Differential pressure type flowmeter

A technology of differential pressure flowmeter and differential pressure sensor, which is applied in the direction of volume measurement, flow/mass flow measurement, liquid/fluid solid measurement, etc., and can solve the problems of large flow measurement error and differential pressure measurement error, etc. Achieve the effect of reducing pressure measurement error and flow measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

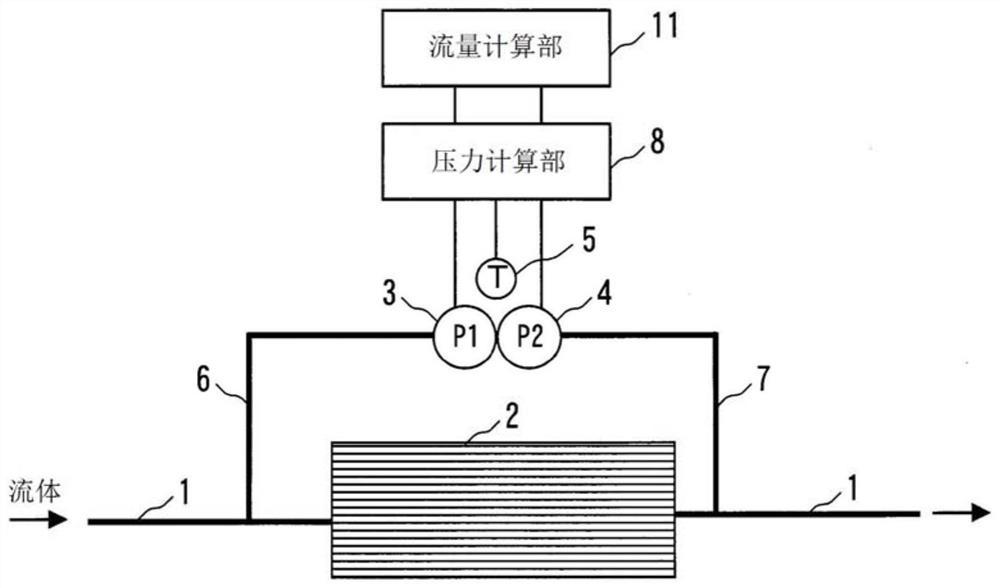

[0057] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a diagram showing the configuration of a laminar flow meter (differential pressure flow meter) according to a first embodiment of the present invention. The laminar flow type flowmeter includes: a pipe 1 that allows the fluid to be measured to circulate; a laminar flow element 2 that is installed in the pipe 1 and is a differential pressure generating mechanism that generates a differential pressure between the fluid on the upstream side and the fluid on the downstream side; Absolute pressure sensor 3, which measures the absolute pressure P1 of the fluid on the upstream side of the laminar flow element 2; an absolute pressure sensor 4, which measures the absolute pressure P2 of the fluid on the downstream side of the laminar flow element 2; a temperature sensor 5, which measures the absolute pressure sensor 3 , the ambient temperature of 4; conduits 6, 7, ...

no. 2 example

[0081] Next, a second embodiment of the present invention will be described. Image 6 It is a diagram showing the configuration of a laminar flow meter (differential pressure flow meter) according to a second embodiment of the present invention. The laminar flow meter of this embodiment includes: a pipe 1, a laminar flow element 2, a differential pressure sensor 9 for measuring the differential pressure ΔP of the fluid on the upstream side and downstream side of the laminar flow element 2, and a pressure sensor 9 for measuring the downstream side of the laminar flow element 2. Absolute pressure sensor 4, temperature sensor 5, conduits 6, 7 of the absolute pressure P2 of the fluid, based on the temperature T measured by the temperature sensor 5, the output signal of the differential pressure sensor 9 is corrected and converted into a differential pressure ΔP, and based on the temperature T corrects the output signal of the absolute pressure sensor 4 and converts it into an abso...

