Full automatic intelligent measuring apparatus for gelatineous layer of mixed coal and measuring method thereof

An automatic measurement and intelligent measurement technology, applied in the direction of measuring devices, instruments, flow characteristics, etc., can solve the problems of affecting the pressure measurement accuracy, low displacement measurement accuracy, and affecting the measurement progress, so as to improve the measurement displacement accuracy, flexible installation and operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

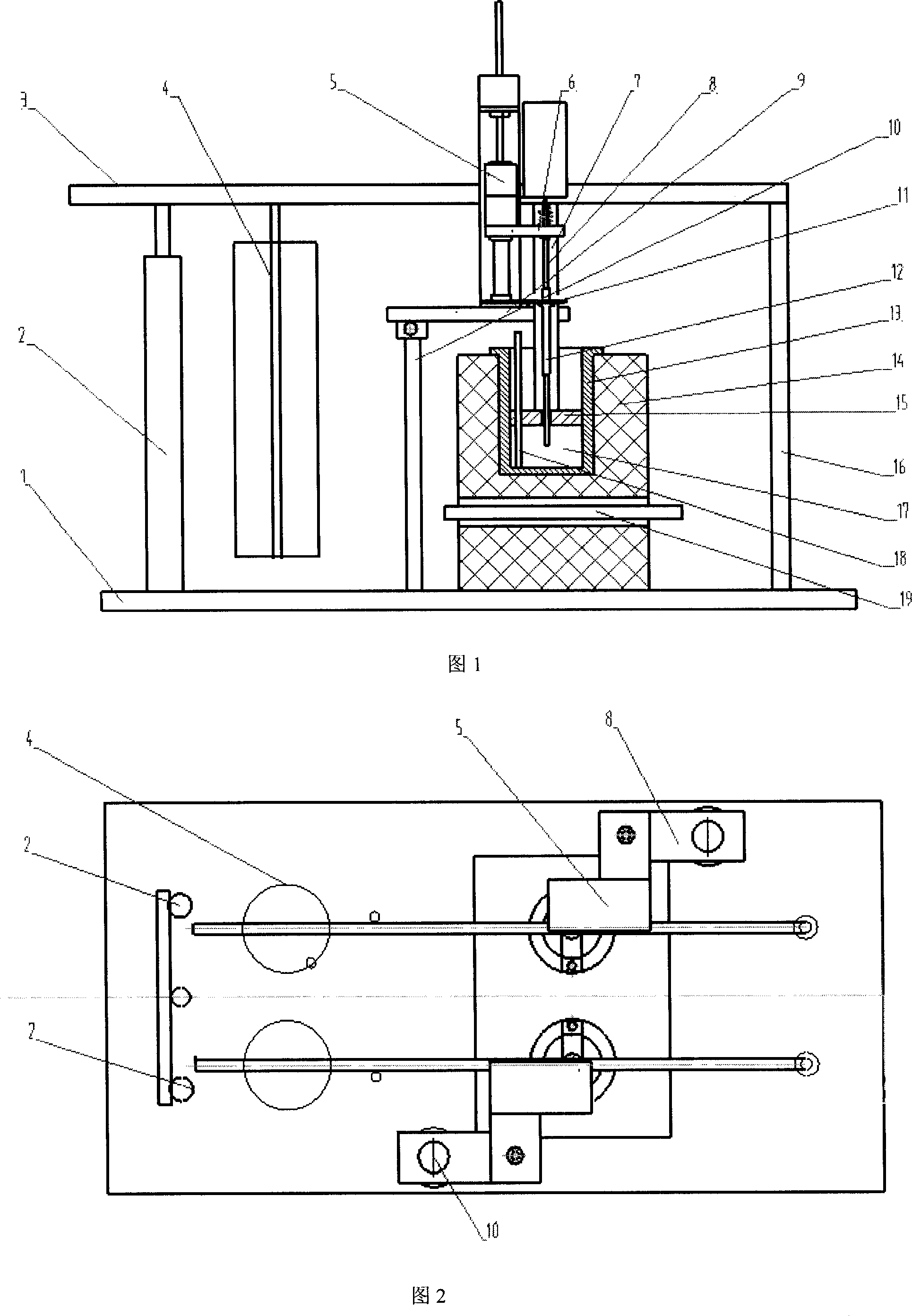

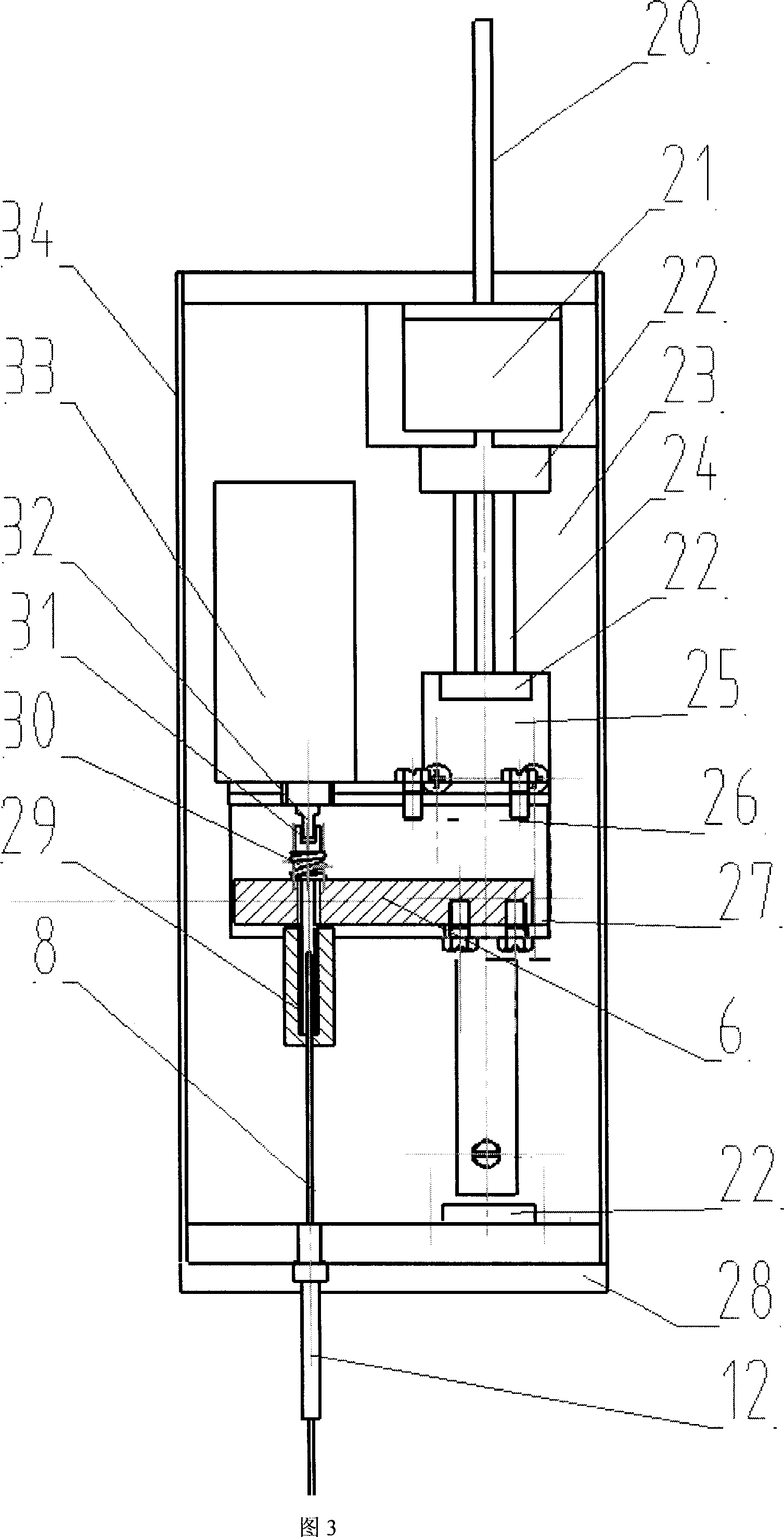

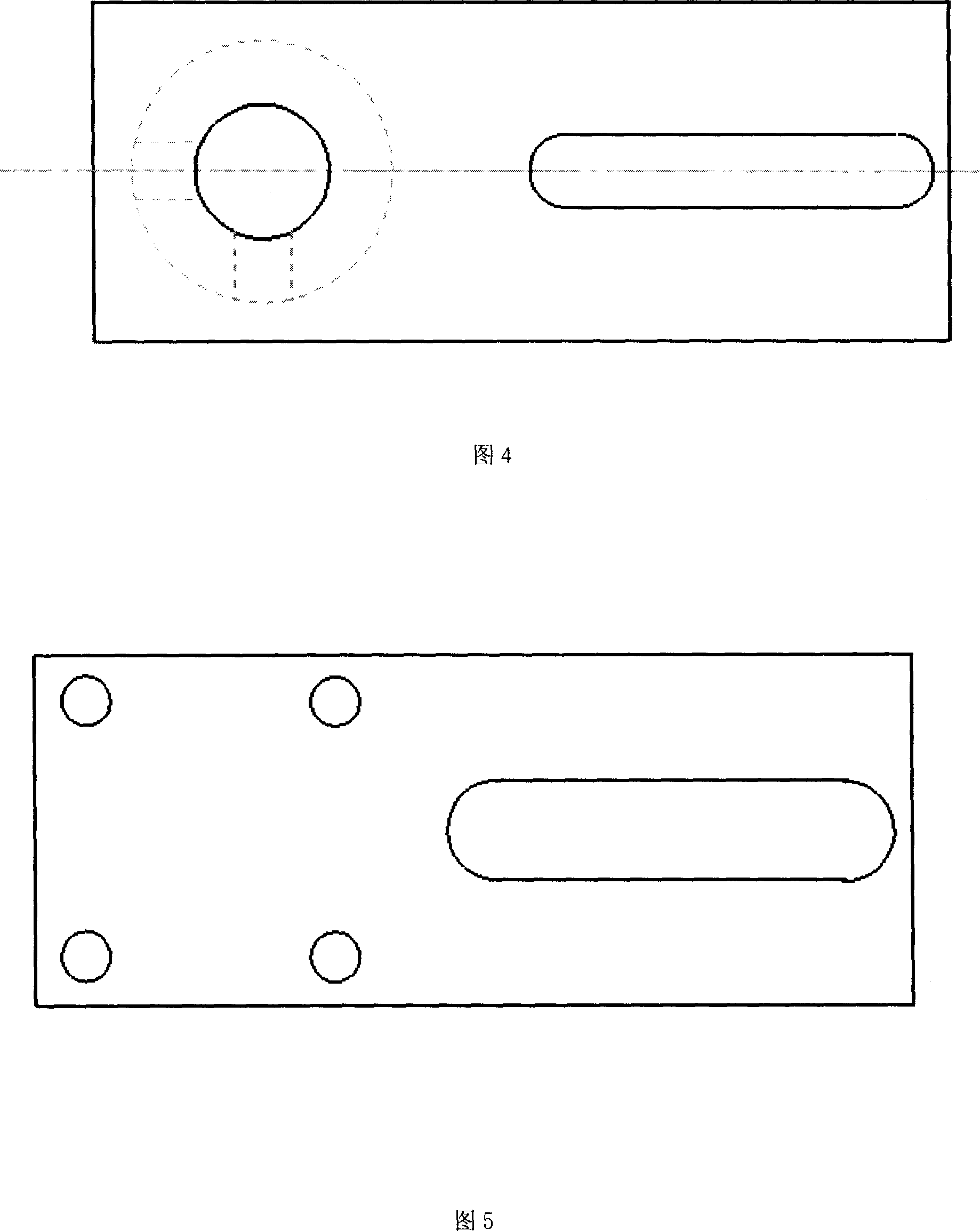

[0023]As shown in Fig. 1-5, the automatic intelligent measuring instrument for coal colloid layer of the present invention, wherein: 1. measuring instrument base, 2. displacement sensor, 3. pressure rod, 4. weight, 5. probe driving mechanism, 6. Load cell, 7. Pressure plate strut, 8. Probe, 9. Installation base of probe driving mechanism, 10. Fixing pole, 11. Conduit fixing plate, 12 Conduit, 13. Coal cup, 14. Heating furnace, 15. Coal sample pressure plate, 16. Pressure rod column, 17. Coal sample, 18. Thermocouple, 19. Silicon carbide rod, 20. Lead screw, 21. Linear stepper motor, 22. Limit switch, 23. Groove driving bracket, 24. Rolling guide rail, 25. Lead screw fixing frame, 26. Slider, 27. Pressure sensor fixing frame, 28. Probe driving mechanism extension plate, 29. Probe fixing cap, 30. Spring , 31. Chutes, 32. Rotary motor shafts, 33. Rotary motors, 34. Probe driving mechanism packaging shell.

[0024] The temperature of the heated coal sample (17) is detected by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com