Method for automatically correcting tracking process of heating furnace

A heating furnace and automatic technology, which is applied in the direction of heat treatment process control, heat treatment furnace, lighting and heating equipment, etc., can solve the problems of increased labor intensity, untimely adjustment, and reduced heating quality of billets, so as to ensure the performance of the final product, improve the Temperature quality, the effect of eliminating the accumulation of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

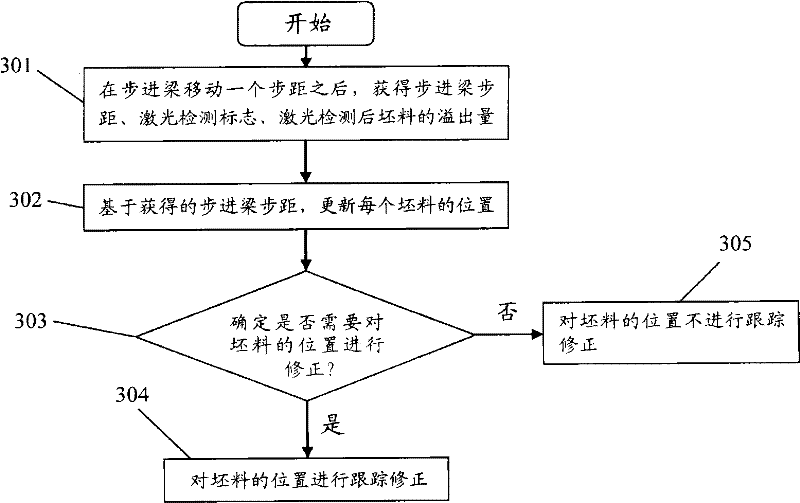

[0012] Embodiments of the invention will now be described in detail, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to like parts throughout. The embodiments are described below in order to explain the present invention by referring to the figures.

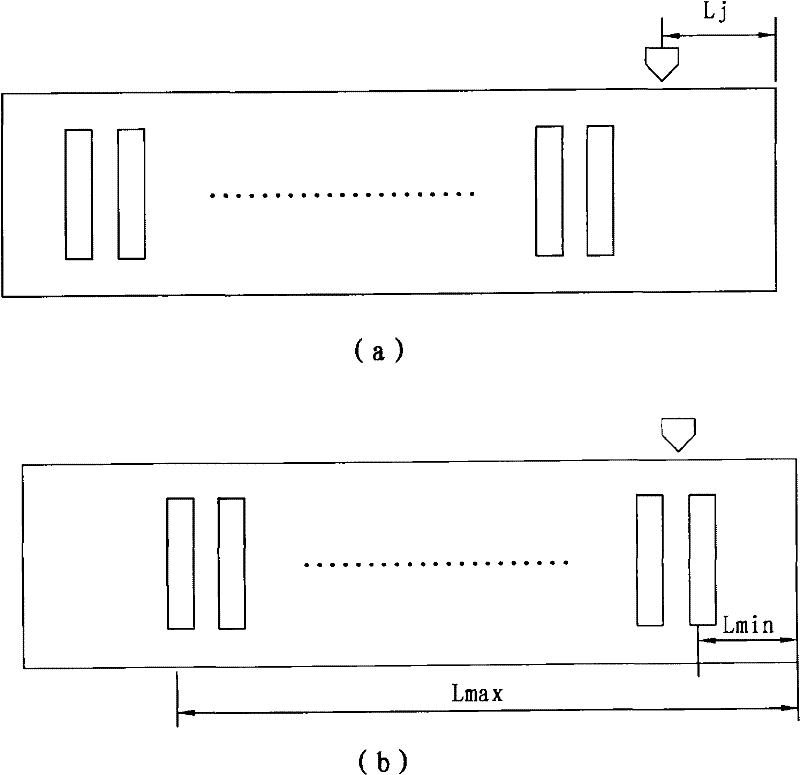

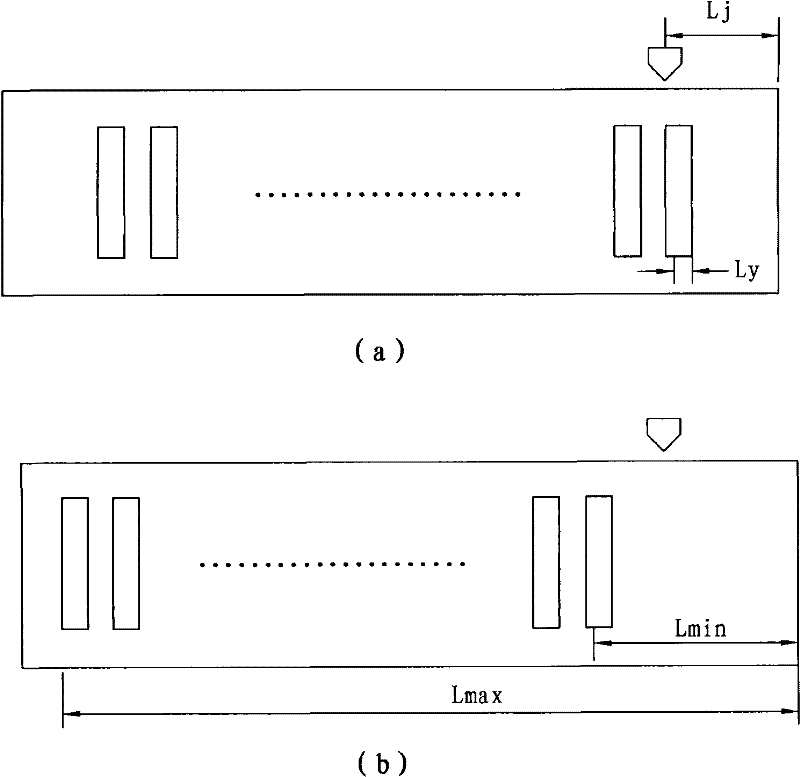

[0013] In the following description, unless otherwise described, the billet position refers to the distance between the billet and the tapping end of the heating furnace.

[0014] There are generally two situations for tracking abnormalities in the heating furnace. refer to figure 1 , one situation is that the actual position of the blank is greater than the theoretical position. That is to say, the positioning laser arranged at the tapping end does not detect the blank (refer to figure 1 (a)), but the results obtained by calculation indicate that the blanks are in place (i.e., at least one blank has passed the positioning laser, cf. figure 1 (b)). In this case, it is nec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com