Fully-automatic roller sorting machine

A kind of sorting machine, fully automatic technology, applied in sorting and other directions, can solve the problems of inaccurate and reliable positioning, affecting sorting efficiency, slow slide-type blanking, etc., to achieve simple and convenient blanking process, improved measurement accuracy, The effect of standing upright

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

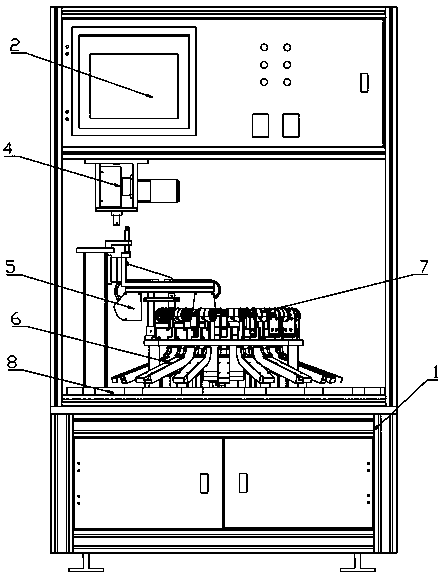

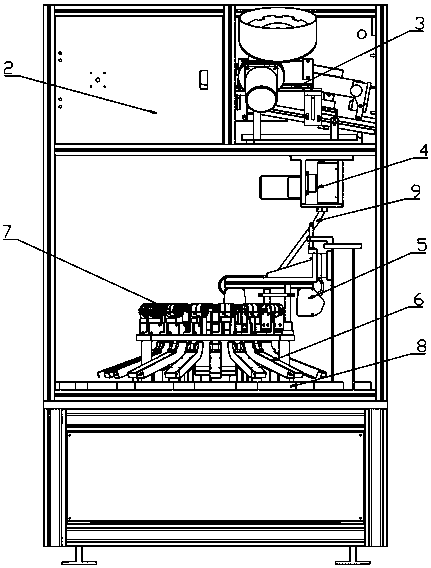

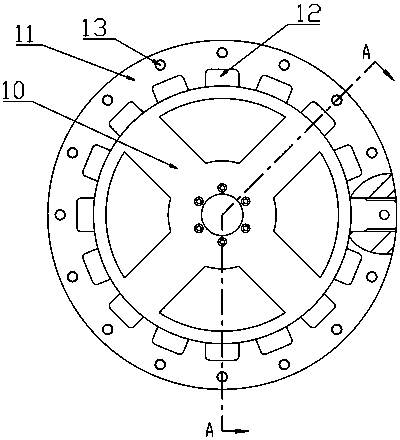

[0027] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a kind of automatic roller sorting machine described in this embodiment includes a frame 1, a rolling bar 17 feeding mechanism 3 is arranged at the upper end of the frame 1, and the frame 1 below the rolling bar 17 feeding mechanism 3 A U-turn mechanism 4 is arranged on the top, and the U-turn mechanism 4 is connected with the rolling rod 17 feeding mechanism 3 through the No. 1 conveying pipeline 29, and a detection turntable 10 is set on the frame 1 below the U-turn mechanism 4, and the detection turntable 10 is a concave structure in the middle , and a detection ring 11 is extended outward on the upper edge of the detection turntable 10, and a plurality of detection holes 12 are evenly spaced on the detection ring 11. The detection holes 12 are along the diameter direction of the detection ring 11, and each detection hole 12 The middle position of the center is provided with mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com