Device and method for measuring viscosity of petroleum

A technology of measuring devices and measuring methods, which is applied in the directions of measuring devices, flow characteristics, instruments, etc., can solve the problems of increasing the workload of measuring personnel, cumbersome processes, and reducing accuracy, and achieves easy popularization and application, high measurement accuracy, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

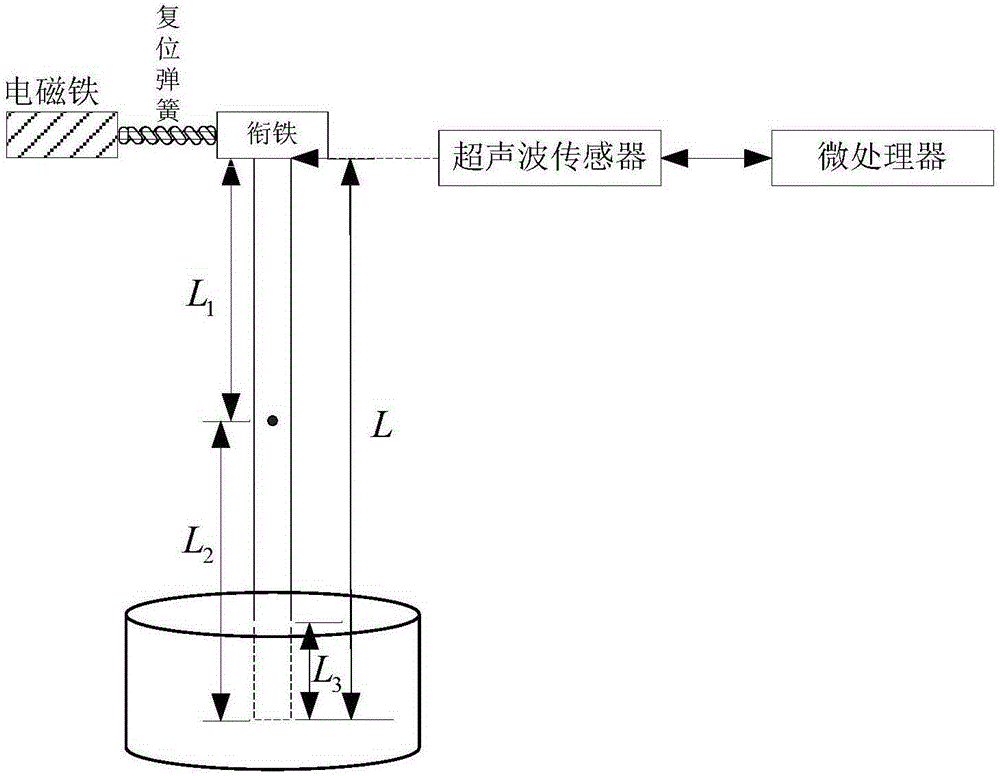

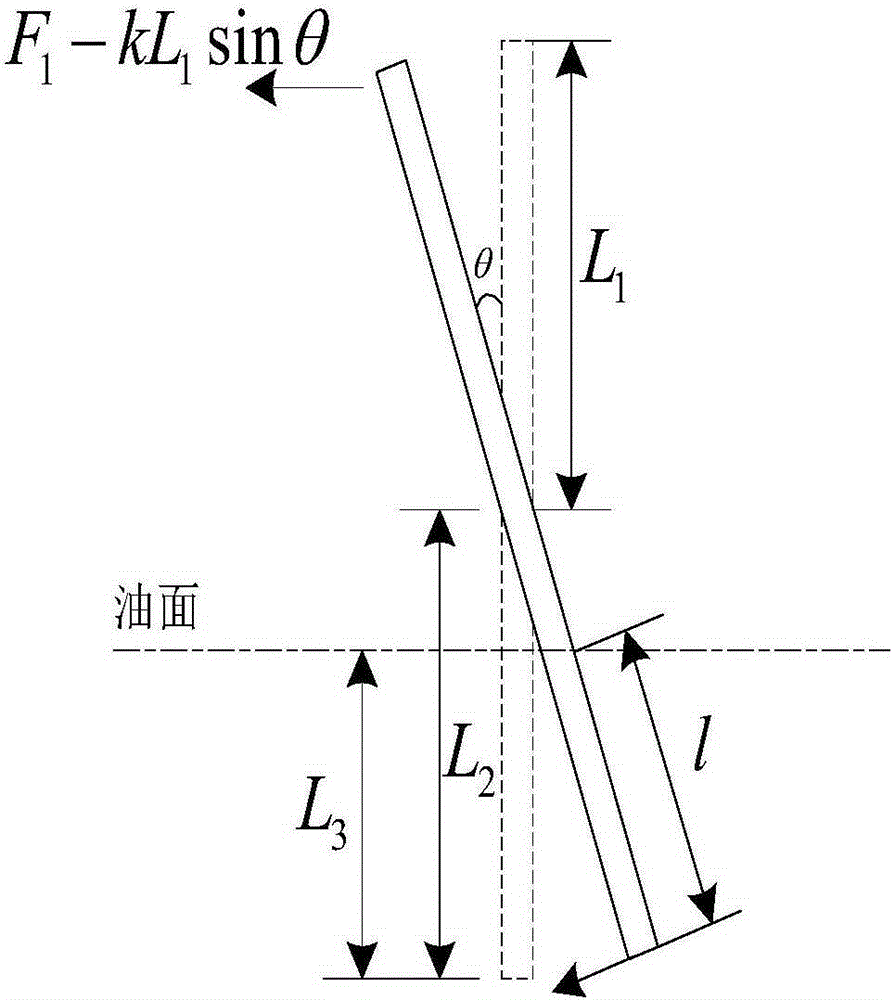

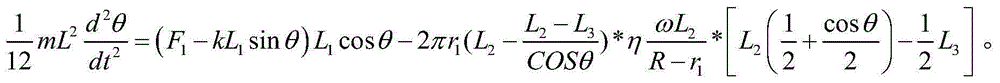

[0031] A petroleum viscosity measuring device, comprising a traction mechanism, a rotating mechanism, a detection mechanism and a control mechanism, wherein: the traction mechanism is an electromagnet, the electromagnet includes an armature and a return spring, and is started under the control of the control mechanism; The upper end of the rotating mechanism is connected to the armature, the lower end of the rotating mechanism is arranged in the oil body to be tested, and a support shaft is arranged in the middle of the rotating mechanism, and the armature can drive the rotating mechanism along the The support shaft rotates; the detection mechanism is used to detect the rotation angle or / and rotation displacement or / and rotation time of the rotation mechanism; the control mechanism is used to control the start of the traction mechanism, and according to the detection mechanism The detected parameters calculate the viscosity of the oil body to be tested.

[0032] As a preferred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com