Patents

Literature

46results about How to "Adaptability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

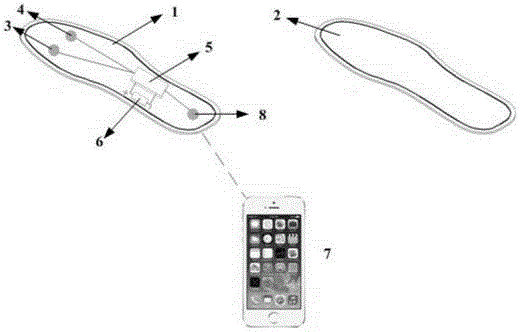

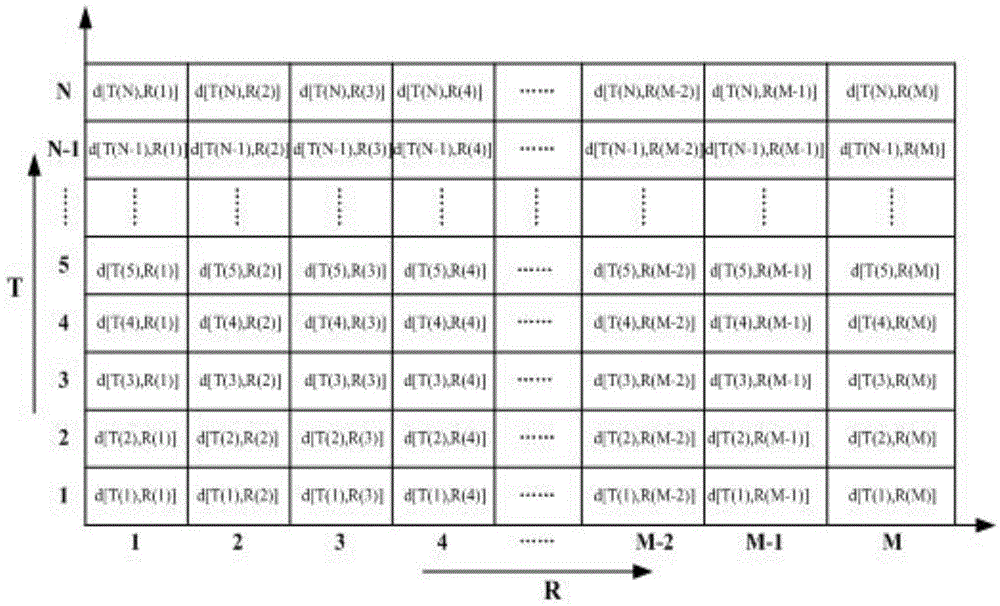

Multifunctional intelligent insole and gait similarity detection method

ActiveCN104082905AImprove adaptabilityImprove acceleration performanceInsolesDiagnostic recording/measuringTerminal equipmentLarge Calorie

The invention relates to the technical field of articles for daily use, in particular to a multifunctional intelligent insole and a gait similarity detection method. The multifunctional intelligent insole is convenient to use, light, convenient to carry, flexible to use and multifunctional, and has a series of functions of weighing, step counting, distance measuring, calorie consumption measuring, lostness prevention, warning while people fall off and wireless data transmission. According to the method, step postures and coordination of a detected object are judged mainly by analyzing triaxial accelerated speed, triaxial angular speed and pressure information of three positions of feet when the detected object moves, accordingly incorrect or abnormal gaits can be effectively found and corrected, and the insole has important application value for dancing lovers, babies learning to walk and patients walking for rehabilitation. Meanwhile, the gait detection method can be matched with an intelligent system for use, and test results can be presented to users visually through an intelligent terminal device.

Owner:杭州华亭科技有限公司

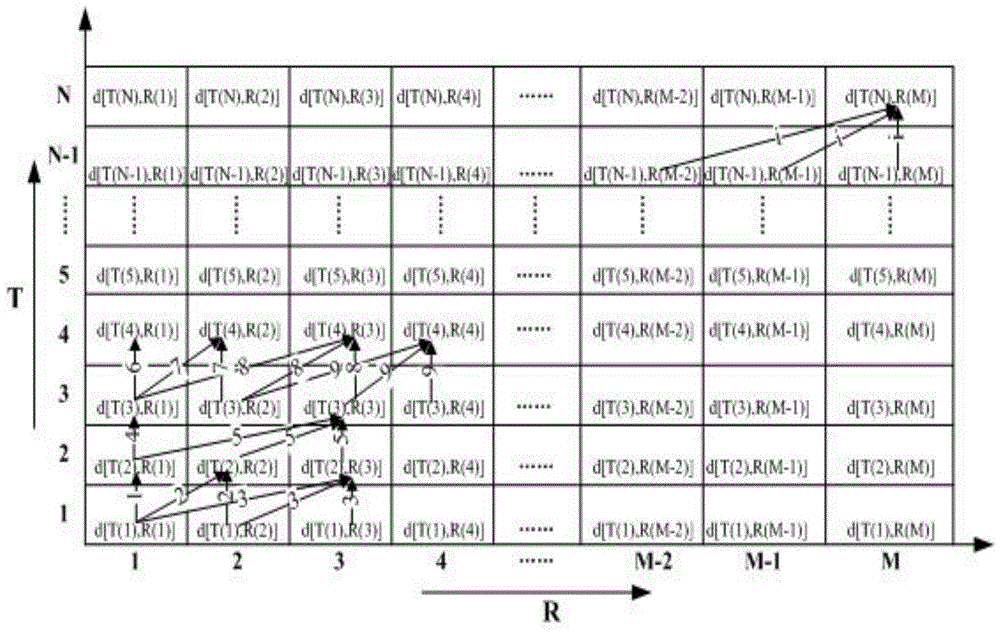

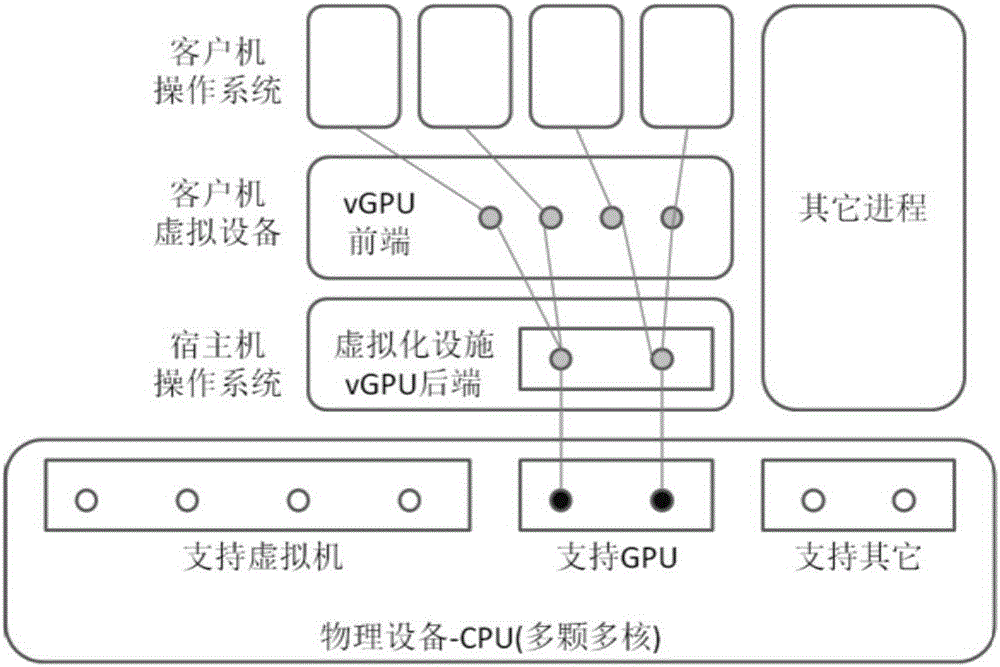

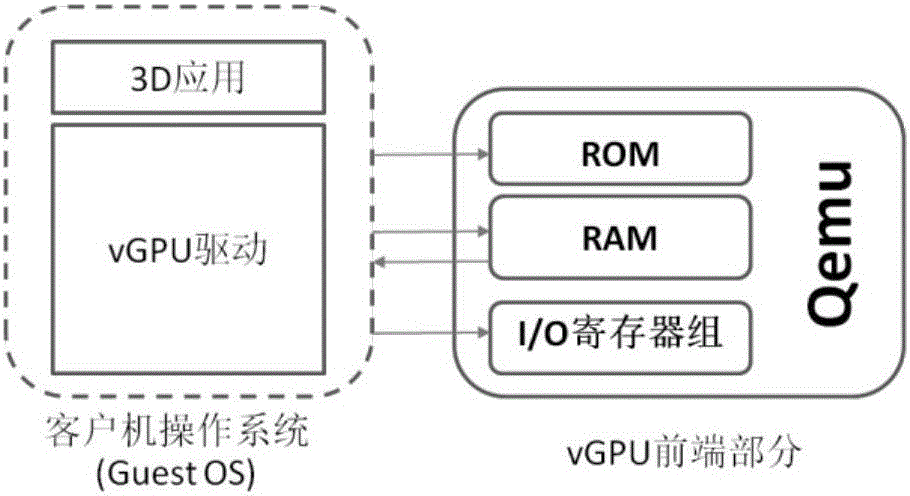

Virtualization implementation system and method of GPU (Graphics Processing Unit)

ActiveCN106406977AAdaptabilityCost advantageResource allocationSoftware simulation/interpretation/emulationVirtualizationAssistive technology

The invention discloses a virtualization implementation system and method of a GPU (Graphics Processing Unit). The virtualization implementation system comprises a vGPU driving module, a vGPU front-end module and a vGPU rear-end module which respectively belong to three layers of a guest operating system, guest virtual equipment and a host machine operating system, moreover, the whole system finally requires hardware resources such as a physical layer CPU and a memory to support, while hardware GPU is not required; and the vGPU function is jointly achieved by mutual coordination of the parts. Compared with hardware assistive technologies such as a GRID technology and XENGT / KVMGT, the virtualization implementation system has the advantages that a GRID display card is not required to externally insert / internally install, a CPU model with the GPU function is also not required to upgrade, replace and carry, and thus, the virtualization implementation system has the advantages in aspects of adaptability and cost control implementation.

Owner:MASSCLOUDS

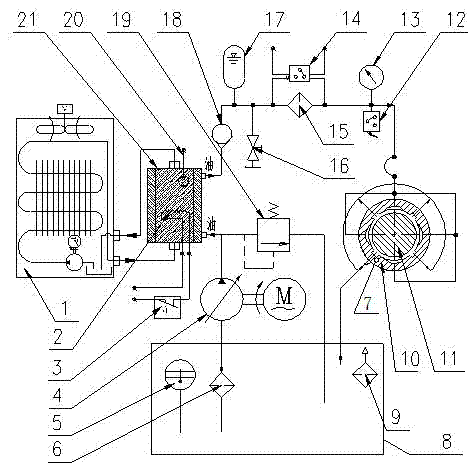

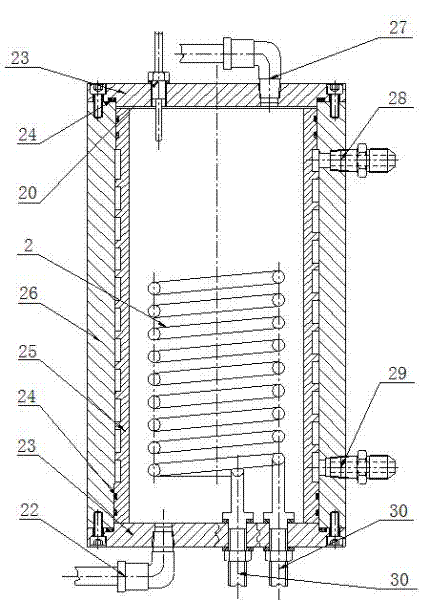

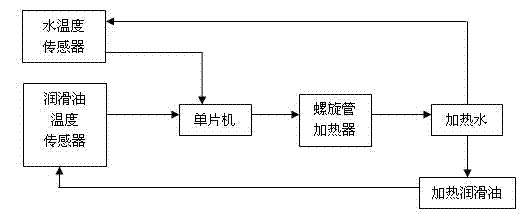

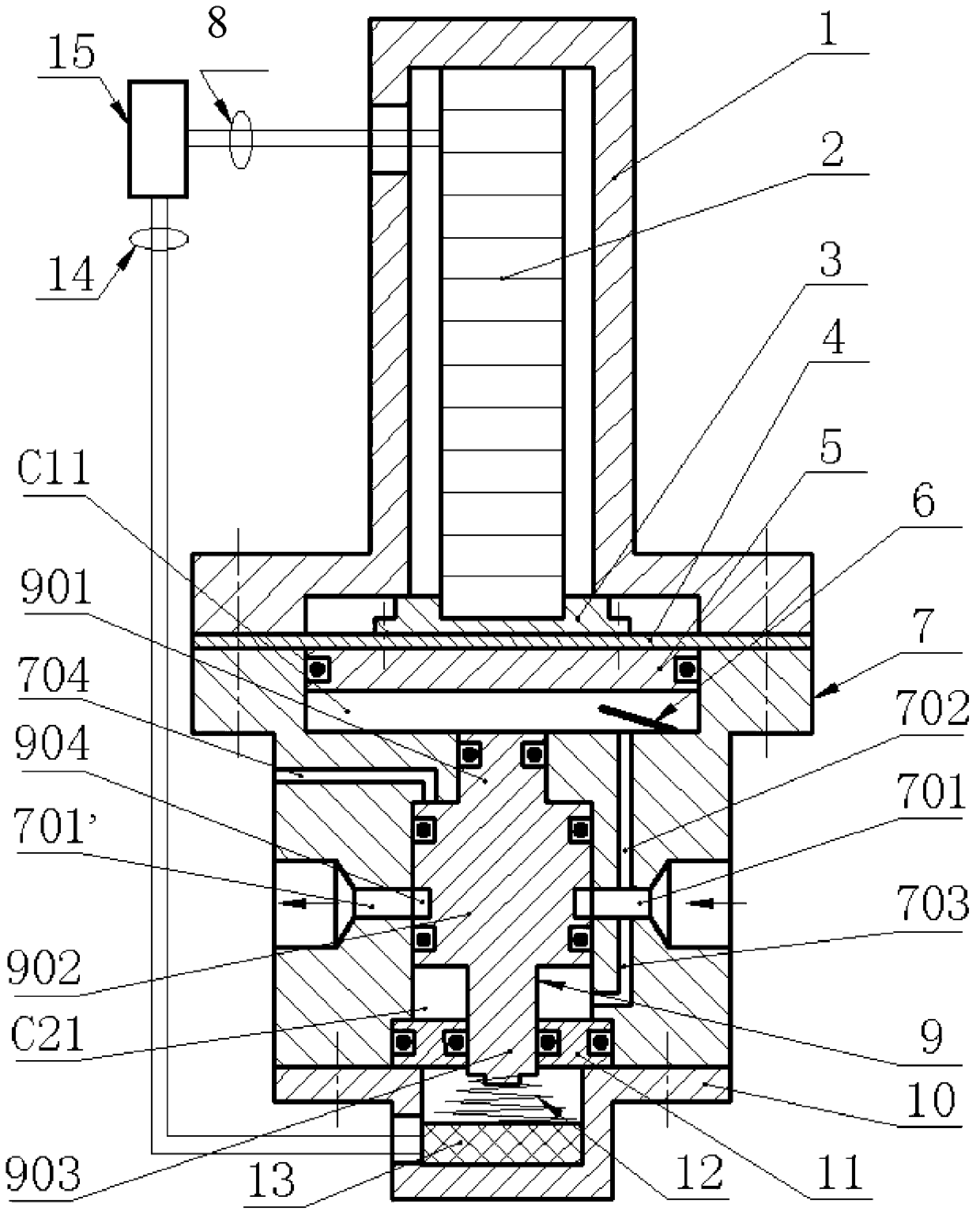

Method for adjusting oil film temperature of dynamic and static hybrid grinding head

InactiveCN102240923ATemperature can be adjustedPrevent spoilageLubrication elementsBearing coolingEngineeringHeat exchanger

The invention relates to a method for adjusting oil film temperature of a dynamic and static hybrid grinding head. The method comprises the following step: heating or cooling water according to an oil temperature and water temperature detection result from a temperature sensor, thereby utilizing water to directly heat or cool the lubricating oil which enters into a dynamic and static hybrid spindle bearing. According to the method, a temperature adjusting device is additionally arranged in a traditional working oil passage for supplying the lubricating oil to the dynamic and static hybrid spindle bearing, wherein water is taken as a heat conduction medium of the temperature adjusting device. The temperature adjusting device comprises an oil supply system, a water cooler and a heat exchanger, wherein the heat exchanger with a built-in spiral pipe heater is connected with the water cooler through a cooling water inlet pipe and a cooling water outlet pipe and is connected to the oil supply system through an oil inlet pipe and an oil outlet pipe. According to the method, the water cooler and the spiral pipe heater are arranged in an interlocked state. According to the method, the oil film temperature of the dynamic and static hybrid grinding head can be automatically adjusted by controlling the heat exchanger, thereby achieving the win-win effect of adjusting the temperature of the lubricating oil and preventing the oil from deteriorating under the influence of excessive heating. The method for adjusting the oil film temperature of the dynamic and static hybrid grinding head is suitable for temperature adjustment of the lubricating oil of a hydraulic or static system of large and middle sized machine tool.

Owner:JACK MACHINE TOOL

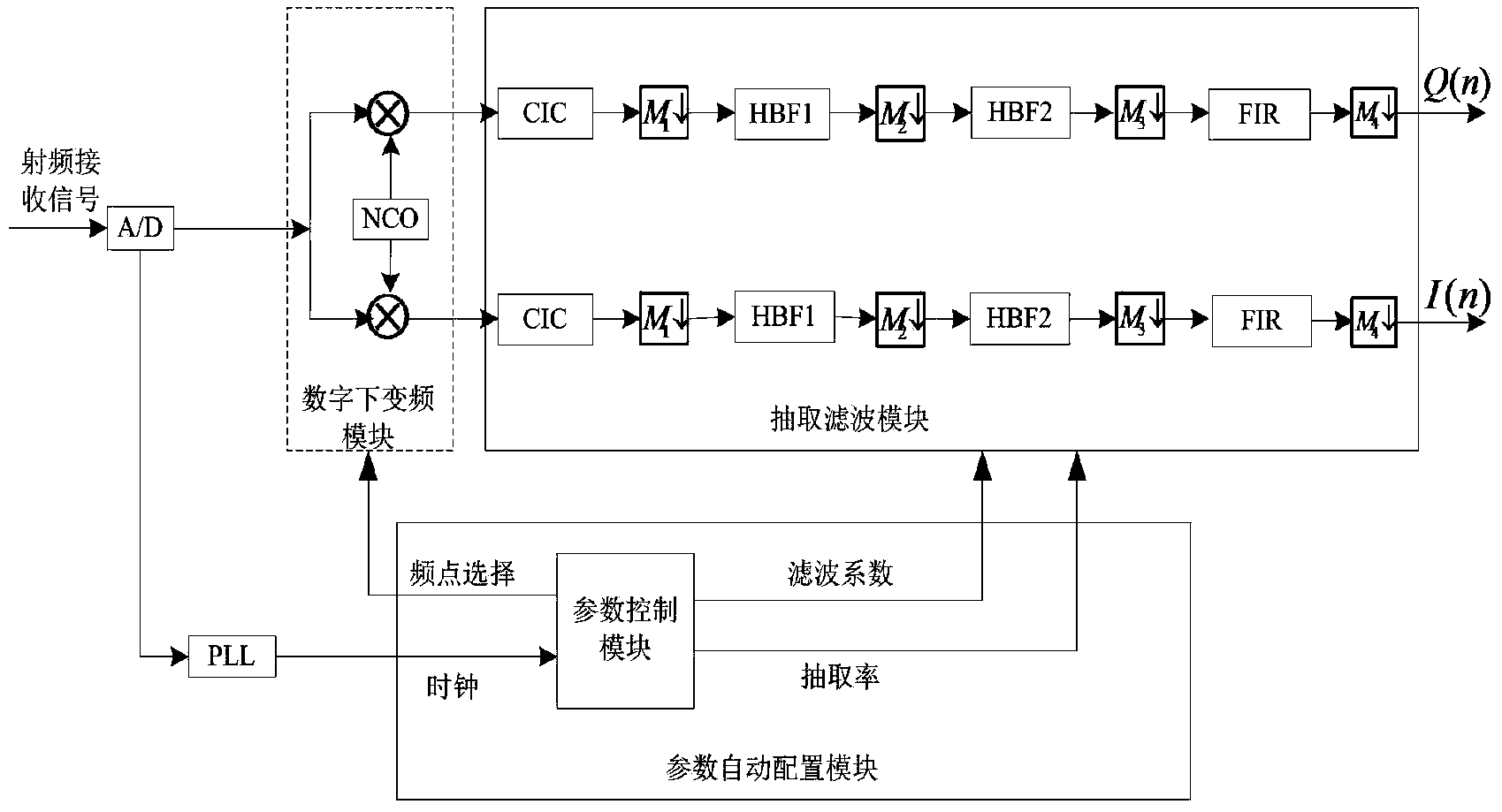

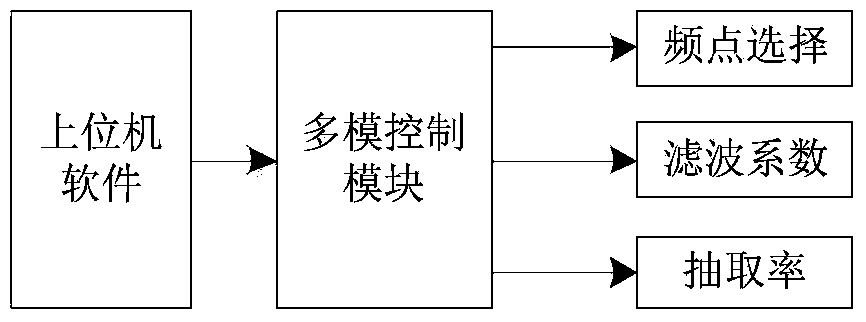

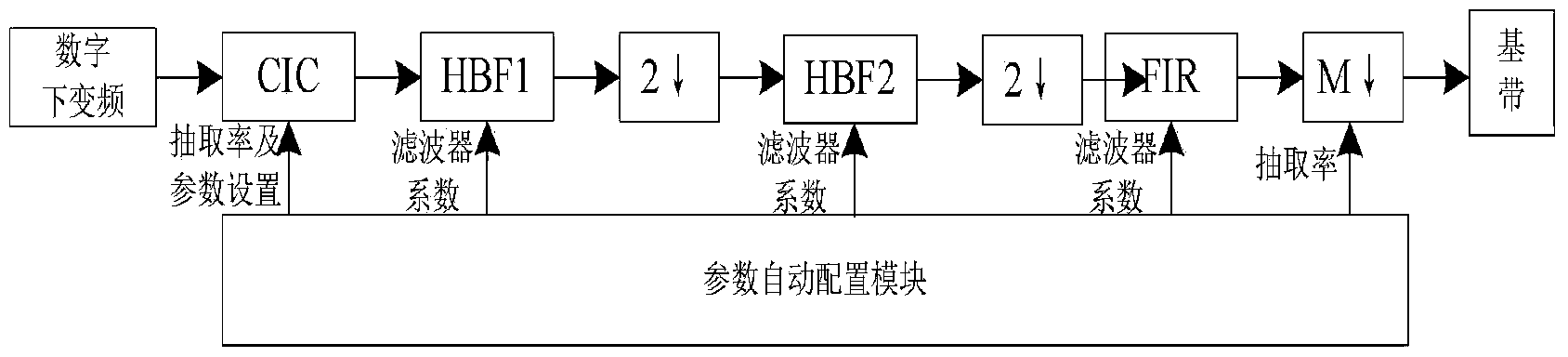

Signal intermediate-frequency receiving device suitable for multimode mobile communication system

ActiveCN103957020ASimple structureReduce volumeTransmissionWireless communicationTD-SCDMADigital down conversion

A signal intermediate-frequency receiving device suitable for a multimode mobile communication system comprises an AD sampling module, a decimation filter module, a digital down-conversion module, a PLL module and an automatic parameter configuration module. The AD sampling module is used for carrying out DA conversion on an input signal to obtain a 54.24 MHz intermediate-frequency signal. The PLL module is used for providing a clock for the whole intermediate-frequency receiving device. The automatic parameter configuration module is used for generating the frequency control word of the digital down-conversion module and the filter coefficient and decimation ratio needed by the decimation filter module according to diffident communication standards. The digital down-conversion module is used for carrying out down-conversion on a signal output by the AD sampling module to achieve baseband zero frequency of the signal. The decimation filter module is used for carrying out decimation and filtering according to the filter coefficient and the decimation ratio, and comprises a four-stage filter. The digital down-conversion module comprises a digital mixer. The signal intermediate-frequency receiving device can meet various communication standards like LTE / CDMA / WCDMA / TD-SCDMA, and is simpler in system structure, small in equipment size and low in manufacturing cost.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

