Method for adjusting oil film temperature of dynamic and static hybrid grinding head

A dynamic and static pressure, dynamic and static pressure bearing technology, applied in the direction of engine lubrication, engine components, maintenance and safety accessories, etc., can solve the problems of affecting the service life of oil products, oil aging and deterioration, and low efficiency, so as to avoid oil deterioration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

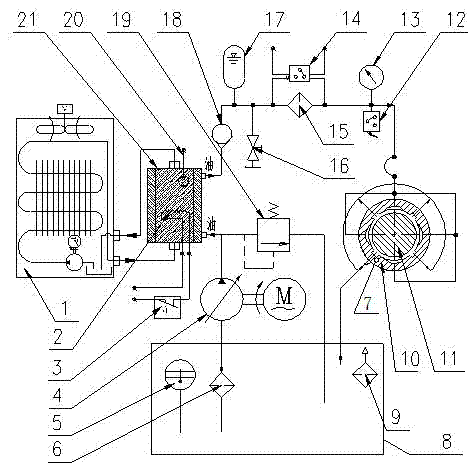

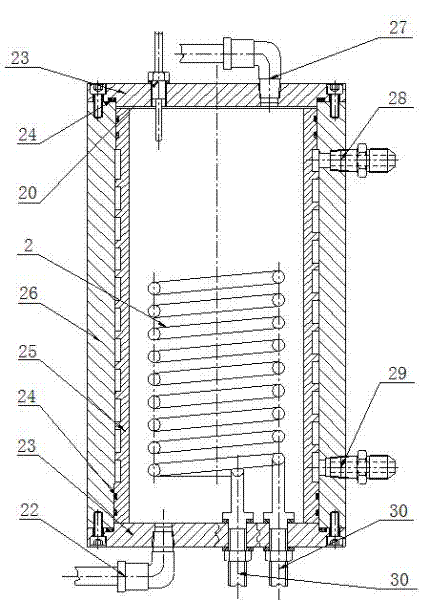

[0020] figure 1 Shown is the structural diagram of the concrete implementation of the present invention, figure 2 Schematic diagram of the heat exchanger.

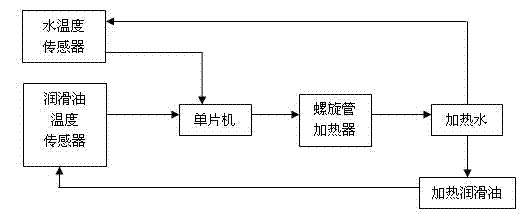

[0021] The embodiment of the present invention is composed of an oil supply system, a water cooler 1, a heat exchanger 21, a single-chip microcomputer system and a lubricating oil temperature sensor. Heat exchanger 21 is the key component that the inventive method implements, and by heat exchanger 21, the lubricating oil with low temperature is heated by hot water here, and the lubricating oil with high temperature is cooled by cooling water at this; The spiral heater 2 in the device is heated, and the cooling water is provided to the heat exchanger by the water cooler 1 through the cooling water inlet and outlet pipes 22, 27 installed on the heat exchanger 21, but the water cooler 1 and the spiral tube heater 2 are in mutual lock state.

[0022] The heat exchanger is mainly composed of cooling water inlet pipe 22, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com