Measuring method for cumulative error of involute cylindrical gear tooth pitch based on machine vision

An involute cylinder, accumulating error technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of poor accuracy, low efficiency of involute cylindrical gear pitch accumulation error, cumbersome process, etc. The effect of simplified measurement process, improved measurement accuracy and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

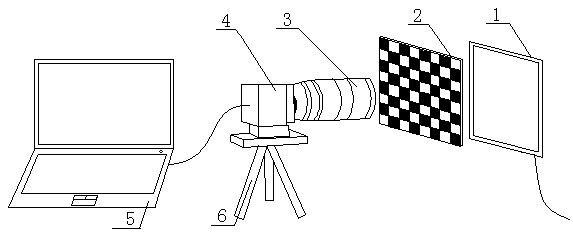

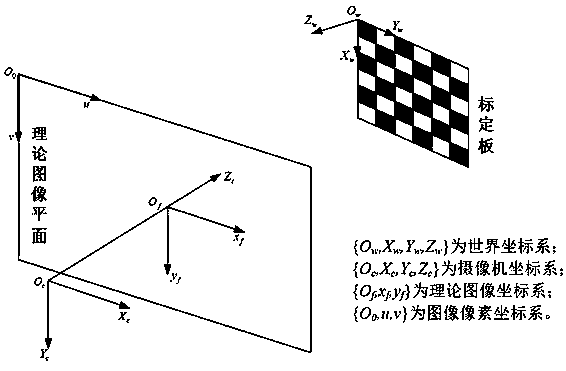

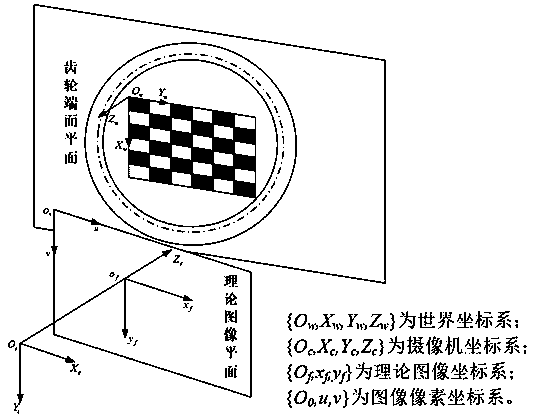

[0038] see Figure 1 to Figure 6 As shown, the method for measuring the cumulative error of involute cylindrical gear tooth pitch based on machine vision of the present invention firstly proposes the method of geometrically fitting the expression of the involute equation of the tooth profile to realize the accumulation of pitch of involute cylindrical gear Non-contact measurement of errors. First set the world coordinate system and the imaginary coordinate system, and let the origin of the imaginary coordinate system be on the rotation axis of the gear. The X′-Y′ plane of the imaginary coordinate system is coplanar with the X-Y plane of the world coordinate system. In the plane beam whose axis is the line connecting P and the starting point Q of the involute of the base circle, there must be a plane perpendicular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com