Radial runout measuring method for straightening machine long axis workpiece, and device thereof

A radial runout measurement technology, applied in the field of straightening machines, can solve the problems of slow measurement speed and low accuracy of manual straightening measurement, and achieve the effect of reducing costs, realizing radial runout measurement, and the method is simple and universal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

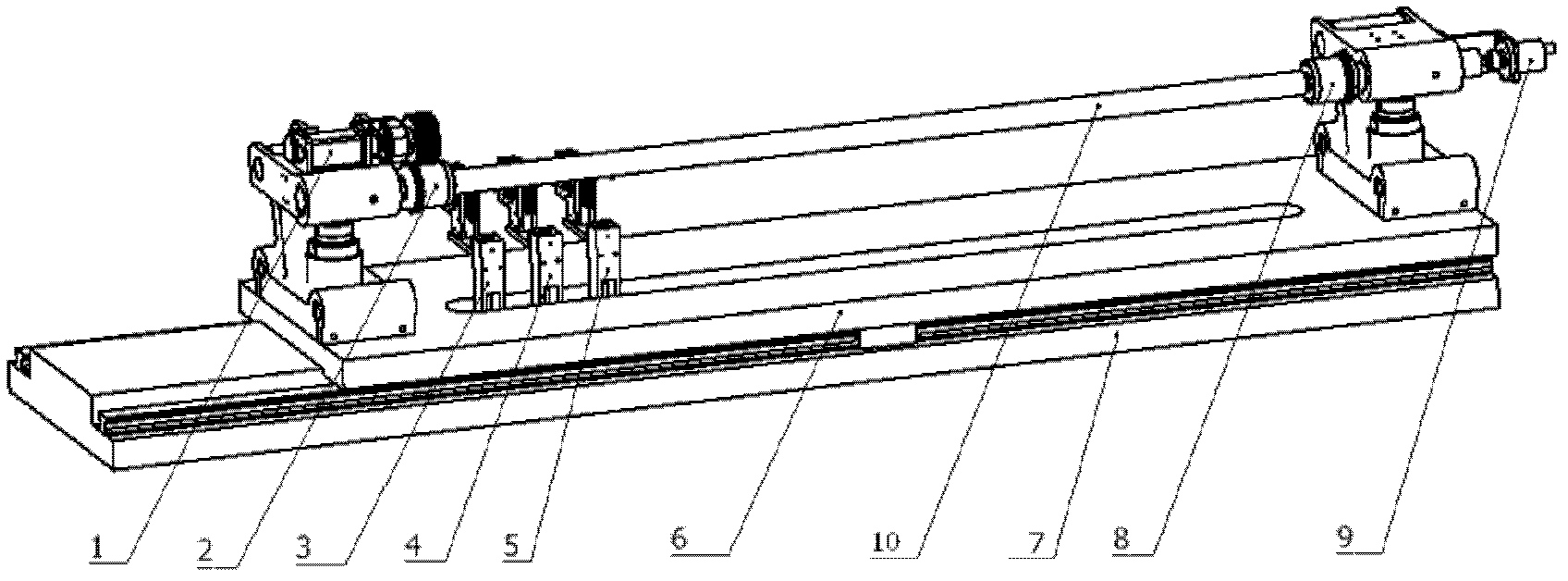

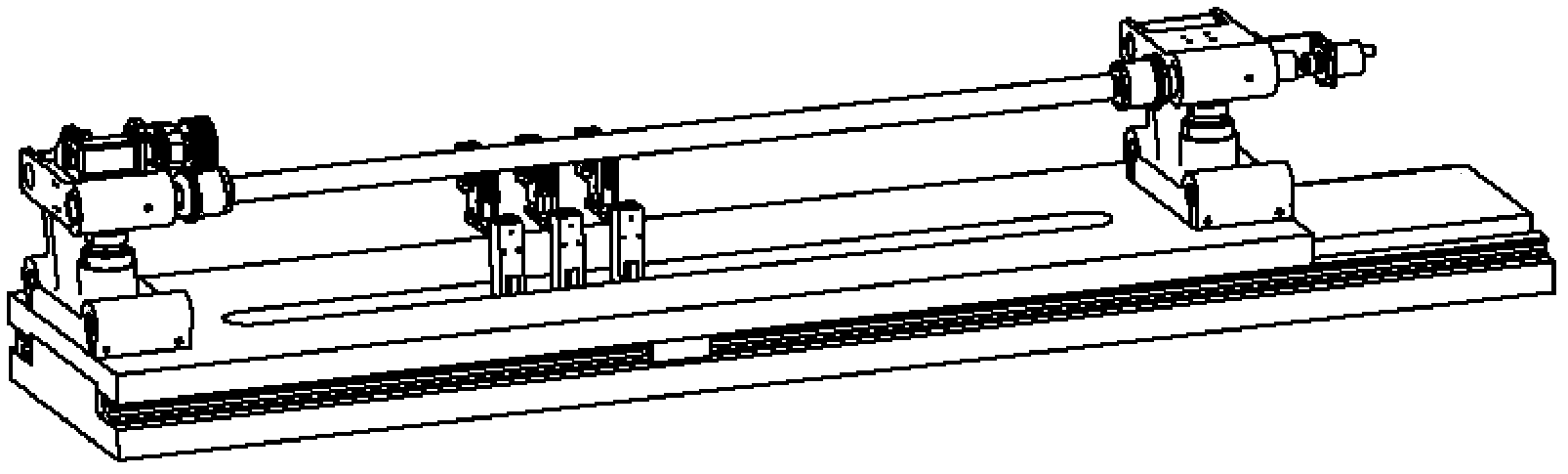

[0022] There are left top 2 and right top 8 on the working platform 6, the working platform 6 is slidingly connected to the workbench 7, the motor 1 is connected to the left top 2 in rotation, the photoelectric encoder 9 is fixedly connected to the right top 8, and