Harmonic type reducing mechanism

A deceleration mechanism and harmonic technology, applied in the field of harmonic deceleration mechanism, can solve problems such as limited strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

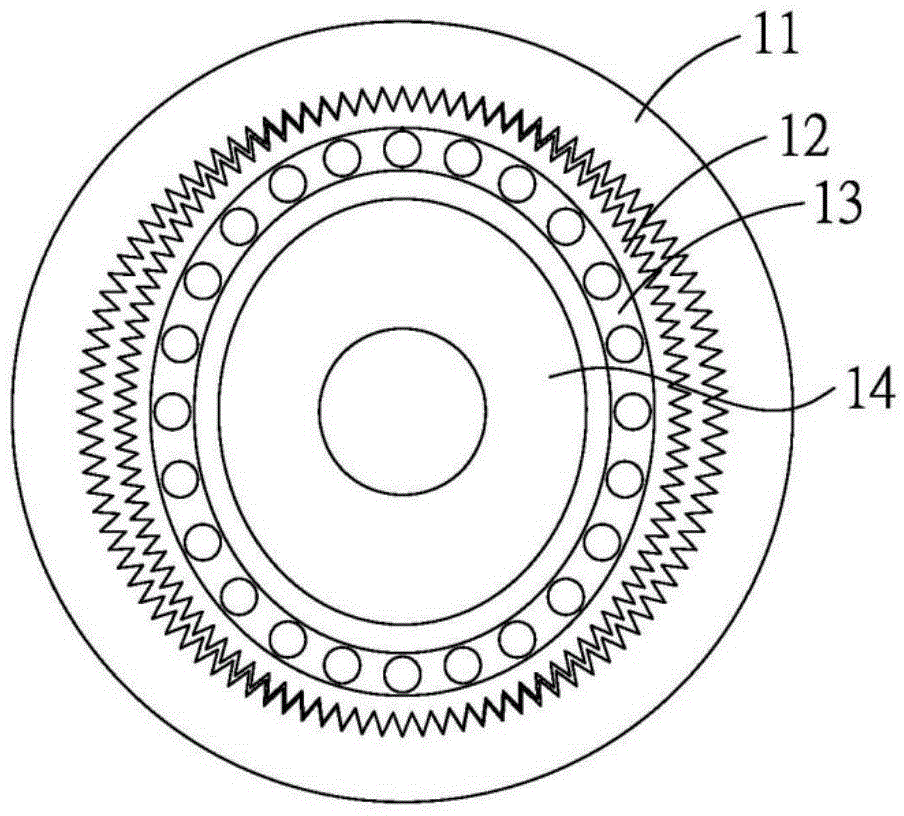

[0066] refer to Figure 14A As shown, the harmonic reduction mechanism provided by the first embodiment of the present invention is mainly composed of a rigid internal gear 20, a flexible external gear 30, a flexible bearing 40, and a wave generating wheel 50. composed of:

[0067] The rigid internal gear 20 is hollow, with a number of teeth of 2 (n+1) and a modulus of m; in this embodiment, each tooth shape of the rigid internal gear 20 is an involute tooth shape.

