Improved ratchet ring spanner

A ring wrench and ratchet technology, applied to wrenches, manufacturing tools, wrenches, etc., can solve the problems of inconvenient use, affecting the strength of the handle 81, and the inability to increase the torque of the ratchet block 91, etc., to increase the number and area of teeth, large torque, The effect of increasing the width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

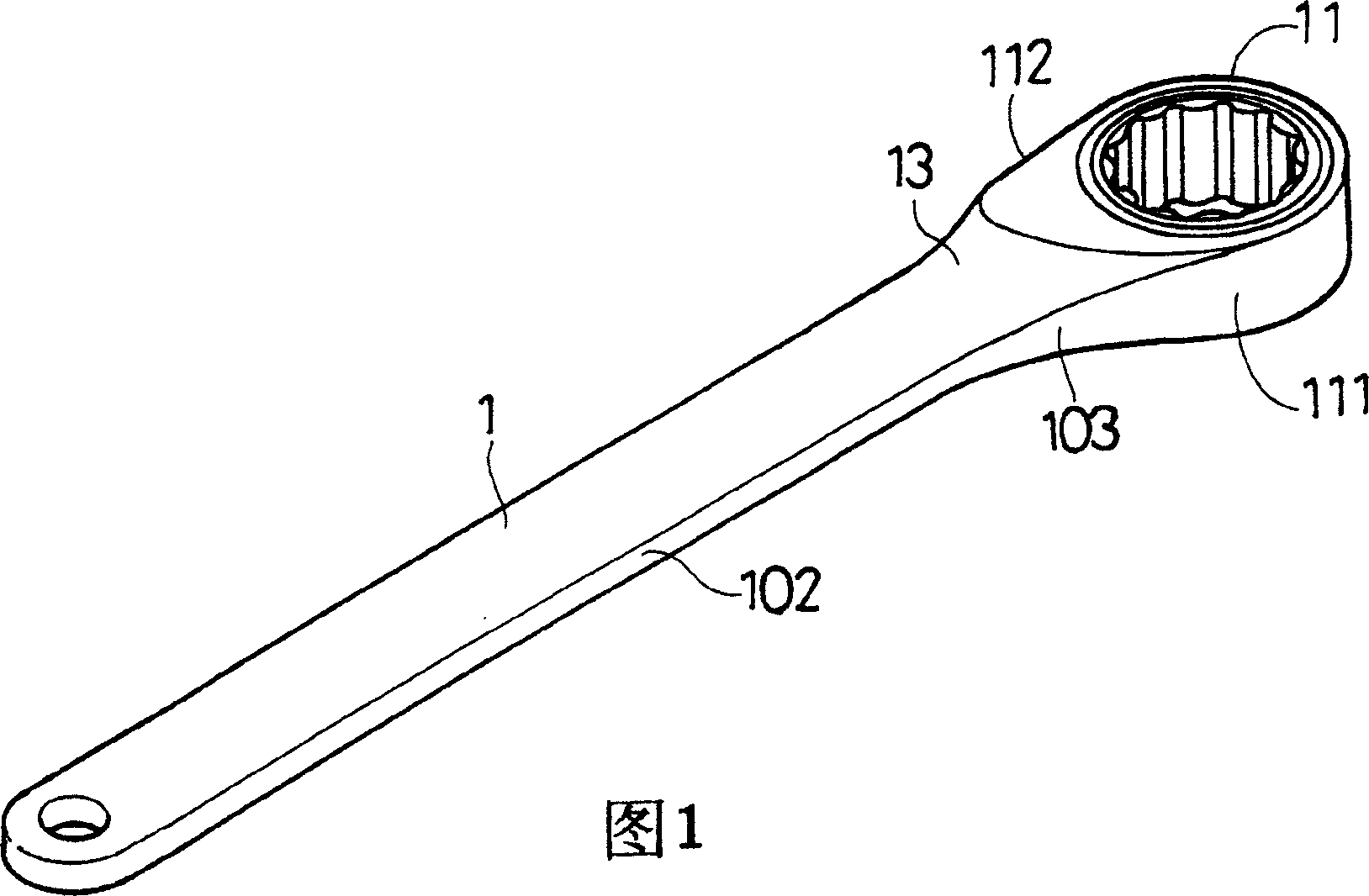

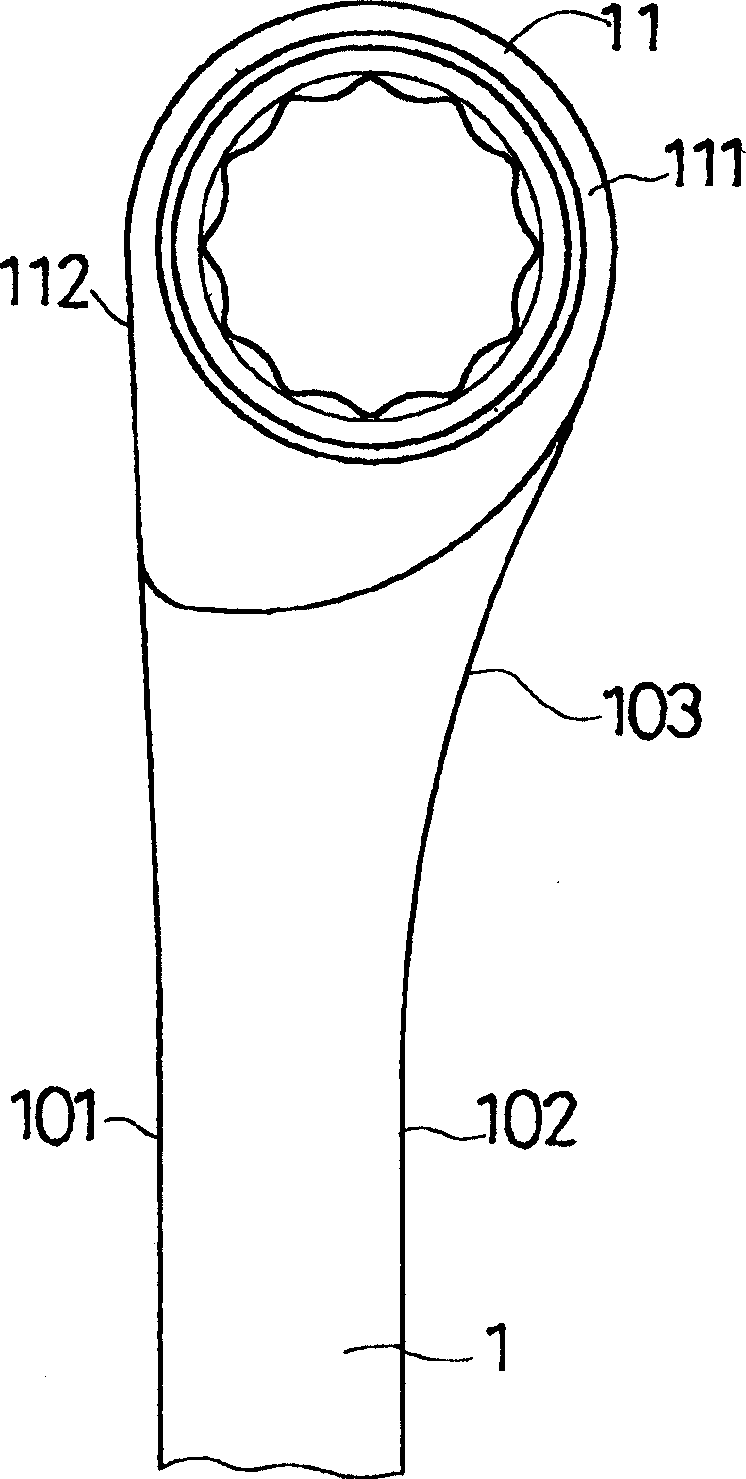