no. 3 example

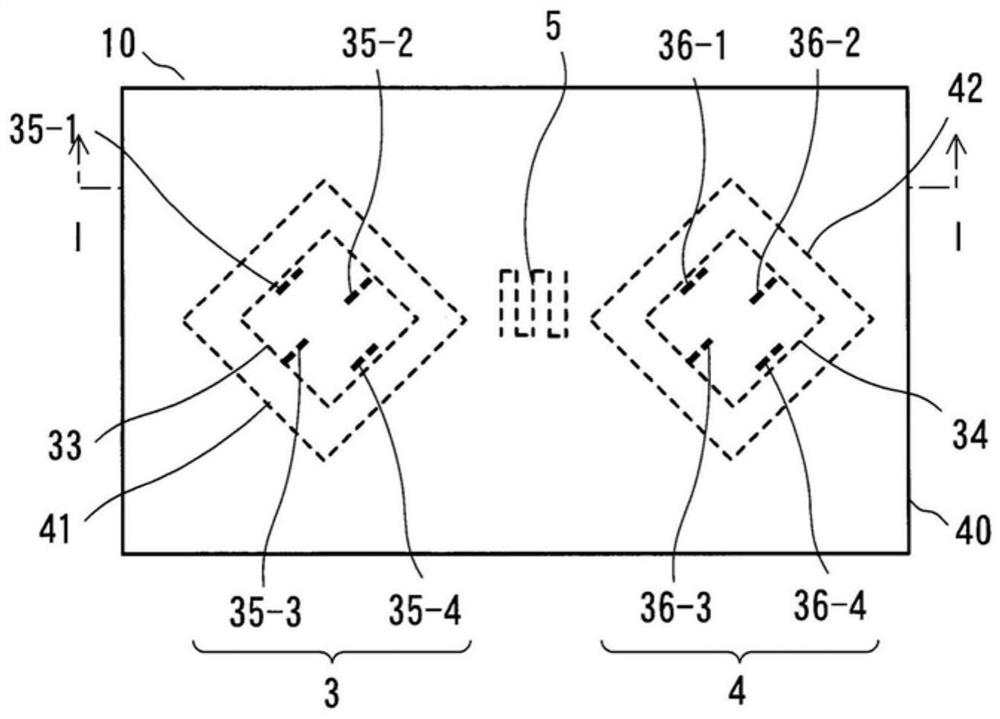

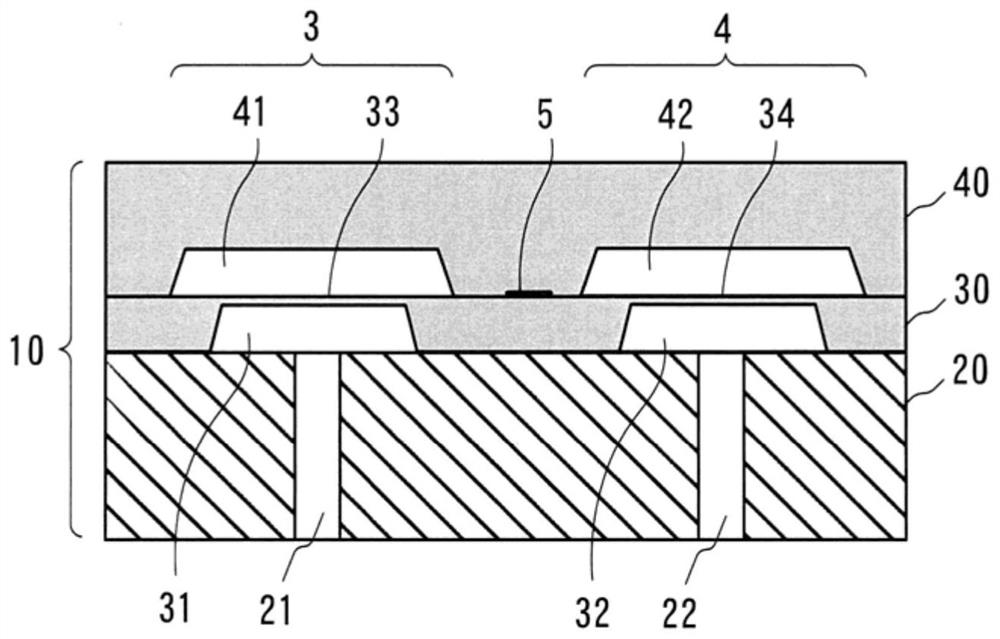

[0103] In the first and second embodiments, the two diaphragms for pressure detection and the temperature sensor are integrated on one chip, but it is also possible to house the two sensor chips and the temperature sensor in the same package. Figure 10 It is a top view of a sensor package of a laminar flow meter (differential pressure flow meter) according to a third embodiment of the present invention, Figure 11 yes Figure 10 I-I line sectional view. In addition, in Figure 10 In , the inside of the sensor package is shown transparently for easy observation of the structure.

[0104] The piping 1, the laminar flow element 2, the conduits 6, 7, the pressure calculation unit 8, and the flow rate calculation unit 11 are the same as those described in the first embodiment, and the laminar flow meter of this embodiment corresponds to figure 1 A device obtained by replacing the temperature sensor 5 with the temperature sensor 5b.

[0105] For example, the sensor chip 10 b o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com