Harmless reduction resourceful treatment process system for waste and industrial sludge

A technology for industrial sludge and treatment process, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. and other problems, to achieve the effect of reducing the production of dioxin, efficient and simple incineration, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

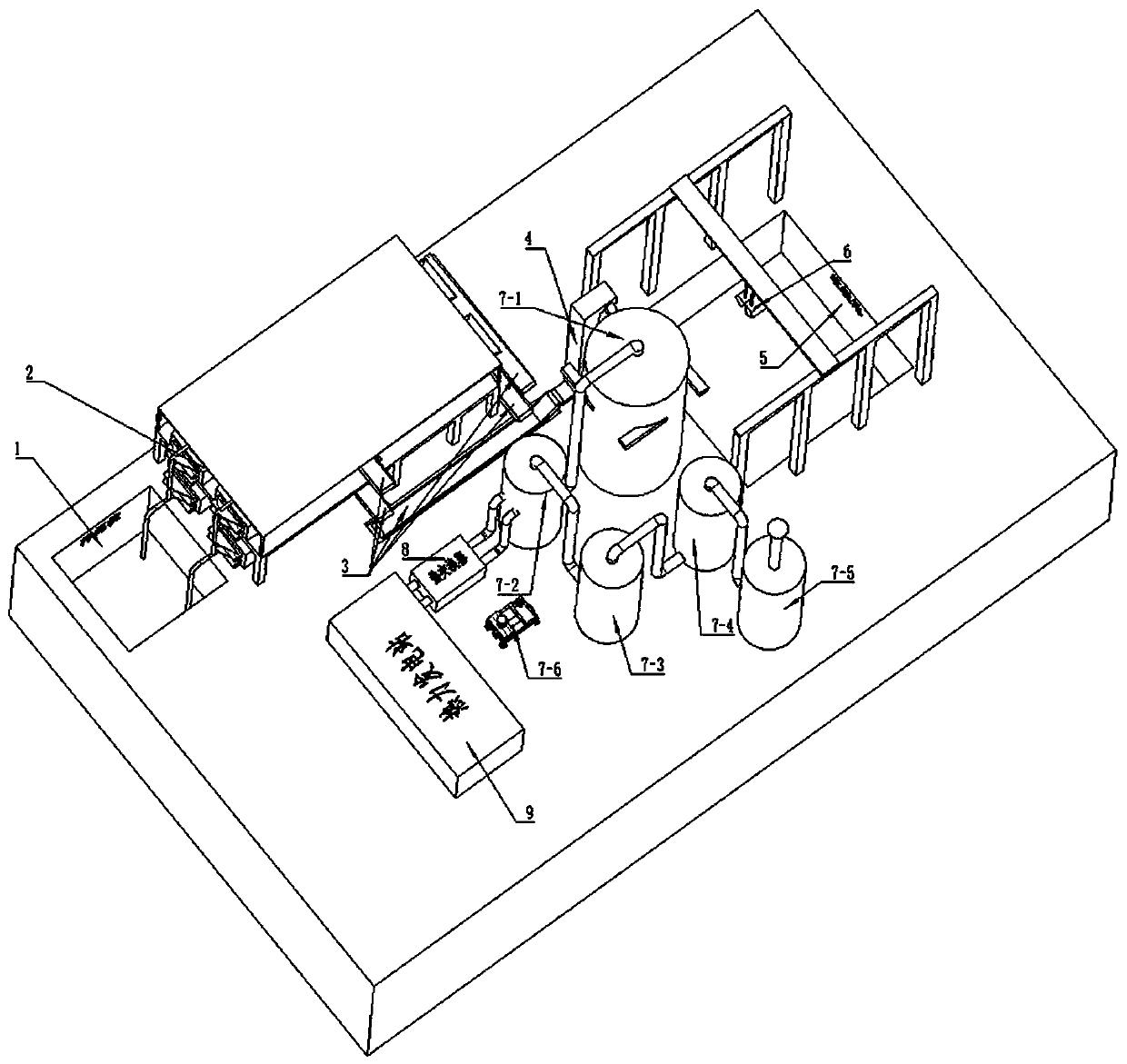

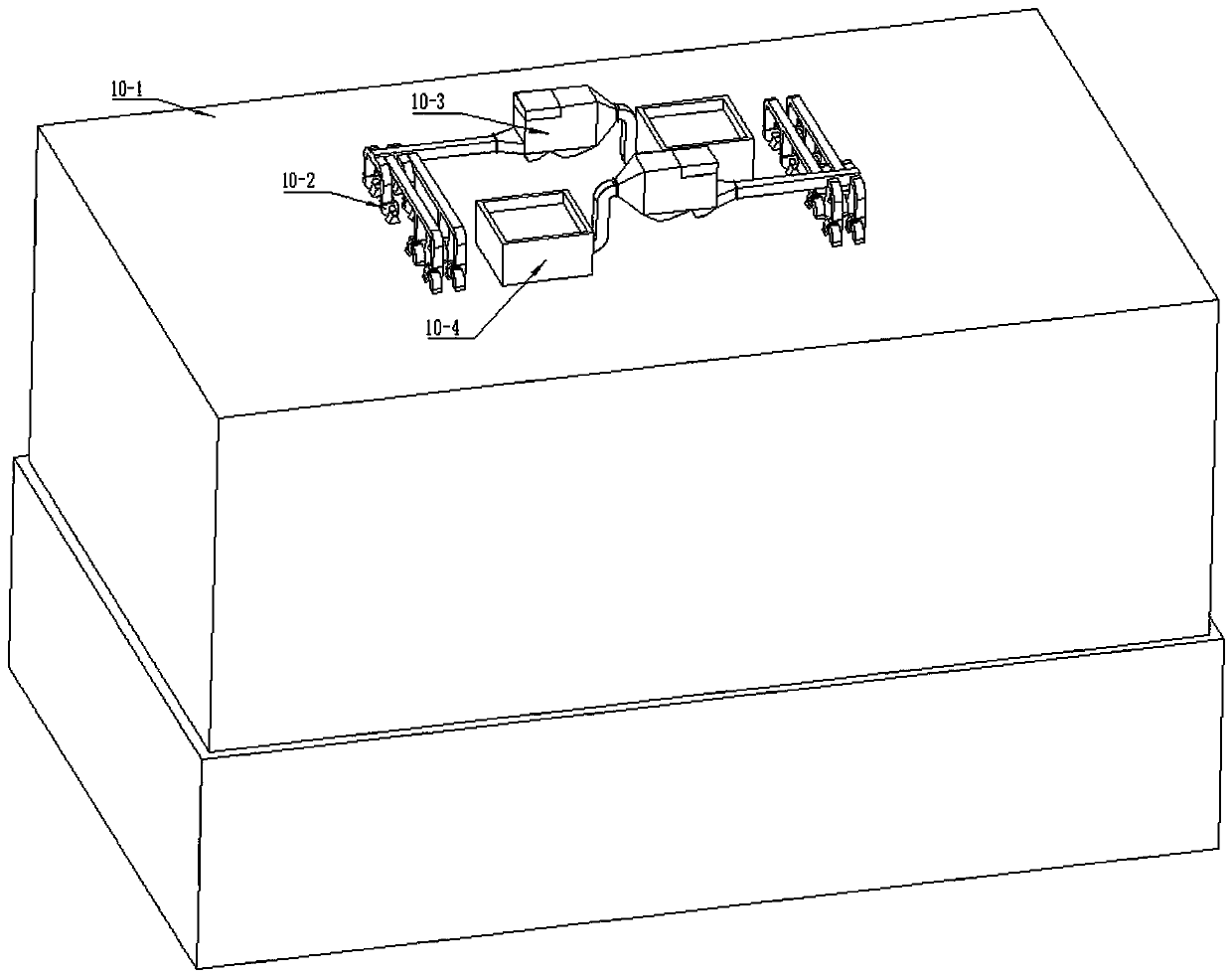

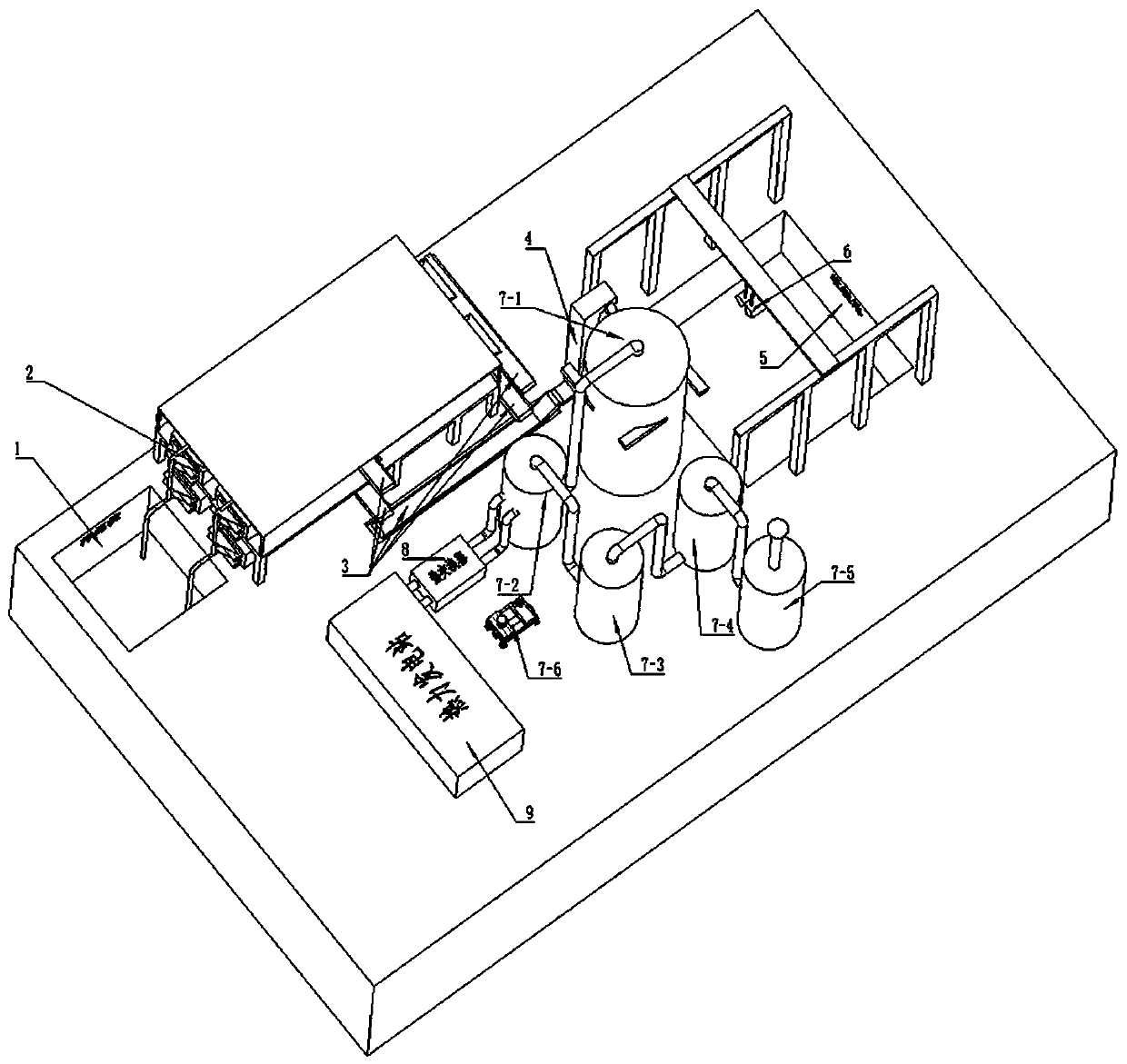

[0024] A waste and industrial sludge harmless reduction resource treatment process system, characterized in that it includes a sludge tank (1), a dehydration module (2), a dewatered sludge feeding module (3), a dewatered sewage Mud transport module (4), waste pool (5), grab mechanism (6), semi-gasification incinerator module (7), heat exchanger (8), thermal power station (9) and deodorization module (10 ); the semi-gasification incinerator module (7) includes a semi-gasification chamber (7-1), a combustion chamber (7-2), a first-stage sedimentation purification chamber (7-3), a second-stage electrostatic purification chamber (7-4), third-stage filter purification room (7-5) and air distribution system (7-6); the deodorization module (10) includes a gas collection hood (10-1), fan unit (10- 2), a combined dust collector (10-3) and a biological filter (10-4); the sludge tank (1) is equipped with a pumping device to pump the sludge in the tank to the dehydration module (2) The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com