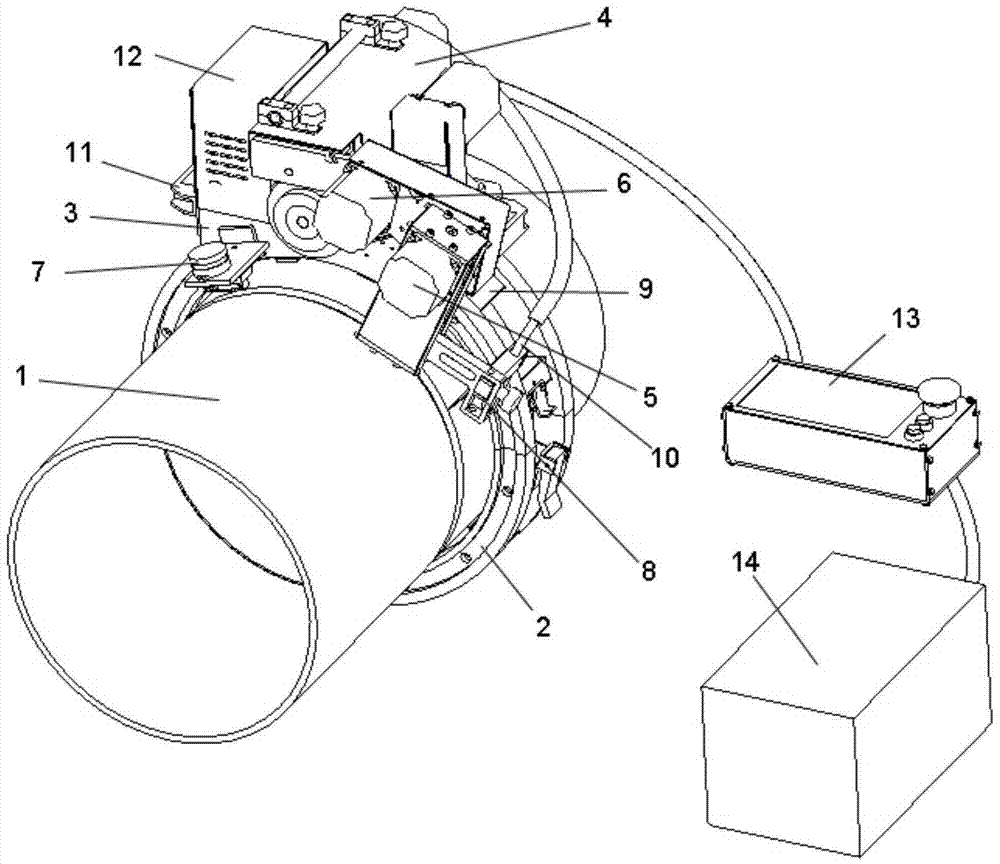

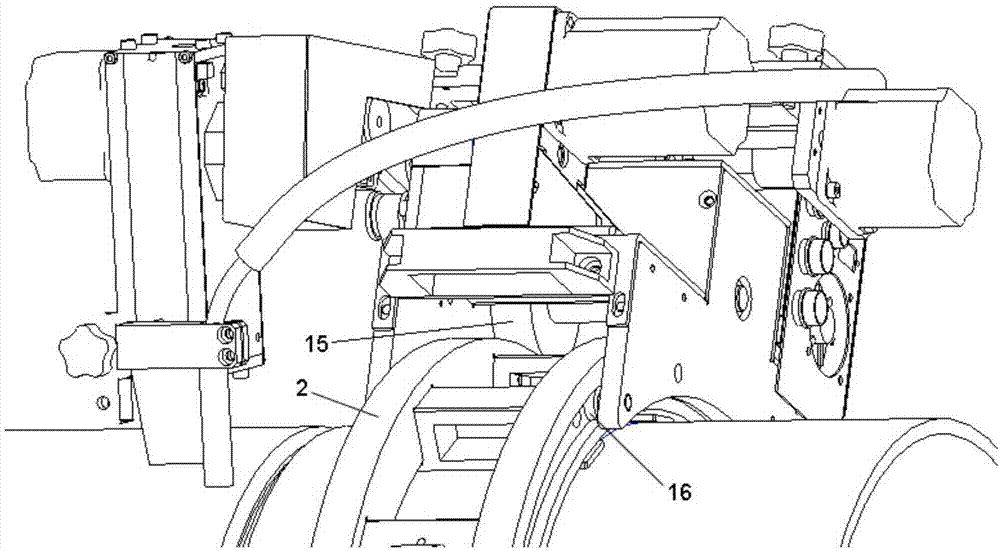

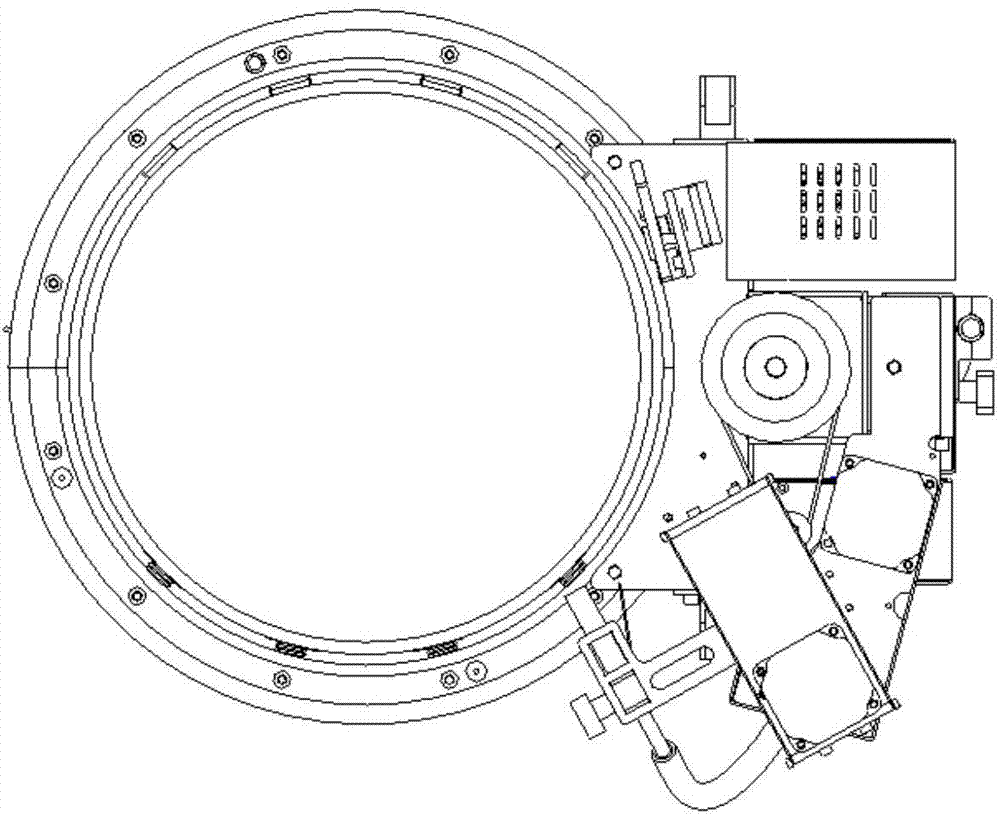

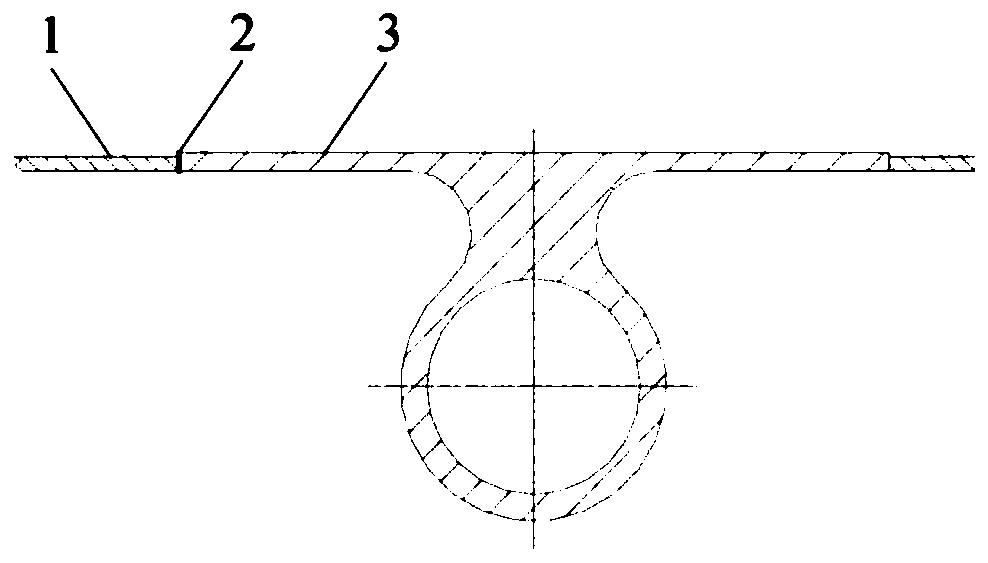

Pipeline all-position operation machine and control method thereof

ActiveCN104708220AFix workSolve quality problemsWelding/cutting auxillary devicesAuxillary welding devicesRadial motionIndependent motion

The invention belongs to the field of mechanical automation, and particularly relates to a pipeline all-position operation machine and control method thereof. The operation machine comprises a guide rail, a motion unit, an executive terminal, a driving unit and a control unit, wherein the motion unit conducts peripheral motion along the guide rail; one end of the motion unit is connected with the executive terminal; the output end of the control unit is connected with the input end of the driving unit; the output end of the driving unit is connected with a driving motor of the motion unit; the driving unit receives pulse signals sent out by the control unit and drives the driving motor of the motion unit to conduct corresponding motions; the motion unit comprises a peripheral motion mechanism, an axial motion mechanism, a radial motion mechanism and a swing mechanism which are capable of conducting independent motion driven by motors; the peripheral motion mechanism is provided with a scan mechanism. The operation machine has the function of automatically conducting pipeline cutting and welding, the defect of manual operation on irregular pipelines is overcome, and real-time detection and automatic adjustments are achieved.

Owner:深圳雷瑞智动机械设备有限公司

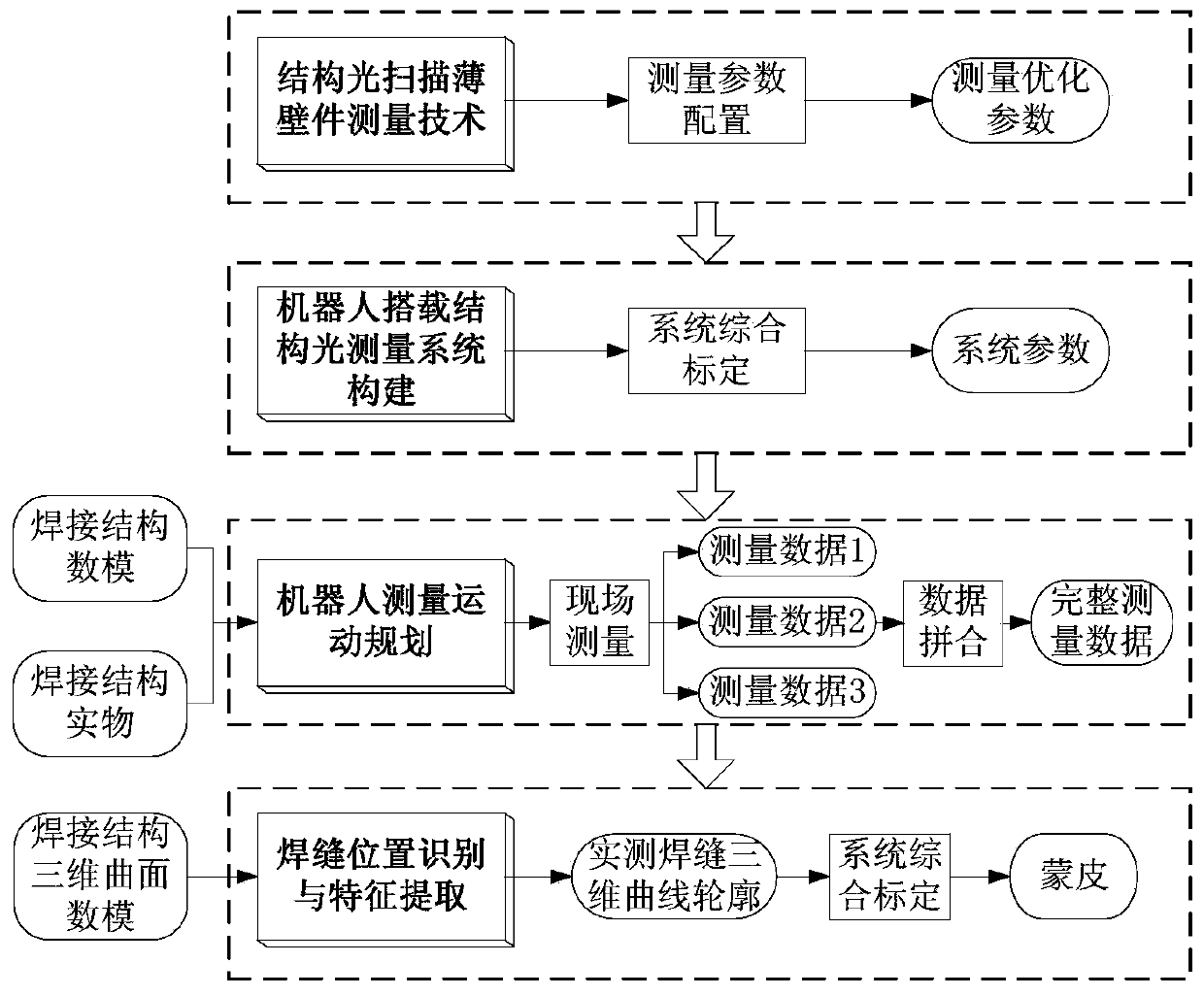

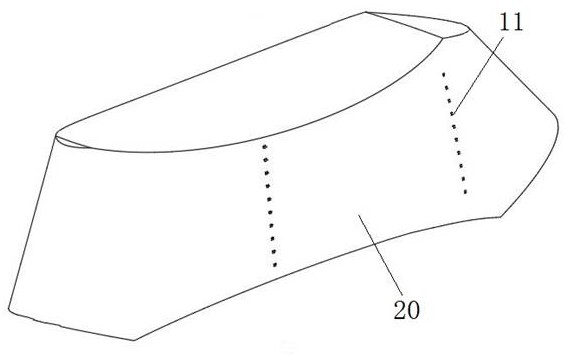

High-precision global vision measurement method for three-dimensional thin-wall structure weld joint

ActiveCN111189393AEasy to measure angleOptimizing Light Field StrengthProgramme-controlled manipulatorUsing optical meansEngineeringWeld seam

The invention relates to a high-precision global vision measurement method for a three-dimensional thin-wall structure weld joint. The method comprises the following steps: (1) preparing a workpiece and a measurement system; (2) calibrating the measurement system and optimizing parameters; (3) measuring a space curve weld joint; (4) carrying out data splicing and welding seam extraction; (5) splicing a skin and blanking; and (6) calibrating a robot welding track. The method is innovatively applied to the field of measurement of the three-dimensional contour weld joint; on-site automatic measurement of the three-dimensional contour of the actual space curve weld joint is achieved, the weld joint position and the contour characteristics of the weld joint are recognized and extracted, on thisbasis, weld joint track calibration in the robot off-line programming process is achieved, and accurate discharging of the skin in the weld joint assembling process can be achieved.

Owner:BEIJING SATELLITE MFG FACTORY

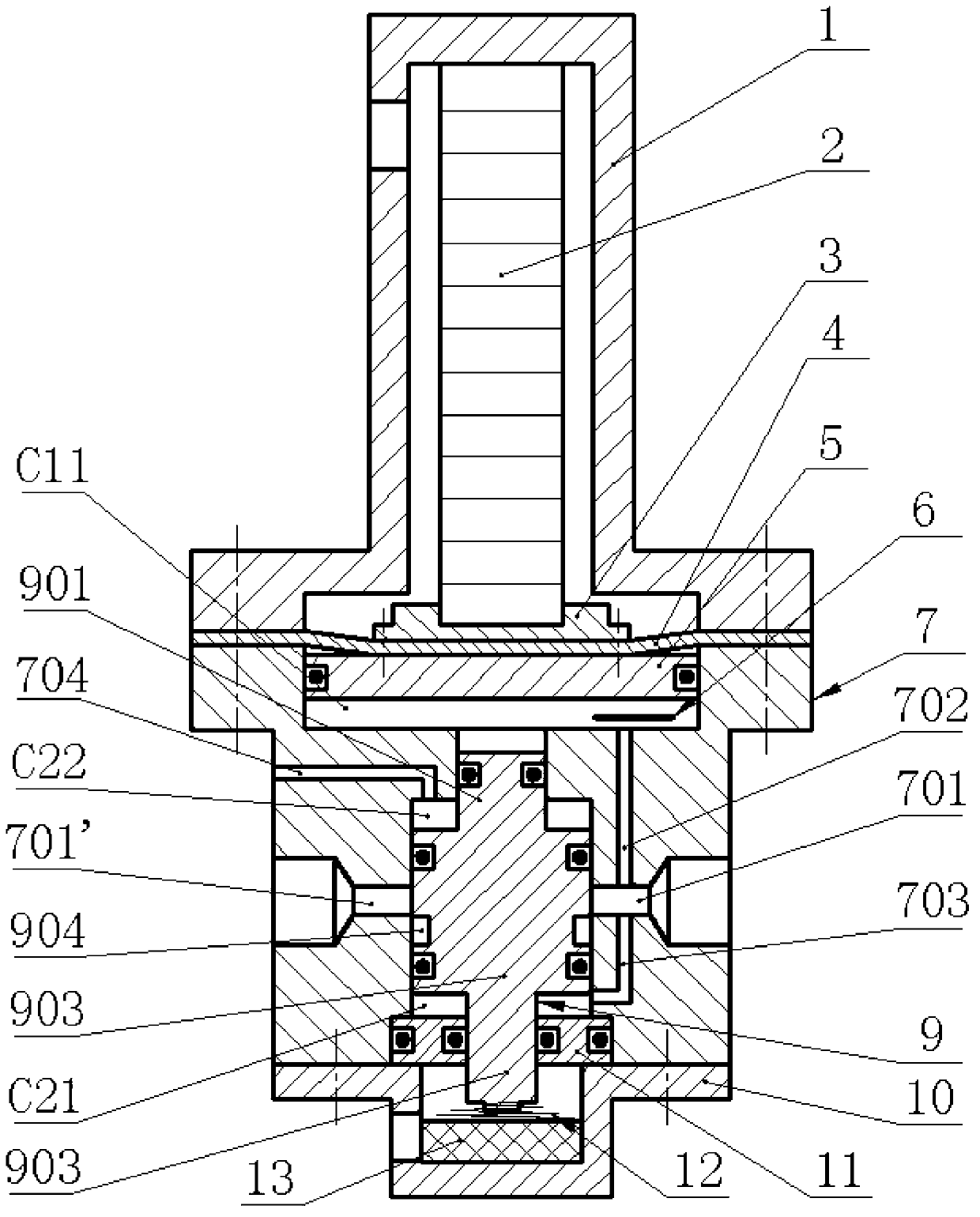

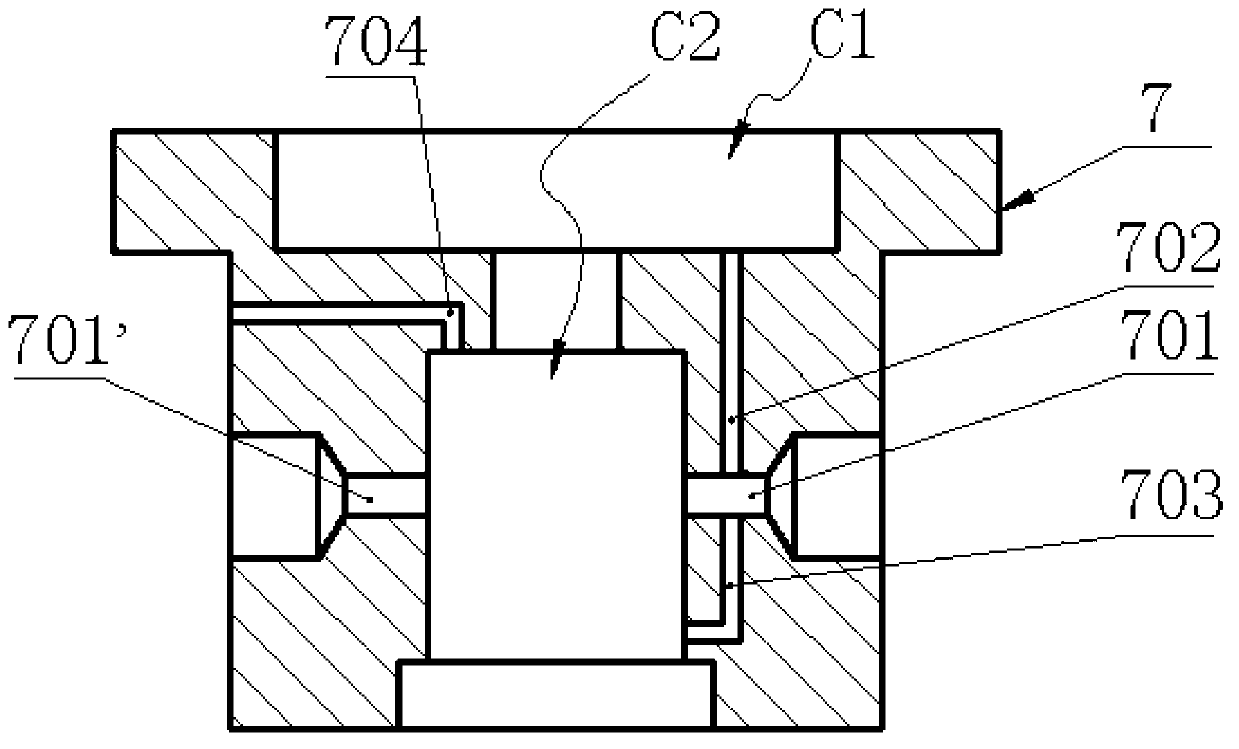

Intelligent large-flow electro-hydraulic valve

InactiveCN102996838ALarge displacementLarge adjustment rangeOperating means/releasing devices for valvesSlide valveElectricityElectro hydraulic

The invention relates to an intelligent large-flow electro-hydraulic valve, and belongs to a hydraulic valve. An upper housing and a lower housing are fixed on a valve seat; an elastic diaphragm is pressed between the valve seat and the upper housing; a partition board is pressed between the valve seat and the lower housing; a valve body is sleeved inside a valve cavity; the valve body is composed of a valve core, and an upper post rod and a lower post rod; a top block and a piston are fixed at two sides of the elastic diaphragm; the top block presses a piezoelectric stack inside the upper housing; the piston, the valve seat, the upper post rod and a one-way valve form an upper compression chamber; the valve core, the lower post rod, the valve seat and the partition board form a lower compression chamber; an inlet and an outlet are communicated through a valve core ring slot and form a valve hole; the inlet is communicated with the upper compression chamber and the lower compression chamber; the lower post rod presses a disk spring and a sensor inside the lower housing; and the sensor and the piezoelectric stack are respectively connected with an electric control unit through lead groups. The intelligent large-flow electro-hydraulic valve has the advantages that the displacement of the valve core is increased by the compression chambers; the movement state of the valve core can be measured by the sensor; and the intelligent large-flow electro-hydraulic valve is large in valve flow and damping regulating range, high in flow control accuracy and high in reliability, and especially suitable for large-scale precise flow and damping regulation.

Owner:ZHEJIANG NORMAL UNIVERSITY

Interaction method of game player and non-player character (NPC) in network games

ActiveCN103116685AIncrease engagementMuch handlingSpecial data processing applicationsGame playerNon-player character

The invention relates to an interaction method of a game player and a non-player character (NPC) in network games. The interaction method of the game player and the NPC in the network games comprise the following steps: at first, identifying an action of the game player to translate the action which is registered in a system to a special information code; afterwards, sending the information code to a NPC response module; enabling the NPC to receive and send the information code to analyze according to a module rule to generate a data response; then storing and managing data generated after responding the NPC data to decay and cancel the data; at last through a NPC action reaction module, enabling the NPC to do different responses. Through the game player continues interacting with the NPC, a gratitude and resentment system can be formed in a world outlook of the games, and the action of the game player influences the interaction judgment of the NPC to the game player. By the adoption of the interaction method, the interaction degree of the game is improved, and lives are given to the NPC in the network games to enable the NPC to have more problem treatment capability and reaction capability in a network world.

