Instrument for measuring startup torque, swing torque and slippage force of constant-velocity universal joint assembly

A constant velocity universal joint and dynamic torque technology, applied in the field of measuring instruments, can solve the problems of no scientific and quantitative detection method, blank performance detection of constant velocity universal joint assembly, and only fatigue test, etc., to achieve Improve measurement accuracy and measurement efficiency, simple and convenient operation, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

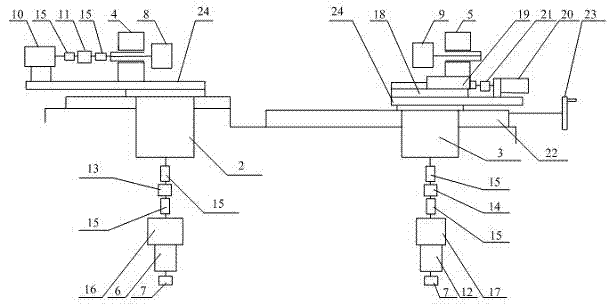

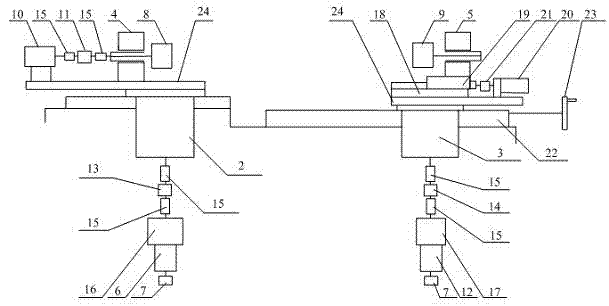

[0019] Such as figure 1 As shown, the present invention mainly consists of an outer cage swing shaft system 2, an inner cage swing shaft system 3, and an outer cage rotating shaft system 4 installed on the upper ends of the outer cage swing shaft system 2 and the inner cage swing shaft system 3 respectively. It is formed with the inner ball cage rotating shaft system 5, and the rotation centerlines of the outer ball cage rotating shaft system 4 and the inner ball cage rotating shaft system 5 are located in the same plane. In practice, in order to facilitate the outer ball cage rotating shaft system 4 and the inner ball cage rotating shaft system Cage rotating shaft system 5 is easy to swing and install. The outer ball cage rotating shaft system 4 and the inner ball cage rotating shaft system 5 can be installed on different platforms 24 respectively, and the outer ball cage rotating shaft system 2 and the inner ball cage can be swung The shaft system 3 is respectively connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com