantages of achieving full-automatic measurement and calculation of the whole straightness and the partial straightness of the long-rail work piece on a straightening machine, confirming the points needing to be straightened, achieving measurement on the long-rail work piece and being simple and applicable.

Owner:中机试验装备股份有限公司

Ballastless track settlement monitoring device

ActiveCN105603841ARealize fully automatic measurementMonitor the amount of subsidenceMeasuring apparatusPhotodetectorEngineering

The invention discloses a ballastless track settlement monitoring device. The ballastless track settlement monitoring device comprises guide rails, a fixing plate fixedly mounted at the front ends of the guide rails, a main plate fixedly mounted in the middles of the guide rails, and a mirror bracket movably mounted at the back ends of the guide rails and being capable of sliding along the axes of the guide rails, wherein a photodetector is arranged on the fixing plate; a laser, a light splitter and a first reflector are arranged on the main plate; a second reflector is arranged on the mirror bracket; the laser, the light splitter, the first reflector, the second reflector and the photodetector form a michelson interferometer; the mirror bracket is connected with a flanged settlement plate through a connecting post. The ballastless track settlement monitoring device measures settlement of a ballastless track in real time through the michelson interferometer, can measure micro-sized or even nano-sized settlement distance, and achieves the purposes of accurately perceiving settlement and monitoring the settlement amount.

Owner:南京城铁信息技术有限公司

Kit for detecting human HTLV virus (1+2) type antibody

InactiveCN109187954AHigh sensitivityIncrease the occurrence areaChemiluminescene/bioluminescenceBiological testingAntigenFully automatic

The invention discloses a kit for detecting a human HTLV virus (1+2) type antibody, comprising a magnetic particle coating suspension, an enzyme conjugate working solution, and a sample diluent; the coating antigen is a HTLV (1+2) fusion antigen; and the enzyme conjugate is a horseradish peroxidase-labeled HTLV (1+2) fusion antigen. According to the kit for detecting a human HTLV virus (1+2) typeantibody, the kit of the invention adopts magnetic particles as a solid-phase carrier and has a large specific surface area, which increases the area where the immune reaction occurs and improves thesensitivity of the reaction; and the spherical and uniform surface of the magnetic particles reduce chemical adhesion and non-specific binding, enhance a specific enzymatic chemiluminescence system toachieve effective amplification of a reaction signal. The kit of the invention is good in specificity, so that the antigen and the antibody achieve high detection sensitivity, and a fully automatic measurement is achieved. The kit of the invention can be used with a fully automatic chemiluminometer, and the influence of human operation on test results is reduced, so that the detection result is more reliable, accurate, fast and repeatable.

