Glass wiping mechanism used for tall building and based on cardan joint

A universal joint and high-rise technology, applied in the field of glass wiping, can solve the problems of difficulty in meeting people's requirements, difficulty in reaching glass wiping mechanisms, and affecting the efficiency of glass wiping mechanisms, etc., to achieve the effect of adapting to the degree of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

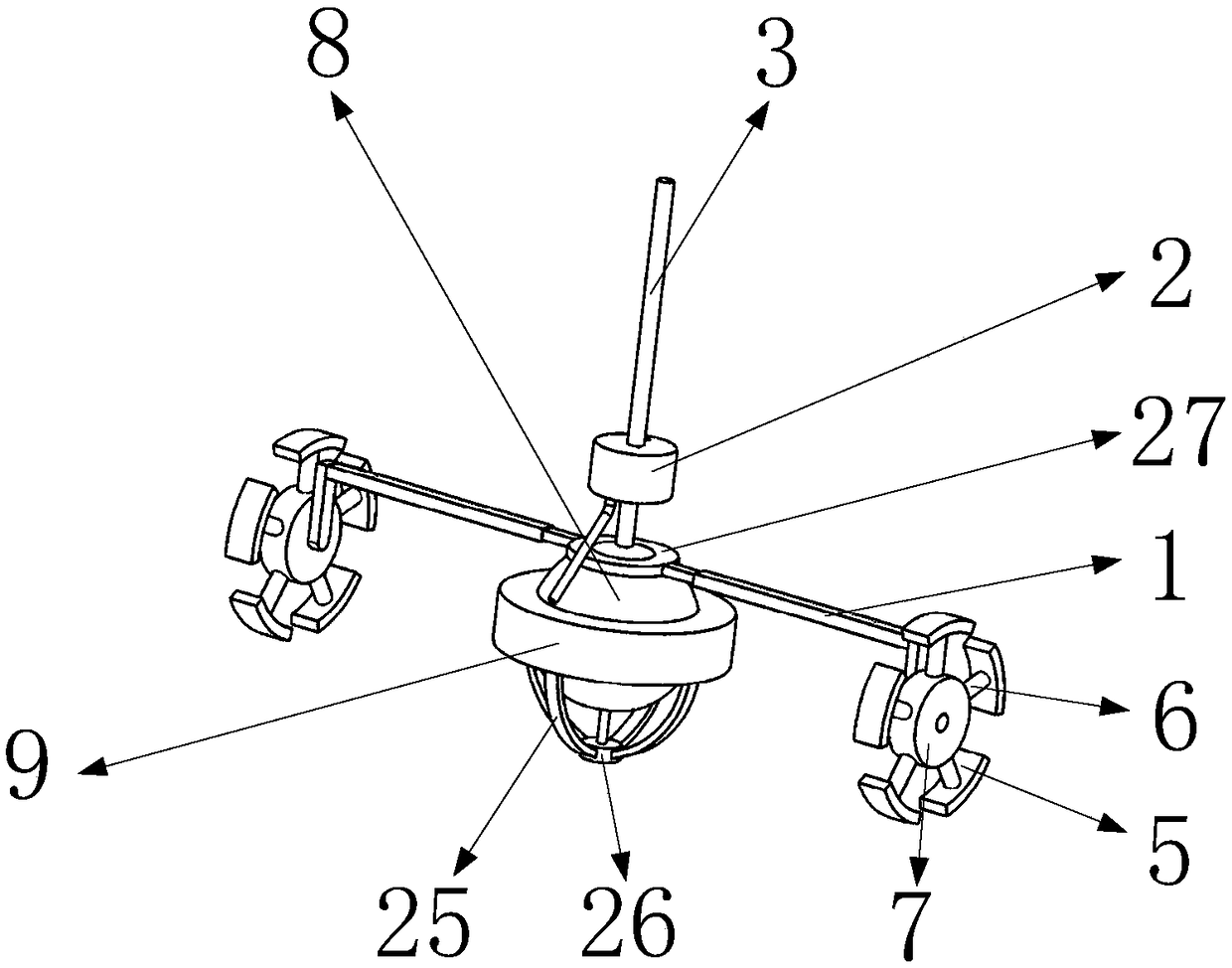

