Upper tooth pitch measuring instrument for large gear hobbing machine

A technology of gear hobbing machine and measuring instrument, which is applied in the direction of mechanical clearance measurement, etc., which can solve problems such as time-consuming and labor-intensive, affecting production efficiency, and existing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

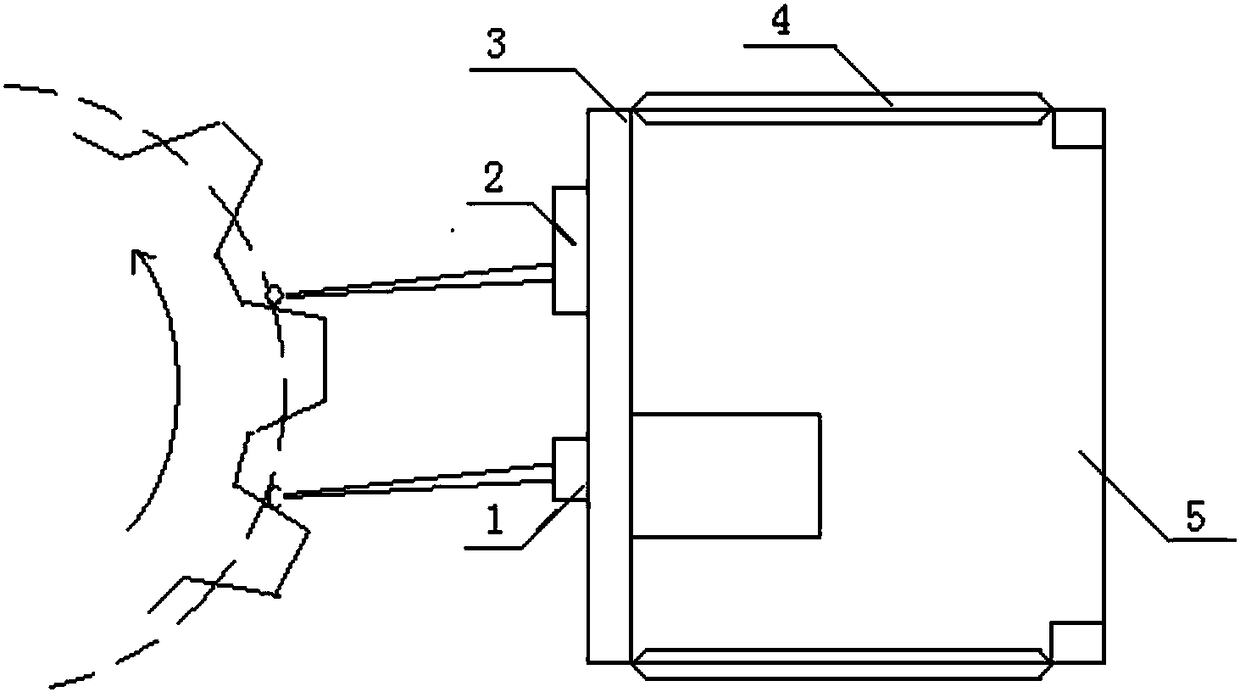

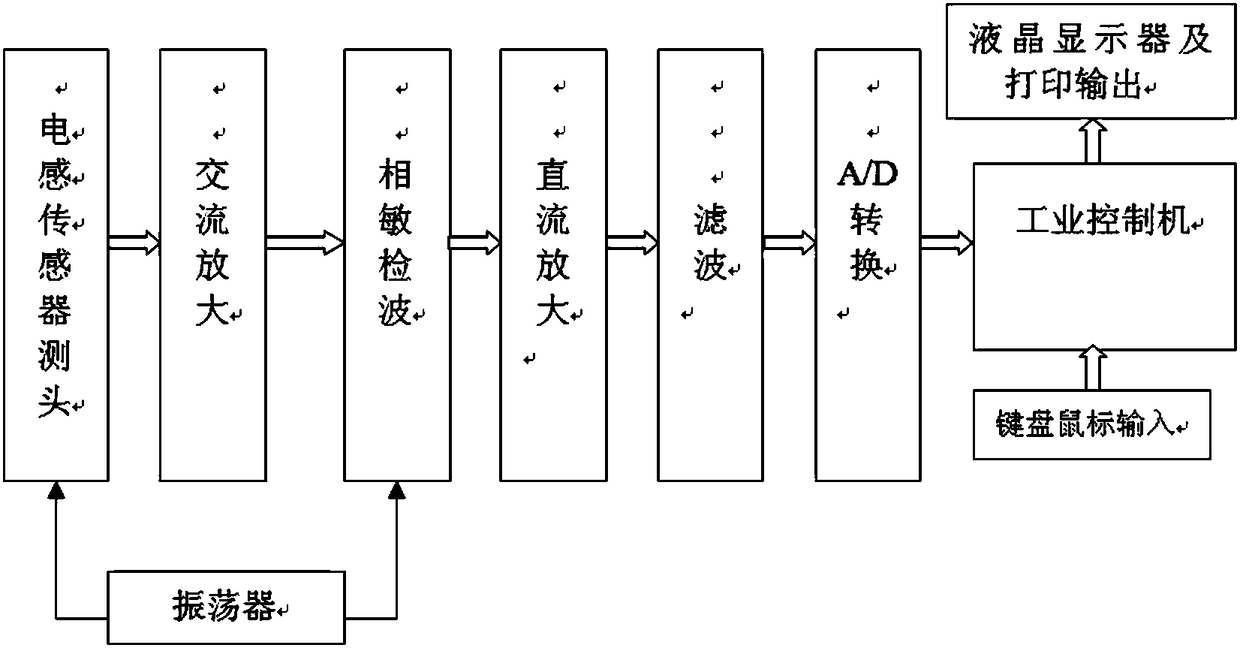

[0031] like figure 1 As shown, the measuring instrument of the present invention realizes the automatic collection of the tooth pitch error data of the measured gear and all the logic actions of the control instrument through the sensor. The