Method for measuring liquid level of liquid in container

A measurement method and container technology, applied in liquid/fluid solid measurement, measurement device, display liquid level indicator through pressure measurement, etc., can solve the problems of regular calibration, heavy maintenance workload, low precision of height h, forced stop of transformer Accidents and other problems, to achieve the effect of small error, high measurement accuracy, and guarantee system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The process embodiment will be described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

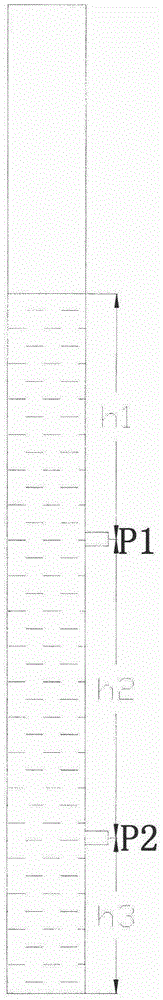

[0022] as attached figure 1 As shown in the calculation principle diagram of the measurement method of the present invention, the figure shows a container containing liquid, and its liquid level needs to be accurately measured. In the figure, the position of P1 is the upper measurement point, the position of P2 is the lower measurement point, P1 is the pressure value measured by the pressure sensor of the upper measurement point, P2 is the pressure value measured by the pressure sensor of the lower measurement point, h1 is the height of the upper measurement point from the liquid surface , h2 is the vertical distance between the upper measuring point and the lower measuring point, h3 is the distance from the lower meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com