Turbine blade coating thickness optical scanning holographic measurement method

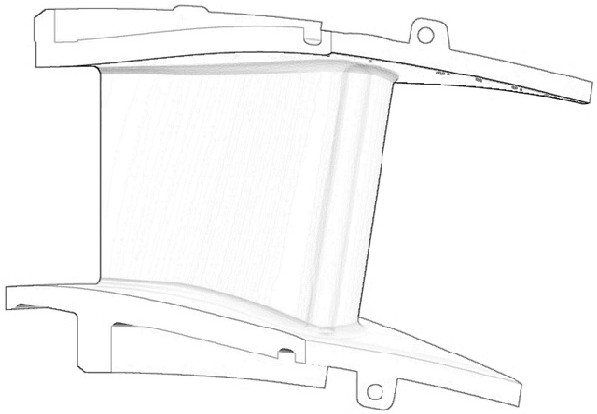

A technology of coating thickness and measurement method, which is applied in the field of turbine blade cooling design, can solve the problems of poor measurement accuracy of turbine blades and difficulty in realizing all-round measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

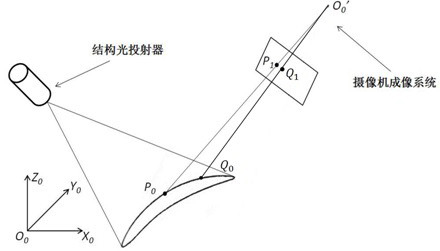

[0030] As a specific embodiment, it also includes a control method of the optical scanning device, specifically:

[0031] Register the initial position and initial angle of the structured light projector and the camera imaging system in the main controller;

[0032] The light scanning device is in trial operation. The structured light projector transmits the speed of light to an area of the blade and then transmits the image to the camera imaging system to form a set of images and transmit the image to the main controller;

[0033] Control the projector moving mechanism to drive the structured light projector to move to the next position, the imaging system moving mechanism drives the camera imaging system to move to the next position, the structured light projector and the camera imaging system work and scan the image of another position of the blade, and at the same time Position information, angle information, and image information are transmitted to the main controller; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com