Owner:SNAIL GAMES

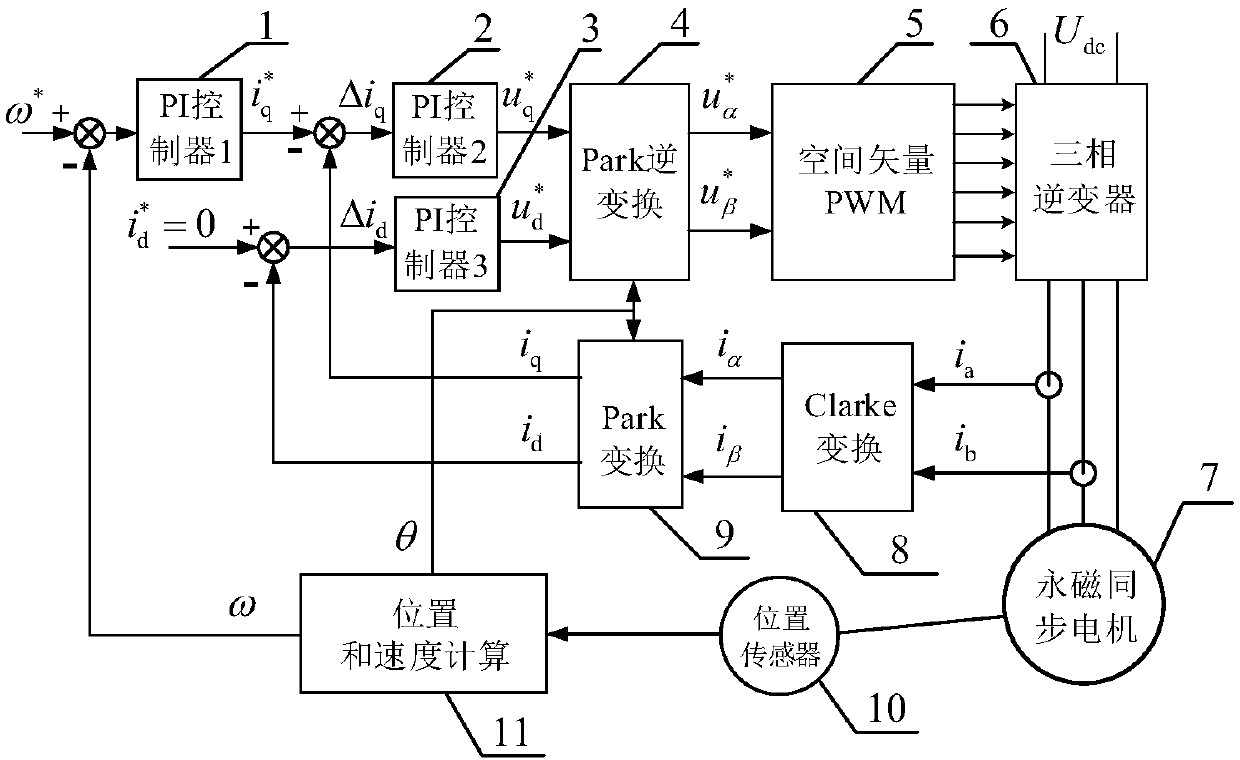

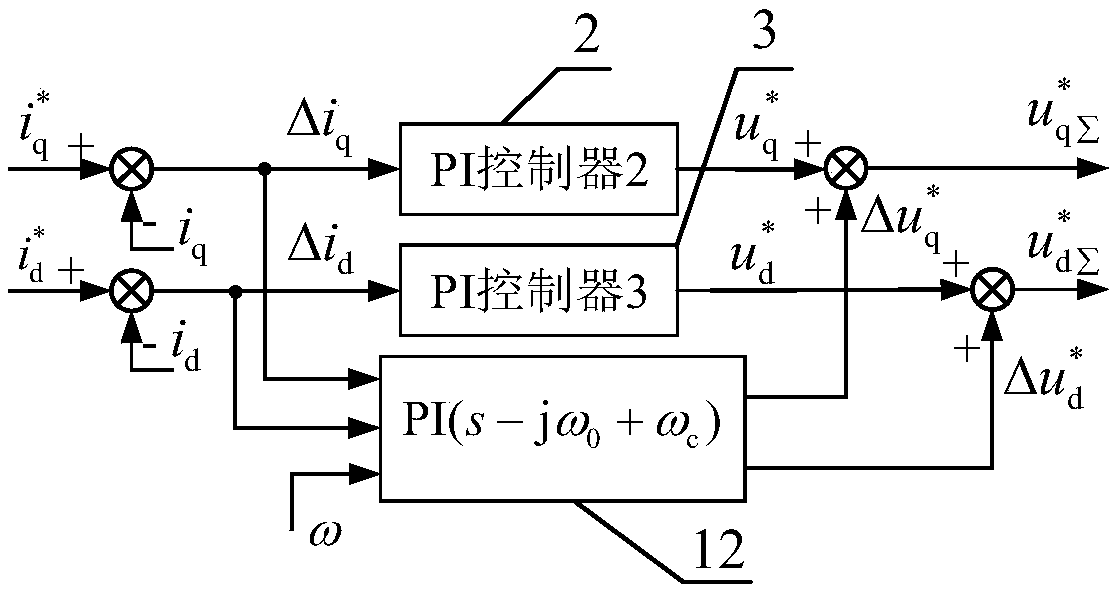

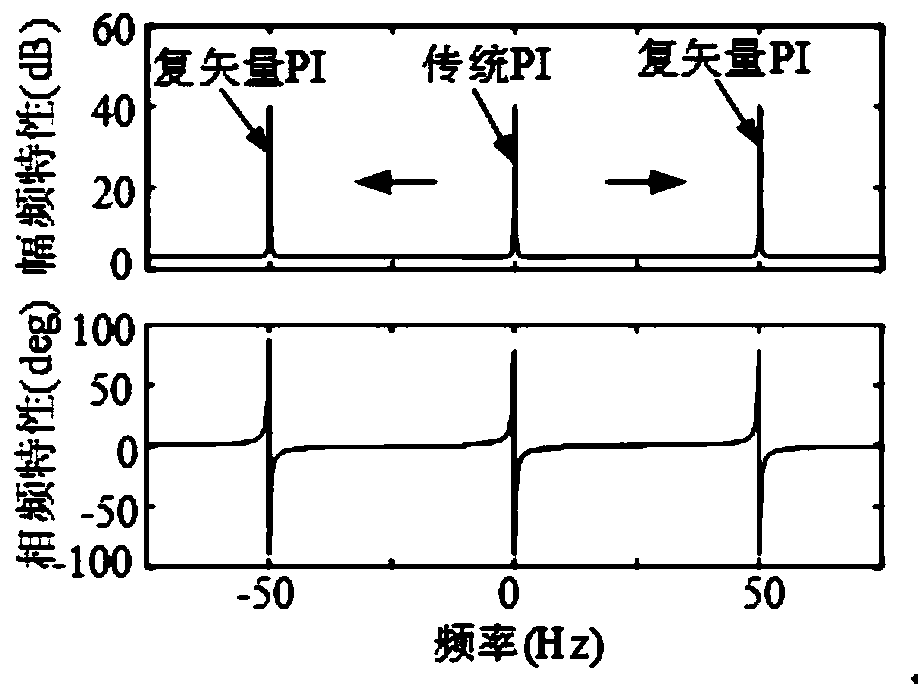

Improved complex vector PI controller employing current harmonic suppression system and method of permanent magnet synchronous motor

ActiveCN108988725AImprove controlHigh bandwidthElectronic commutation motor controlAC motor controlHarmonicElectric machine

The invention provides an improved complex vector PI controller employing current harmonic suppression system and method of a permanent magnet synchronous motor , belonging to the technical field of motor control. A system and method for suppress current harmonics of a permanent magnet synchronous motor improve a complex vector PI controller and a q-axis current PI controller, A d-axis current PIcontrol is connected in parallel, so that that output of the improve complex vector pi controller is separate from the output of the pi controller, A new q-axis and d-axis voltage command is obtainedto control the ac component of q-axis and d-axis currents and to suppress current harmonics.

Owner:HARBIN INST OF TECH

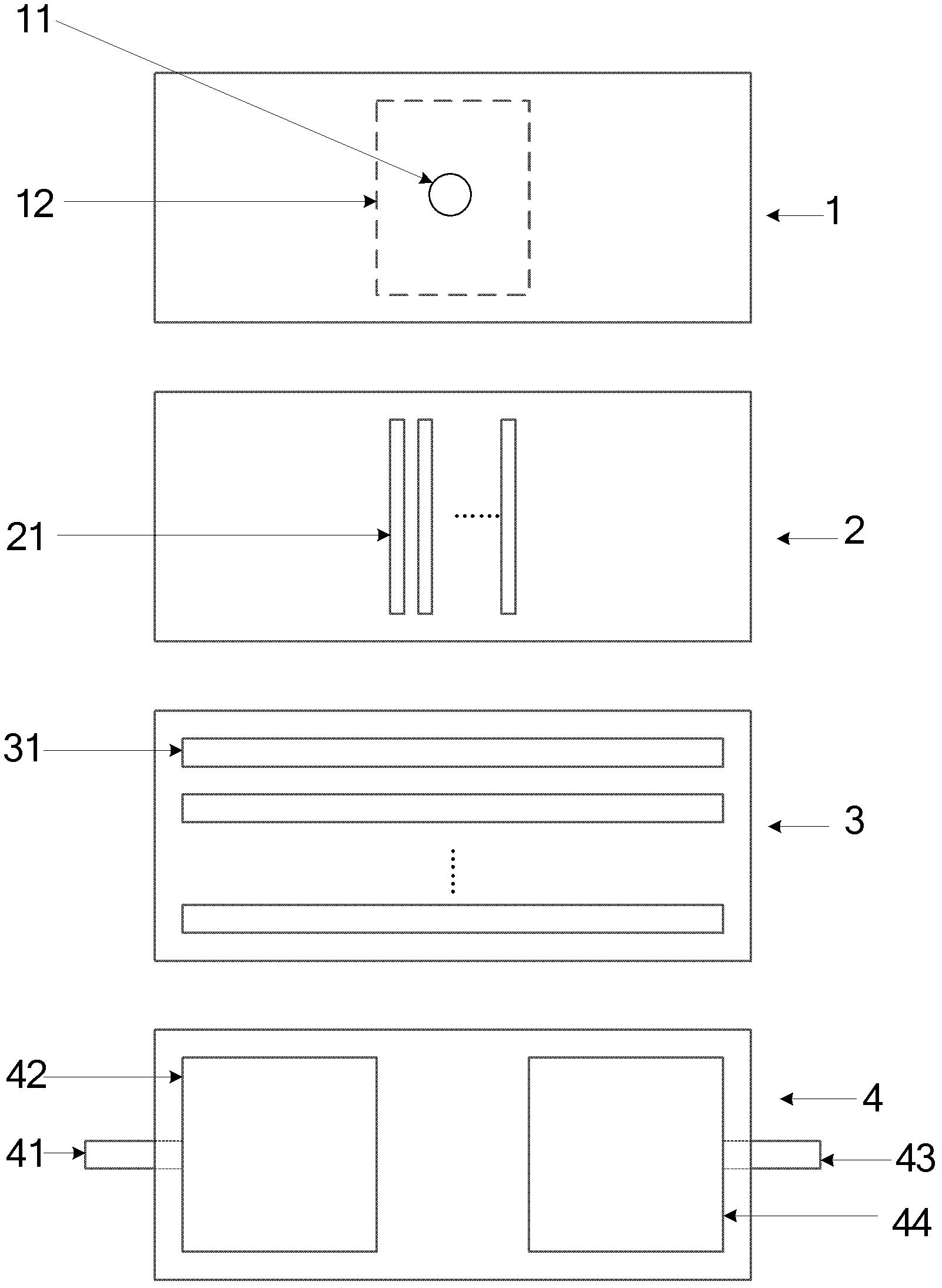

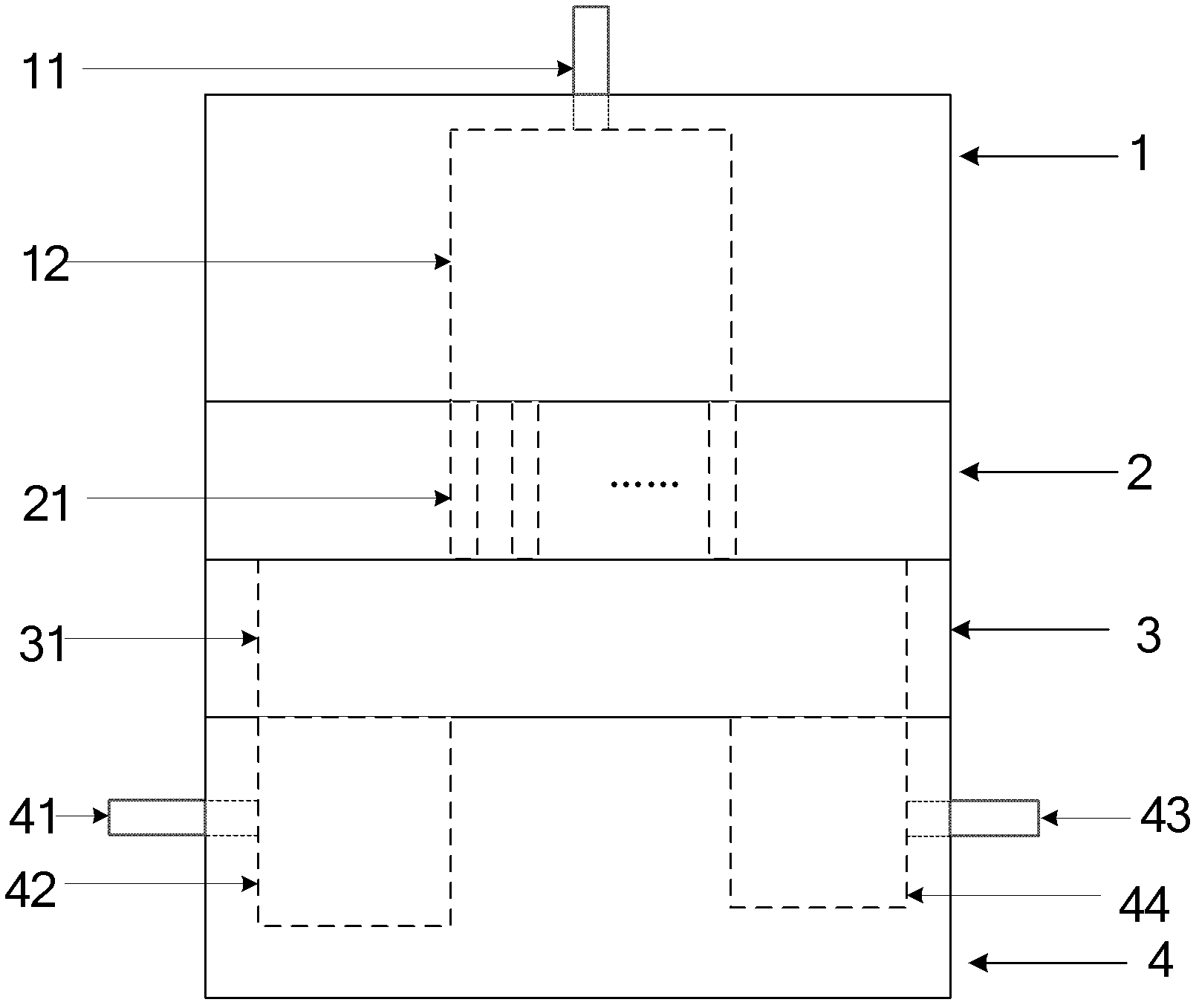

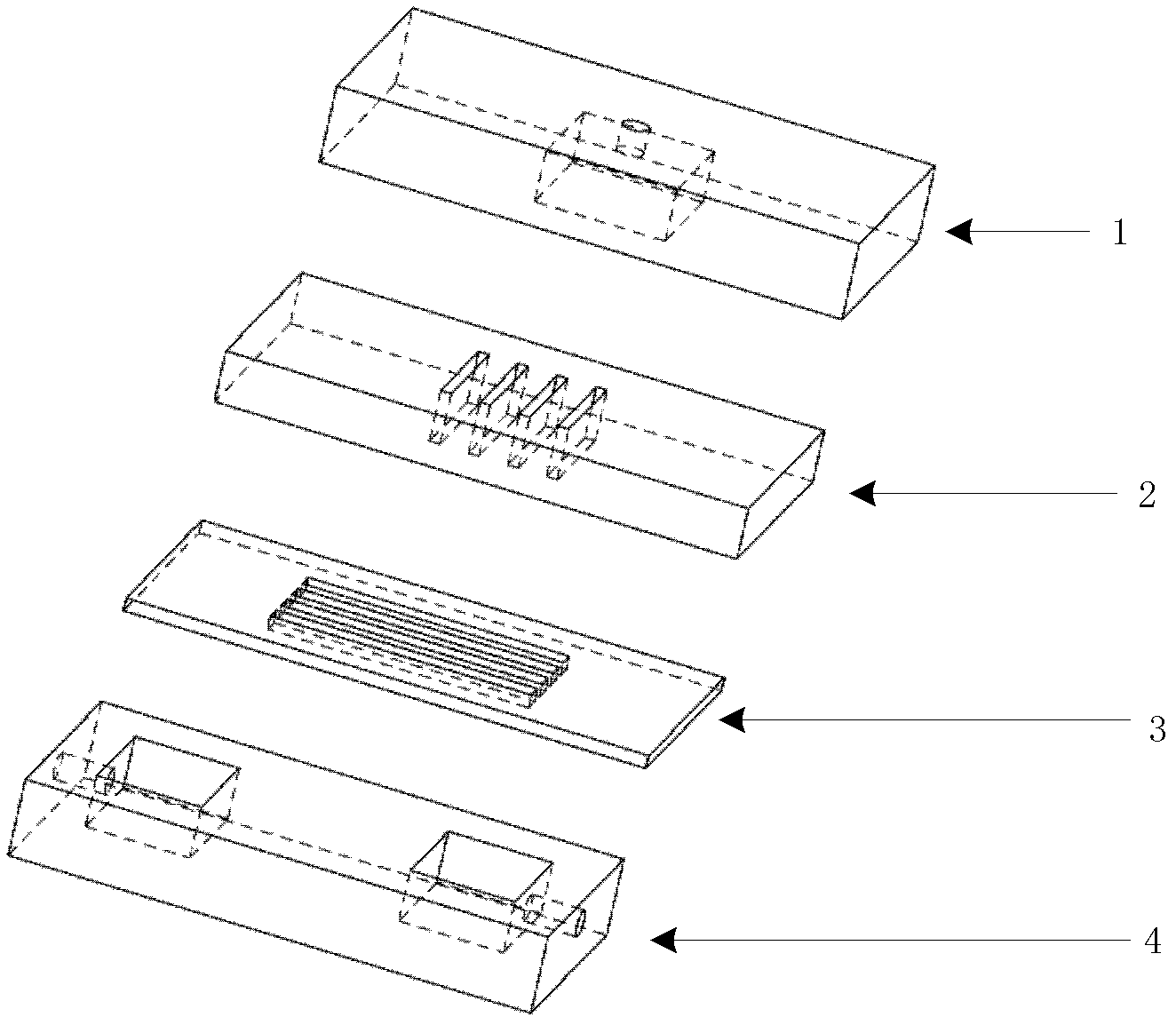

Micro-structured mixer

ActiveCN102847455AAvoid easy-to-block problemsGuaranteed mixing effectFlow mixersEngineeringPetrochemical

The invention discloses a micro-structured mixer, which belongs to the technical field of chemical and chemical engineering. The micro-structured mixer is formed by stacking a first interface board, a first fluid distributing plate, a fluid mixing plate and a second interface board in sequence, wherein the first interface board is provided thereon with a first fluid inlet pipe and a first fluid buffer chamber, the first fluid distributing plate is provided thereon with at least one through slot, the fluid mixing plate is provided thereon with at least one through slot, the second interface board is provided thereon with a second fluid inlet pipe, a second fluid buffer chamber, a mixed fluid buffer chamber and a mixed fluid outlet pipe, when the number of the through slots arranged on the first fluid distributing plate is larger than one, the arranged through slots are parallel through slots, when the number of the through slots arranged on the fluid mixing plate is larger than one, the arranged through slots are parallel through slots. The treatment capacity of unit volume of the micro-structured mixer is larger, the micro-structured mixer is easy to store and enlarge, has low requirement for material cleanliness, and can be used in chemical, chemical engineering, petrochemical, medicine and food industries.

Owner:TSINGHUA UNIV

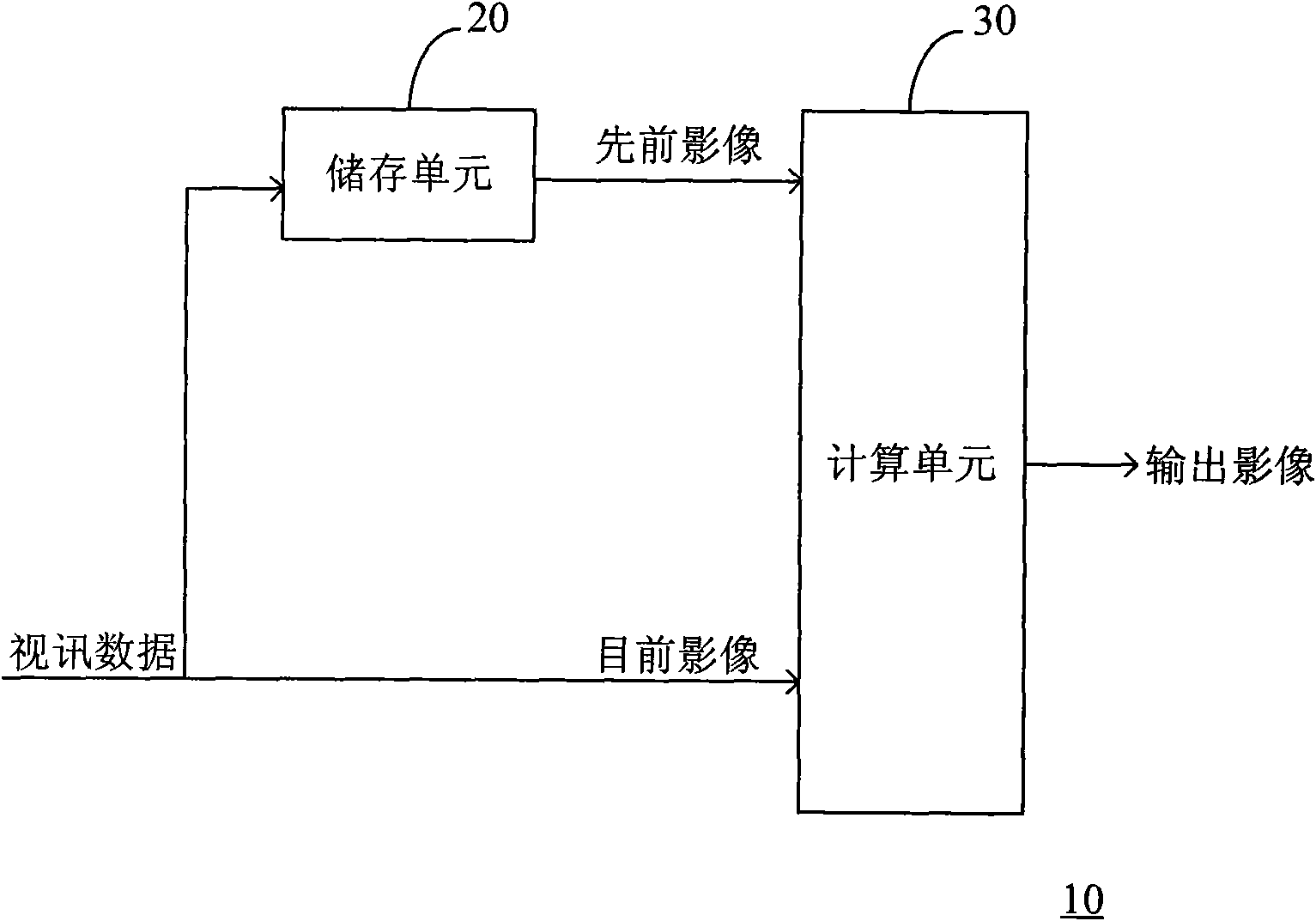

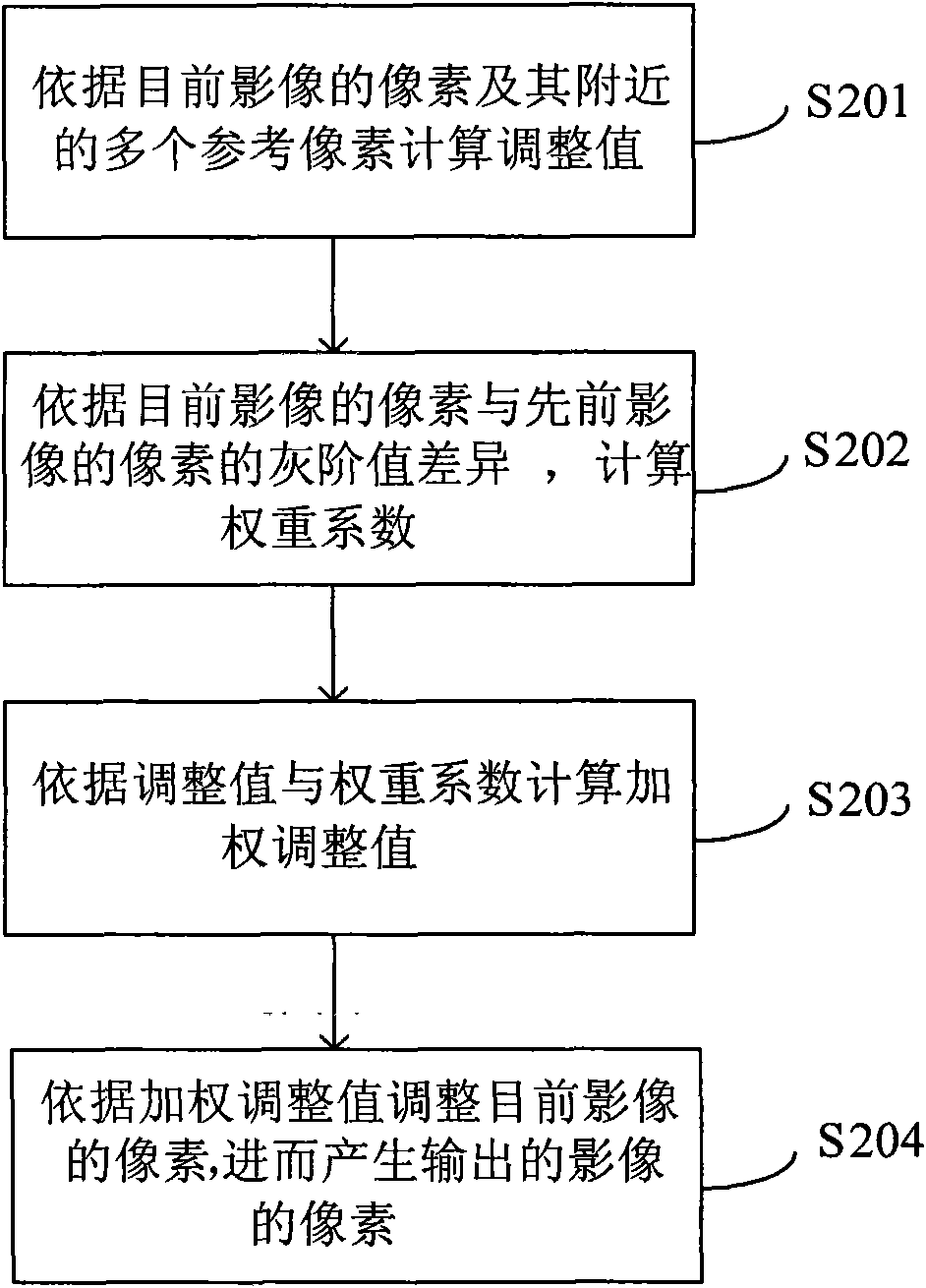

Image processing device and method

InactiveCN101923706AAdaptabilityQuality improvementImage enhancementStatic indicating devicesImaging processingWeight coefficient

The invention provides an image processing device and method. The method comprises the following steps: computing the adjusted value according to the pixel of the current image and a plurality of neighboring reference pixels; computing the weight coefficient according to the gray-scale value difference between the pixel of the current image and the pixel of the previous image; computing the weighted adjusted value according to the adjusted value and the weight coefficient; and adjusting the pixel of the current image according to the weighted adjusted value and further producing the pixel of the output image. The invention can adaptively adjust the current image and elevate the quality of the output image.