Owner:AUTOBIO DIAGNOSTICS CO LTD

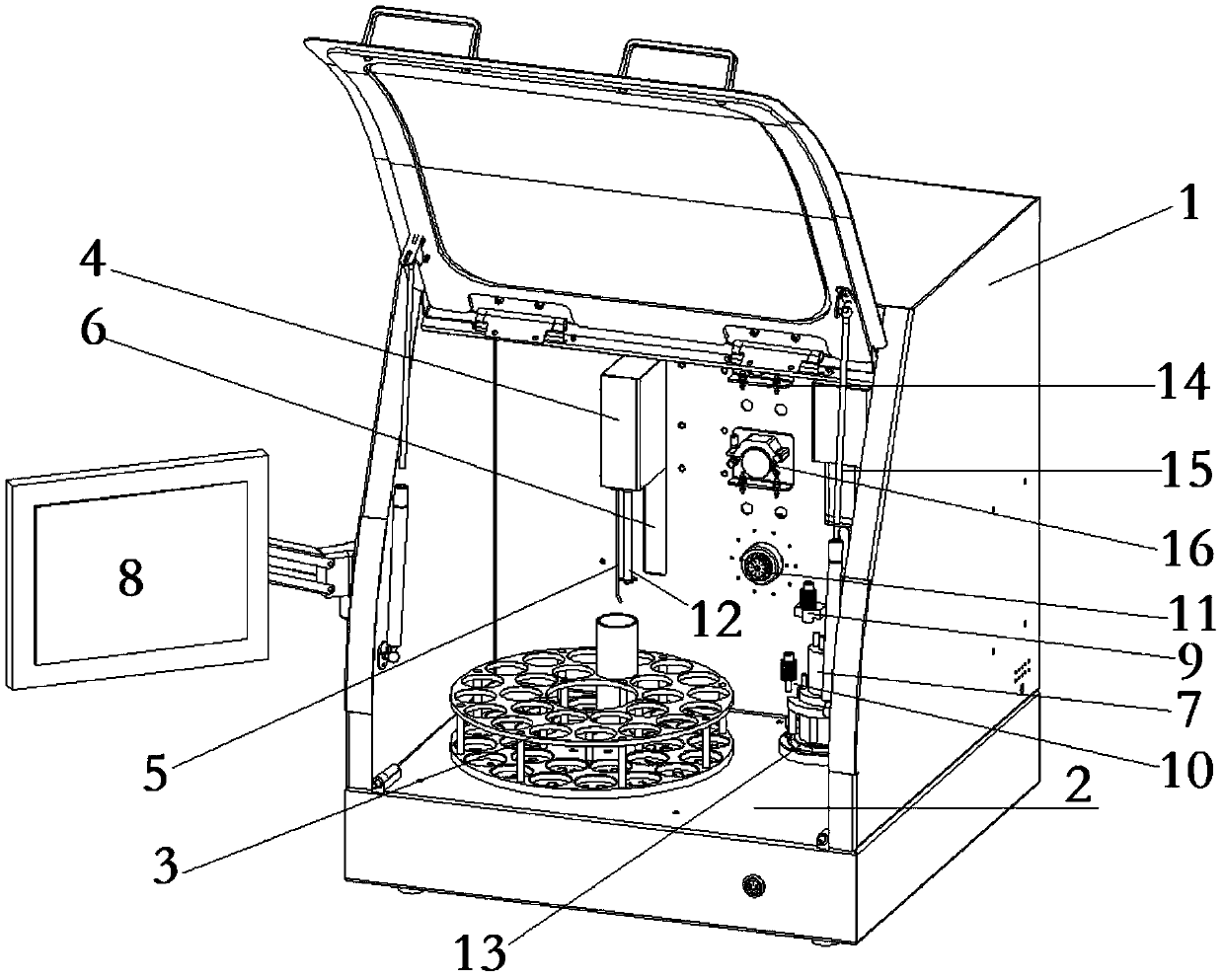

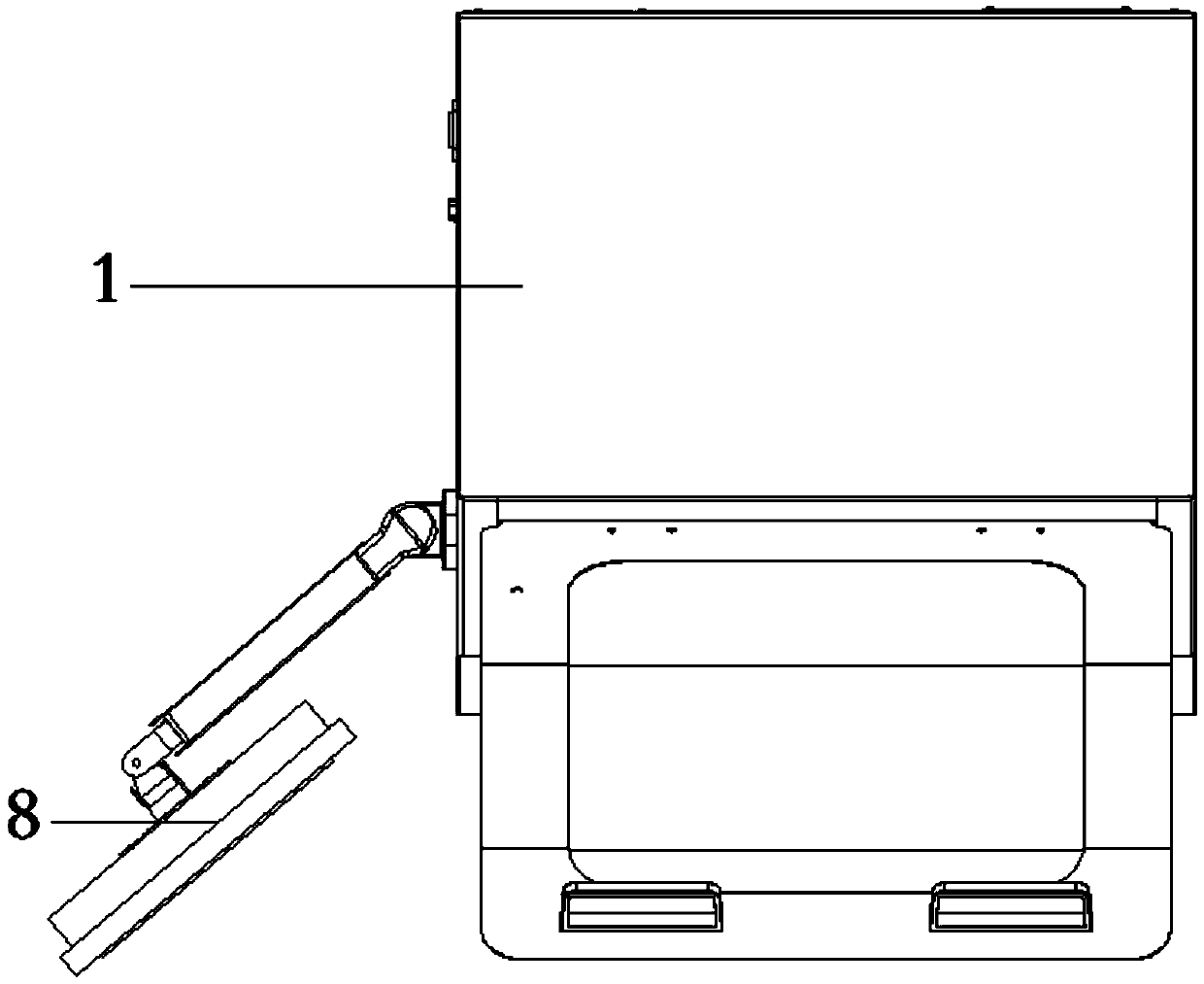

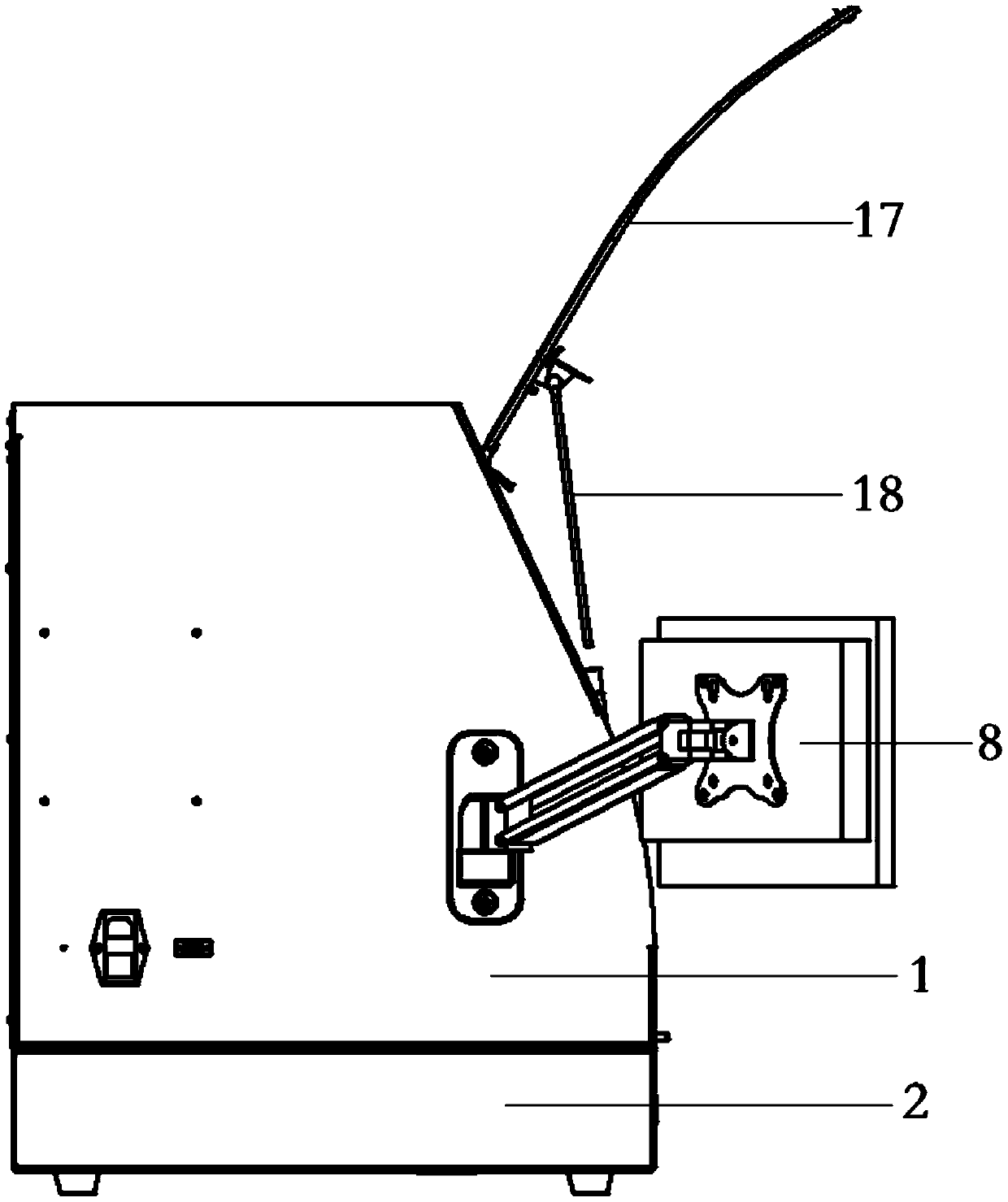

Tester for anionic surfactant in water

PendingCN110794157ARealize fully automatic measurementGuaranteed stabilityPreparing sample for investigationColor/spectral properties measurementsActive agentEnvironmental engineering

The invention relates to a tester for an anionic surfactant in water. The tester comprises a shell and a bottom plate positioned at the bottom of the shell, a