sensor is the key of the instrument, and it will directly affect the accuracy of the measurement work. For this reason, this embodiment adopts double probes for measurement, wherein the inductive probe is the reading probe, and the fixed probe is the positioning probe.

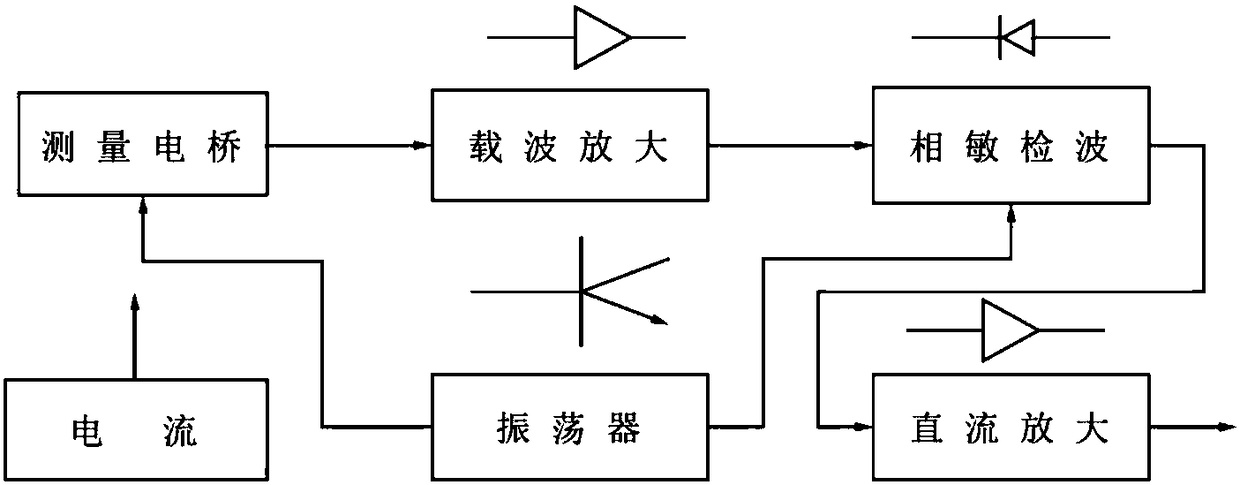

[0032] When the tooth surface of the gear under test touches the two probes, the change in the arc length of the tooth pitch of the gear under test causes the distance between the reading probe and the positioning probe to change accordingly, and is converted into an amplitude modulation signal by the reading probe, and the two probes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com