Owner:华映视讯(吴江)有限公司 +1

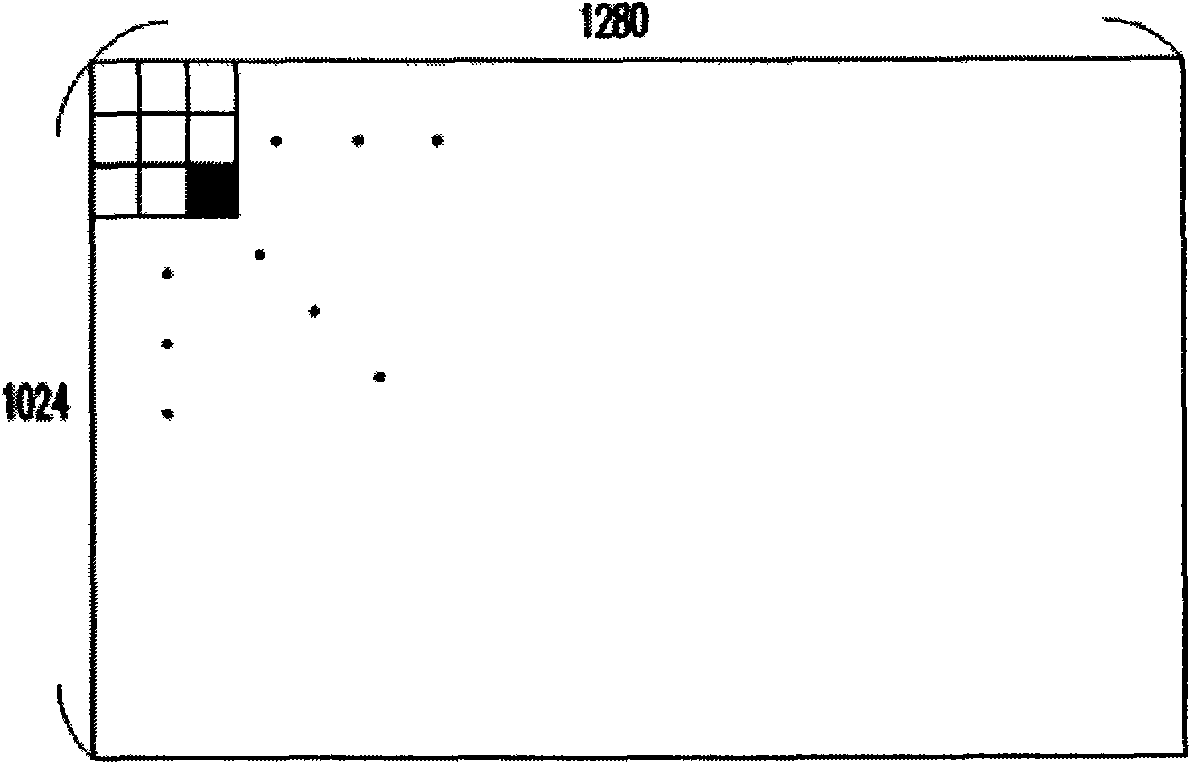

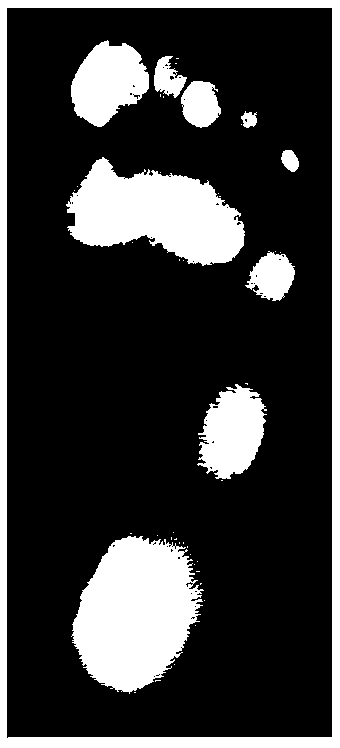

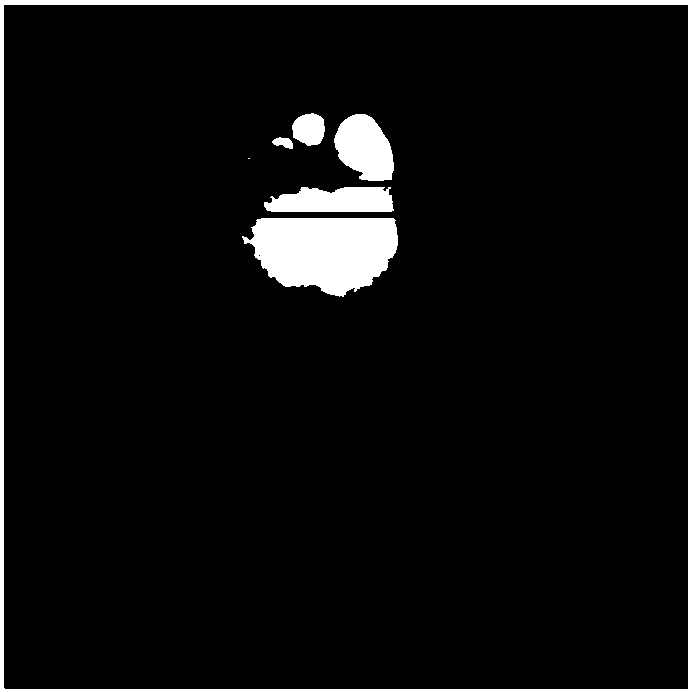

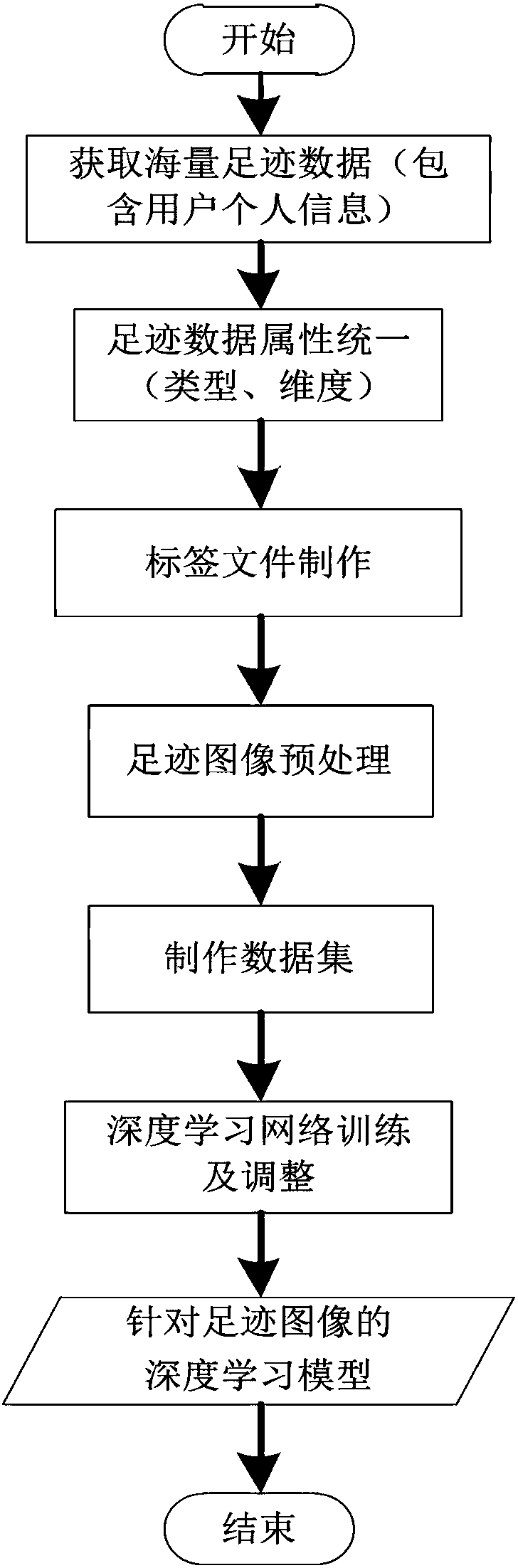

Analysis and processing system for mass plantar pressure data

InactiveCN109583273ARealize processingThe processing method is standardized and effectiveBiometric pattern recognitionNeural learning methodsData setEngineering

The invention discloses a mass sole pressure data analyzing and processing system which comprises a mass footprint data obtaining module, a data processing module and a mass sole pressure data analyzing and processing module, the mass footprint data obtaining module comprises dynamic footprint data obtaining, static footprint data obtaining and personal information input by a user; The data attribute unification module comprises a data type unification module and a data dimension unification module; The label file making module is used for classifying and sorting the acquired mass footprint data and user information; The image preprocessing module is used for preprocessing the barefoot or sock wearing footprint image data; The data set making module is used for dividing the preprocessed barefoot or sock wearing footprint image data into a training set and a verification set; And the deep learning network training and adjusting module is used for designing a deep learning network for massive footprint images and circularly carrying out deep learning network training and adjusting. According to the invention, the processing of mass footprint data is realized, so that the processing mode of mass footprint data is standard and effective.

Owner:DALIAN EVERSPRY SCI & TECH

Resistance-enhancing and growth-promoting farming method for Landaise goslings

ActiveCN105409879APromote growth and developmentImprove the immunityAnimal feeding stuffAccessory food factorsSide effectGrowth promoting

The invention discloses a resistance-enhancing and growth-promoting farming method for Landaise goslings. The method comprises the steps: (S1) carrying out temperature and relative humidity management: controlling the temperature and relative humidity of an environment, where the Landaise goslings are located, to be as follows: at the period of 4-10 days old, the temperature is 25-28 DEG C, and the relative humidity is 65-70%; at the period of 11-16 days old, the temperature is 21-24 DEG C, and the relative humidity is 60-65%; and at the period of 17-20 days old, the temperature is 18-21 DEG C, and the relative humidity is 55-60%; (S2) carrying out feed feeding; (S3) carrying out light control; and (S4) carrying out drinking water management. The farming method disclosed by the invention is natural and is free of toxic or side effects, the growth and development of the Landaise goslings can be greatly promoted, and the resistance of the Landaise goslings is enhanced.

Owner:全椒县王震家禽养殖专业合作社

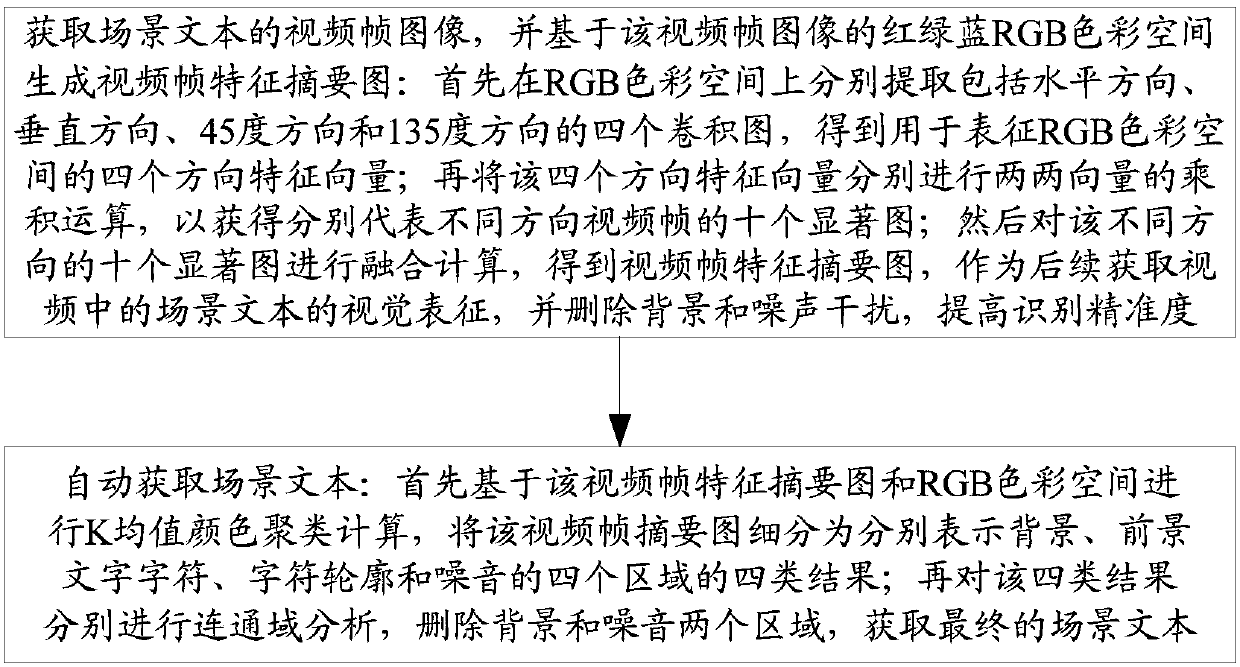

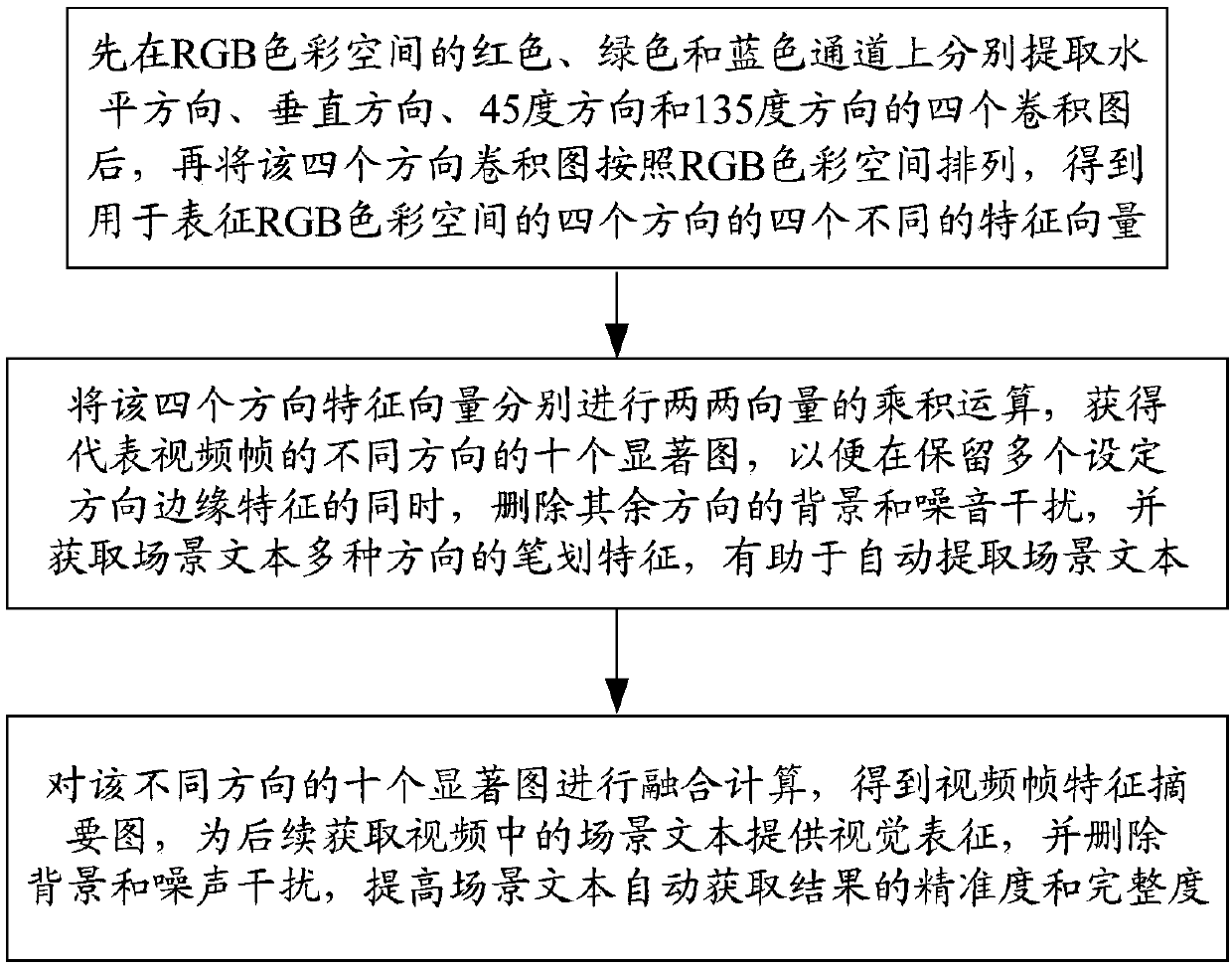

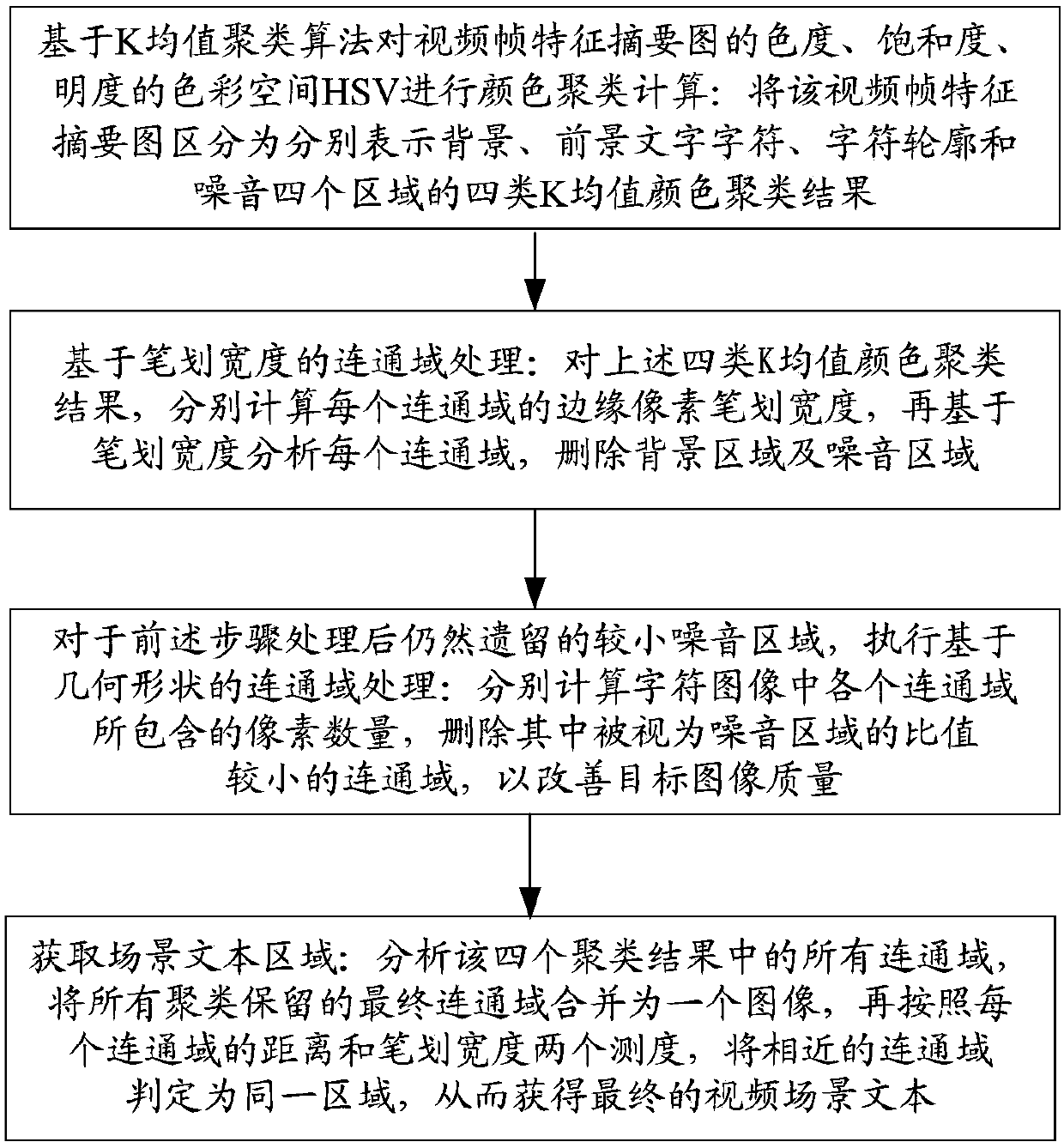

Method for automatically obtaining outdoor scene text in video based on feature summary diagram

ActiveCN108038458AFast and accurate detectabilityFast and accurate extractionCharacter and pattern recognitionFeature vectorSaliency map

The invention discloses a method for automatically obtaining an outdoor scene text in a video based on a feature summary diagram. The method comprises the following steps that: firstly, obtaining thevideo frame image of a scene text, and generating a video frame feature summary diagram on the basis of the RGB (Red, Green and Blue) color space of a video frame image: firstly, independently extracting four convolution diagrams in four directions including a horizontal direction, a vertical direction, a 45-degree direction and a 135-degree direction, obtaining four-direction feature vectors which represent the color space so as to obtain ten saliency maps which represent the video frames in different directions to obtain the video frame feature summary diagram; and then, on the basis of thevideo frame feature summary diagram and the RGB color space, carrying out K mean value color clustering calculation, independently analyzing the connected domains of four categories of results after four categories of results which shows background and foreground word characters, character outlines and noise, deleting two areas of background and noise, and automatically obtaining a final outdoor scene text. The method has the advantages of simple step, easiness in calculation and good popularization and application prospect, and the outdoor scene text can be obtained and identified in real time.

Owner:CAPITAL NORMAL UNIVERSITY

Winding rotor motor for preventing accumulated dust adsorption and creepage

InactiveCN101814799AHigh popularityImprove product qualityManufacturing dynamo-electric machinesSupports/enclosures/casingsMotor driveEngineering

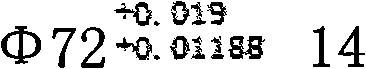

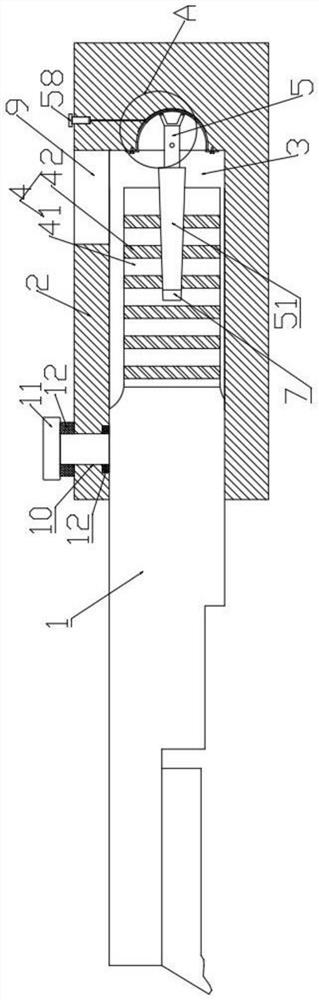

The invention discloses a winding rotor motor for preventing accumulated dust adsorption and creepage. A stator and a rotor of the motor are made of a silicon steel sheet rolled by a high-performance energy-saving process; the electromagnetic design is performed in a standardized form according to the requirement; the motor driving and a collecting ring are treated by isolation; a part with a creepage preventing standard distance is needed to be insulated in a collecting ring area; and the surface of the part is completely treated by using nano particle insulated paint to form an insulated surface low-tension area which has self-clean performance and is not easy to accumulate and adsorb dust. With the fit of a motor end cover bearing chamber hole and a bearing outer ring, and referencing to three difference states of natural assembly, normal work and special work in which different matched materials are positioned as well as a clearance variable difference generated by an expansion coefficient, a normal work state can be selected as a matching reference and a design processing deviation can be determined by replacing the traditional selection mode by a computing mode. An O-shaped ring is additionally assembled to adjust when the expansion variable difference is larger. The invention always ensures that the bearing is operated in the state of oil froth, thereby achieving the aim of improving the non-fault operating time and the quality of the motor.

