High-precision global vision measurement method for three-dimensional thin-wall structure weld joint

A thin-walled structure, visual measurement technology, applied in the field of mechanical engineering, can solve the problems of data distortion, measurement deviation, deviation, etc., to achieve the effect of adapting to identification and measurement, suppressing measurement deviation, and improving identification and measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further elaborated below in conjunction with embodiment.

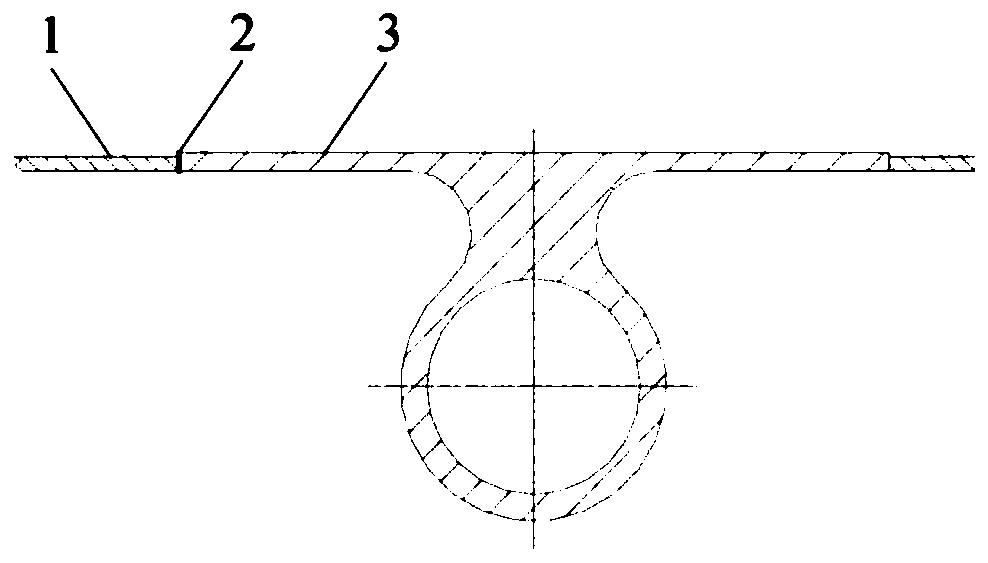

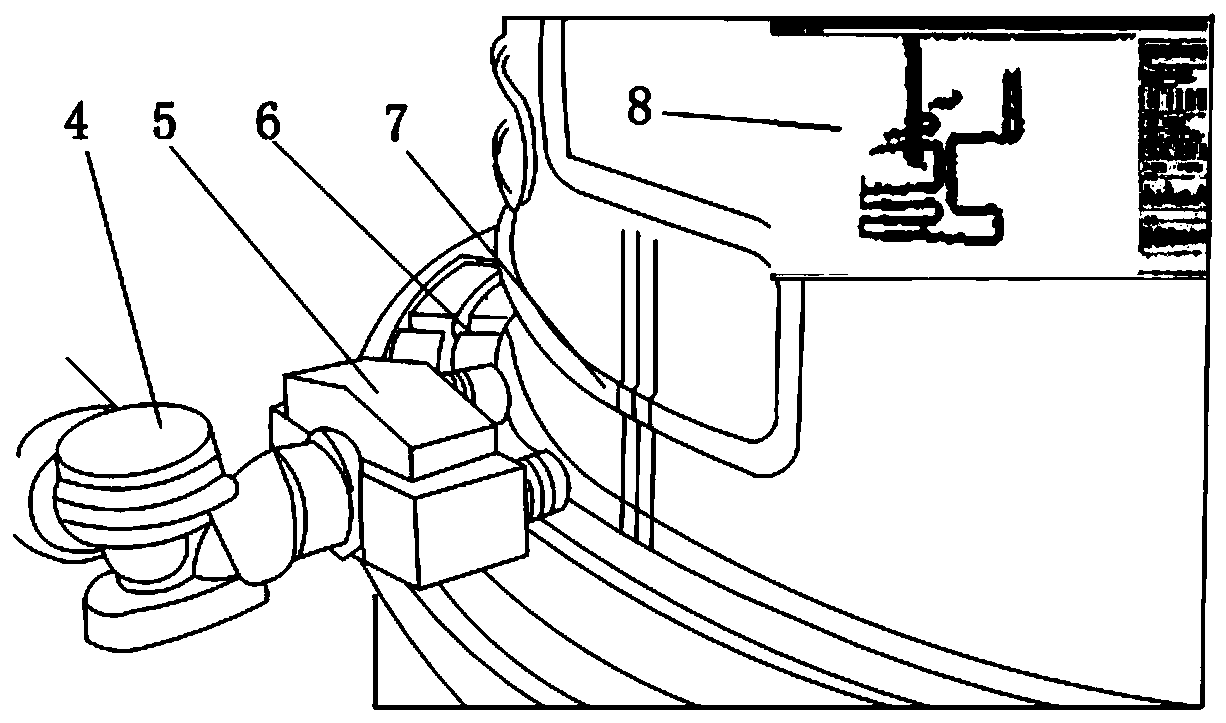

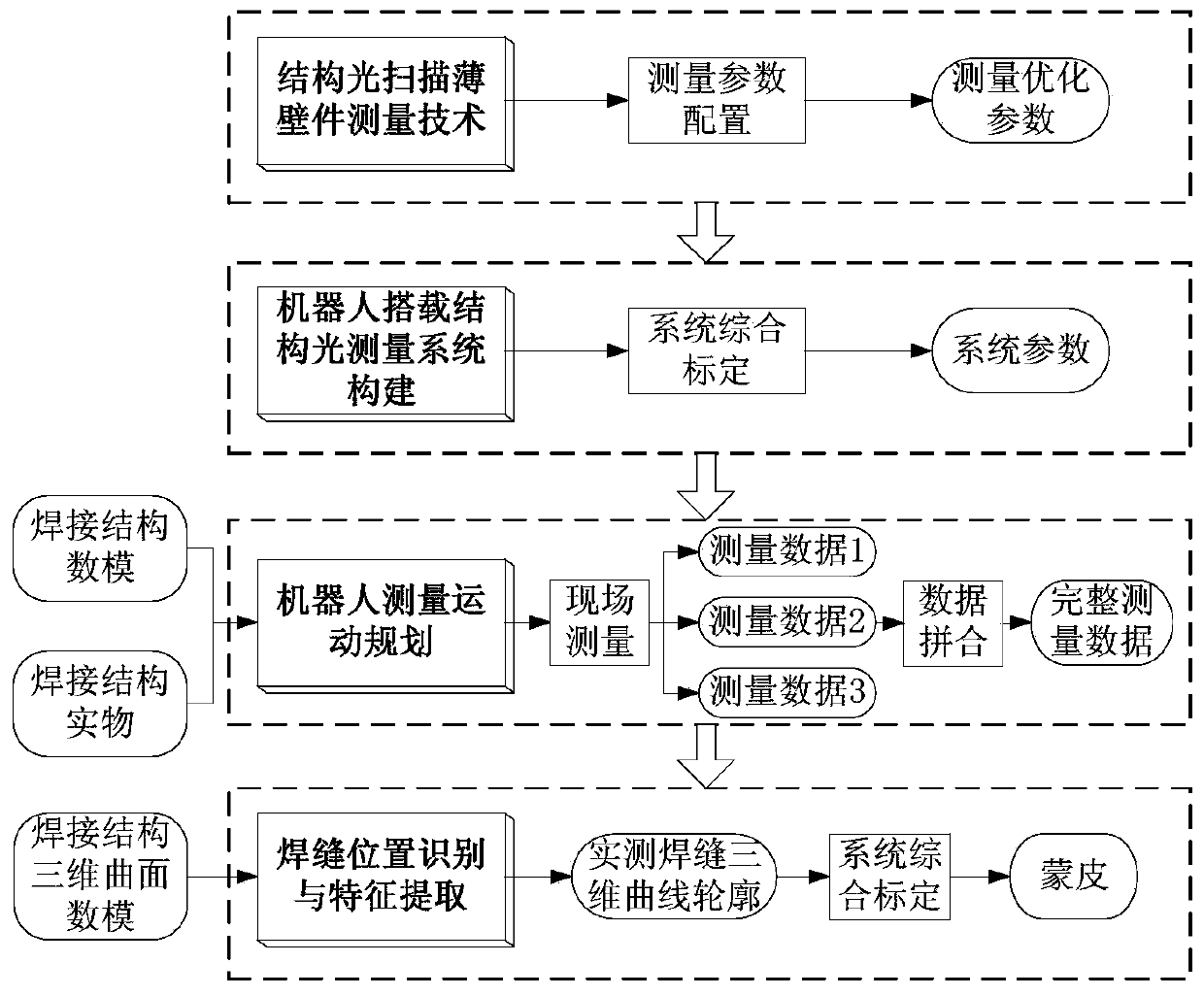

[0030] Such as figure 1 As shown, a typical heat pipe fluid pipe coupling plate radiator includes a thin-walled skin 1 and a heat pipe 3 with fins, and the joint is a weld 2 . Such as figure 2 As shown, the composition of a typical three-dimensional profile measurement system for thin-walled workpieces includes: industrial robots 4, surface structured light and binocular vision measuring heads 5, tooling 6, finned heat pipe workpieces 7, and industrial computers. Install the surface structured light and binocular vision measuring head 5 on the industrial robot 4, install and fix the finned heat pipe workpiece 7 on the tooling 6, and then make the industrial robot 4 realize the scanning of the edge of the finned heat pipe workpiece 7 through pre-programmed planning , the generated measurement data is transmitted to the industrial computer through the field bus, and the measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com