Resistance strain type displacement meter and manufacturing method thereof

A technology of resistance strain type and manufacturing method, which is applied in the field of mechanical engineering, can solve the problems of low dynamic response frequency, limited precision, and small size, and achieve the effects of good compatibility, guaranteed measurement accuracy, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

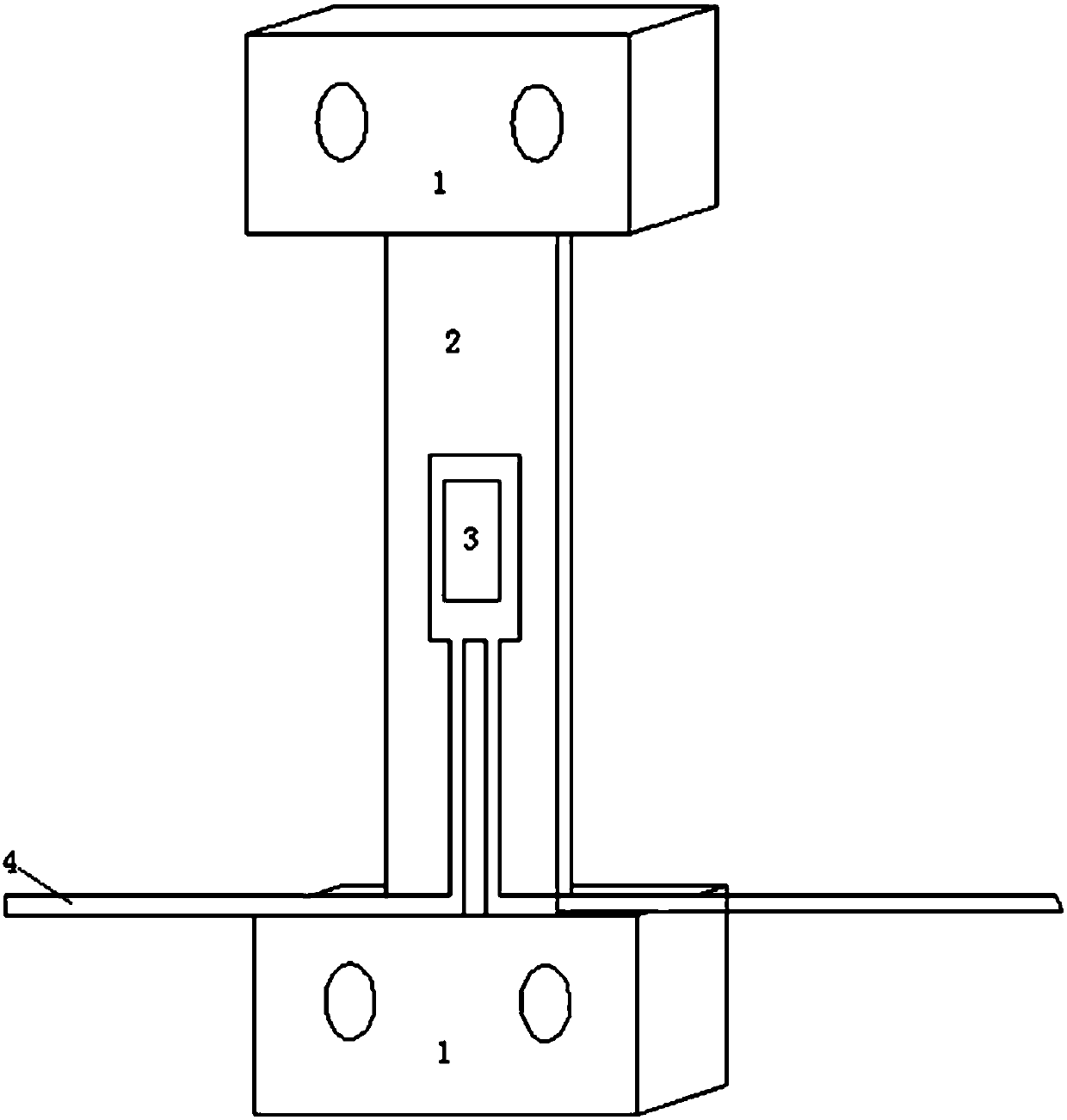

[0068] In this embodiment, the annular seam measurement of the tunnel model shaking table test is selected as the target measurement scene, the target measurement range is 0.5 mm, and the accuracy requirement is 1%. According to the measurement target, the selected displacement meter has a range of 0.6mm and an accuracy of 0.3%. The 3D printing material is nylon, with an elastic modulus of 2.6GPa. Select the strain gauge with a range of 20000 microstrain and an accuracy of 0.3%.