Owner:SHANGHAI DIANJI UNIV +1

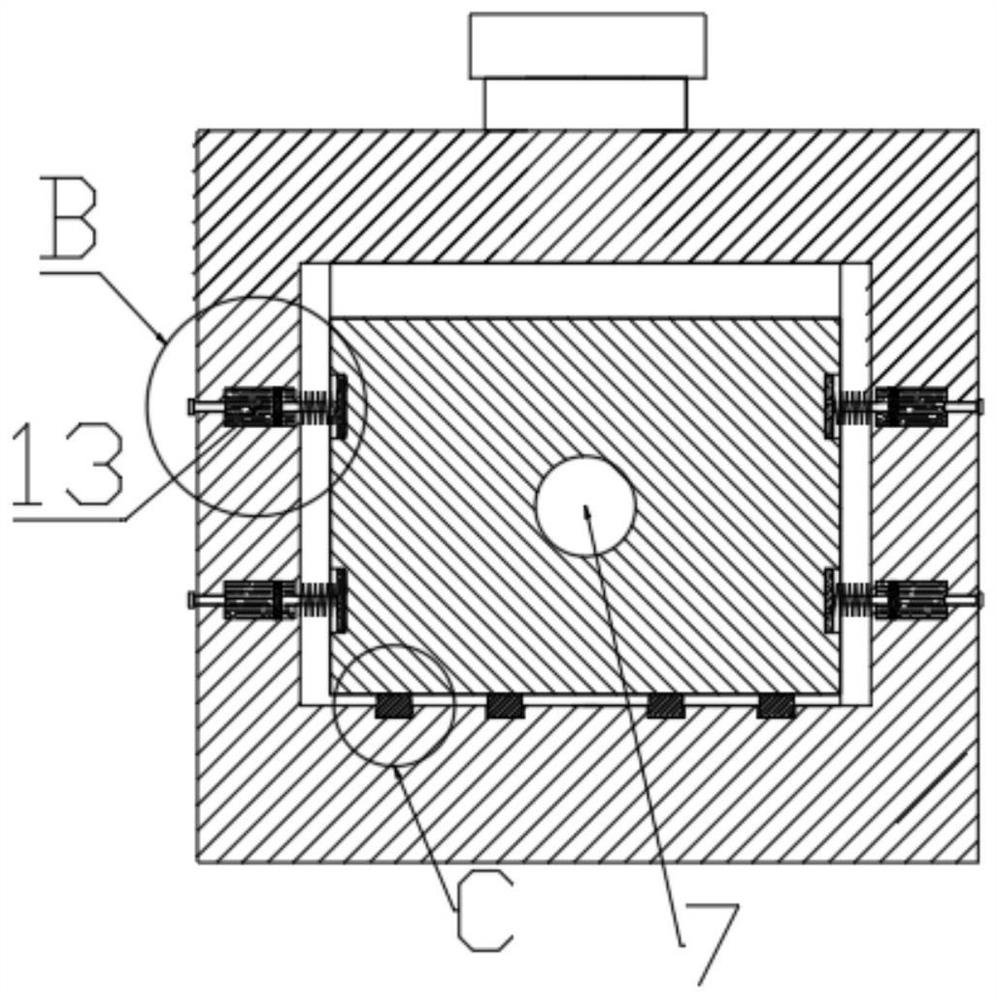

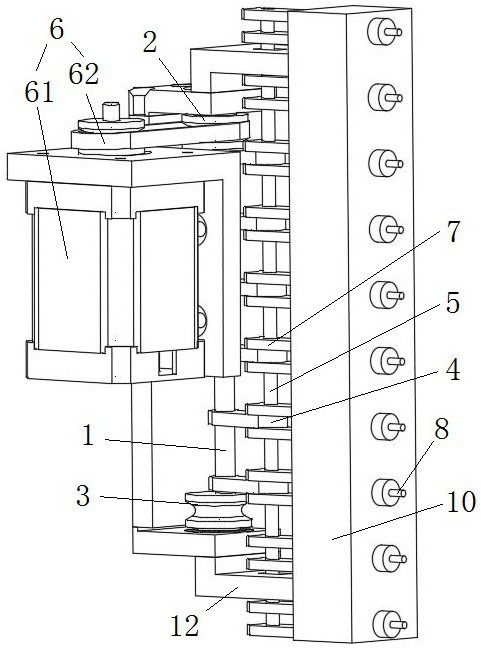

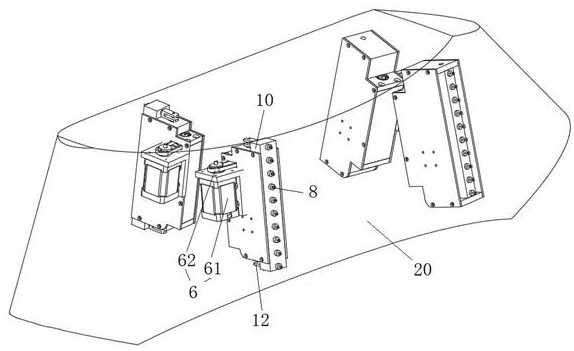

Lathe tool damping device

PendingCN114083004AReduce direct impactGood compensationNon-rotating vibration suppressionBoring barsEngineeringMechanical equipment

The invention discloses a lathe tool damping device, and belongs to the technical field of mechanical equipment. The lathe tool damping device comprises a tool bar and a tool bar mounting seat; one end of the tool bar mounting seat is provided with a mounting groove for mounting the tool bar, and an opening of the mounting groove is provided with a fixing part for fixing the tool bar; the tail part of the tool bar is fixed in the mounting groove, a tool bar extension section is fixedly arranged at the rear end of the tool bar, a movable gap is formed between the tool bar extension section and the inner wall of the mounting groove, and the tool bar extension section is connected with a swing damping device; and the swing damping device comprises a swing rod, a connecting rod, an n-shaped supporting frame, a friction roller and an arc-shaped damping face. According to the device, the influence of vibration of a lathe on the tool bar can be reduced, vibration of the tool bar can be damped at the same time, the damping effect is better, and thus the influence of vibration on processing of the tool bar is reduced, and the processing precision can be effectively guaranteed.

Owner:陈素丽

Foldable packaging material

The present invention discloses a foldable packaging material, comprising the following raw material components in parts by weight: 55 to 95 parts of a polyethylene film, 45 to 80 parts of polyimide, 30 to 60 parts of polytetrafluoroethylene, 25 to 45 parts of cellophane, 40 to 55 parts of linen-cotton fibers, 20 to 60 parts of wood fibers, 10 to 50 parts of nylon, 12 to 35 parts of nano silica and 14 to 26 parts of toughened resin. By the above-described manner, the foldable packaging material has excellent flexibility performance, can promote packaging material folded packaging, adapts to the product shape and performance, and can guarantee the convenient and reliable transportation.

Owner:方益龙

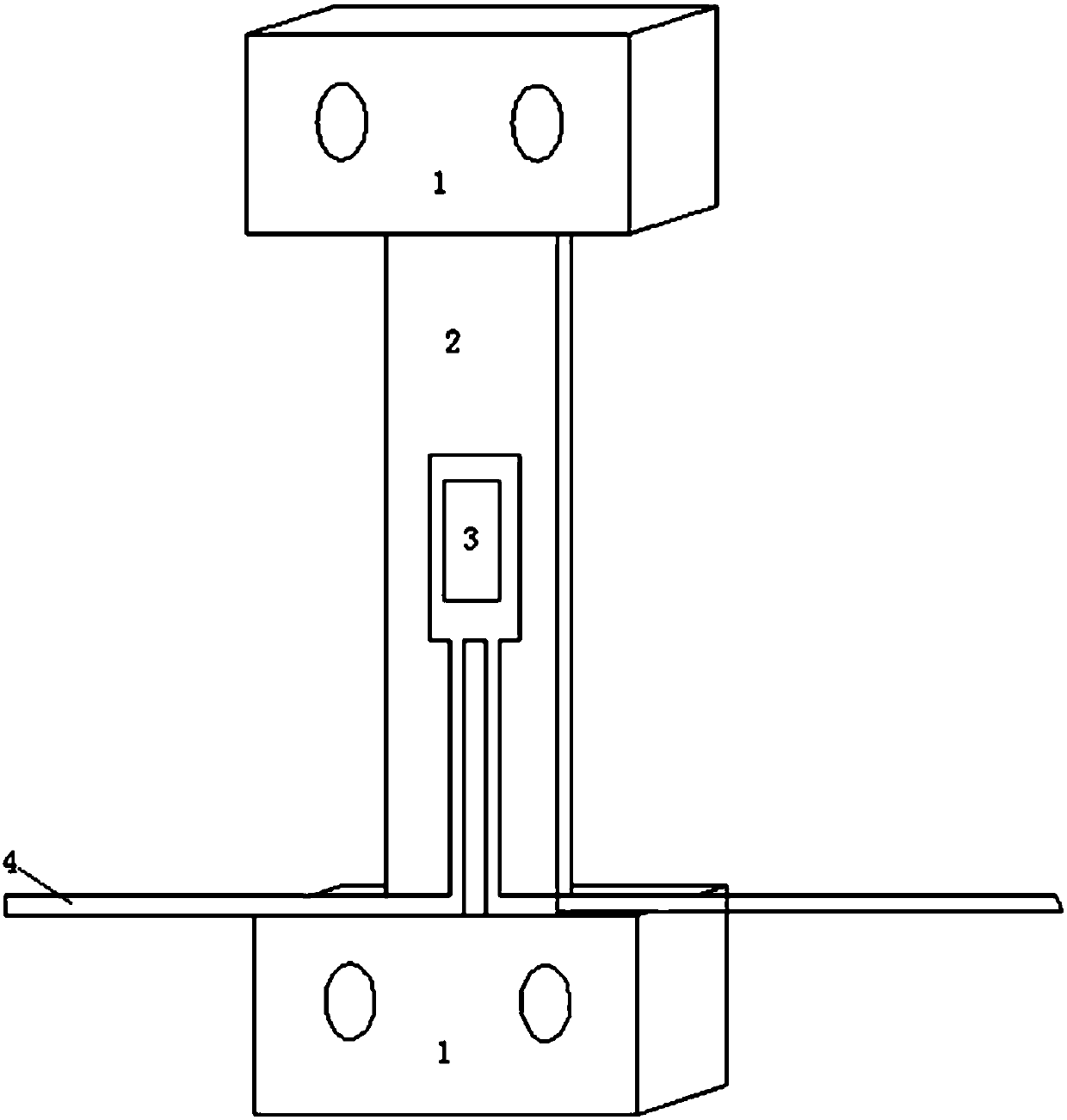

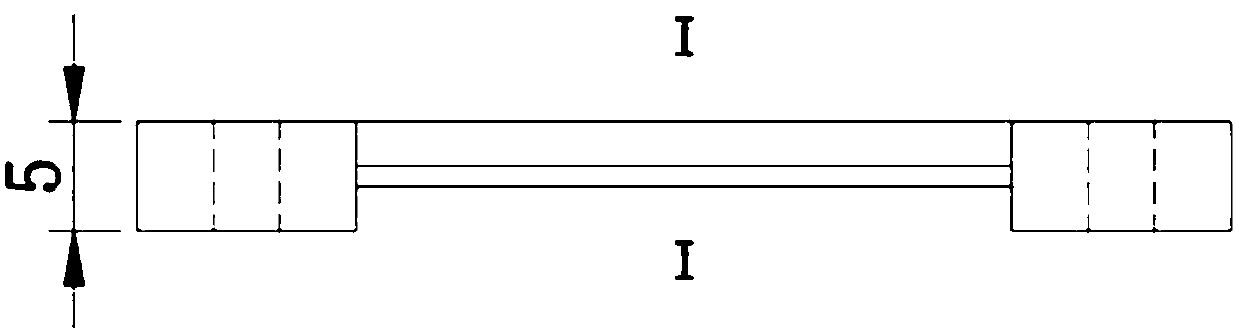

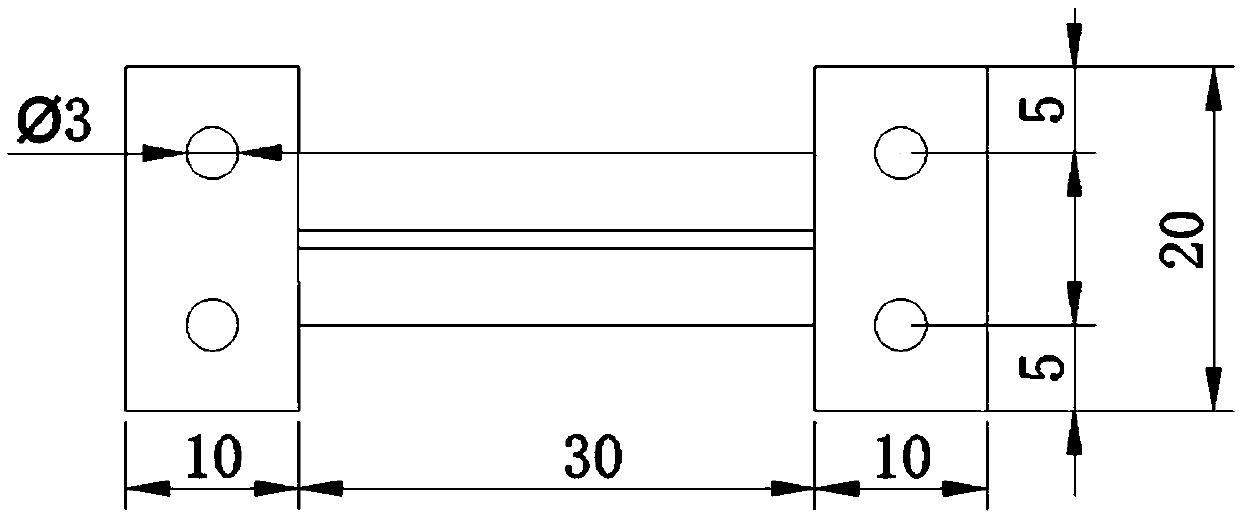

Resistance strain type displacement meter and manufacturing method thereof

InactiveCN109612378AReduce volumeLow costUsing electrical meansElectrical resistance and conductanceAxial compression

The invention relates to a resistance strain type displacement meter and a manufacturing method thereof. The displacement meter comprises an installation supporting seat, a substrate, a strain gauge and an insulation cover layer, the substrate is fixed to the installation supporting seat, the strain gauge is pasted on the substrate, and is covered with the insulation cover layer, and a bolt hole for connecting with a measuring target is formed in the installation supporting seat. The manufacturing method comprises the following steps that according to the requirements of the measuring target,the displacement meter measuring range and the measurement accuracy are determined; the strain gauge measuring range and the displacement meter gauge distance are determined; the cross section form and size of the substrate are designed, so that the substrate meets the axial compression load requirements of the substrate of the displacement meter and the allowable interference external force of the measuring target; according to the target measurement scene, the installation supporting seat is designed; based on the designed substrate and the installation supporting seat, the substrate and theinstallation supporting seat are integratedly formed by 3D printing processing; and the strain gauge is pasted and covered with the insulation cover layer to protect. Compared with the prior art, theresistance strain type displacement meter and the manufacturing method thereof have the advantages of small volume, high measurement accuracy, high dynamic response frequency and the like.

Owner:TONGJI UNIV

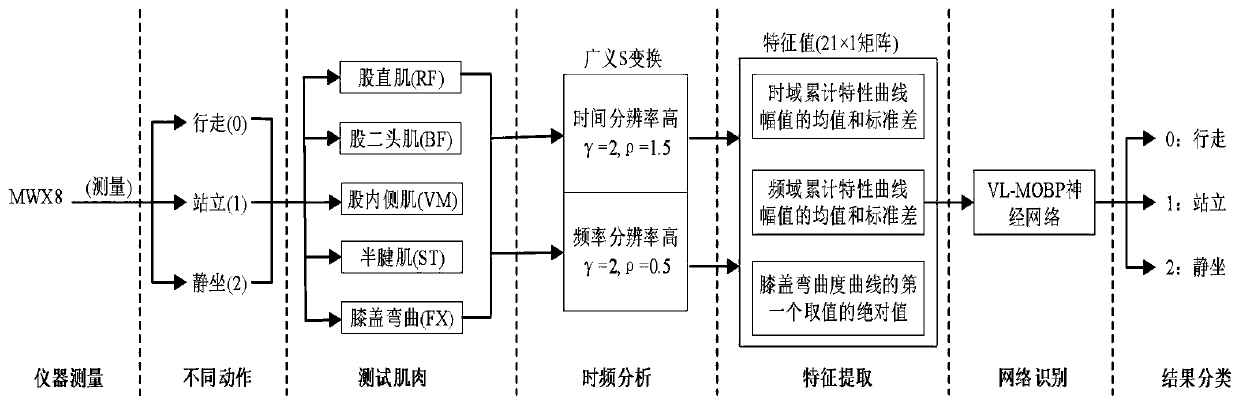

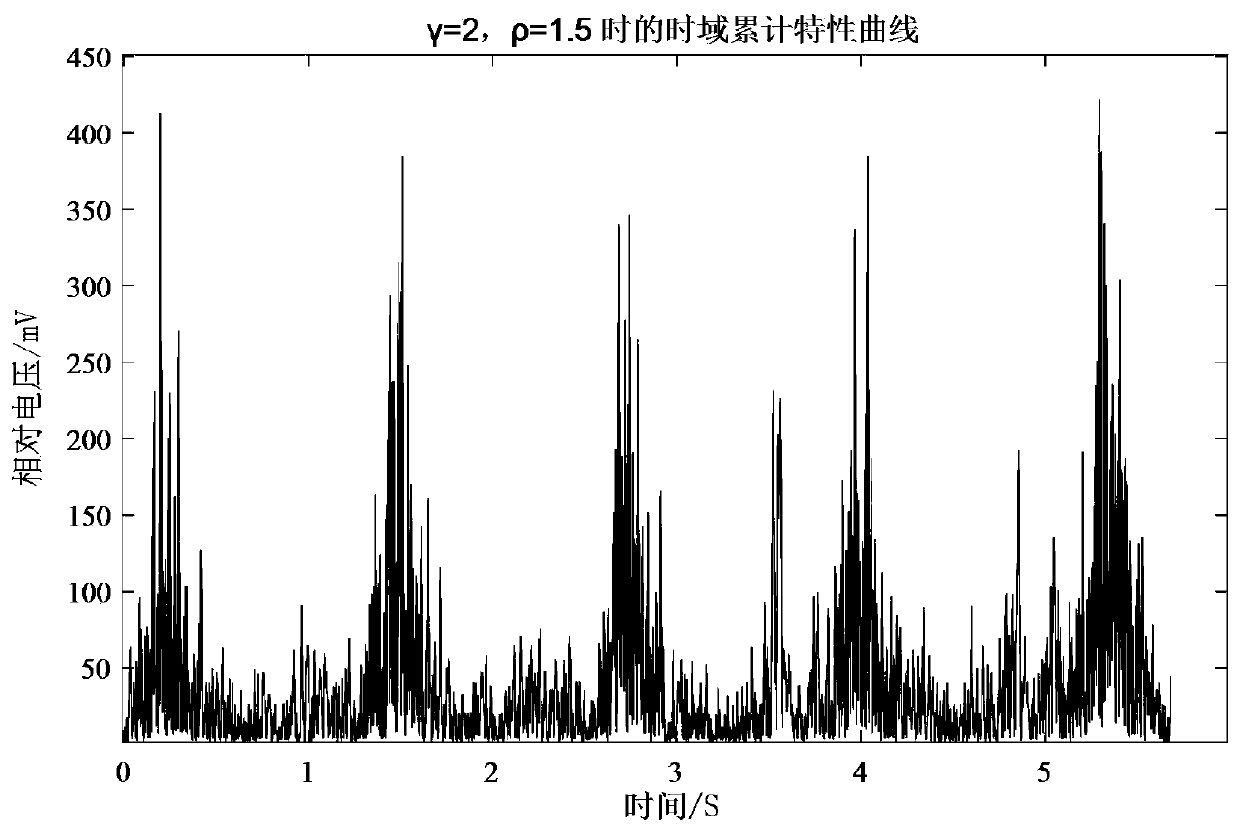

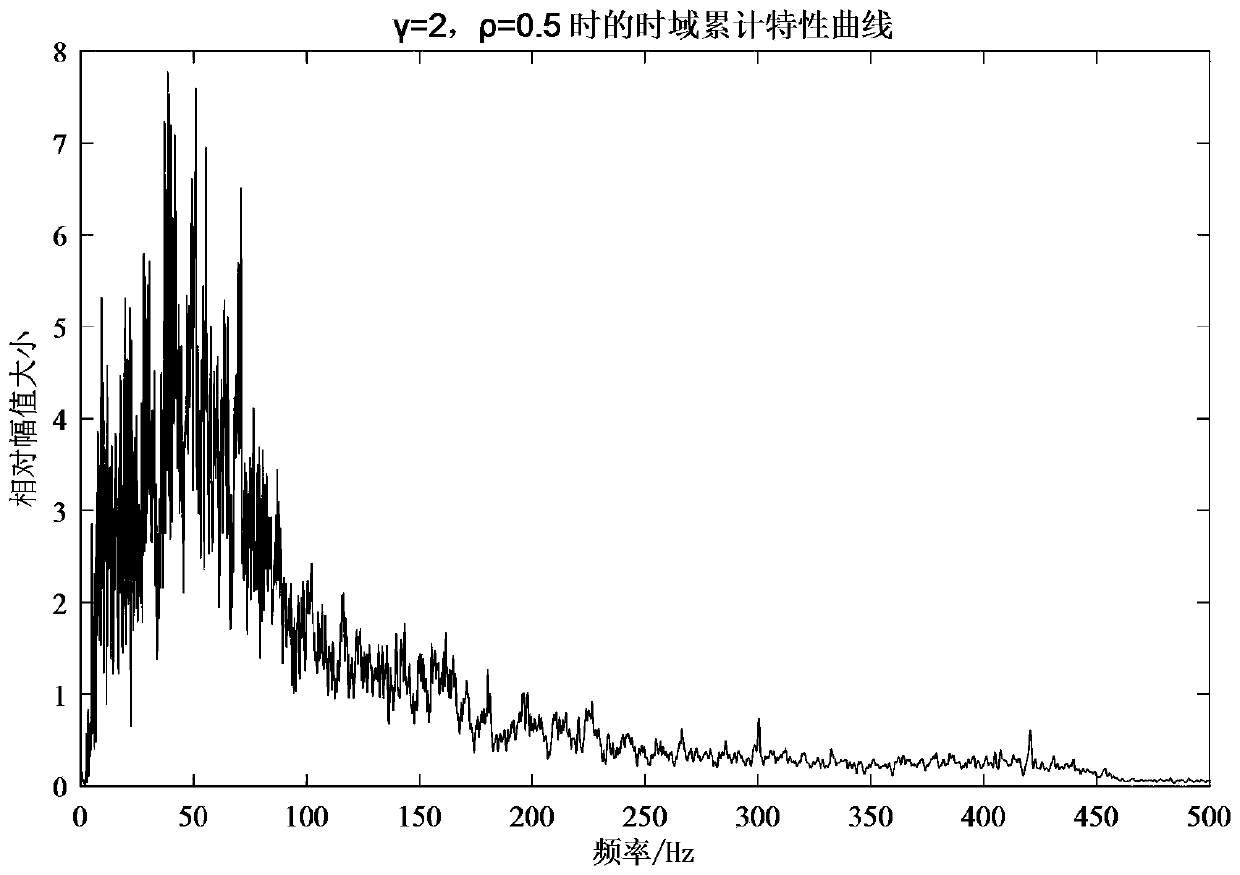

Action recognition method based on GST and VL-MOBPNN

ActiveCN111242100AEasy to handleSolve fixed puzzlesCharacter and pattern recognitionDiagnostic recording/measuringTime–frequency analysisEngineering

The invention relates to an action recognition method based on GST and VL-MOBPNN. The method comprises the steps: acquring sample data of human lower limb electromyographic signals; performing time-frequency generalized S transformation on an electric signal to obtain a time domain cumulative characteristic curve when the time resolution is relatively high and a frequency domain cumulative characteristic curve when the frequency resolution is relatively high; obtaining a feature vector of the signal; and inputting the feature vector into a learning rate variable quantity back propagation neural network for identification and classification to obtain a classification result. According to the invention, time-frequency generalized S transformation is adopted to analyze signals more meticulously, so that the problem that the window width of a Gaussian window is fixed in a traditional time-frequency analysis method is solved; Gaussian window adjustment parameters are introduced into time-frequency generalized S transformation, the inverse proportion change rate of the Gaussian window width along with the frequency can be flexibly adjusted according to the frequency distribution characteristics and the time-frequency analysis emphasis of the electromyographic signals in practical application, the method can better adapt to analysis and processing of specific signals, and therefore the signal processing capacity is improved.

