Non-contact straightening point confirming method for straightness of rectangular-section long-rail work piece

A non-contact, rectangular cross-section technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of low manual measurement accuracy and slow measurement speed, achieve simple and applicable methods, overcome system errors and cumulative errors, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

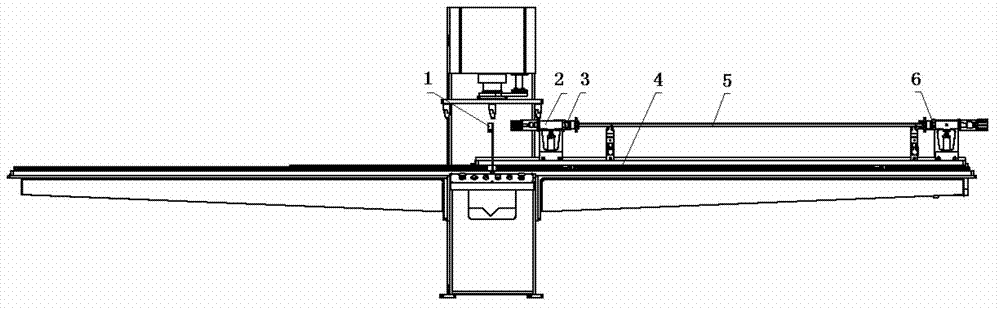

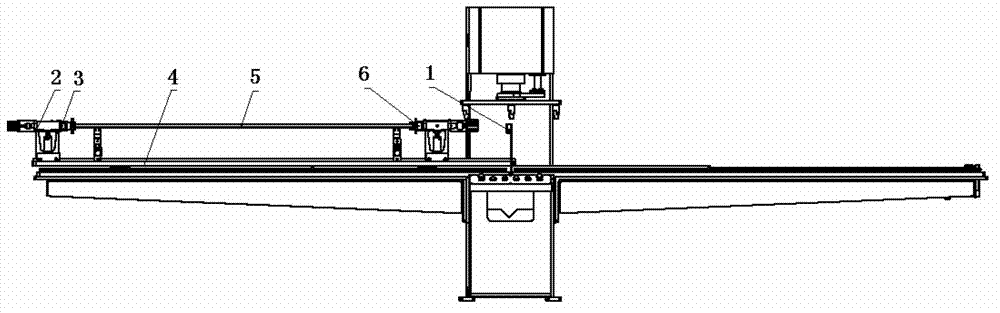

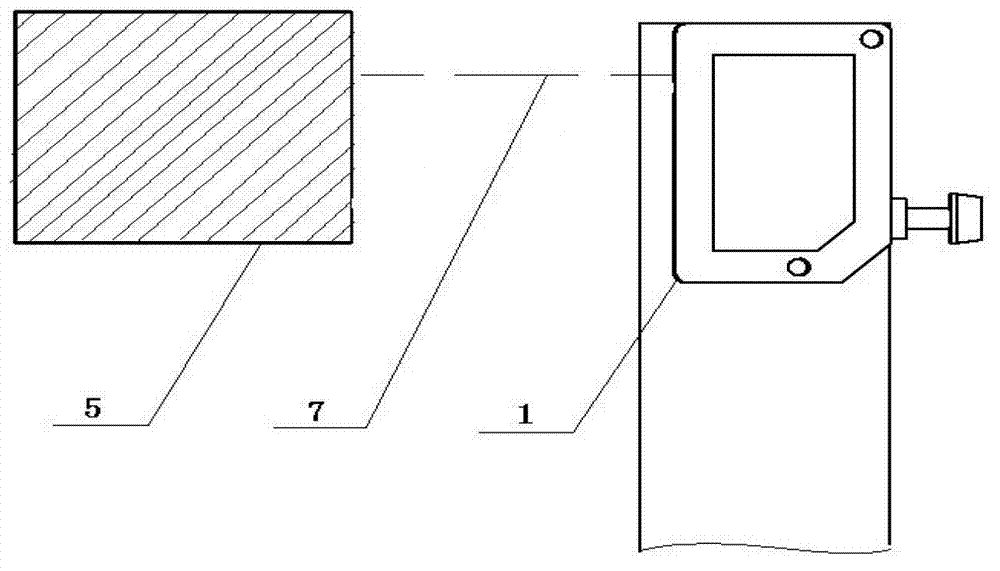

[0034] There is a left clamping mechanism 3 and a right clamping mechanism 6 on the working platform 4, and the two clamping mechanisms can clamp the long track workpiece 5, and the working platform 4 can drive the long track workpiece 5 to move left or right, which can be realized in the long track. The track workpiece 5 is measured with a point laser sensor at different measurement points, and the motor 2 can drive the left clamping mechanism 3 to realize the rotation of the long track workpiece 5, and the right clamping mechanism 6 follows.

[0035] (1) Install the measured length track workpiece 5 on the working platform 4 through the left clamping device 3 and the right clamping device 6. At this time, the working platform is located on the far right side of the straightening machine, and the left clamping device 3. The right clamping device 6 is fixedly connected with the working platform 4, which is slidingly connected with the straightening machine. The point laser sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com