Slitting device for non-woven fabric production

A technology of non-woven fabrics and tailpieces, which is applied in the field of cutting devices for non-woven fabric production. It can solve the problems of low cutting efficiency and inconvenient measurement of non-woven fabric cutting angles, so as to improve design efficiency, facilitate design operations, and project long distance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

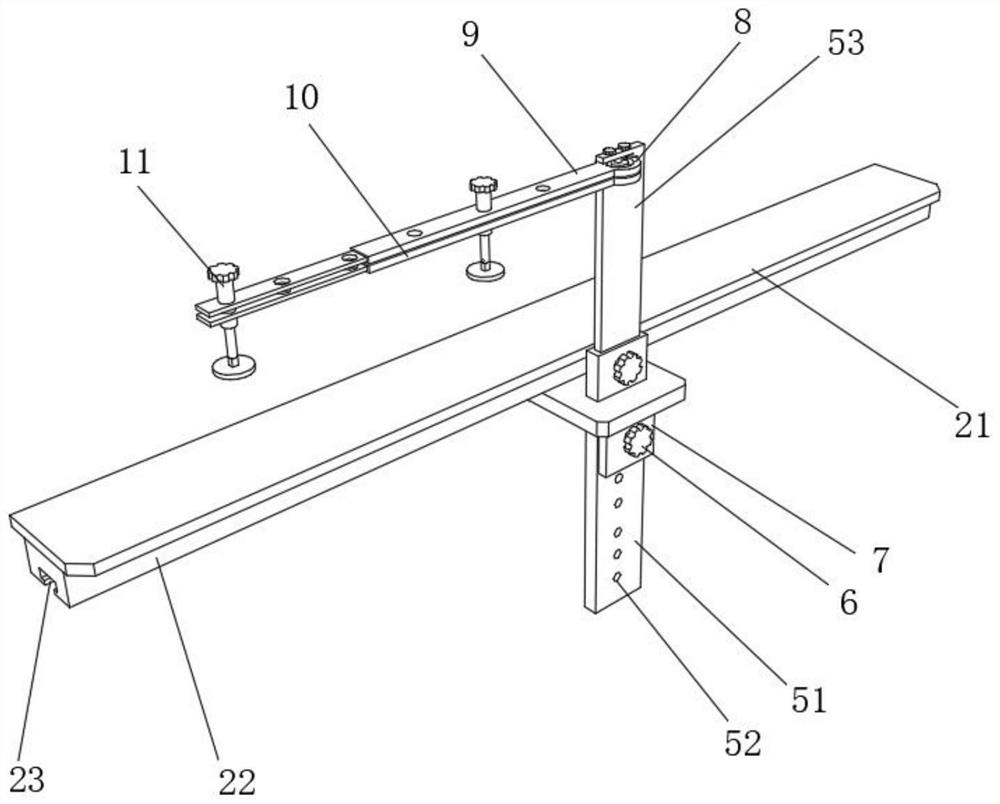

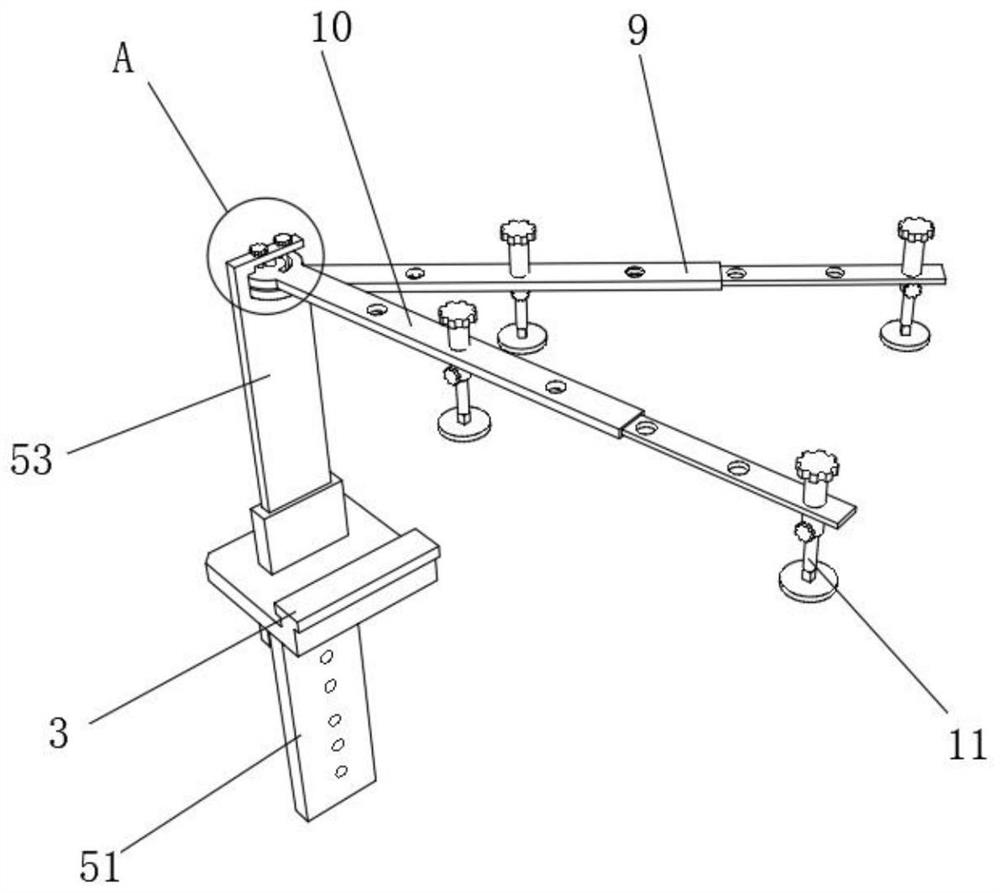

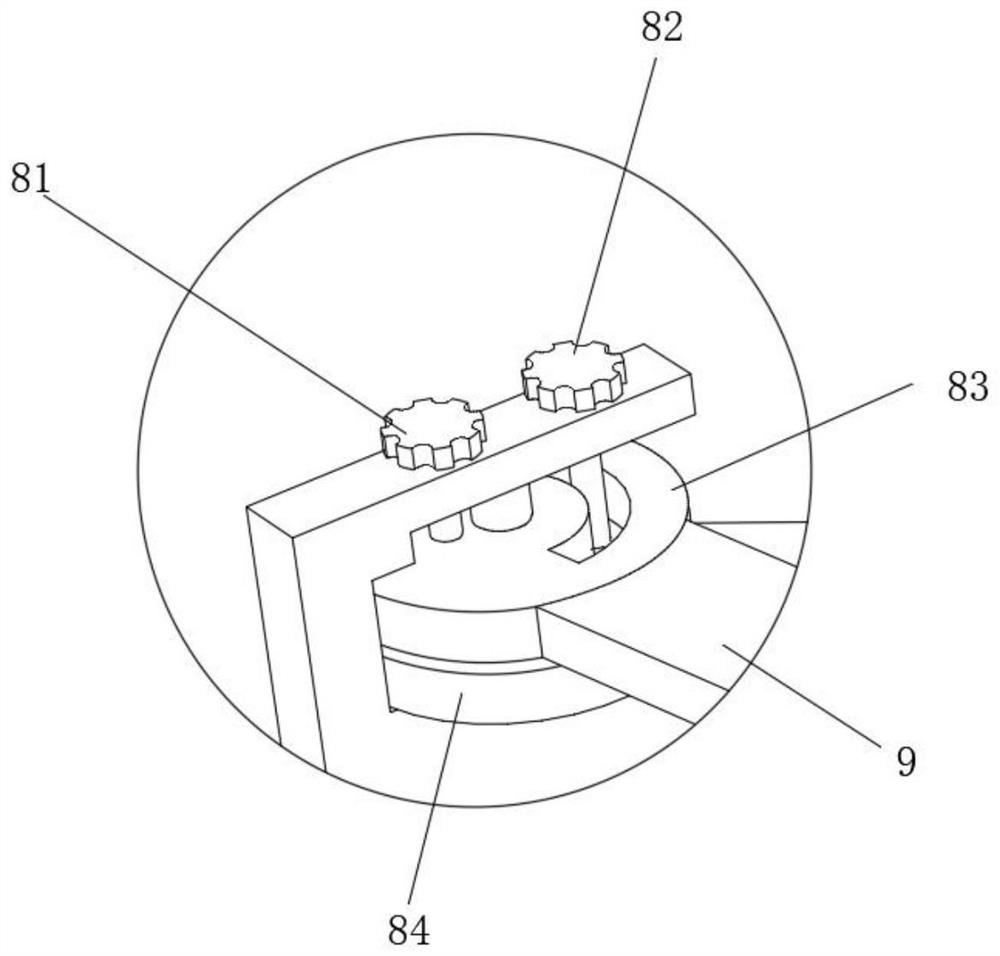

[0033] refer to Figure 1-8 , a cutting device for non-woven fabric production, including a sliding fitting 2 connected to the lower end of the design table 1, an extension seat 4 is slidingly connected to the sliding fitting 2, and an adjustable support member 5 is connected to the upper end of the extension seat 4, extending The upper end of the seat 4 is fixedly connected with a T-shaped slider 3, and the extension seat 4 is also threadedly connected with a bolt for fixing the extension seat 4. The sliding fitting 2 includes a fixed seat 21 and a sliding seat 22, and the fixed seat 21 is fixedly connected to the lower end of the design table 1. , the sliding seat 22 is fixedly connected to the lower end of the fixed seat 21, and the lower end of the sliding seat 22 is provided with a T-shaped chute 23 for sliding the T-shaped slider 3, and the adjustable support member 5 includes a sleeve 51 and a sleeve plate 53, and the sleeve 51 Connected with the extension seat 4, the c...

Embodiment 2

[0039] refer to Figure 5 and Figure 6 , a cutting device for non-woven fabric production. Compared with Embodiment 1, this embodiment is provided with an opening 12 at the lower end of the first tail cover 91, and a positioning light source is connected to the lower end of the first tail cover 91 and the first tail plate 92. 13. The positioning light source 13 is provided with multiple sections, and the end of the multi-section positioning light source 13 away from the hinge 8 is rotatably connected with the tail piece 19. For longer non-woven fabrics, the positioning light source 13 can be manually rotated to realize oblique projection, and the projection distance is longer. Far, the measurement range is wider, and a damping structure is connected between the positioning light source 13 and the tail piece 9, and the self-fixing effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com