turntable system is arranged on the bottom plate, a rotary tray for placing a plurality of sample cups is arranged on the turntable system, a mechanical arm capable of moving up and down is arranged above the rotary tray, and the mechanicalarm is provided with a liquid pumping pipe for pumping extracted chloroform extraction liquid and an injection cleaning pipe for injecting pure water to clean the sample cups. Full-automatic measurement of an anionic surfactant in the sample is achieved, the water sample extraction stability is guaranteed, organic reagents are completely and automatically added and waste liquid is collected in theextraction process, experimenters do not need to make contact with toxic organic reagents at all, the humanized design is met, the working efficiency of the experimenters is improved, and manpower iseffectively saved.

Owner:宁波然诺科学仪器有限公司

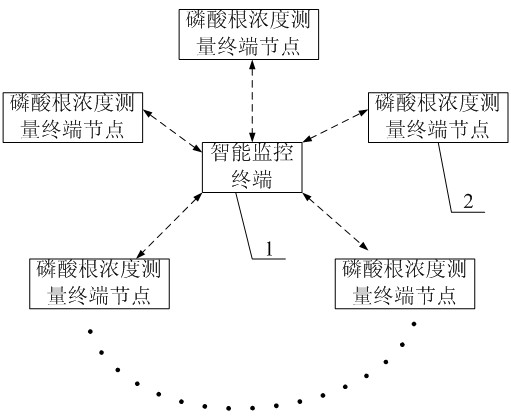

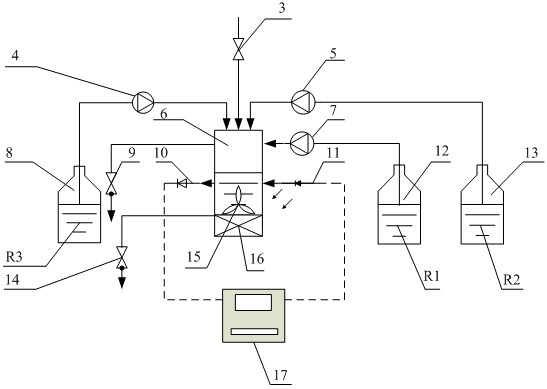

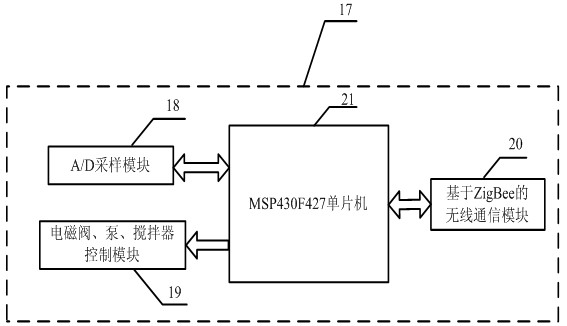

Intelligent phosphate concentration online analysis recorder based on wireless network