Owner:HEFEI UNIV OF TECH

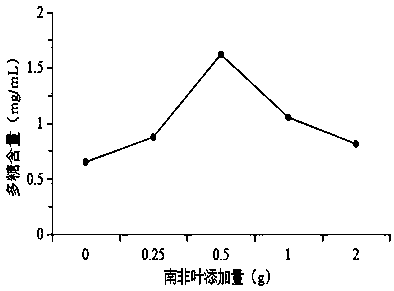

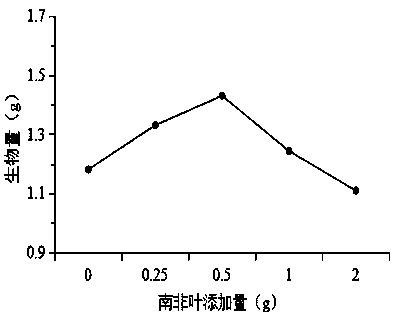

Fermentation medium for promoting inonotus hispidus mycelium growth and generating exopolysaccharides

ActiveCN108410921AEasy to makeEasy to operateFungiMicroorganism based processesMicroorganismInonotus hispidus

The invention provides a fermentation medium for promoting inonotus hispidus mycelium growth and generating exopolysaccharides, and belongs to the field of microbial fermentation. A preparation methodof the medium includes the steps: adding 200g of potatoes and 20g of glucose into 1000ml of water together, boiling the water for 10 minutes, filtering waste residues and collecting filtrate; adding0.45-0.55g of vernonia amygdalina, adding water to supplement the filtrate to 1000ml, and performing sterilization for 30 minutes at the temperature of 121 DEG C. The medium is used for liquid fermentation of inonotus hispidus, and under the same culture condition, compared with a reference medium without vernonia amygdalina, the fermentation medium has the advantage that mycelium yield and exopolysaccharide yield are improved by 1.21 times and 2.52 times. The fermentation medium plays an important role in further deep development and application of inonotus hispidus to health food and medicalappliances.

Owner:福建原培真牛樟芝生物科技有限公司

Spunlace non-woven fabric for medical mask

InactiveCN111910341AImprove the protective effectEasy to useNeedling machinesMonocomponent polyesters artificial filamentPolyesterPolymer science

The invention discloses a spunlace non-woven fabric for a medical mask, relates to the technical field of medical devices, and provides the following scheme aiming at the problem of low protection effects in the prior art. The spunlace non-woven fabric comprises randomly distributed polyester fibers, wherein an antibacterial agent is added into the polyester fibers. The spunlace non-woven fabric is simple in structure and convenient to use, and the overall use performance of the mask is improved. The storage time is prolonged, and besides, the use effect is improved. Multiple layers are stacked to form more air channels, bacteria and the like are further intercepted, the use effect is improved while the use of the mask and the use function of the mask are guaranteed, and the mask adapts todifferent production and use requirements.

Owner:苏州中宝材料科技有限公司

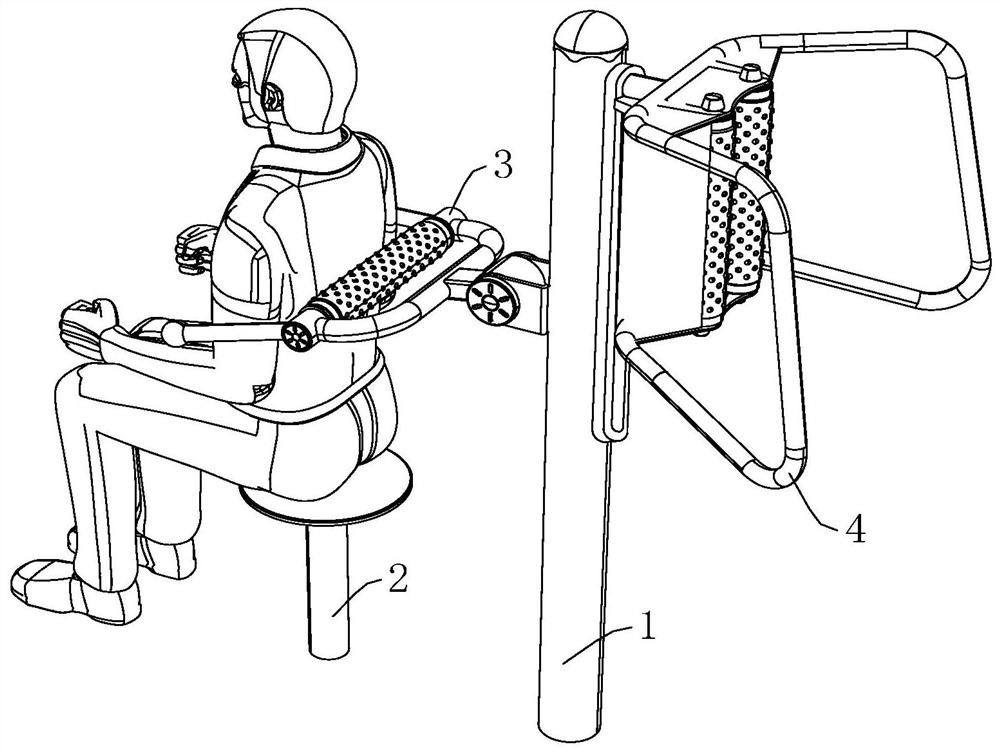

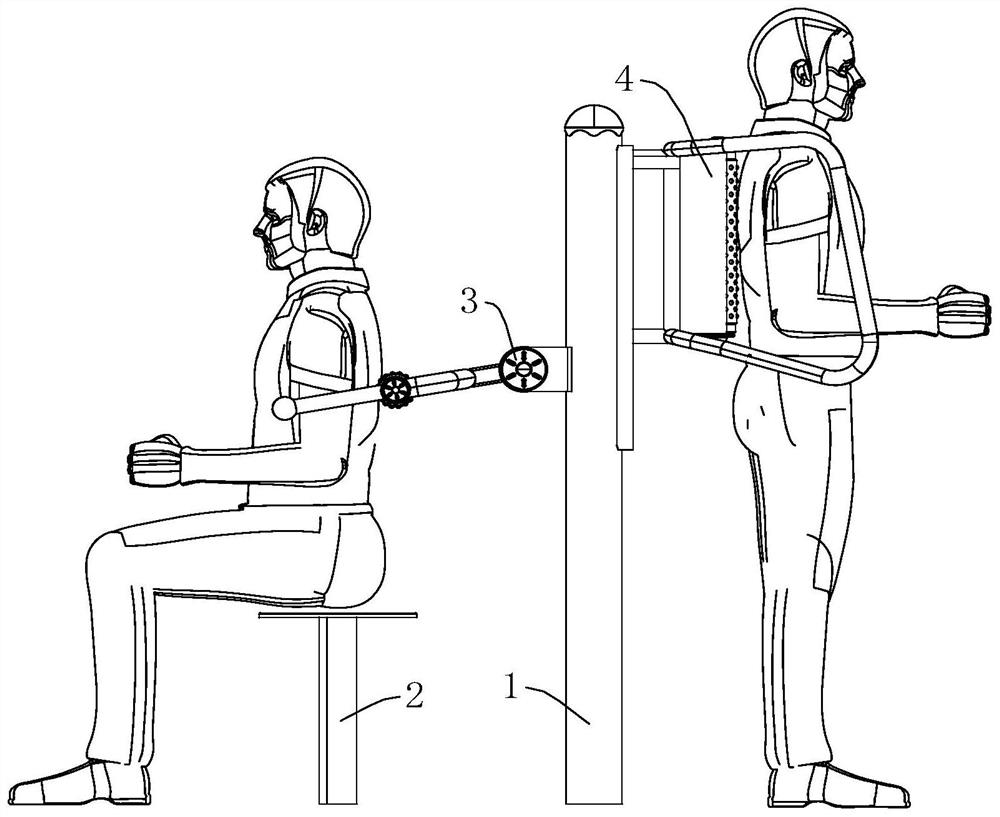

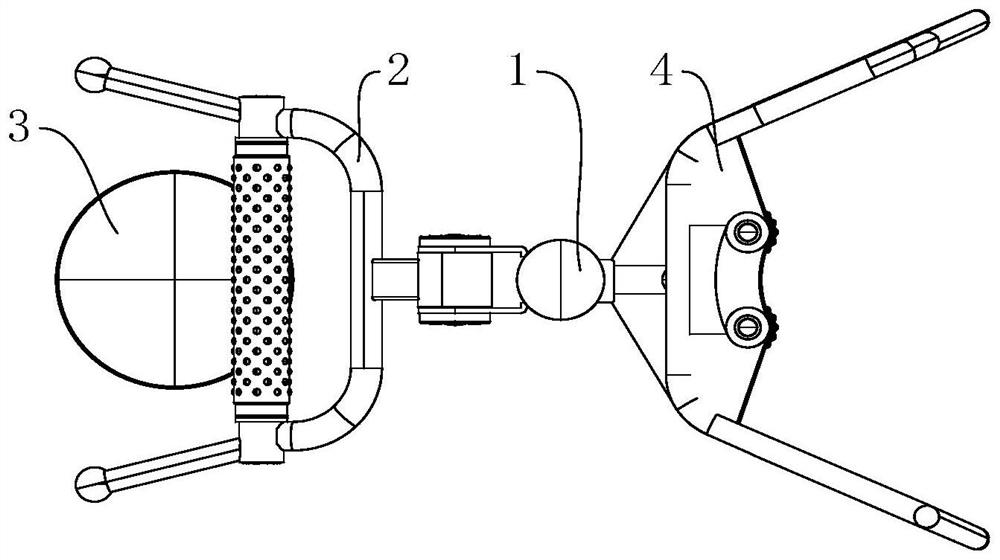

Waist and back massage instrument

ActiveCN113181024AAdapt to body typeAdaptabilityRoller massagePhysical medicine and rehabilitationMassage

The invention relates to the technical field of fitness equipment, in particular to a waist and back massage instrument which comprises a stand column, a waist massage instrument, a stool and a back massage instrument. The stand column is vertically erected on the ground, the waist massage instrument is hinged to the side edge of the stand column, a sliding groove is formed in the other side of the stand column, and the stool is erected on the ground and located between two arms of the waist massage instrument; the back massage instrument comprises a main frame, a pair of rocker arms, a pair of connecting rods and a pair of massage modules. The main frame is in sliding connection in the sliding groove. One end of the rocker arm is hinged in the main frame, and the other end is suspended; one end of the connecting rod is hinged to the rocker arm, and the other end is rotationally connected with the massage module; a massage rail is arranged on the main frame, and the massage module slides in the massage rail; different positions of the back can be massaged, the shoulders can be exercised at the same time, and the fitness and strength of different people can be adapted.

Owner:绍兴上虞大康体育健身设施制造有限公司

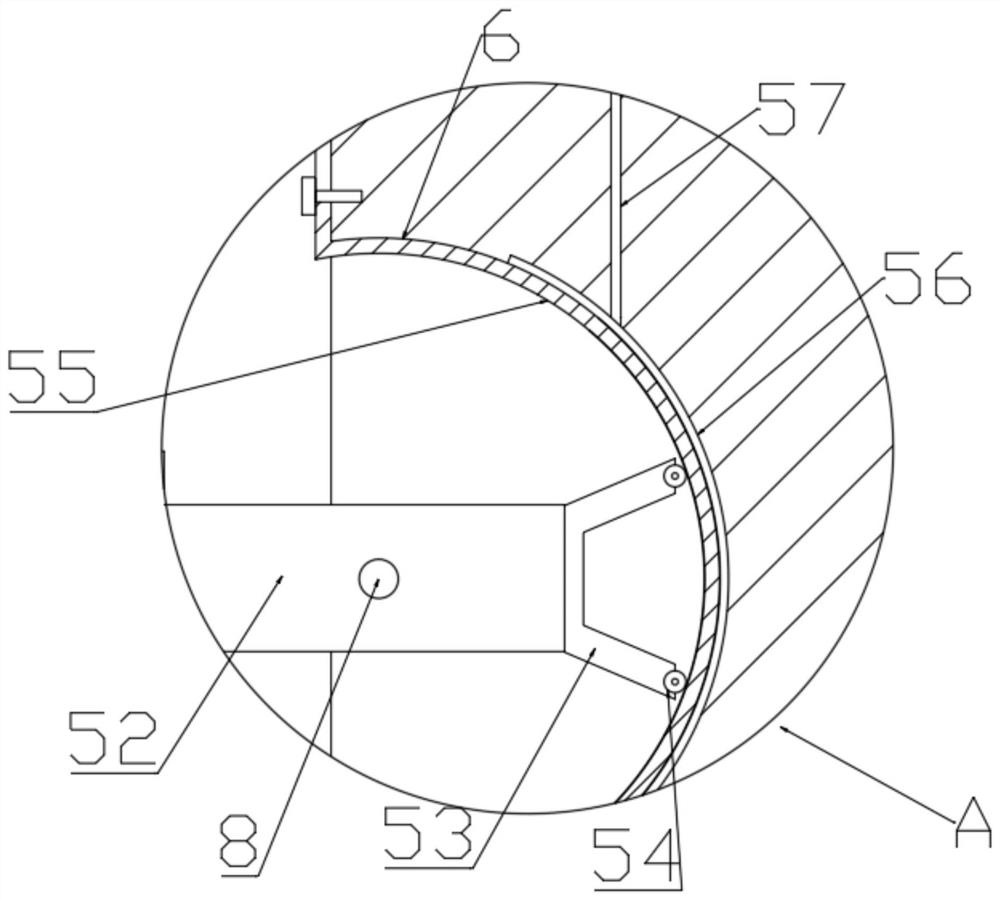

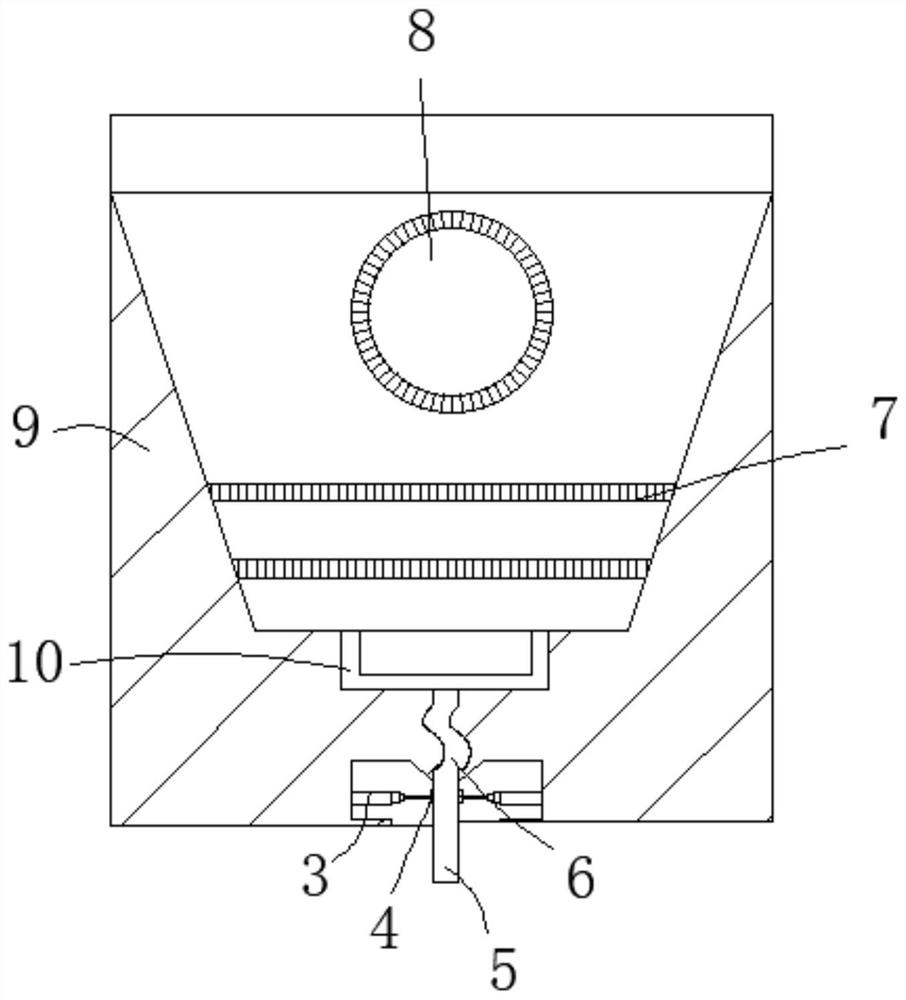

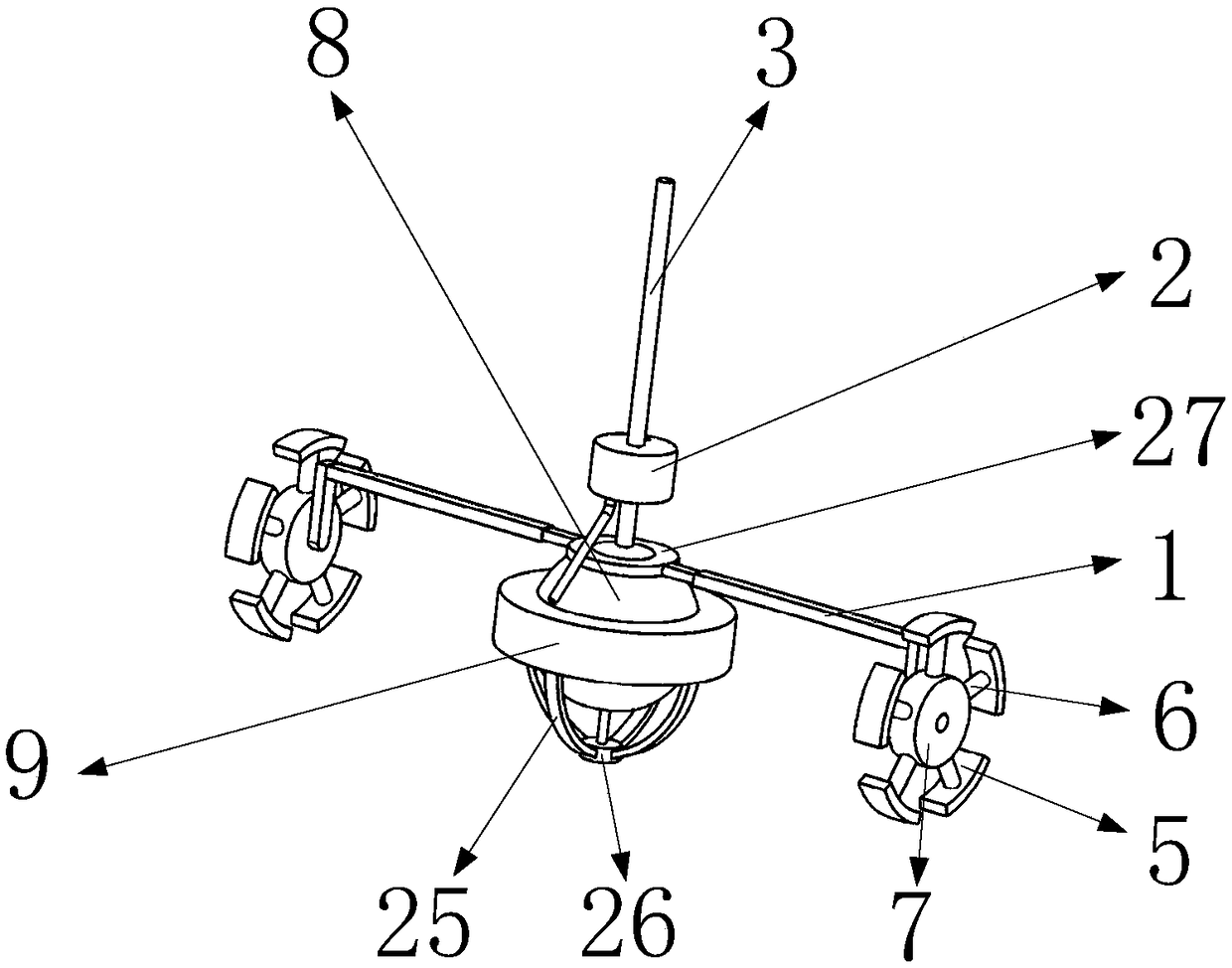

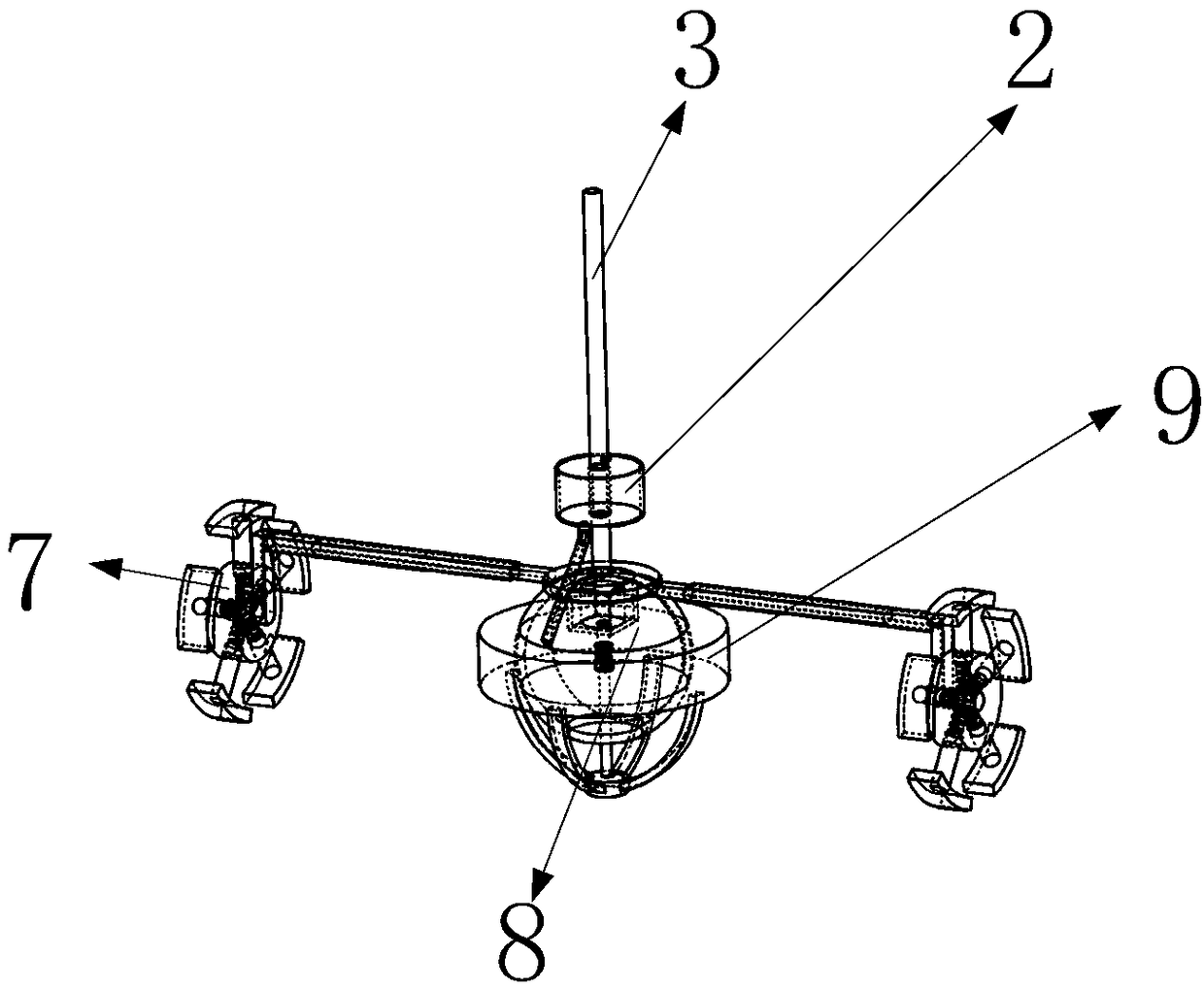

Glass wiping mechanism used for tall building and based on cardan joint

The invention belongs to the technical field of glass wiping, in particular to a glass wiping mechanism used for a tall building and based on a cardan joint. The glass wiping mechanism comprises a steel sling, a drive motor, a spherical support, an annular wiping structure, a semicircular heavy block. When people use the designed glass wiping mechanism, the pressure between the annular wiping structure and glass is adjusted through the steel sling and the semicircular heavy block according to the difficulty degree of glass wiping; after the adjustment is completed, the drive motor is driven towork, and the drive motor can drive a drive shaft to rotate through the cardan joint; the rotation of the drive shaft can make four drive arc slices rotate; the rotation of the four drive arc slicesdrives the annular wiping structure to rotate; and the glass is wiped through the rotation of the annular wiping structure; during the use, the designed glass wiping mechanism can ensure that the drive motor keeps still in the use process through an arc-shaped limiting piece, and the pressure between the annular wiping structure and the glass can be controlled through the semicircular heavy block,thereby being suitable for the difficulty degree of glass wiping.

