Shower head and vapor deposition equipment

A sprinkler head and gas cavity technology, applied in the field of semiconductor equipment, can solve the problems of uncontrollable surface temperature of the sprinkler head, and achieve the effects of enhanced adaptability, increased temperature, and improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

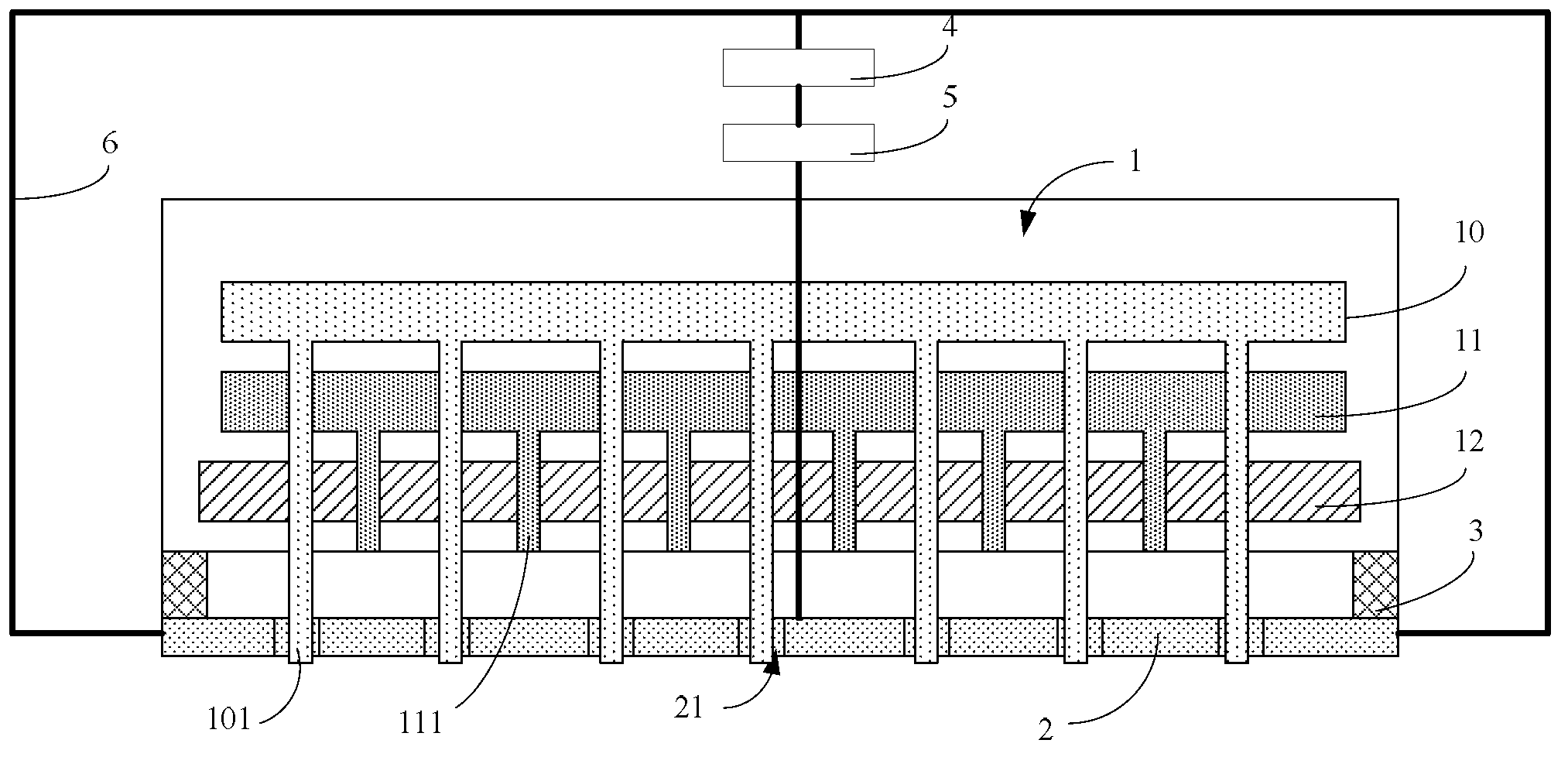

[0012] It can be seen from the content recorded in the background art that the shower head in the prior art has the problem of uncontrollable temperature. The core idea of the present invention is that by introducing at least a conductive layer, the thermal wall plate under the shower head is connected to a power source, so that the temperature control of the thermal wall plate can be realized.

