Full-automatic coal colloidal layer index measuring apparatus

A colloidal layer index, measuring instrument technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of difficult to master and control the accuracy of measurement work, high production cost of measuring devices, and cumbersome measurement methods and processes. The measurement method and process are clear and clear, the structure is simple and reasonable, and the technical level is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

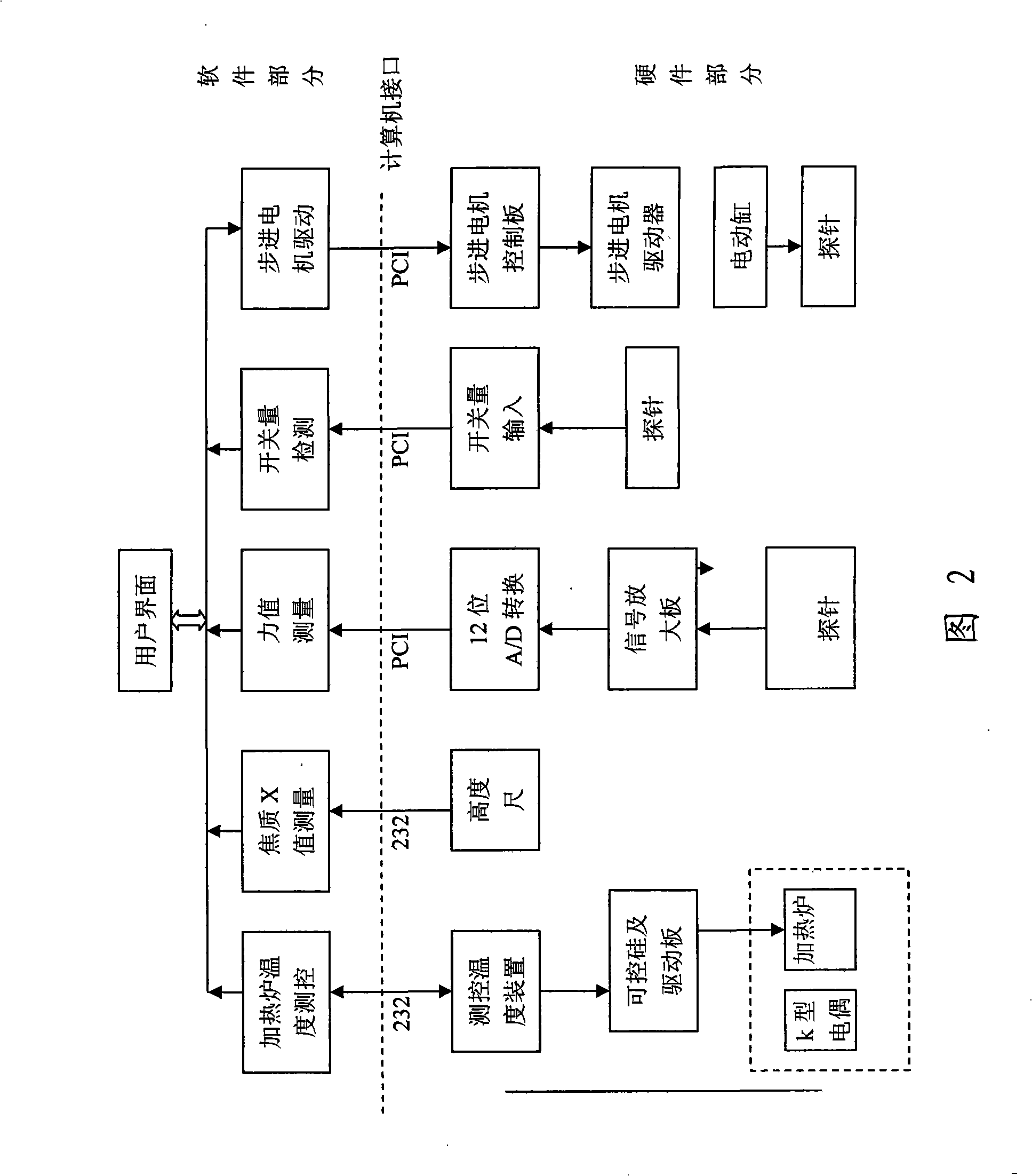

[0064] In order to further elaborate the technical means and effects that the present invention takes to achieve the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, its specific implementation and structure of the fully automatic coal jelly layer index measuring instrument proposed according to the present invention , test methods, steps, features and their efficacy, detailed as follows.

