Automated test device of bituminous coal caking index

A technology of automatic testing and bonding index, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effects of increasing scientificity, preventing tampering, and reducing human errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

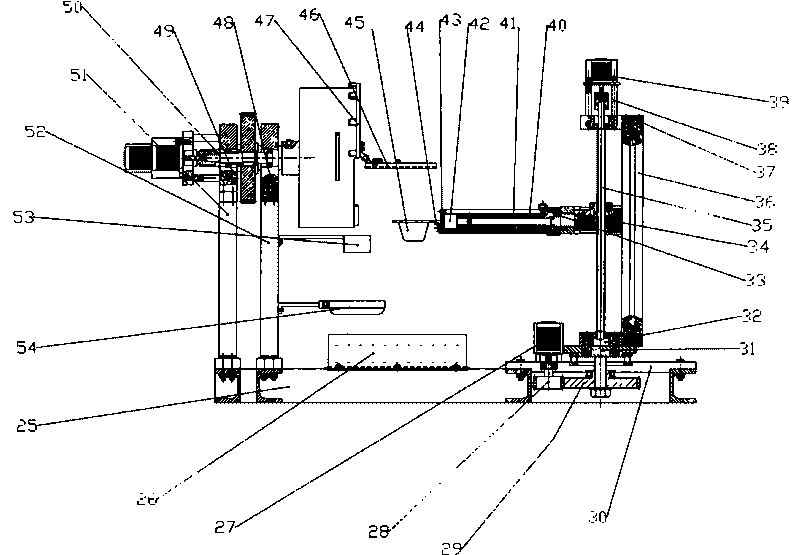

[0012] The lifting motor 39 drives the ball screw 35 to rotate, drives the ball screw nut 34 to move up and down, and the telescopic cross-arm module moves up and down together with the sieve 45 .

[0013] The overall rotation of the lead screw: the rotating motor 27 drives the rotating gear 28 to rotate, and the rotating gear 28 meshes with the turntable gear 29, thereby driving the rotating module connected with the turntable gear 29 to rotate.

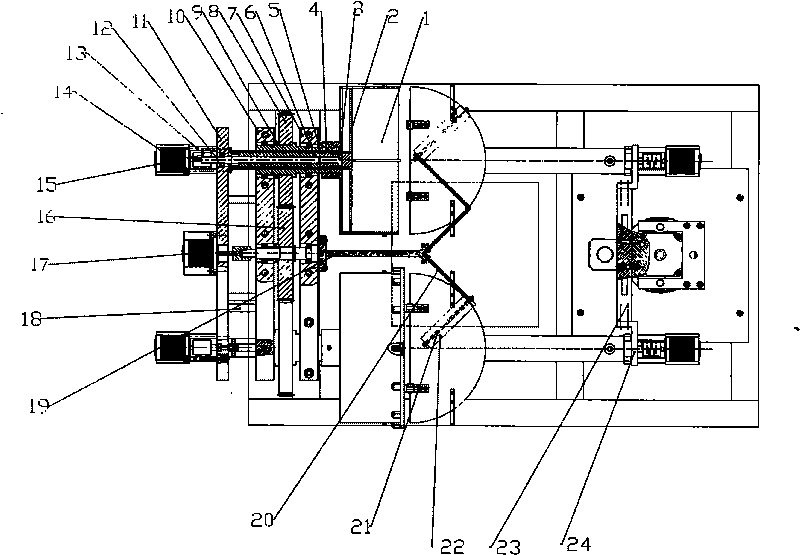

[0014] The drum motor 17 is connected with the main shaft gear 16 through a coupling and drives it to rotate. The main shaft gear 16 meshes with the drum gears A8 and B8 respectively, and simultaneously drives the drum gears A8 and B8 to rotate in the same direction, thereby driving the drum A1 Rotate simultaneously with drum B1. Piston 2 in drum A1 and drum B1 advances synchronously to push the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com