a tappet displacement measuring device 3. Tappet-type displacement measuring device 2 4. Tappet-type displacement measuring device 3 5 is fixedly connected to the workbench 7 respectively.

[0023] figure 1 It is a schematic diagram of the long-axis workpiece measurement of the straightening machine. The two tops can hold the long-axis workpiece 10, and the working platform 6 can move the long-axis workpiece 7 to the left or right to realize the measurement of different measurement points of the long-axis workpiece. 1 drives the left top 2 to realize the rotation of the long-axis workpiece 7, and the right top 8 follows to drive the photoelectric encoder 9 to rotate.

[0024] The invention works like this:

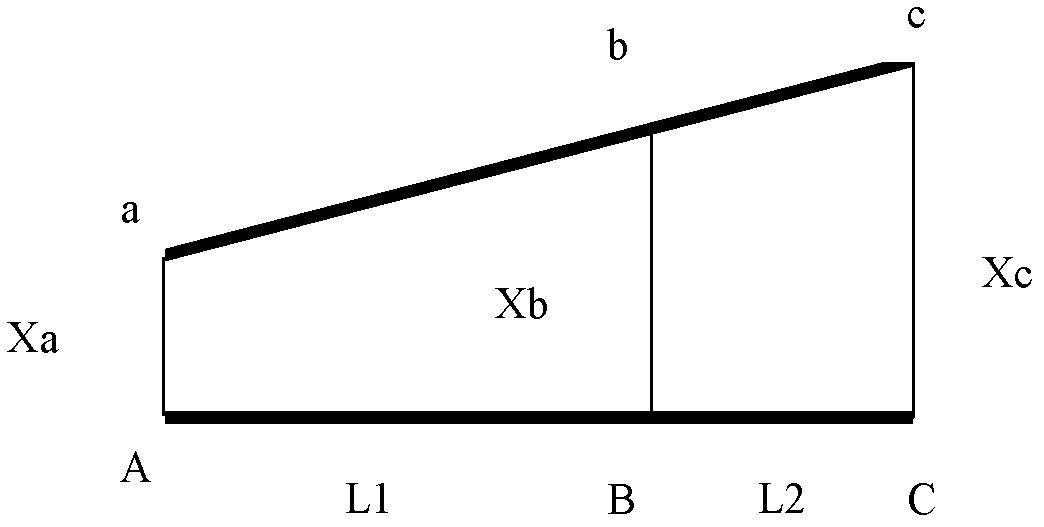

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com