Owner:泉州台商投资区润通商贸有限公司

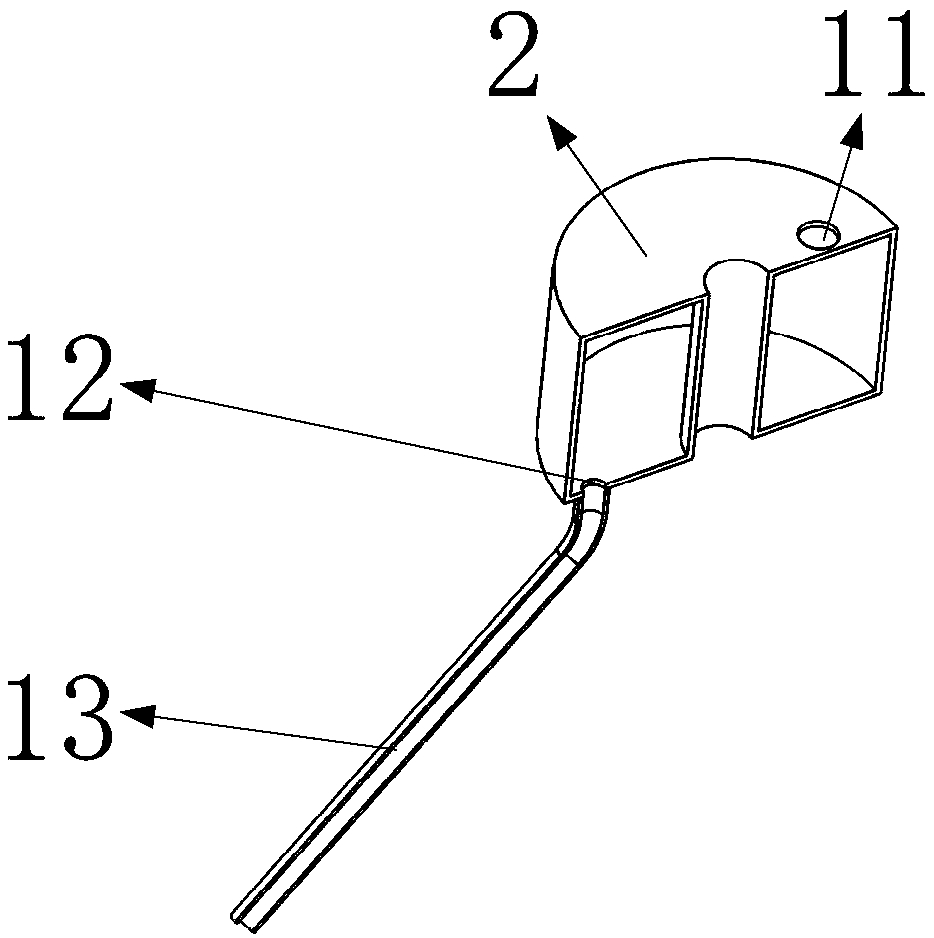

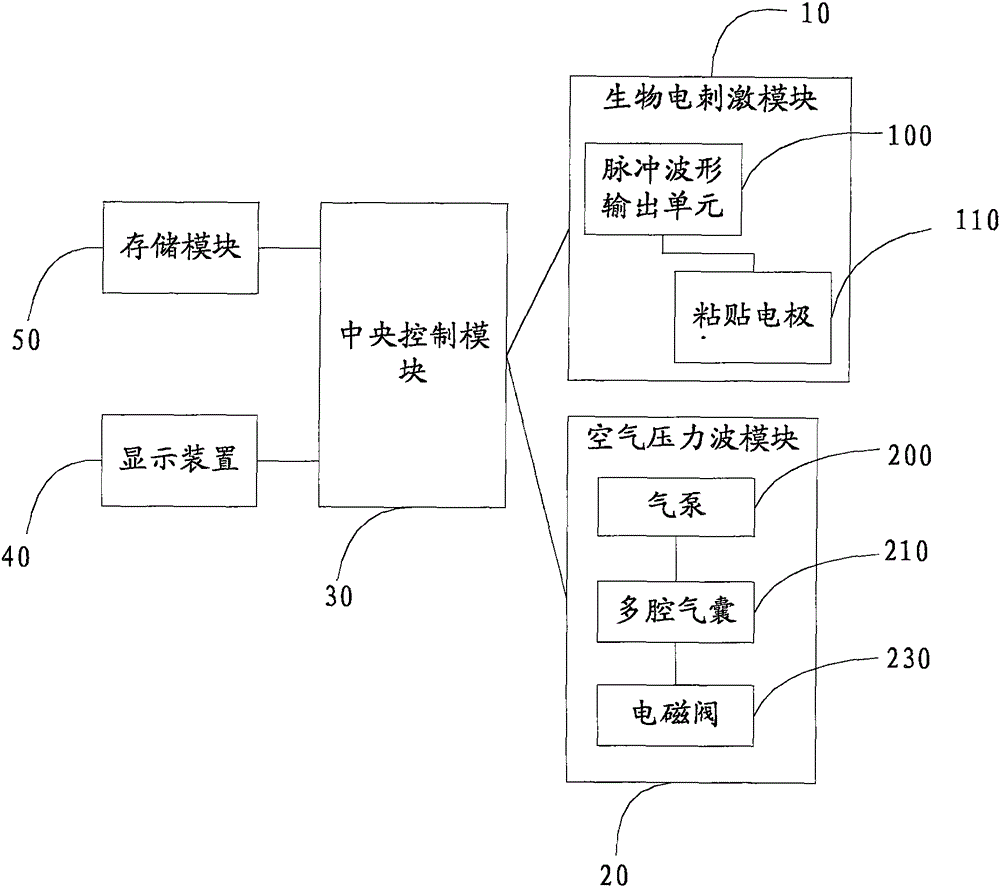

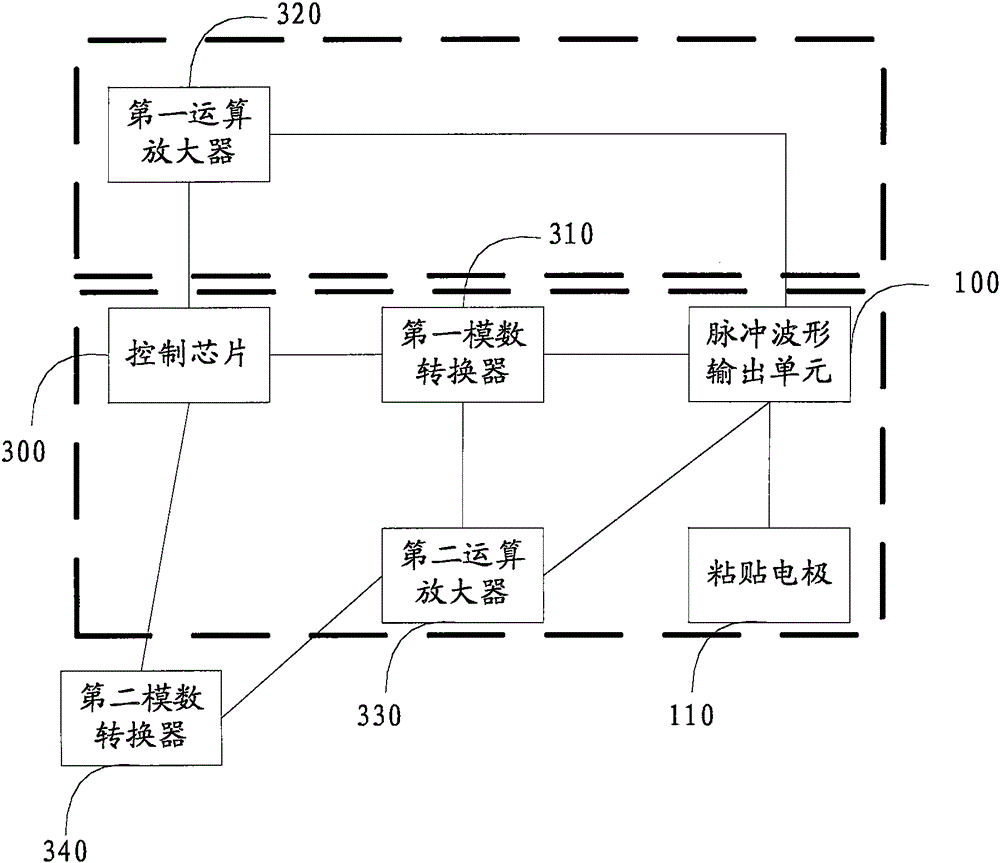

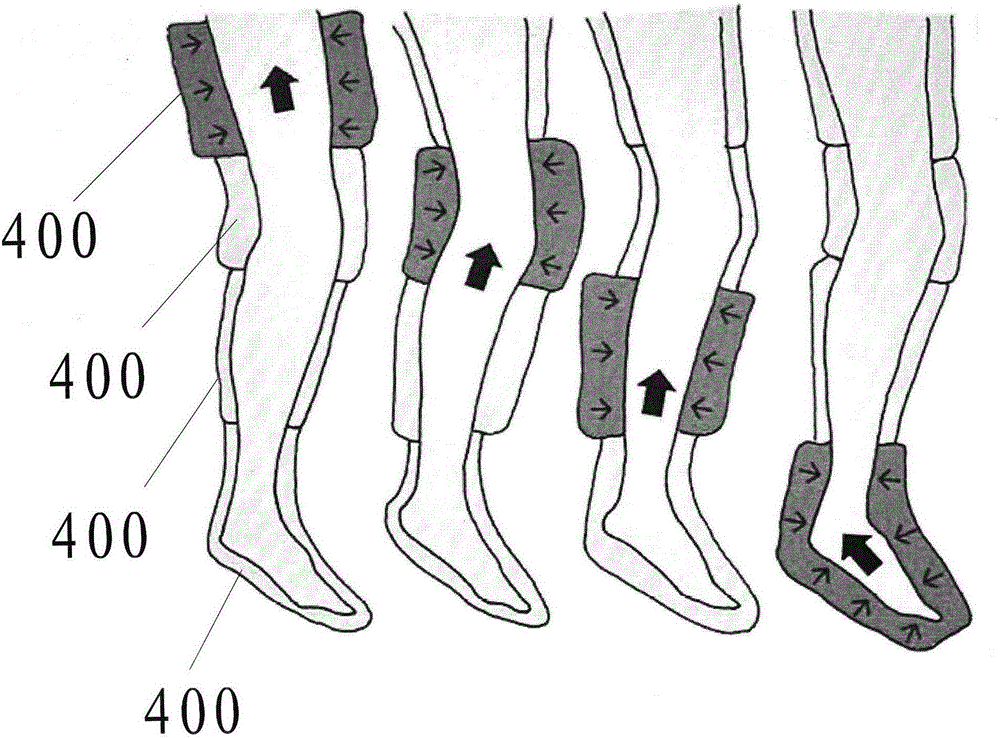

Neurology treatment system

InactiveCN106621030AGood treatment effectAdapt to bioelectric characteristicsArtificial respirationSolenoid valveEngineering

The invention discloses a neurology treatment system which is characterized in that the treatment system comprises a bioelectrical stimulating module, an air pressure wave module and a central control module, wherein the bioelectrical stimulating module comprises an impulse waveform output unit and a number of pasting electrodes; the impulse waveform output unit is used for outputting impulse sawtooth waves, impulse triangular waves and impulse sine waves; the pasting electrodes are connected with an output end of the impulse waveform output unit via output conductors; the air pressure wave module comprises a multi-cavity air bag, an air pump and a solenoid valve; the multi-cavity air bag is connected with the air pump via an air guide tube, the solenoid valve is arranged on an air outlet opening of the multi-cavity air bag and is used for controlling opening and closing of the air outlet opening, the central control module is connected with the air pump and the impulse waveform output unit, and the central control module is used for controlling gas and waveform output conditions. The neurology treatment system can be used for bioelectrical stimulating treatment and air pressure wave treatment, and good treatment effects can be provided for patients.

Owner:李莉

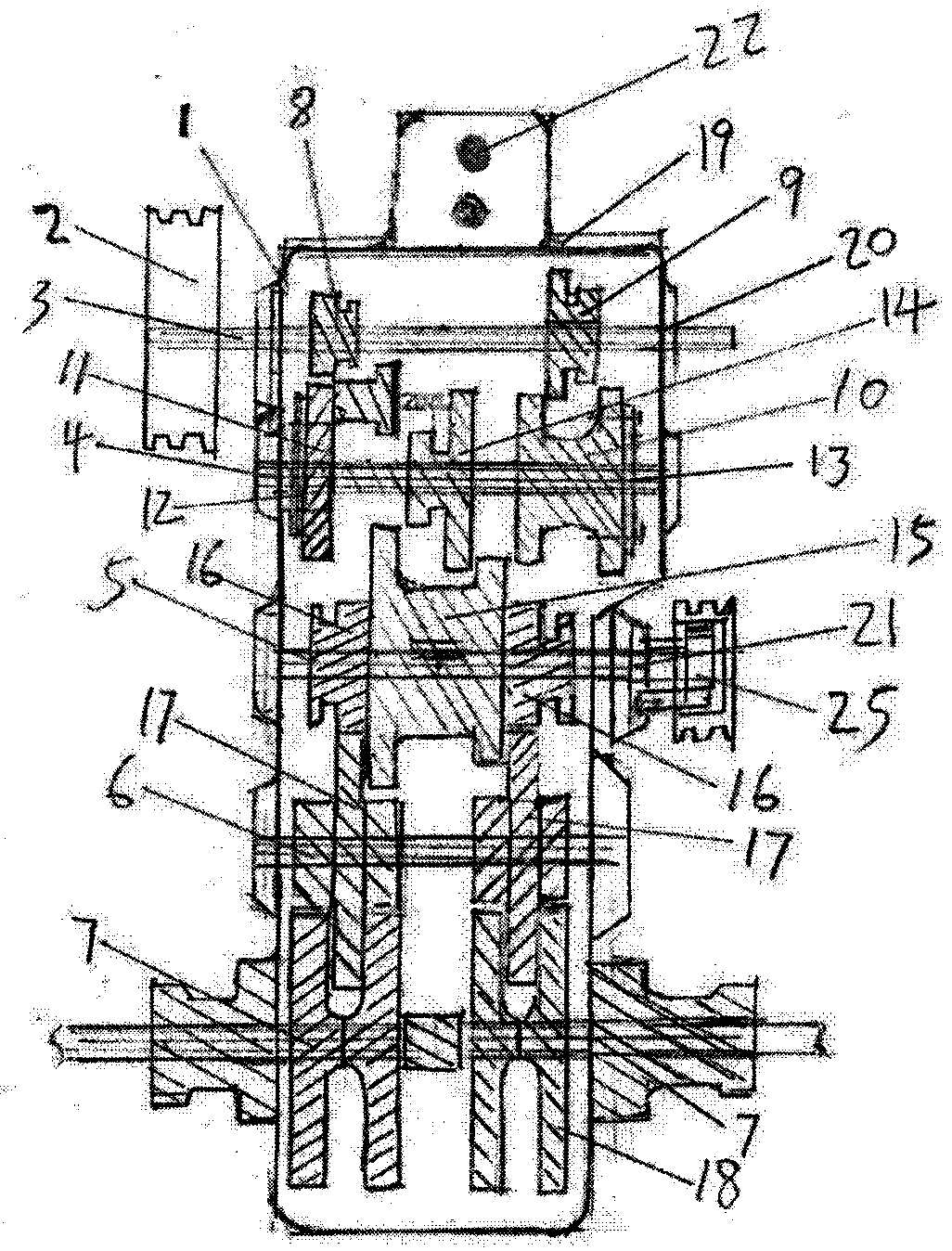

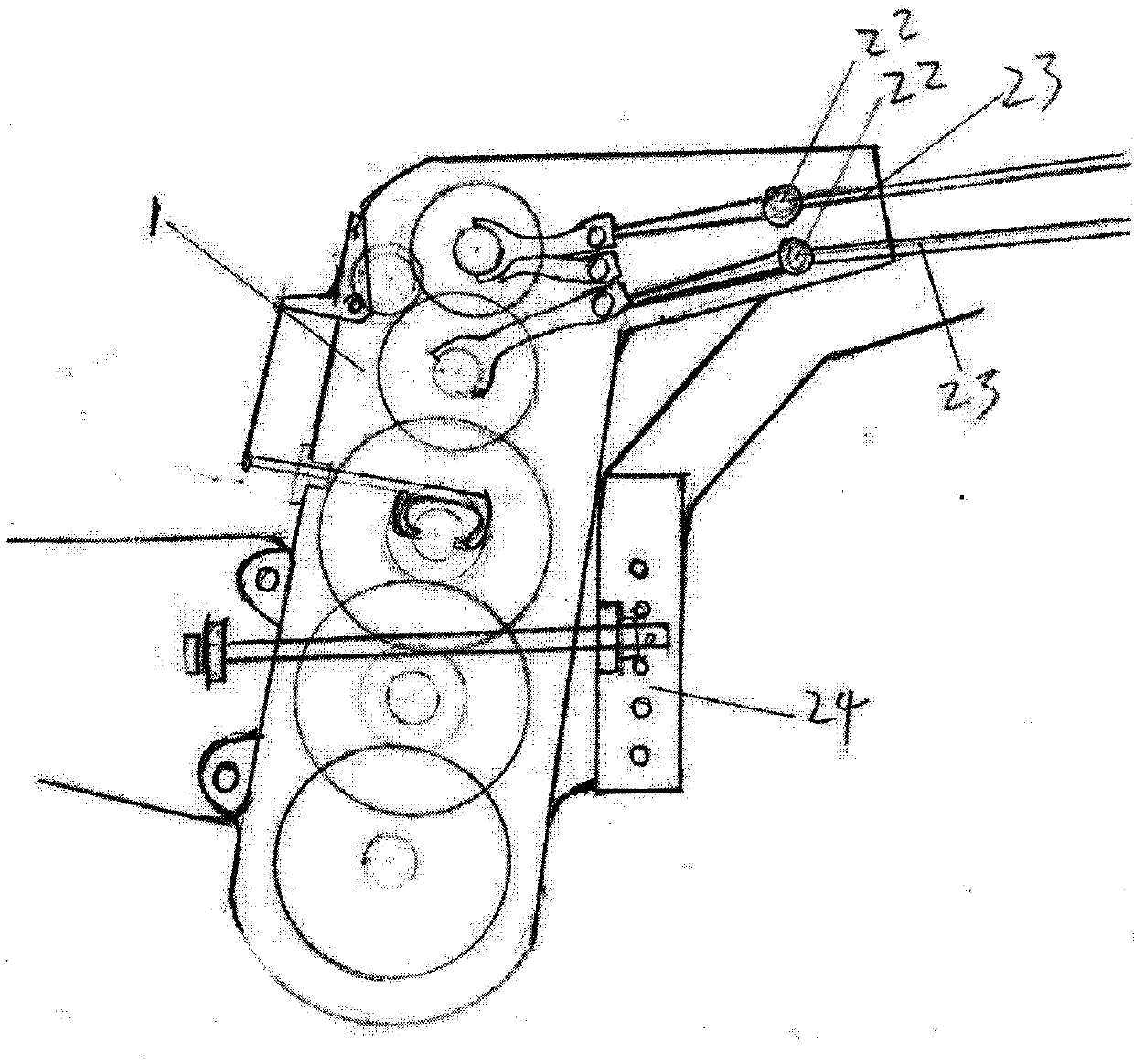

Special hand tractor for tail-wheel operating pedal front-loaded hand tractor

InactiveCN104948677ADifficulties in reducing pinch forceAdapt to retrofitGearboxesToothed gearingsGear wheelTractor

The invention relates to a special hand tractor for a tail-wheel operating pedal front-loaded hand tractor, in particular to a seat frame assembly on the tail-wheel operating pedal front-loaded hand tractor and solves the problems of unmatched types and unadaptable performance. The special hand tractor structurally comprises a power output shaft structure adopting five vertical shafts and three shafts and being synchronous with gears, so as to solve the problem that space under conventional girders is limited and the seat frame assembly and the tail wheel driver are not easy to additionally mount. By adopting a two or three-shaft high-to-low gearshift gear set, a tri-shaft intermediate dual gear, two lateral steering gears, a double-shaft upper-barrier type connecting two- or three-gear dual gear and a one-gear main gear structure, the problems that steering is heavy, high- and low-gears are dropped and the gears are stressed too much are solved. By a double-gear lever and a box structure, the hand tractor is formed.

Owner:冯明勋

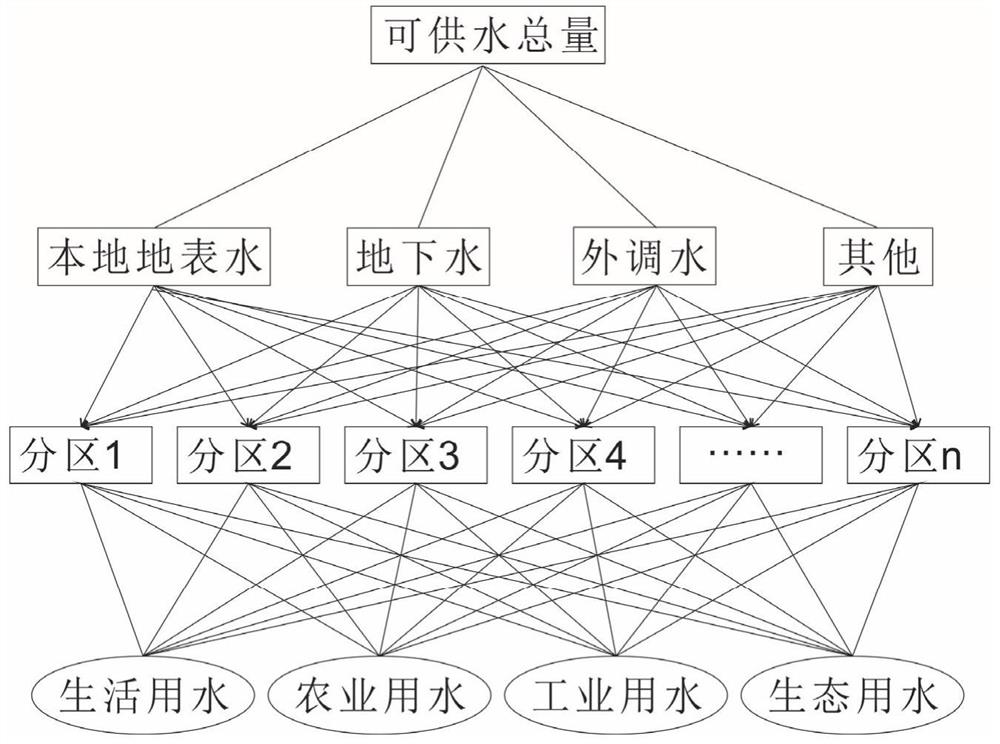

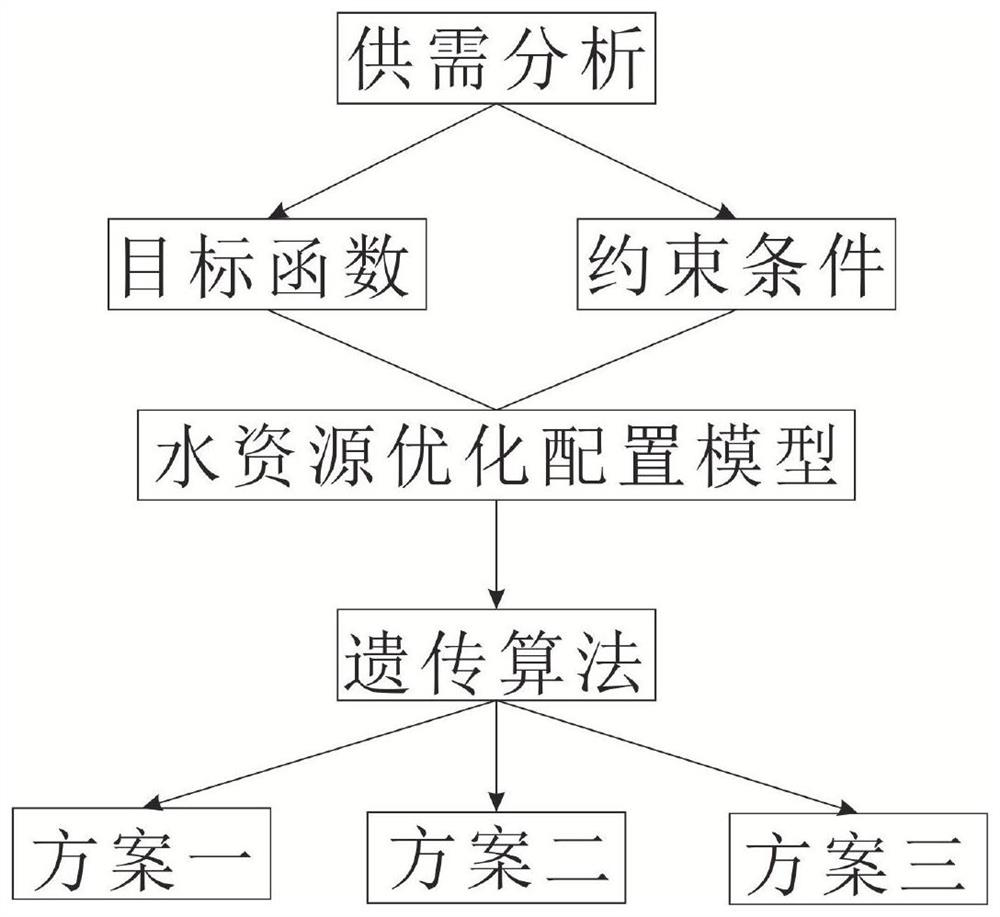

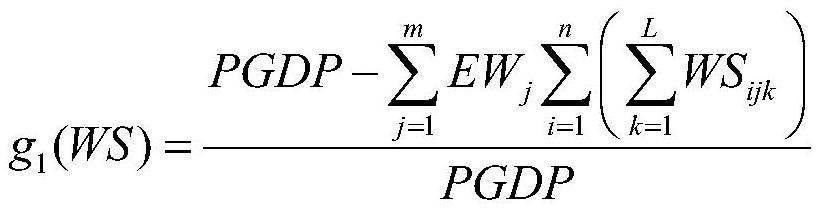

Water resource optimal allocation method and system based on genetic algorithm

ActiveCN112668909ASolve the accuracy is not highMultivariateGenetic modelsResourcesAlgorithmGenetics algorithms

The invention provides a water resource optimal allocation method based on a genetic algorithm, and the method achieves the normalization of an economic target, a social target and an ecological target, enables all targets to be subjected to weighted calculation under the same dimensional condition, and enables the weights of all targets to have more practical significance after normalization. Meanwhile, the constructed water resource optimization model has the characteristics of multiple variables, multiple targets, multiple constraints and the like, when the model is solved, a genetic algorithm is adopted, and compared with a traditional solving method, the provided method has great advantages in the aspects of calculation speed, precision, convergence, adaptability and mobility.

