Gear hobbing tooth surface error compensation method and system based on equivalent transmission chain error calculation

An error compensation and error calculation technology, applied in the field of error analysis and precision control of CNC machine tools, can solve problems such as gear hobbing errors, affecting accuracy, affecting gear pitch and tooth profile accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0177] The present invention will be further described below in conjunction with drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not as limitations of the present invention.

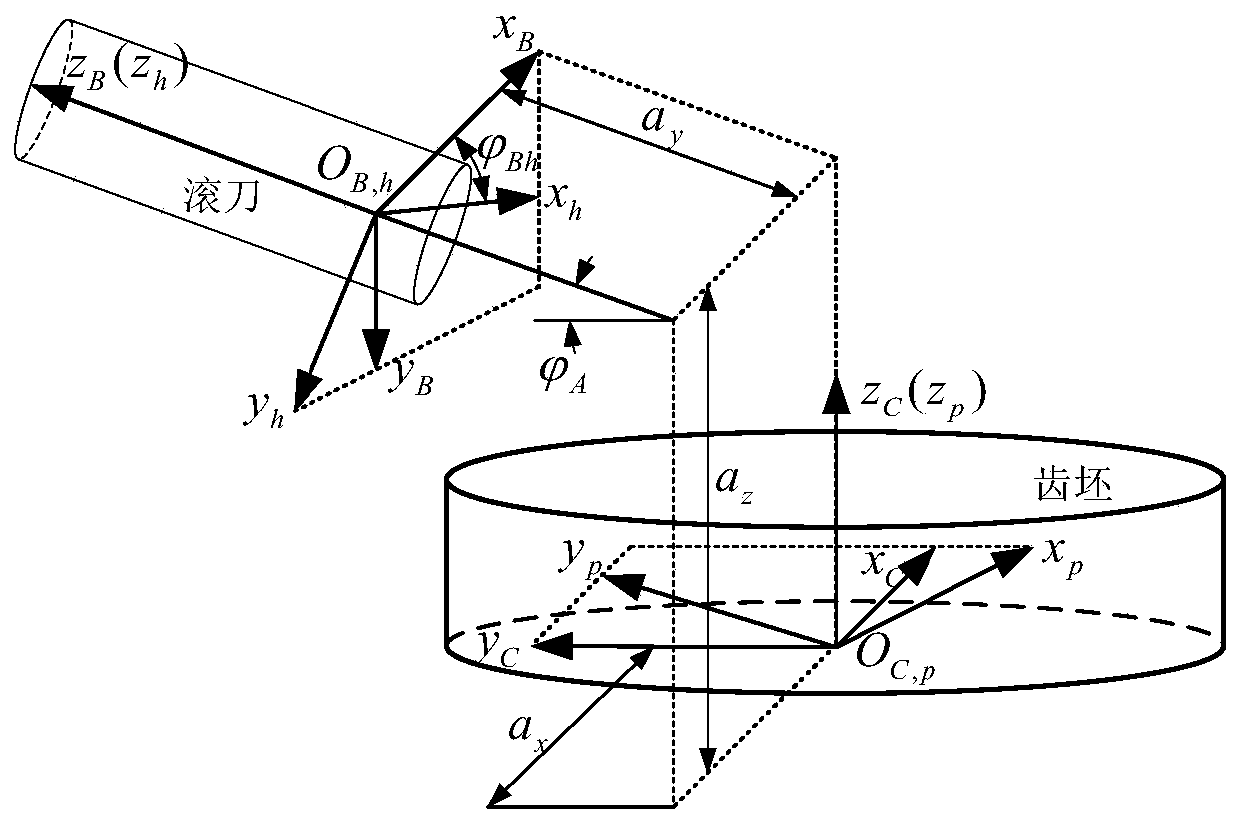

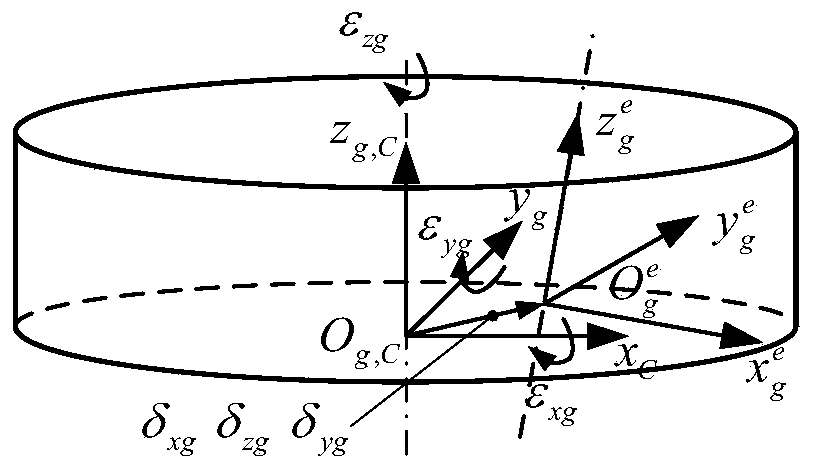

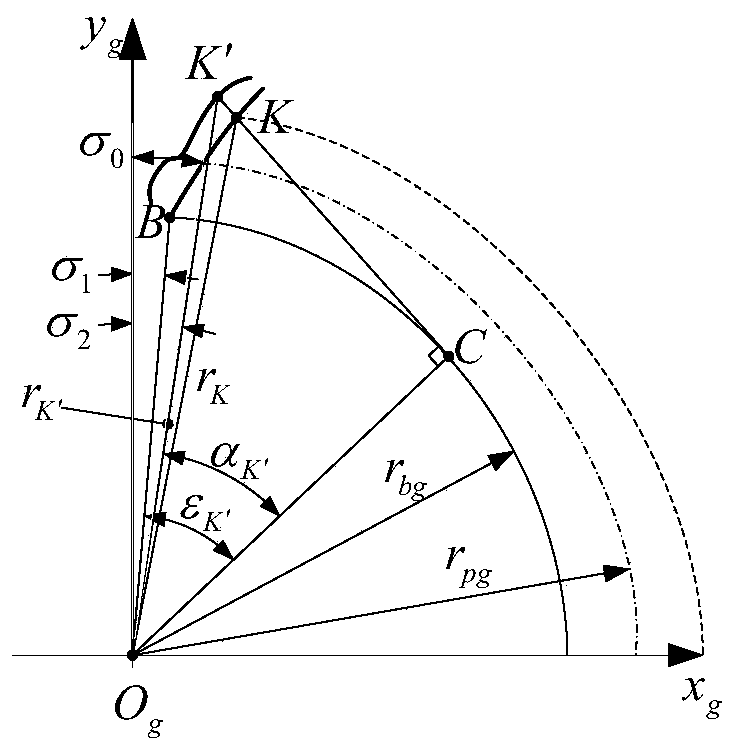

[0178] The hobbing tooth surface error compensation method based on the equivalent transmission chain error calculation provided in this embodiment, this method establishes a hobbing machining error prediction model based on the hobbing double-parameter envelope theory, considers the transmission chain error and the workpiece gear installation error, and predicts Process the tooth shape and pitch errors of gears; then decompose the hobbing process into several end sections, convert each error source into the equivalent eccentricity on the end sections, and reveal the transmission chain error, installation error and tooth surface error The mapping relationship between them; finally, the equivalent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com