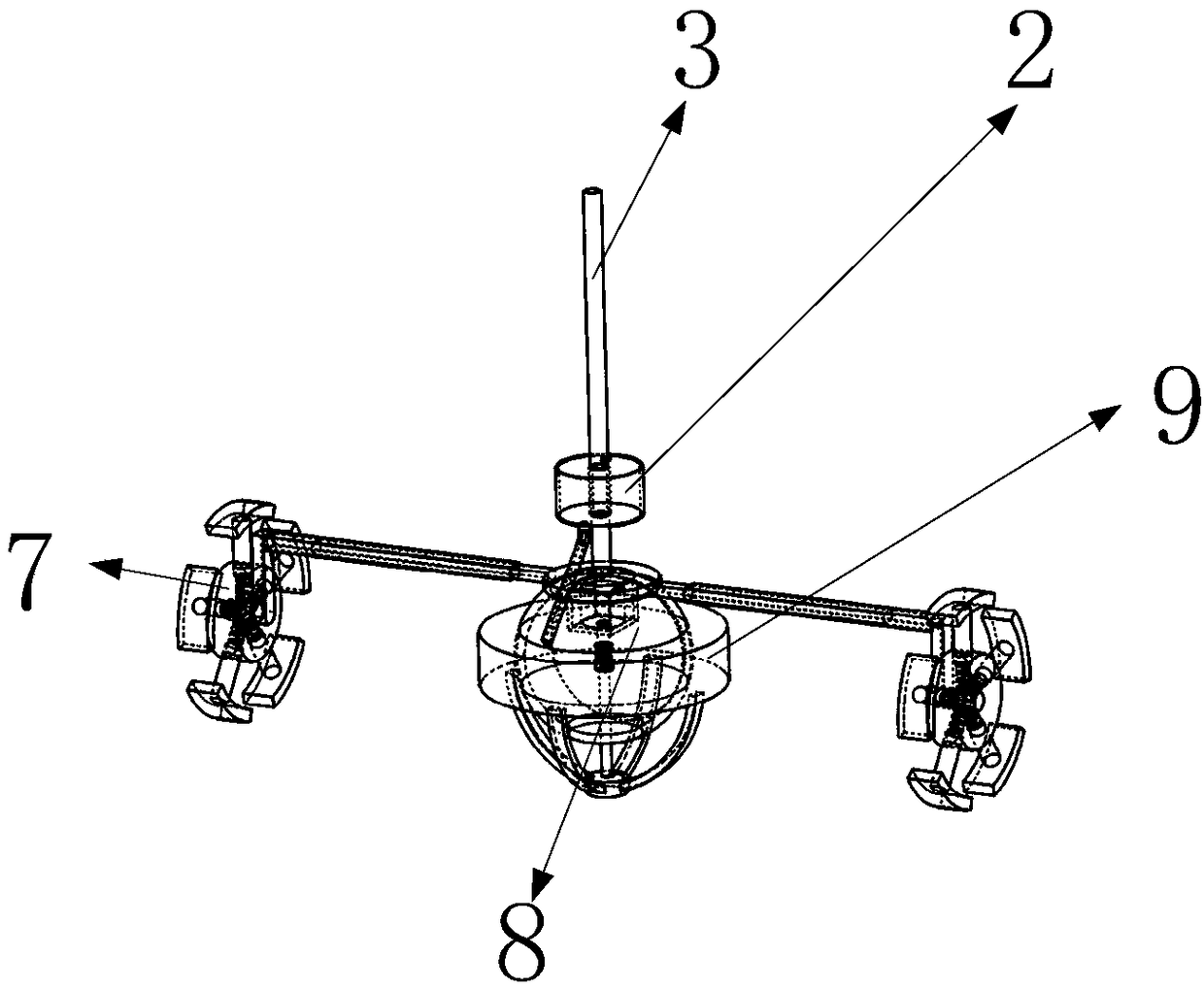

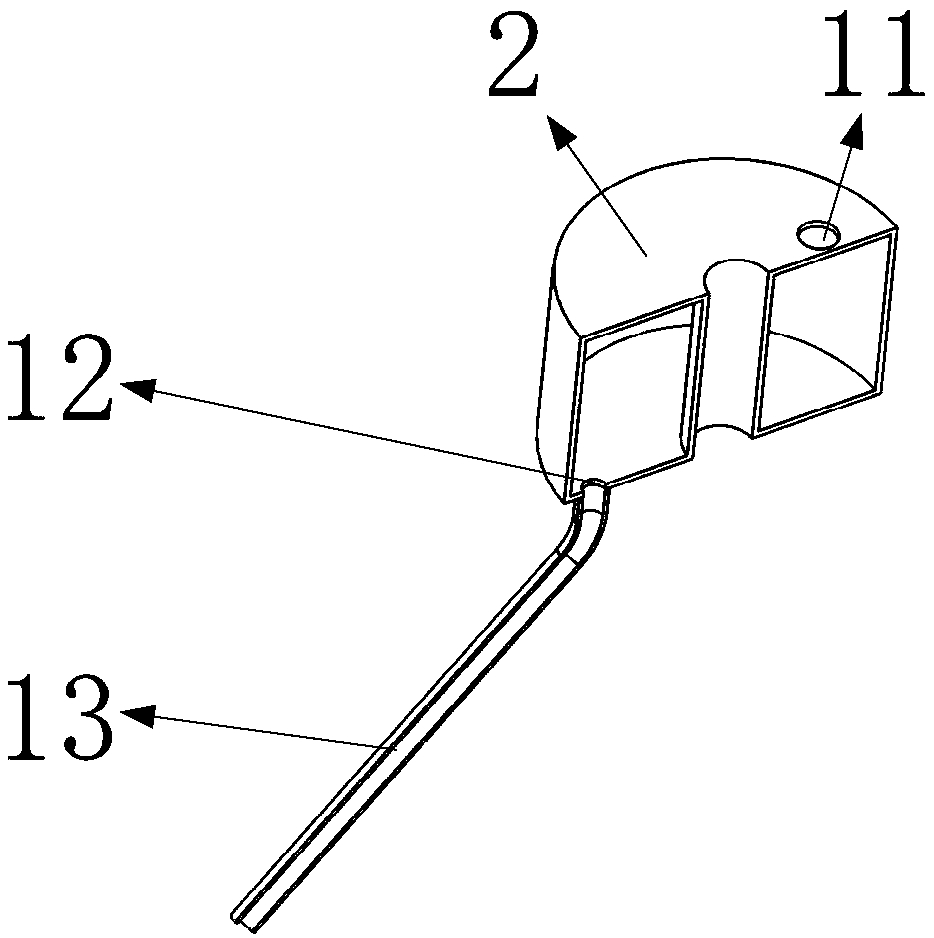

[0051]Specific embodiments: when people use the glass wiping mechanism designed by the present invention, the pressure between the annular wiping structure 9 and the glass is adjusted through the steel rope 3 and the semicircular weight 22 according to the degree of difficulty of glass wiping; after the adjustment is completed, Drive the drive motor 4 to work, the drive motor 4 will drive the drive shaft 10 to rotate through the universal joint 24; the drive shaft 10 will drive the connecting disc 26 to rotate; The ring-shaped wiping structure 9 rotates; the glass is wiped by the rotation of the ring-shaped wiping structure 9; at the same time, the glass is cleaned by the water stored in the water storage tank 2; and the ring-shaped wiping structure 9 can also be humidified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com