InactiveCN102262068AReduce testing costsRealize centralized online monitoringTransmission systemsColor/spectral properties measurementsMicrocontrollerPhosphate

The invention discloses an intelligent phosphate concentration online analysis recorder based on a wireless network, which includes a plurality of phosphate concentration measurement terminal nodes and an intelligent monitoring terminal communicating with the phosphate concentration measurement terminal nodes, capable of simultaneously monitoring multiple Centralized online monitoring of sample water. Phosphate concentration measurement terminal node In the process of measuring the phosphate concentration of the sample water, the standard solution, the reagents contained in the first reagent bottle and the second reagent bottle are realized by programming the single-chip controller of the phosphate concentration measurement terminal node. Carrying out software liquid level calibration reduces the cost of liquid level detection and eliminates misoperations caused by failure of liquid level detection devices. The intelligent monitoring terminal not only realizes the functions of automatic measurement, automatic calibration, large-capacity data storage, touch screen control, Chinese and English menu selection, but also provides serial communication interface and Ethernet interface, which can realize remote monitoring and online release of measurement information.

Owner:HOHAI UNIV CHANGZHOU

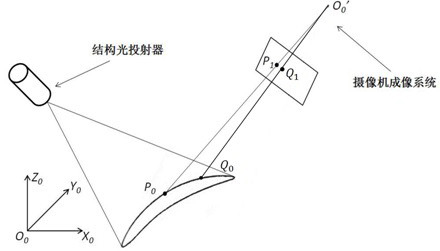

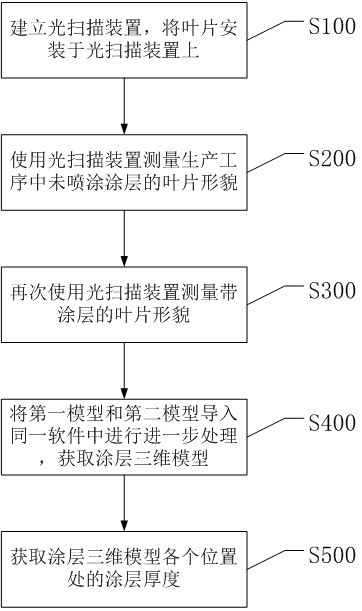

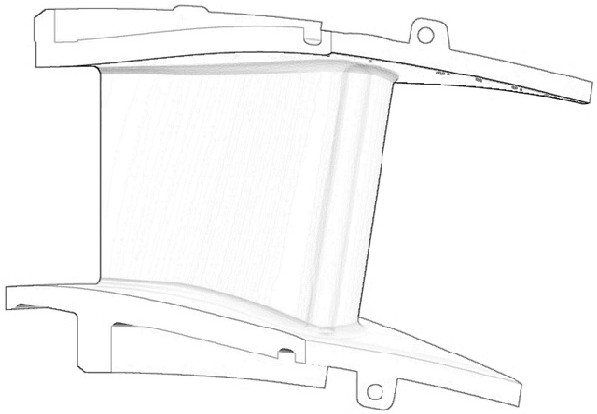

Turbine blade coating thickness optical scanning holographic measurement method

The invention belongs to the field of turbine blade cooling design, and relates to a turbine blade coating thickness optical scanning holographic measurement method, when the coating thickness of a blade is measured, the blade sprayed with a coating is firstly installed on an optical scanning device through an optical scanning technology, the blade is comprehensively scanned through the optical scanning device, and three-dimensional parameters are recorded; forming a first model; the blade is taken down and then subjected to coating spraying, the blade subjected to coating spraying is installed on the optical scanning device again to be subjected to comprehensive scanning, three-dimensional parameters are recorded, a second model is formed, the first model and the second model are imported into the same software to be compared and analyzed, and a coating three-dimensional model is obtained; and the thickness of each position of the coating can be accurately and quickly obtained. The device is simple in structure, convenient to operate, high in measurement precision and capable of effectively avoiding the problem that the thermal barrier coating is damaged in the measurement process, meanwhile, full-automatic measurement can be achieved, and the quality stability and consistency of the thermal barrier coating are guaranteed.

