Tester for anionic surfactant in water

A surfactant and measuring instrument technology, applied in the field of anion testing devices in water, can solve problems such as unsafe and reliable, poor stability of measurement results, and risk of carcinogenicity, and achieve the effects of improving work efficiency, saving manpower, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

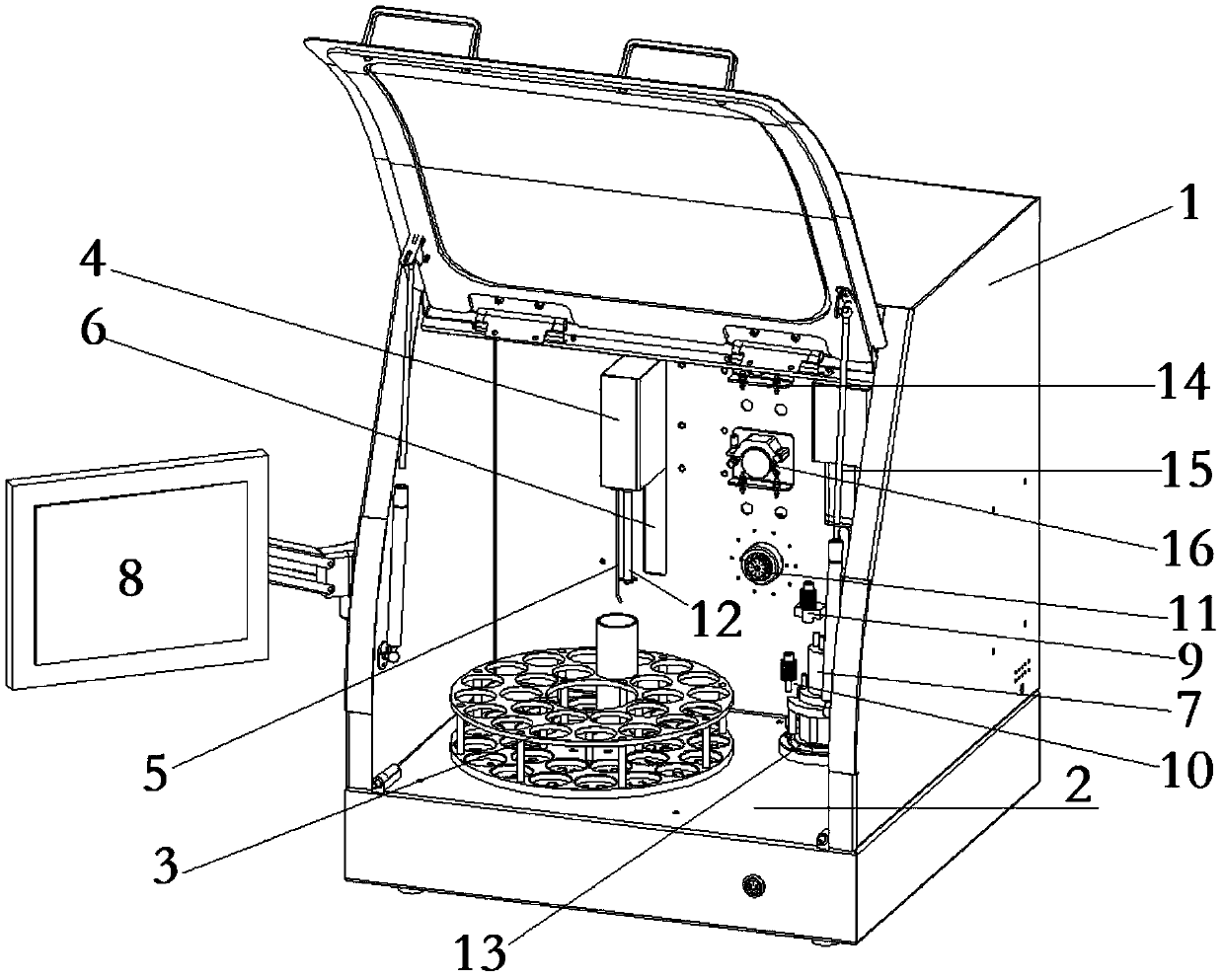

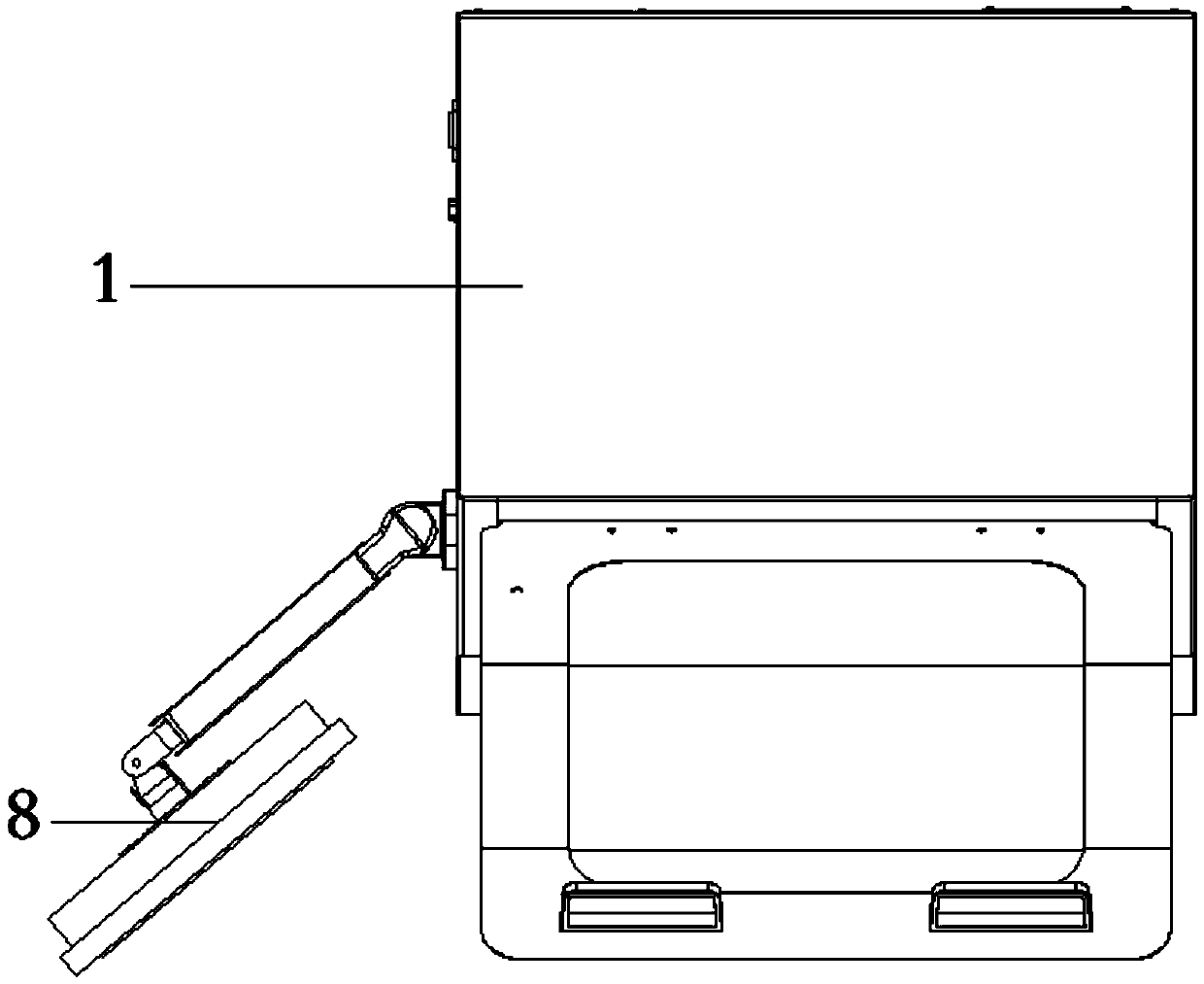