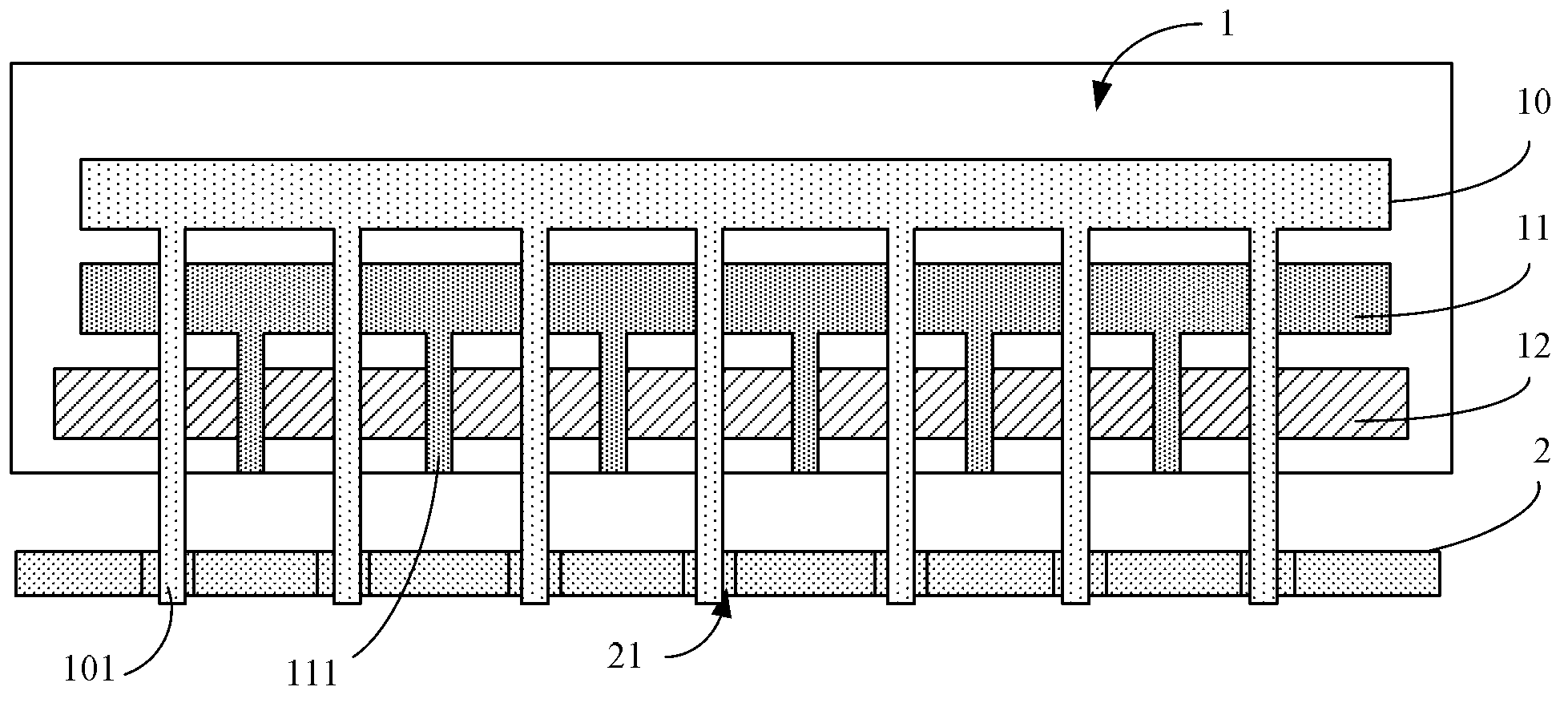

[0013] Please refer to figure 2 , the present invention provides a shower head for MOCVD process, including a shower head body 1, the shower head body 1 has at least two gas chambers 10, 11 and a water cooling chamber 12; in this embodiment, The gas chamber at least includes a Group III source chamber 10 and ammonia gas (NH 3 ) cavity 11, the group III source cavity 10 and the ammonia gas cavity 11 are stacked, for example, it can be figure 2 The shown group III source chamber 10 is located above the ammonia gas chamber 11, the water cooling chamber 12 is located below the ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com