Device for automatically measuring surface chromium content on tin plate by using electrolytic process and determination terminal point judgment method

A technology of automatic measurement and electrolysis, applied in the direction of electrochemical variables of materials, etc., can solve problems such as differences, and achieve the effects of high measurement accuracy, improved work efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

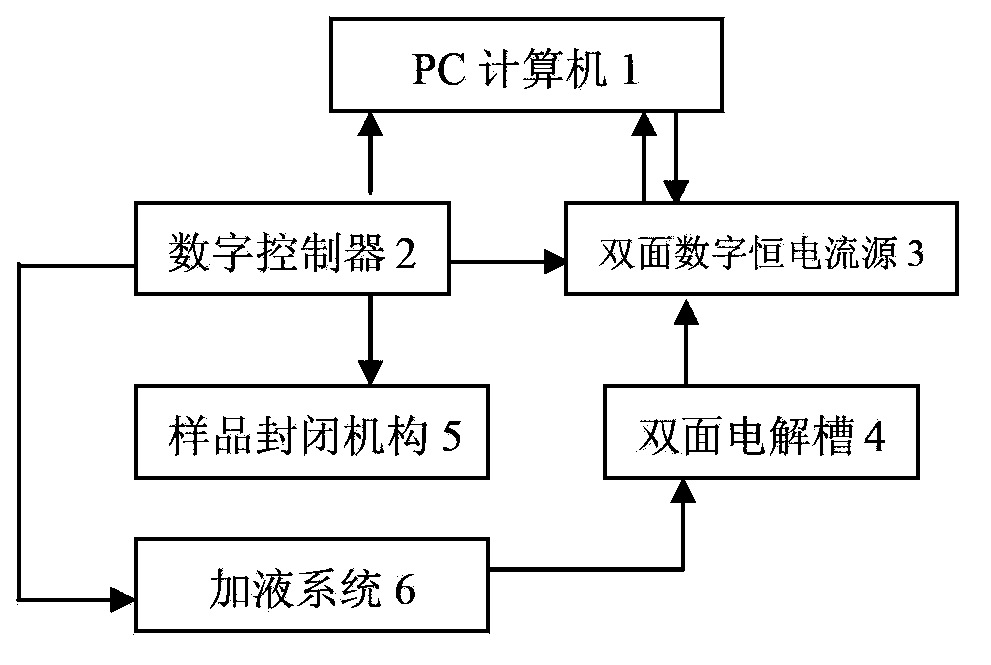

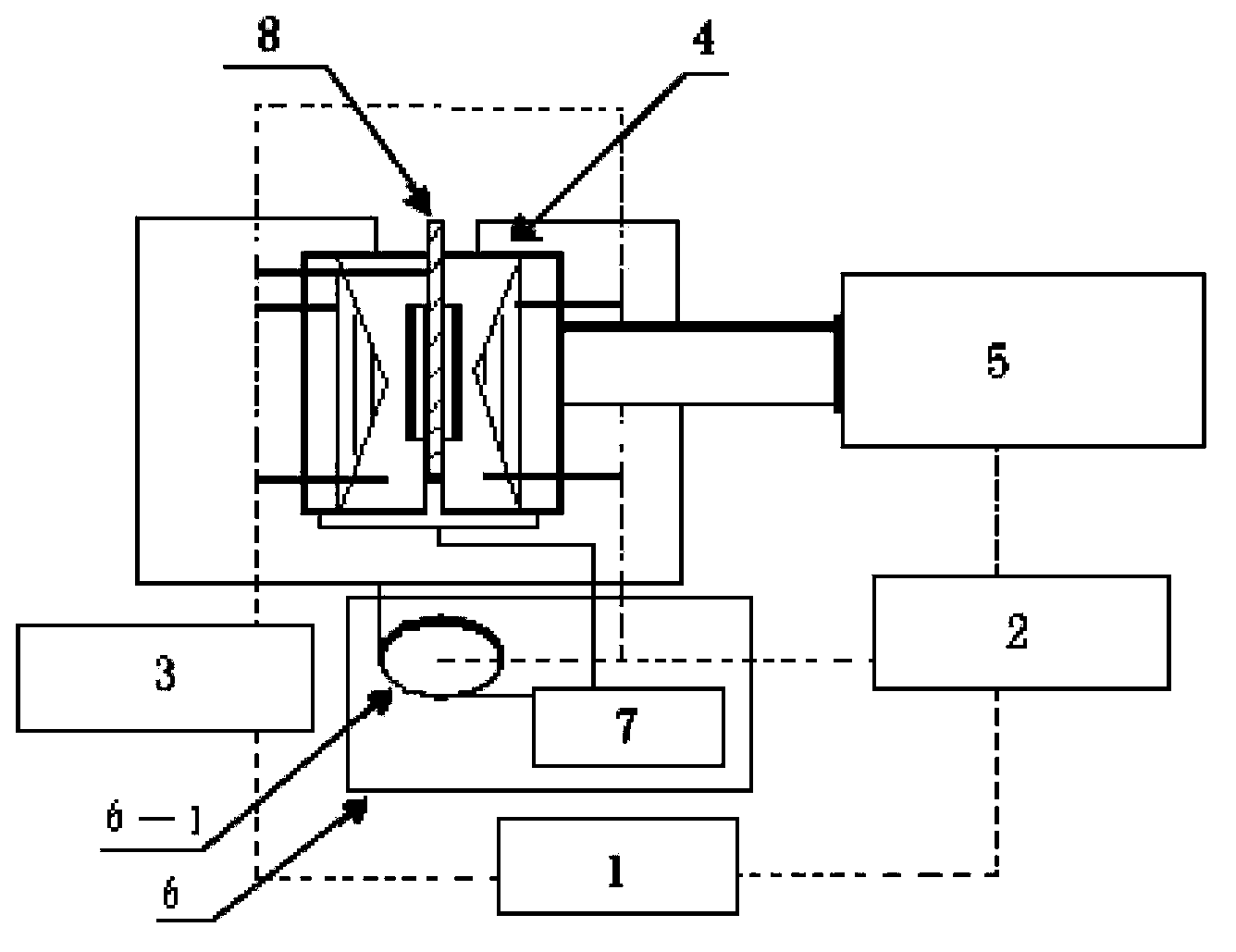

[0051] The present invention will be further described below in conjunction with the accompanying drawings.

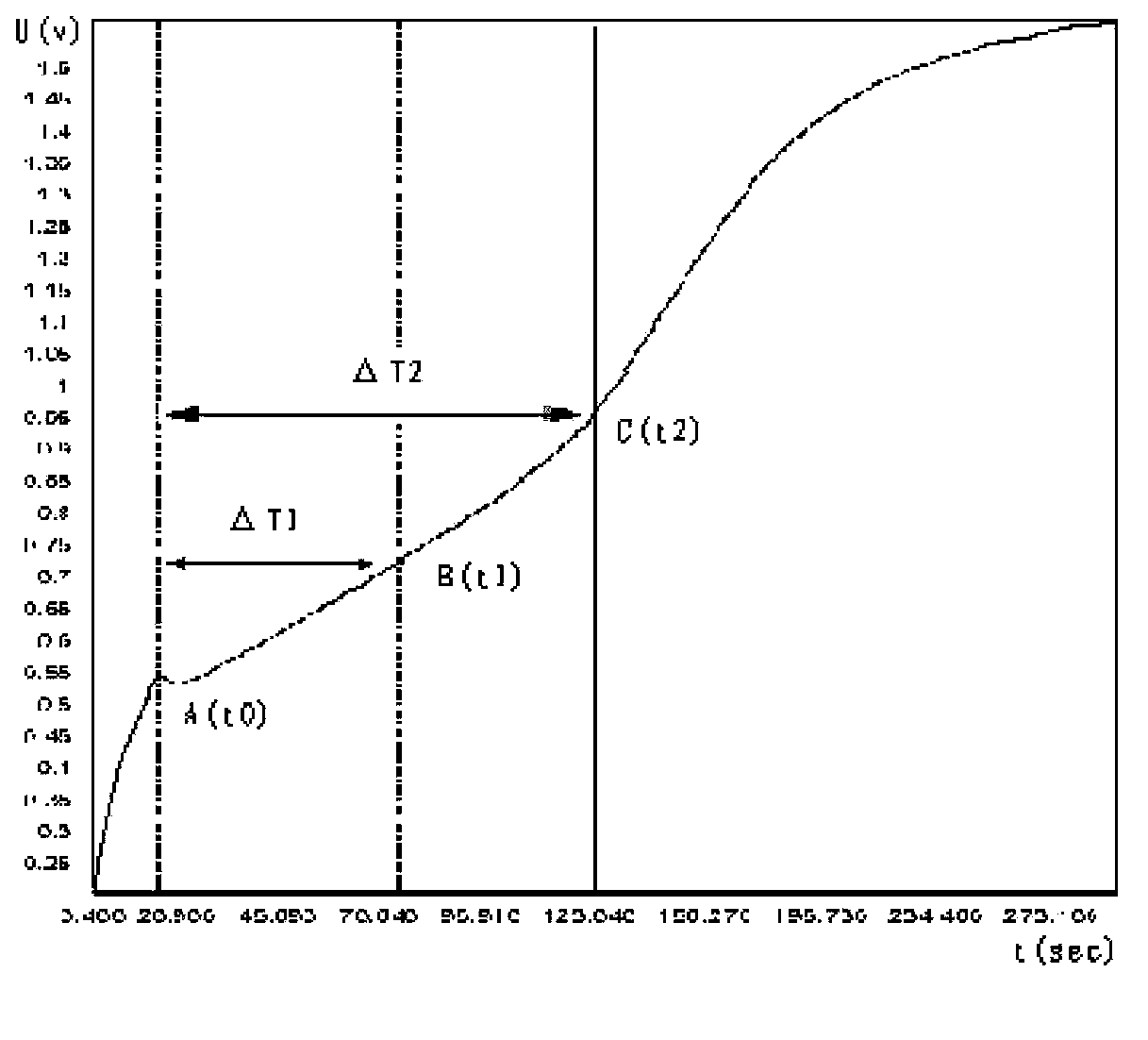

[0052] figure 1 Among them, there are two methods for judging the end point of electrolytic stripping of chromium on the surface of tinplate. The first method is the national standard GB / T18290-2012 "Test method for chromium content on the surface of electrolytic tin plate". From point A, the potential rises by 200mV as the end point B of the electrolytic stripping of chromium on the surface of the tinplate, and the time required from point A (t0, sec) to point B (t1, sec) (ΔT1=t1-t0, sec ) is the time required for electrolytic stripping of chromium on the surface. This method is easy to judge the end point of stripping, and the instrument is easy to realize automation; the second method is the method "Tinplate Guide" provided by the International Tin Institute (International Tin Institute, translated by Zhou Qiliang) , this method starts from the first sharp point A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com