[0069] The specific parameters of each part of the displacement meter in this embodiment are designed as follows:

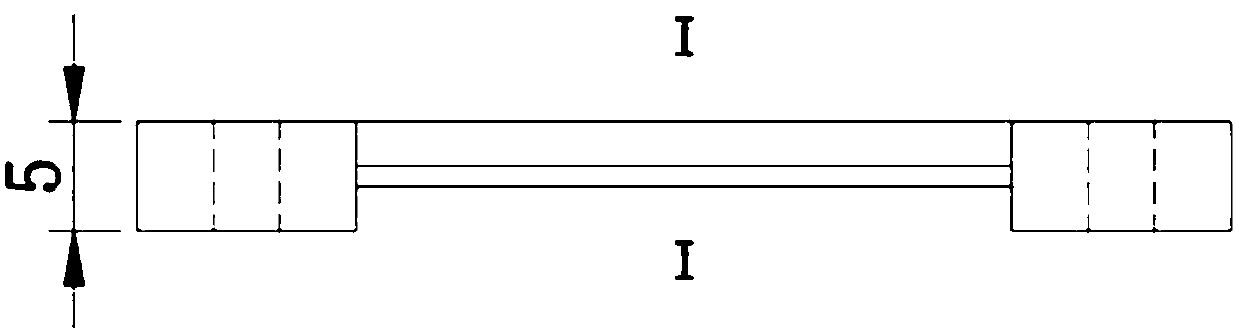

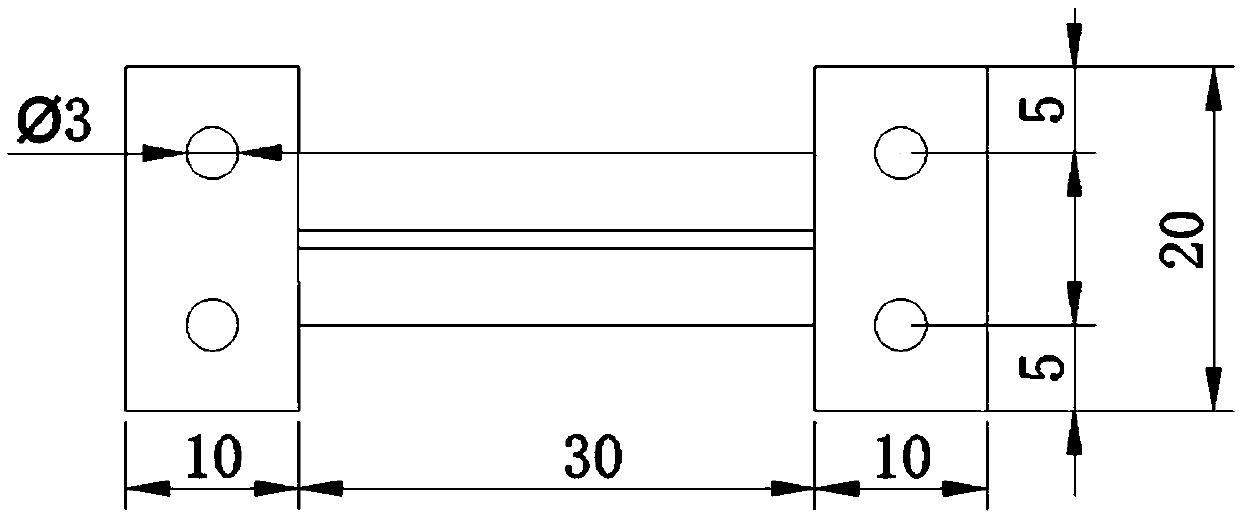

[0070] Applied formula (1), D FS = 0.6mm, S FS =0.02, it can be calculated that the gauge length of the displacement gauge is 30mm.

[0071] The cross-section of the base is selected as a T-shaped cross-section. The T-shaped cross-section has a web width of 10 mm, a thickness of 1 mm, a wing plate width of 1.5 mm, and a height of 2 mm. Applied formula (2), F cr =801.3N, E=2.6GPa, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com