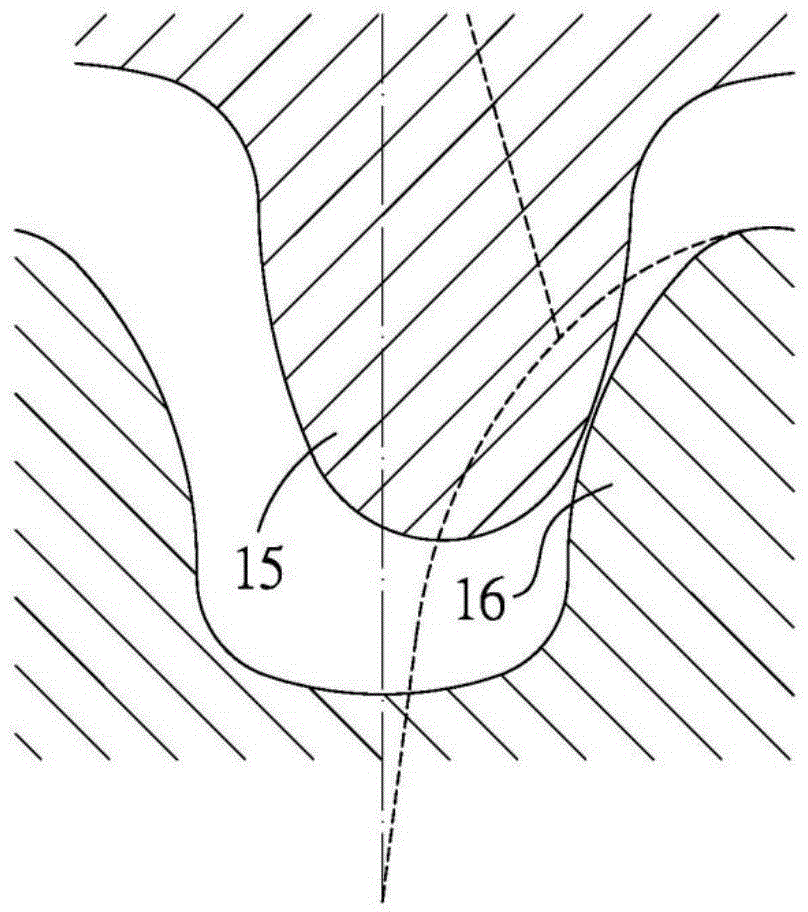

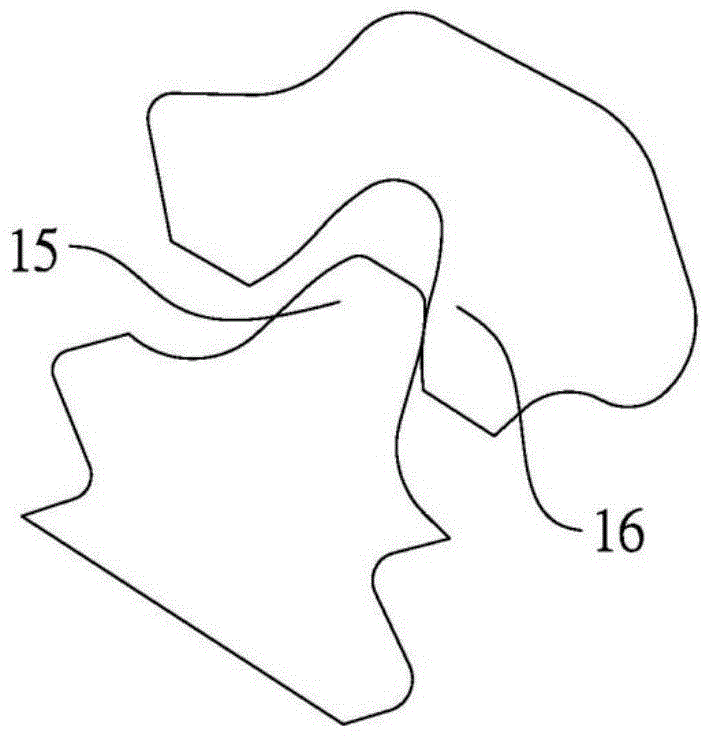

[0068] The flexible external gear 30 is hollow, pierced through the rigid internal gear 20, and is provided with a number of teeth of 2n and a modulus m that is the same as the modulus m of the rigid internal gear 20; in this embodiment, Each tooth profile of the flexible external gear 30 is an involute tooth profile, and the tooth profiles of the flexible external gear 30 and the rigid internal gear 20 are the same in the effective area. The part where the gear 30 and the rigid internal gear 20 mesh and drive e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com