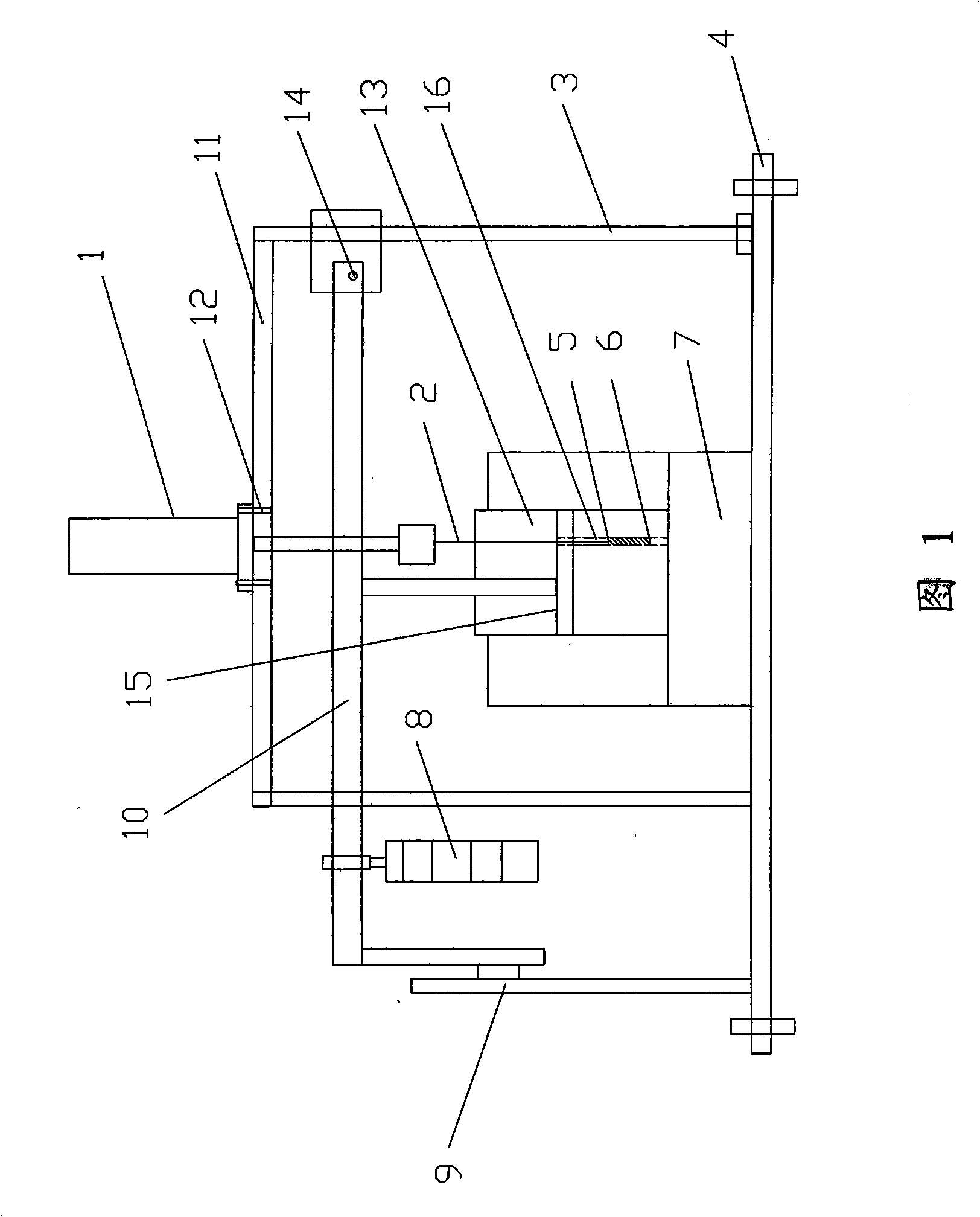

[0065] Please refer to FIG. 1 , which is a schematic structural view of a fully automatic coal jelly layer index measuring instrument according to a preferred embodiment of the present invention.