Owner:QILU UNIV OF TECH +1

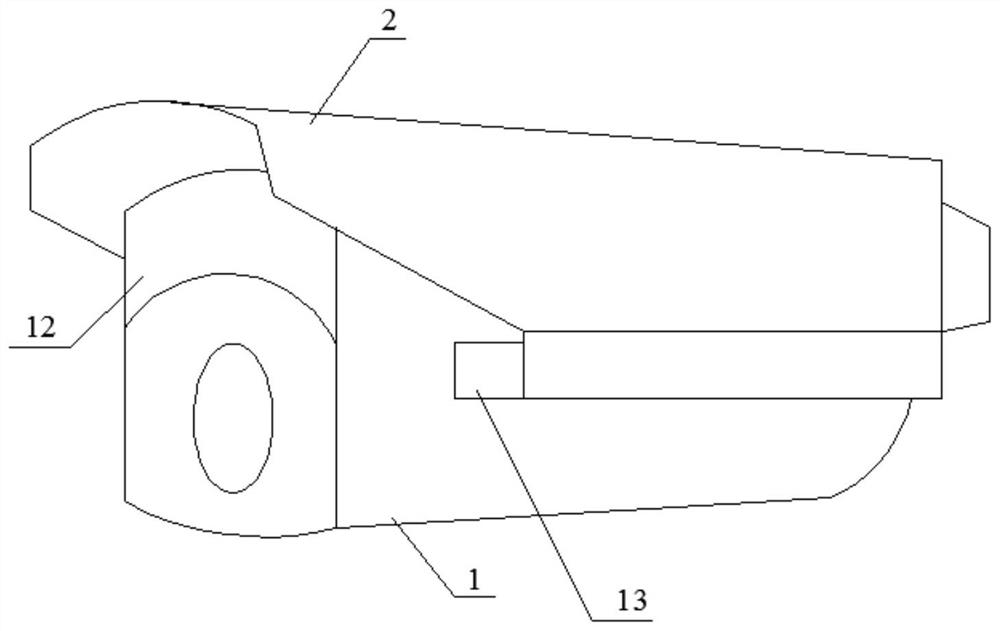

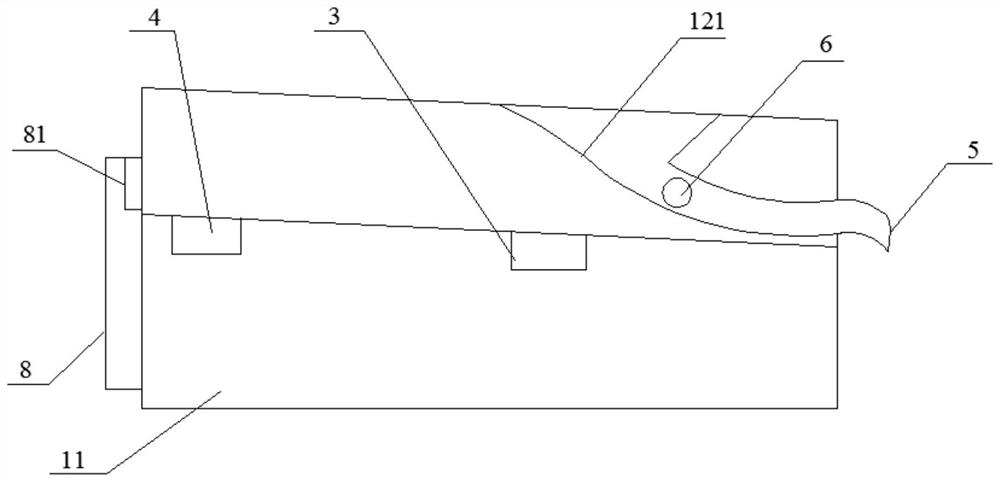

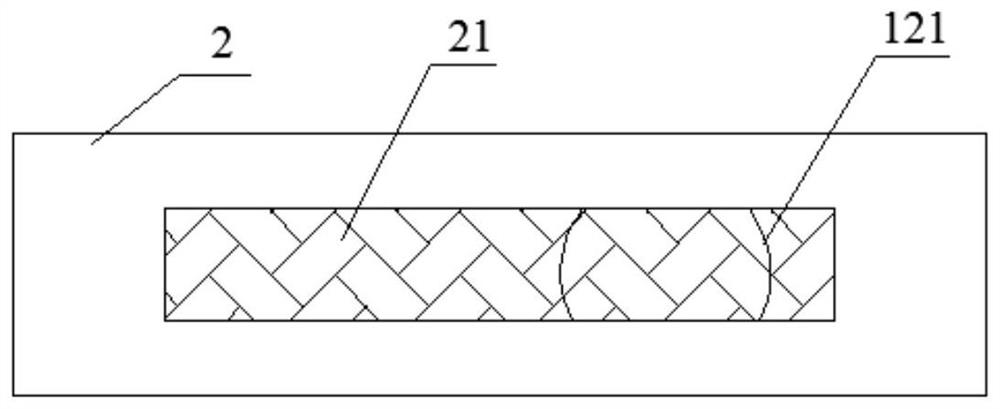

Artificial intelligence monitoring camera capable of rainproof adjustment

ActiveCN111866342AAdaptabilityPlay the role of rain and sun protectionTelevision system detailsMachine supportsSurveillance cameraStormwater

The invention belongs to the technical field of monitoring equipment, and particularly relates to an artificial intelligence monitoring camera capable of rainproof adjustment, which comprises a cameraand a mounting base, and the top of the mounting base is slidably connected with a rainproof cover in the length direction; a mounting cavity is formed in the bottom in the mounting base, and a controller used for controlling the rainproof cover to slide is mounted in the mounting cavity; the inner top of the mounting base is a solid part, a rainwater flow guide channel is formed in the solid part, a top opening of the rainwater flow guide channel is located in the top of the solid part of the mounting base, a side opening is located in the rear side of the solid part of the mounting base, and a water flow meter is mounted in the rainwater flow guide channel and electrically connected with the controller; a skylight opening is formed in the position, corresponding to the top opening of the rainwater flow guide channel, of the top of the rainproof cover, and a filter screen is installed in the skylight opening. The artificial intelligence monitoring camera can adjust the rain shieldingrange of the rainproof cover to the camera according to whether it rains or not, and has a rainproof adjusting effect.

Owner:SHAANXI TECHN INST OF DEFENSE IND

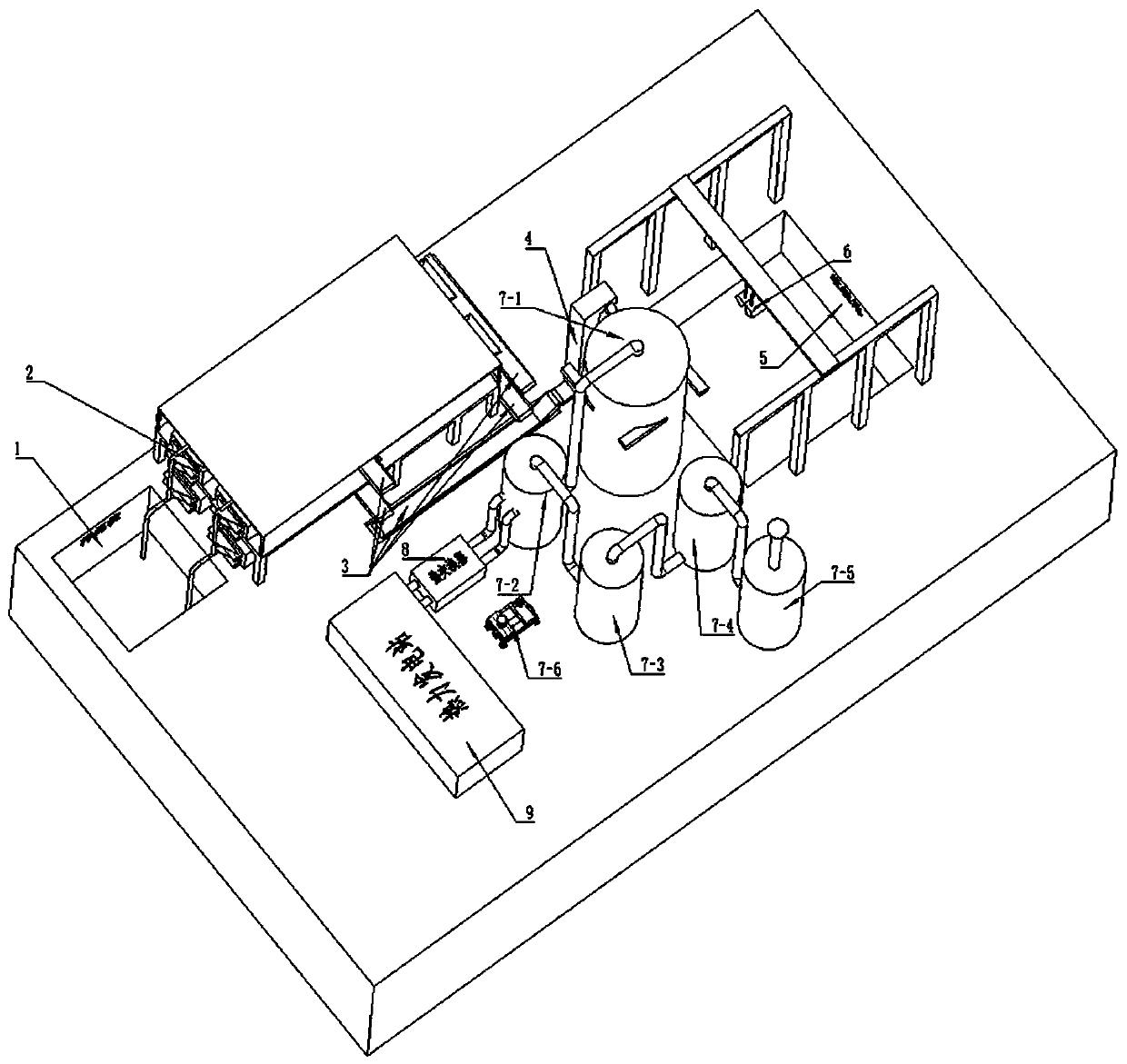

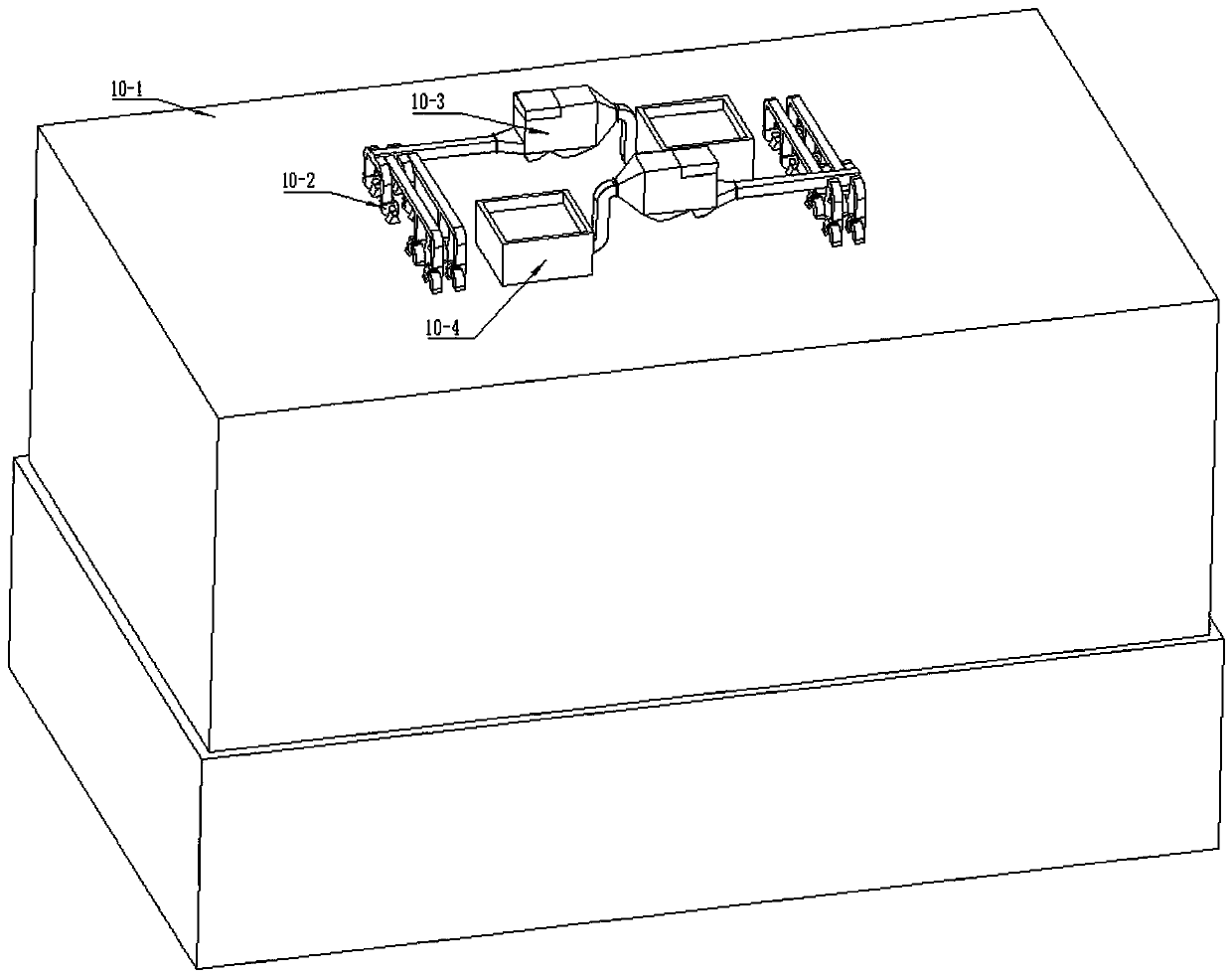

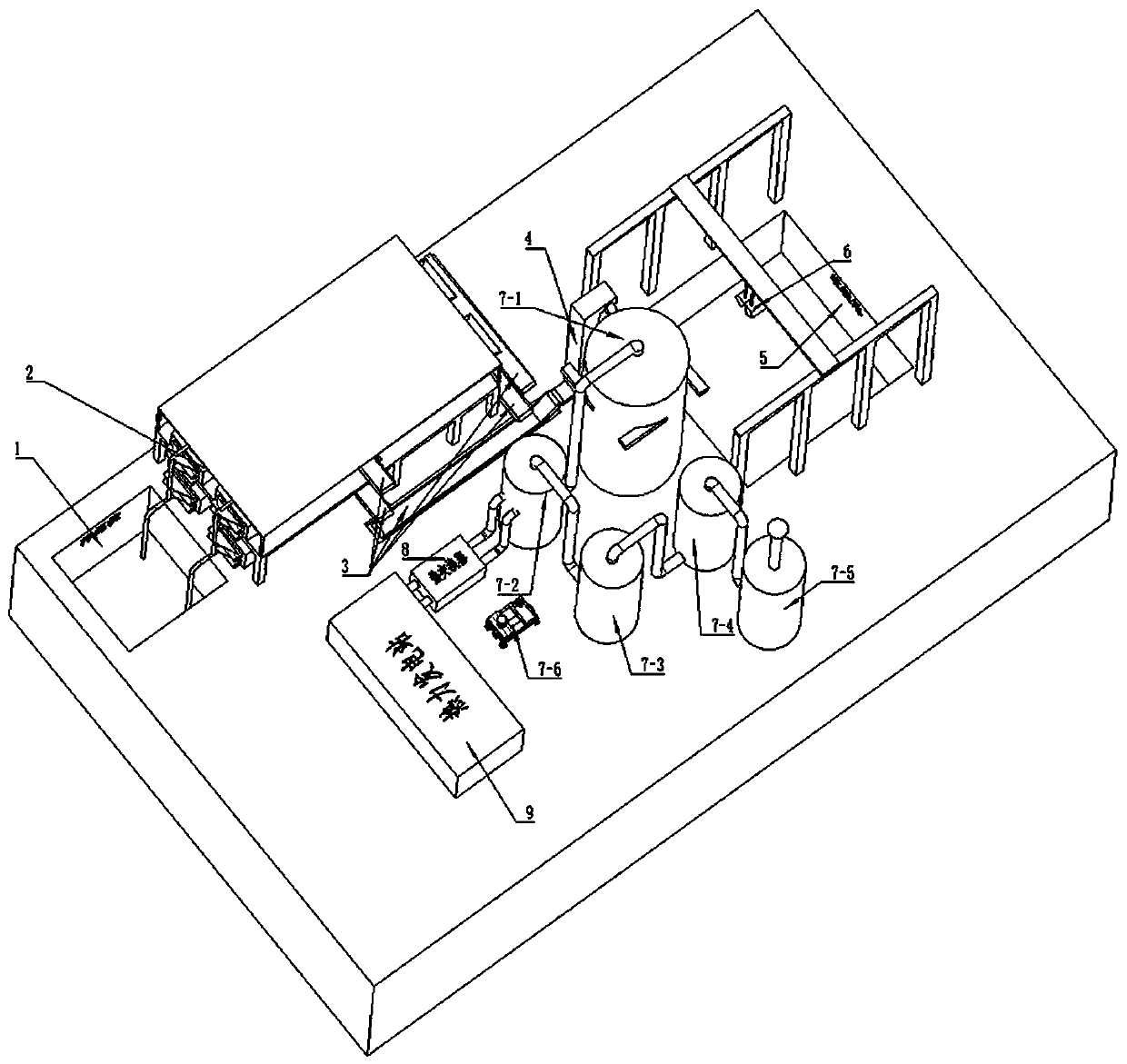

Harmless reduction resourceful treatment process system for waste and industrial sludge

InactiveCN109990298AReduce energy consumptionIncinerate completelySludge treatment by de-watering/drying/thickeningIncinerator apparatusEmission standardSmall footprint

A harmless reduction resourceful treatment process system for waste and industrial sludge is characterized by comprising a sludge tank, a dewatering module, a dewatered sludge receiving module, a dewatered sludge conveying module, a waste tank, a grab bucket mechanism, a semi-gasification incinerator module, a heat exchanger, a thermal power station and a deodorization module. The system providedby the invention has the advantages of pertinence for slightly polluted industrial sludge and waste, small occupied area, low operation energy consumption, simultaneous treatment of sludge and waste,harmlessness, reduction, recycling, and realization of reaching of national emission standards with low energy consumption.

Owner:蔡永辉

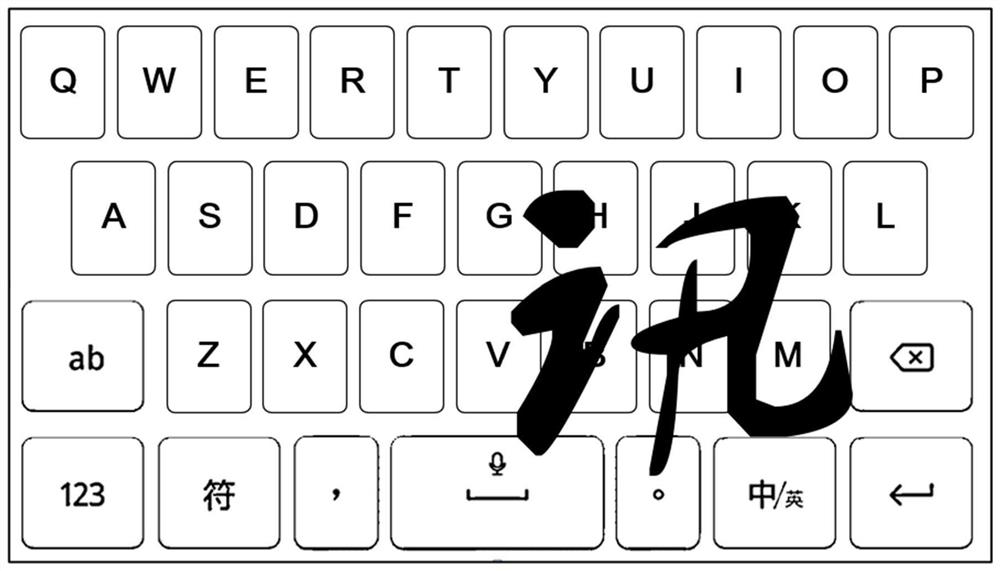

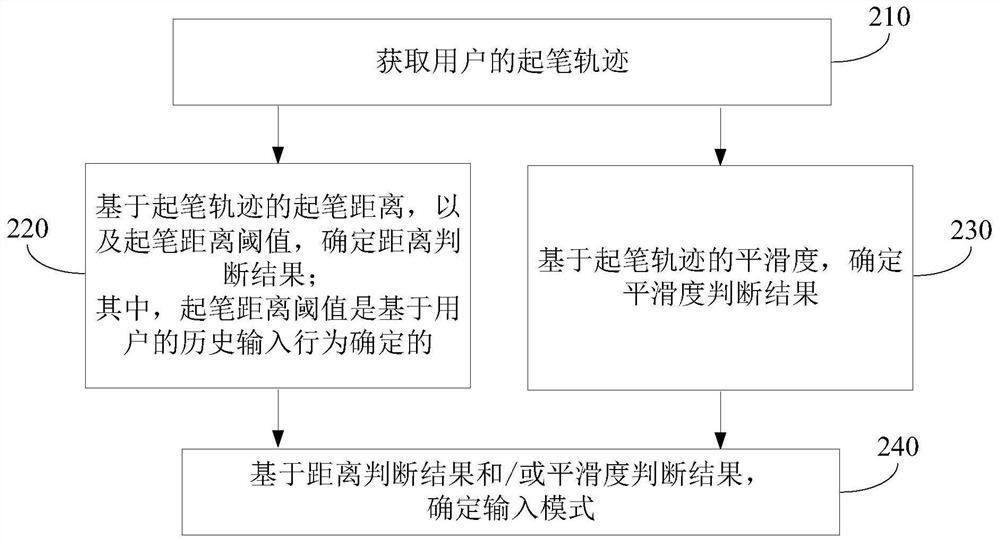

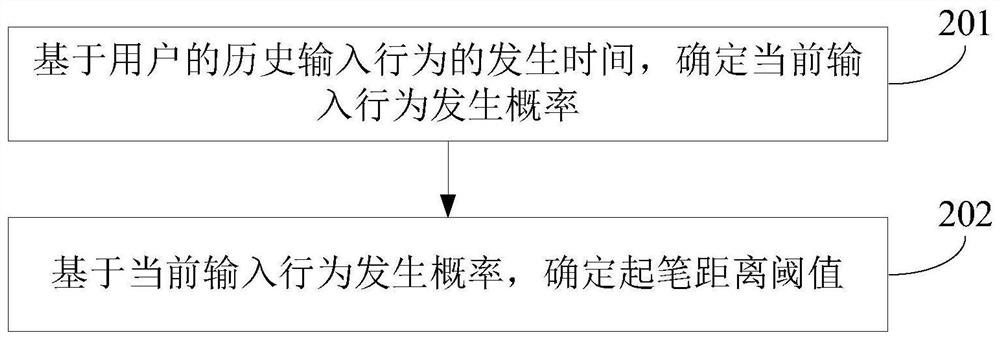

Input switching method, device, electronic device and storage medium

ActiveCN111124222BAdaptabilityAdapt to usageInput/output processes for data processingReal-time computingElectronic equipment

Embodiments of the present invention provide an input switching method, device, electronic device, and storage medium, wherein the method includes: acquiring the user's pen-starting trajectory; determining the distance judgment result based on the pen-starting distance of the user's pen-starting track and the threshold of the pen-starting distance; wherein, the pen-starting distance The threshold is determined based on the user's historical input behavior, and the historical input behavior is updated in real time; and / or, based on the smoothness of the pen trajectory, determine the smoothness judgment result; based on the distance judgment result and / or the smoothness judgment result, determine the input model. The method, device, electronic device, and storage medium provided by the embodiments of the present invention dynamically adjust the pen-start distance threshold based on the user's historical input behavior, thereby better adapting to the user's usage habits and usage conditions; in addition, based on the smoothness of the pen-start trajectory The input mode highlights the difference between different input modes, realizes accurate discrimination of different input modes, avoids false triggering of input modes, and improves user experience.

Owner:IFLYTEK CO LTD

Telescopic vortex generator and propeller hub formed by same

ActiveCN113830290AWith telescopic functionEasy loading and unloading of the structurePropellersInfluencers by generating vorticesConvex structurePropeller

The invention discloses a telescopic vortex generator and a propeller hub formed by the same. The telescopic vortex generator comprises a pivot, a rotary connecting block, a connecting rod, a driving device, a connecting rod base and a protruding structure, the pivot is connected with the driving device, and the driving device is used for driving the pivot to do circular motion on the plane orthogonal to the center line of the pivot shaft; the pivot is connected with the rotary connecting block, the rotary connecting block is rotationally connected with the connecting rod, the connecting rod is connected with the connecting rod seat, the connecting rod seat is connected with the convex structure, and the convex structure can penetrate through an intermediate shaft fairing of the propeller hub. The problems that in the prior art, loading and unloading are troublesome, adjustment is difficult, operability is poor, and adaptability is poor are solved.

Owner:LOW SPEED AERODYNAMIC INST OF CHINESE AERODYNAMIC RES & DEV CENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com