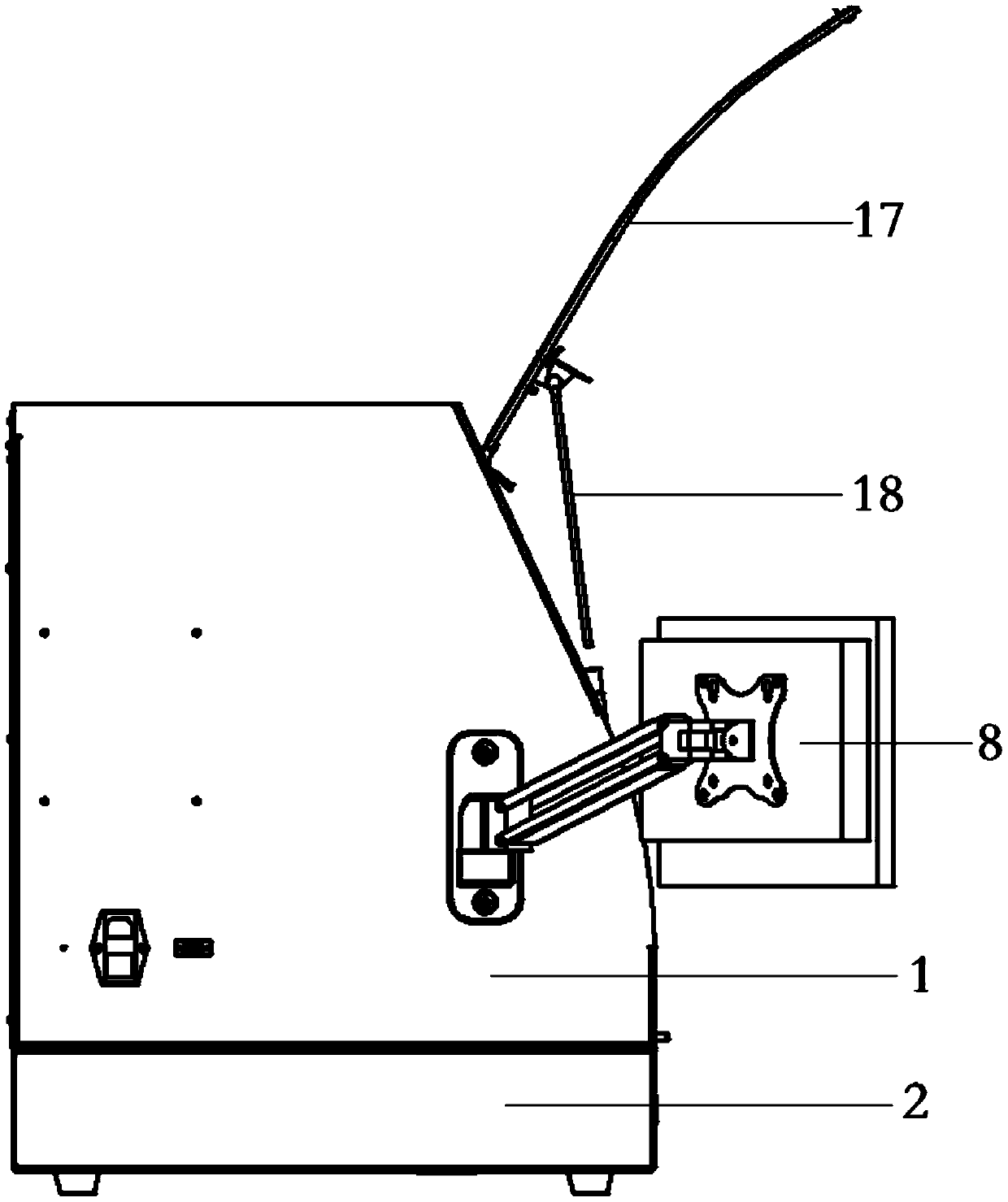

[0023] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0024] like figure 1 As shown, the anionic surfactant measuring instrument in water includes a casing 1 and a bottom plate 2 positioned at the bottom of the casing 1. The bottom plate 2 is provided with a turntable system 3, and the turntable system 3 is provided with a place for placing a plurality of sample cups. The rotating tray has a mechanical arm 4 that can move up and down on the top of the rotating tray. The mechanical arm 4 is provided with a suction tube 5 for extracting the extracted chloroform extract, an injection cleaning for injecting pure water to clean the sample cup. Pipe 6; the pumping pipe 5 is connected to the washing constant volume cup 7; the injection cleaning pipe 6 is connected to the pure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com