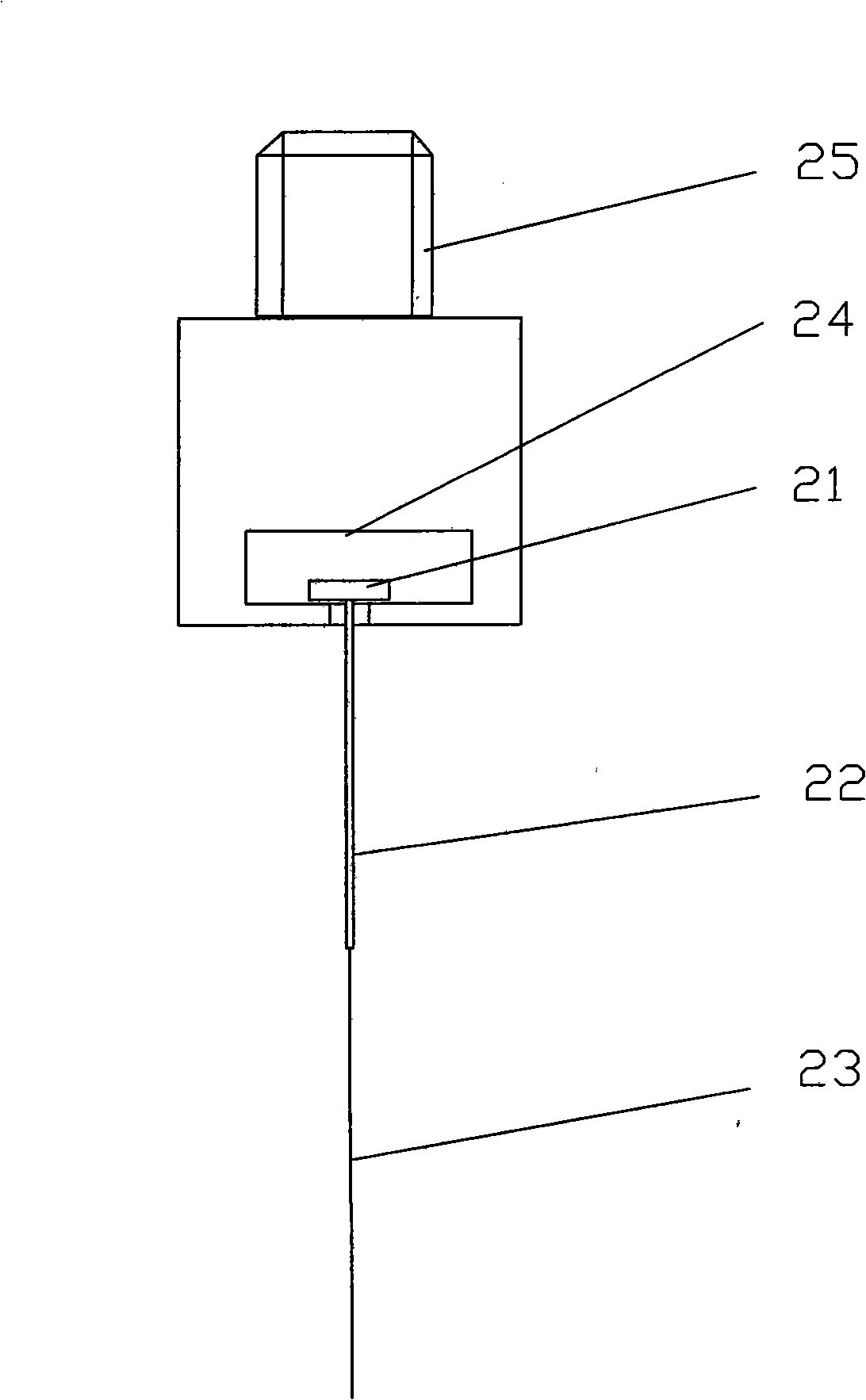

[0066] It mainly includes: stepping motor driving device 1, probe 2 of force measuring device, bracket 3, base 4, heating furnace 7, weight 8, automatic height measuring device 9, lever 10, electric cylinder bracket 11, connecting screw 12 , a coal cup 13 placed in the heating furnace, a rotating shaft 14 and a pressure plate 15 etc. const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com