Owner:AECC SHENYANG ENGINE RES INST

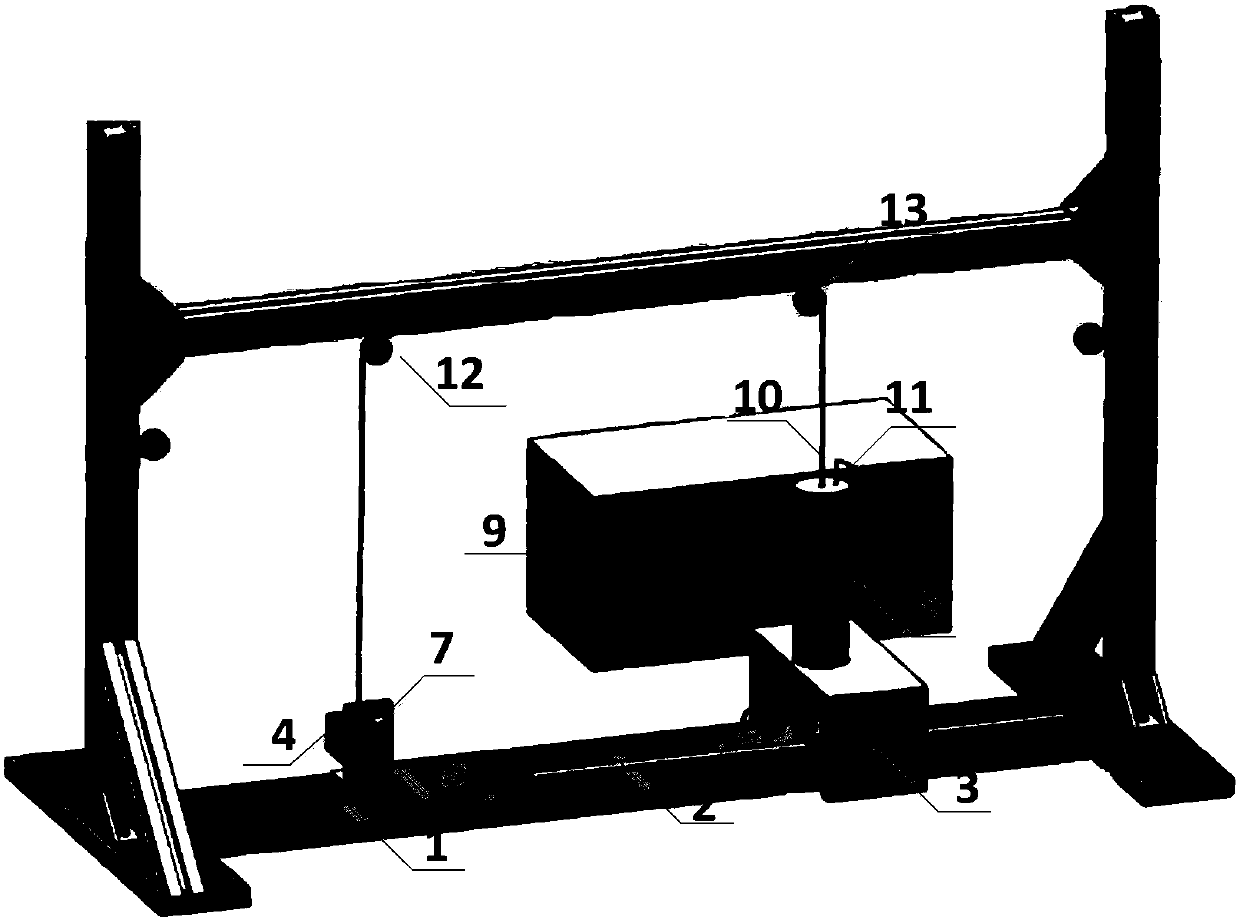

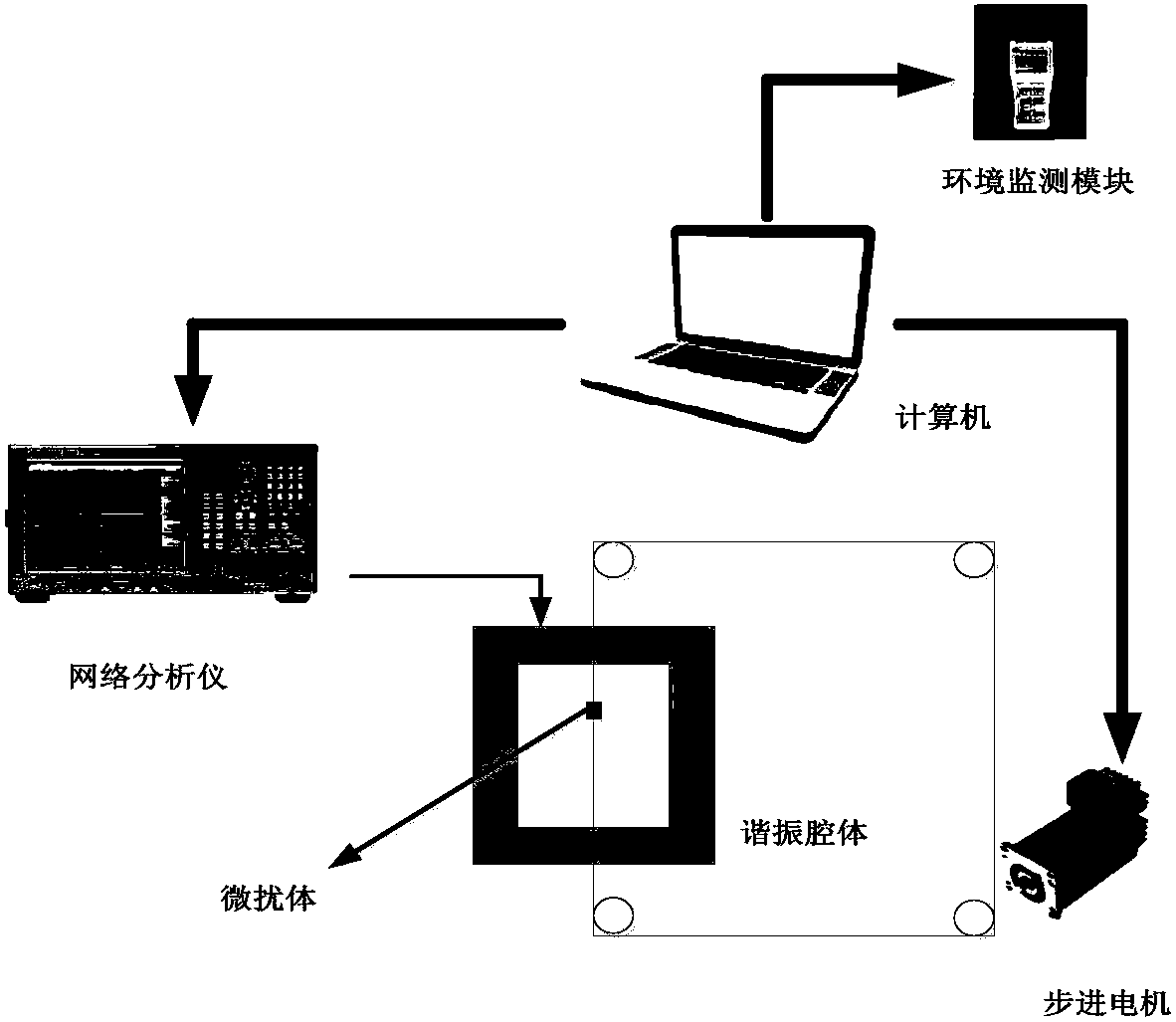

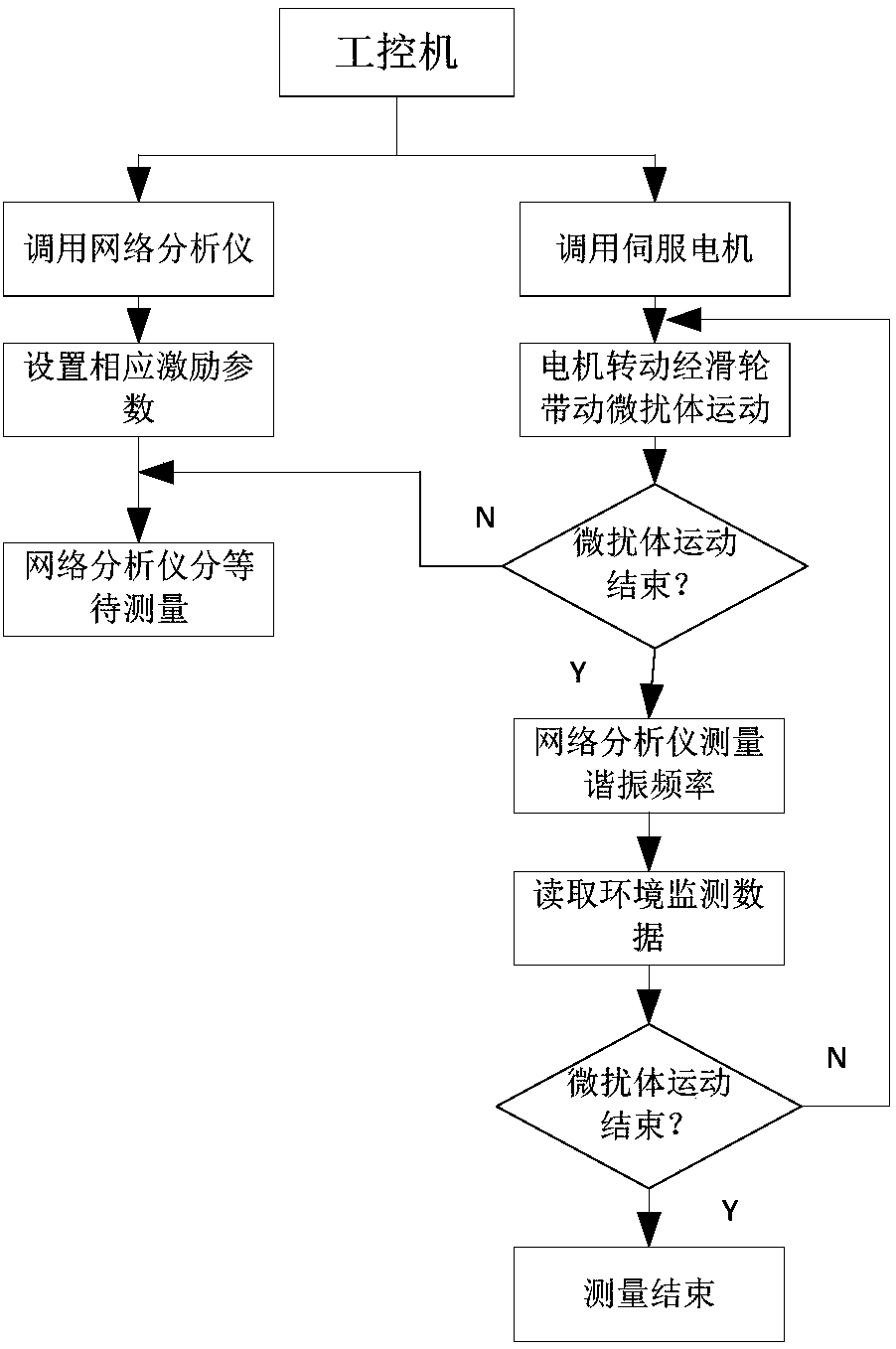

Resonant chamber axial electric field measurement device and measurement method thereof

ActiveCN107589313AHigh concentricityAccurate measurementElectrostatic field measurementsMeasurement deviceElectrical field strength

The invention discloses a resonant chamber axial electric field measurement device and a measurement method thereof. The device comprises a mechanical structure part and a measurement control part. The mechanical structure part comprises a body frame, pulleys, a driving structure, a pulling wire and a micro-disturbance member. The measurement control part comprises an existing module, an environment monitoring module and an analyzing module. The micro-disturbance member is arranged on the pulling wire in the vertical state, and through driving the pulling wire to move through the pulleys, movement of the micro-disturbance member in the central axis of a measured resonance chamber is ensured. Through an exciting module, an exciting signal is transmitted to the measured resonance chamber, and feedback signals when the micro-disturbance member are at different positions are acquired, thereby acquiring resonant frequency of the resonant chamber when the micro-disturbance member are at different positions, and obtaining the resonant chamber electric field strength at the current position according to the resonant frequencies of the resonant chamber when the micro-disturbance member is at different positions and the resonant frequency of the resonant chamber in the current environment. The resonant chamber axial electric field measurement device improves electric field strength accuracy through ensuring coaxiality between the movement track of the micro-disturbance member and the central axis of the measured resonance chamber.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com