Device and method for automatic workpiece inspection

A workpiece and measuring device technology, applied in the field of determining the mechanical properties of workpiece samples, can solve problems such as short test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

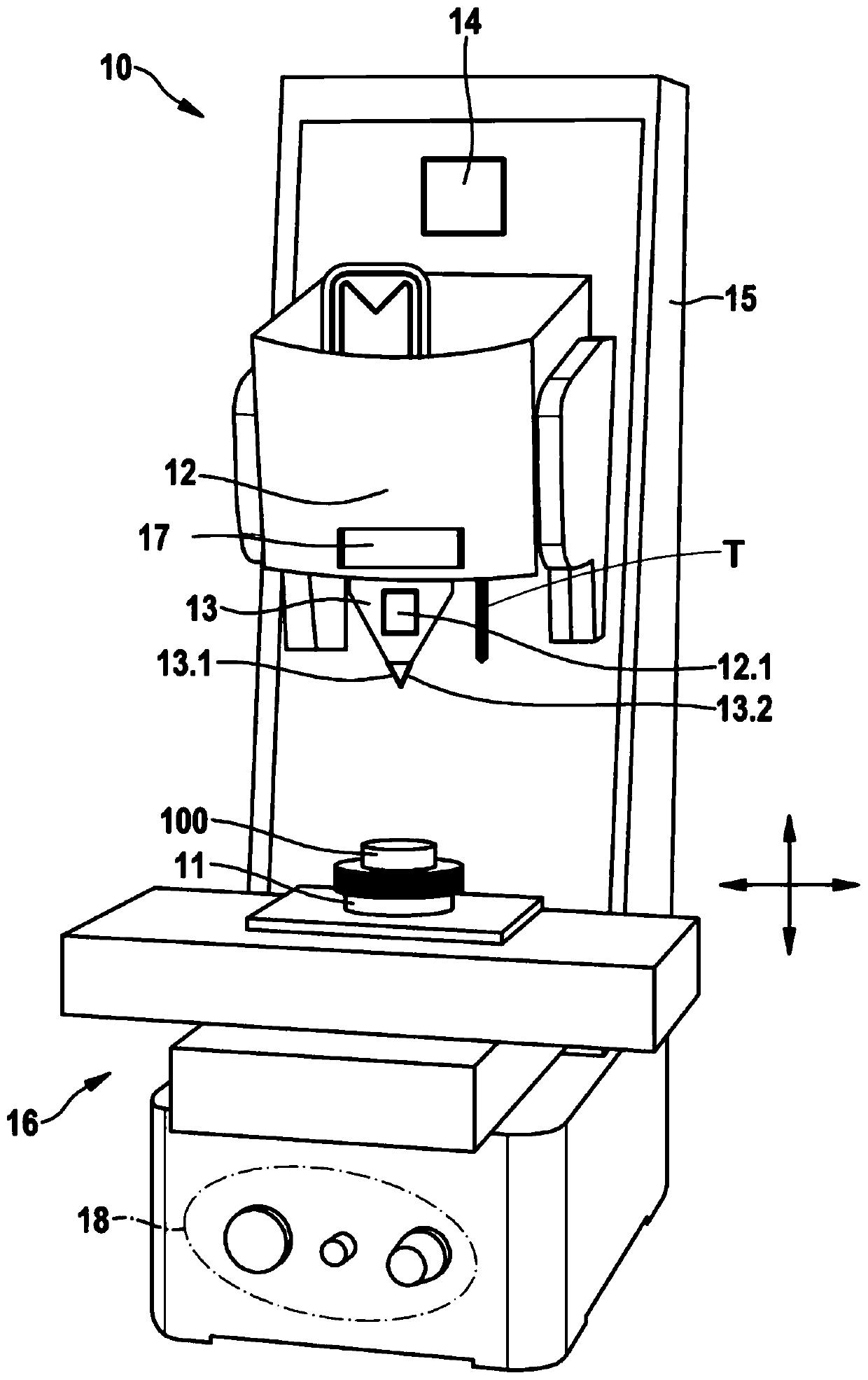

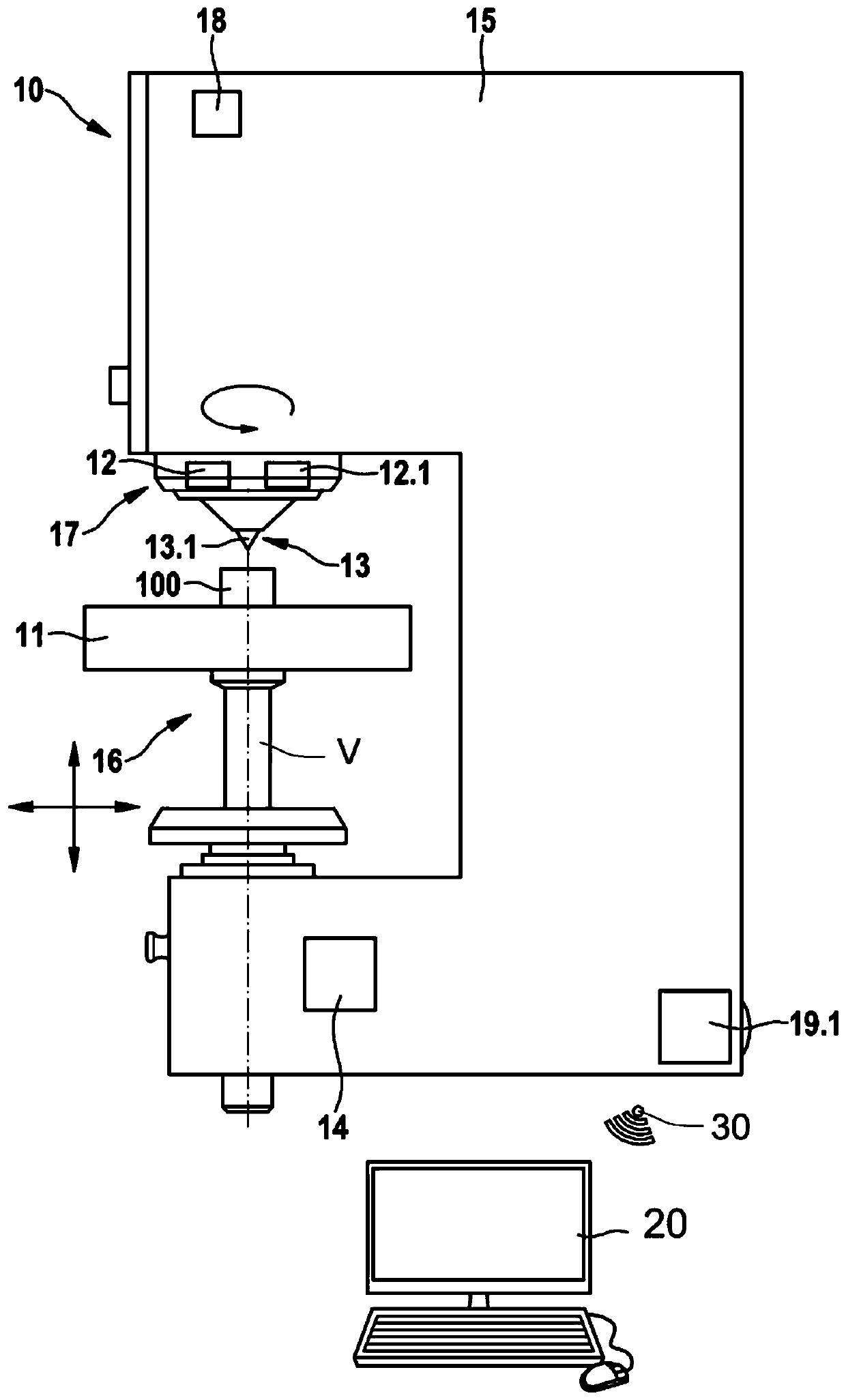

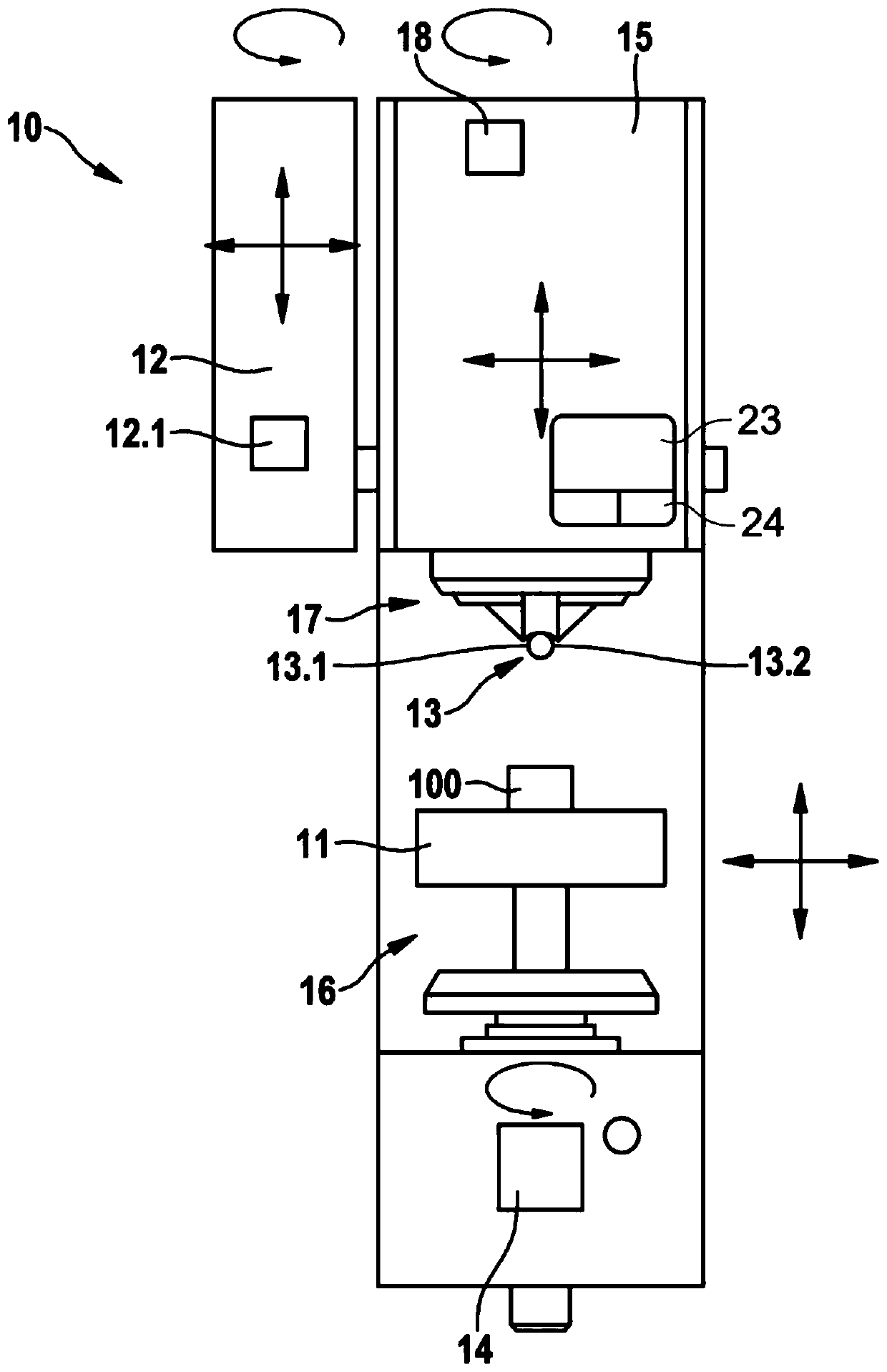

[0082] In the following figures, the same reference numerals are used for identical technical features even in different exemplary embodiments.

[0083] exist figure 1 A first embodiment of a measuring device 10 according to the invention for determining the mechanical properties of a workpiece sample 100 is shown in . The workpiece sample 100 is now arranged in the workpiece holder 11 of the measuring device 10 for testing. In addition, the measuring device 10 has an image acquisition unit 12 for the optical determination of the workpiece shape of the workpiece sample 100 . Alternatively or in addition, a depth gauge T can also be provided for determining the shape of the workpiece sample 100 in contact. The image acquisition unit 12 is in this case arranged in or on the test frame 15 in the region of the mechanical probe 13 . In this case, the image acquisition unit 12 can be arranged at a distance from or adjacent to the probe head 13 in such a way that an optical acquis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com