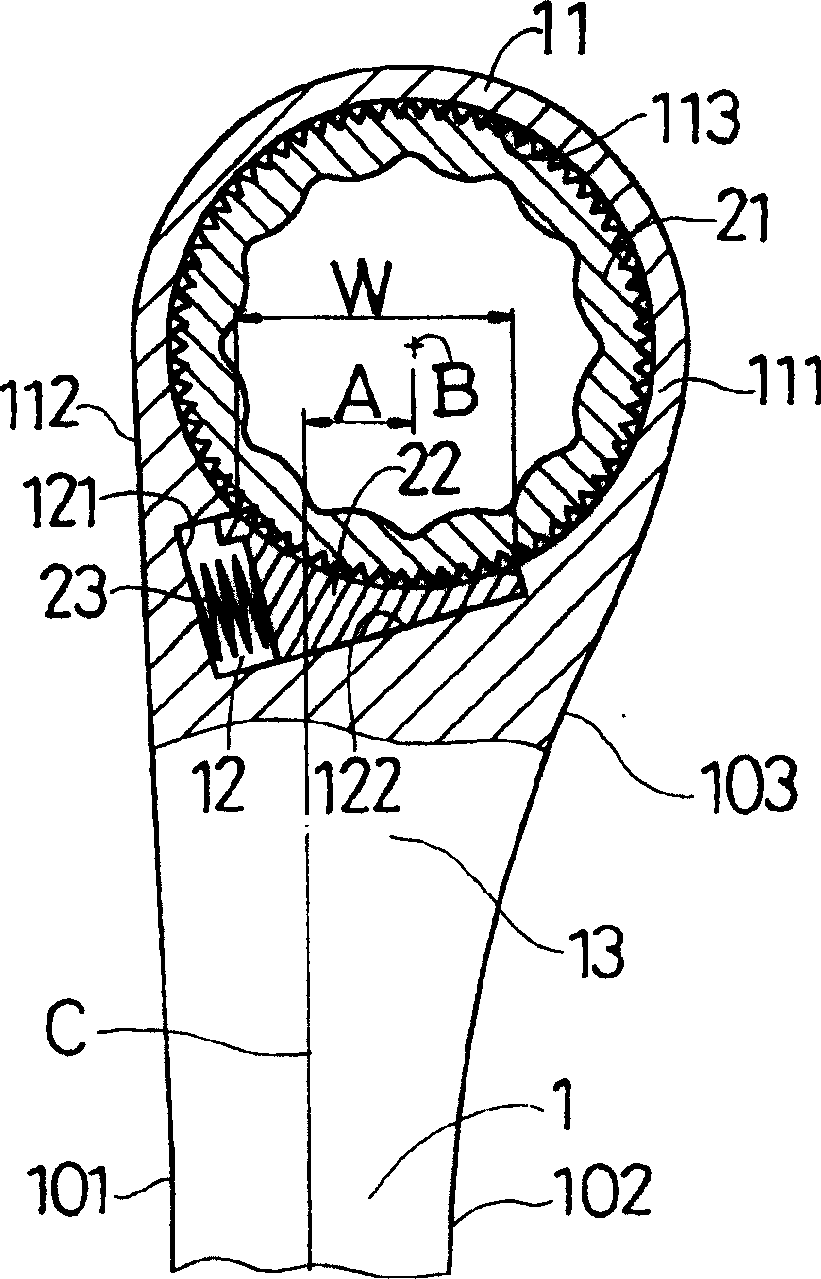

[0017] Please refer to Figure 1 to image 3 , the present invention has a handle 1, the handle 1 has a first side 101 and a second side 102, the handle 1 also has a head 11, the head 11 has a groove 113 for setting a ratchet 21. Between the handle 1 and the head 11 there is an accommodating groove 12 for setting a ratchet block 22. The accommodating groove 12 has a side surface 121 and a bottom surface 122 perpendicular to each other. The side surface 121 is located adjacent to the accommodating groove 12. One side of the first side 101 . The bottom surface 122 is for the ratchet block 22 to lean against and slide thereon, and a spring 23 is disposed between the side surface 121 and the ratchet block 22 to push the ratchet block 22 to engage with the ratchet wheel 21 under normal conditions. There is a distance A between the center point B of the head 11 and the centerline C of the handle 1, so that the head 11 protrudes laterally from the second side 102 of the handle 1 to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com