Industrial robot with self-failure detection function

A technology of industrial robots and self-failure, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as increased workload, prone to major accidents, error accumulation, etc., and achieve the effect of maintaining stability and rapid replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

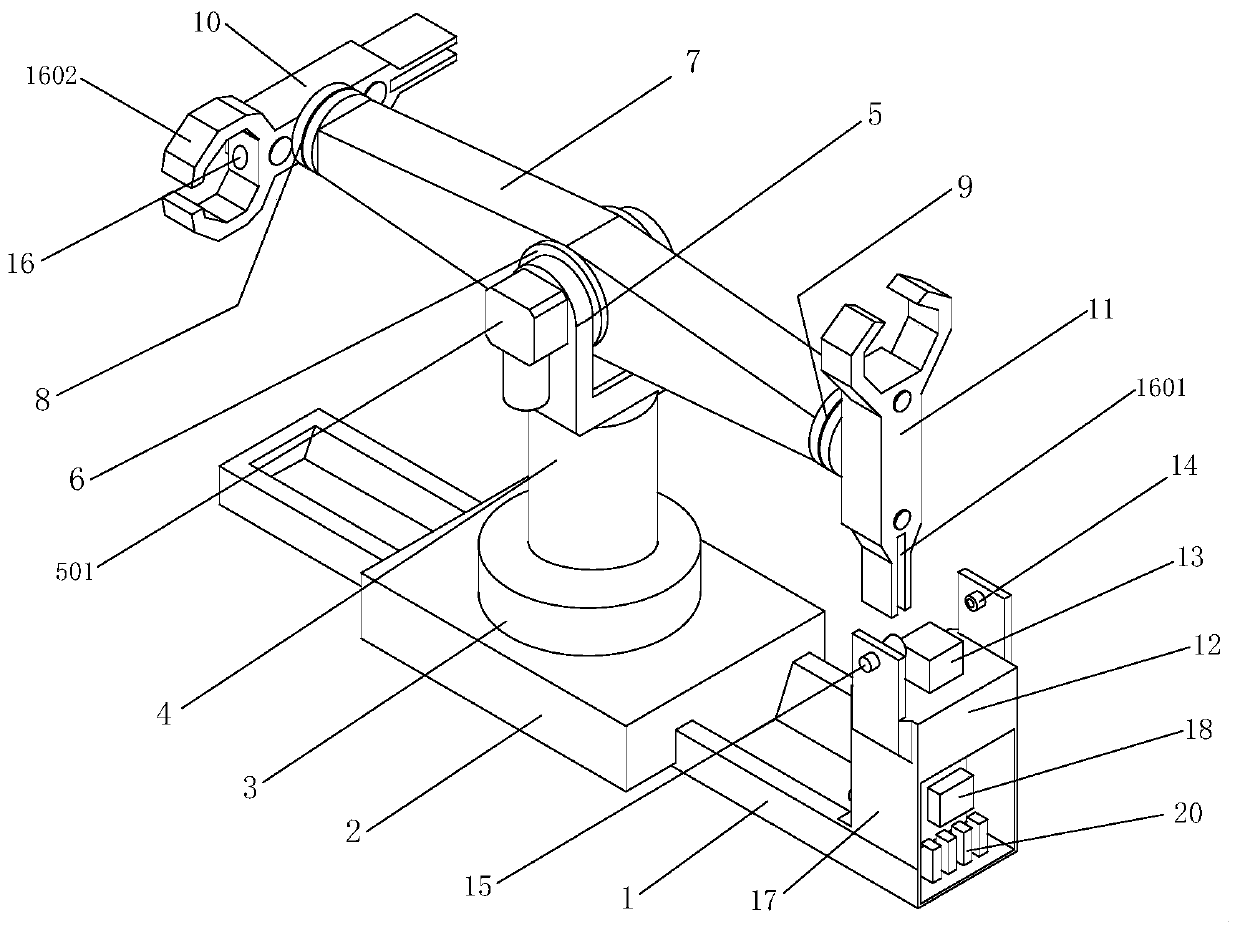

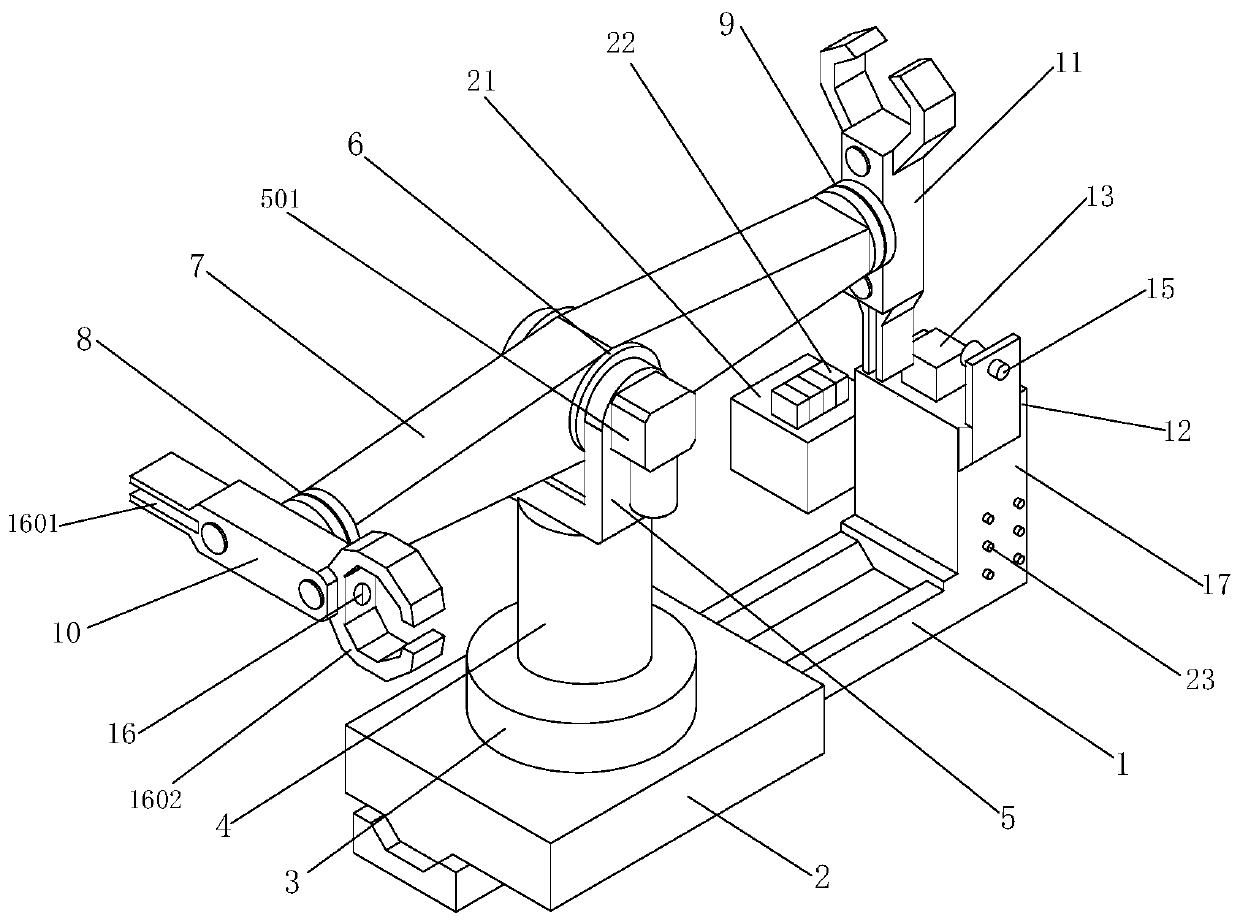

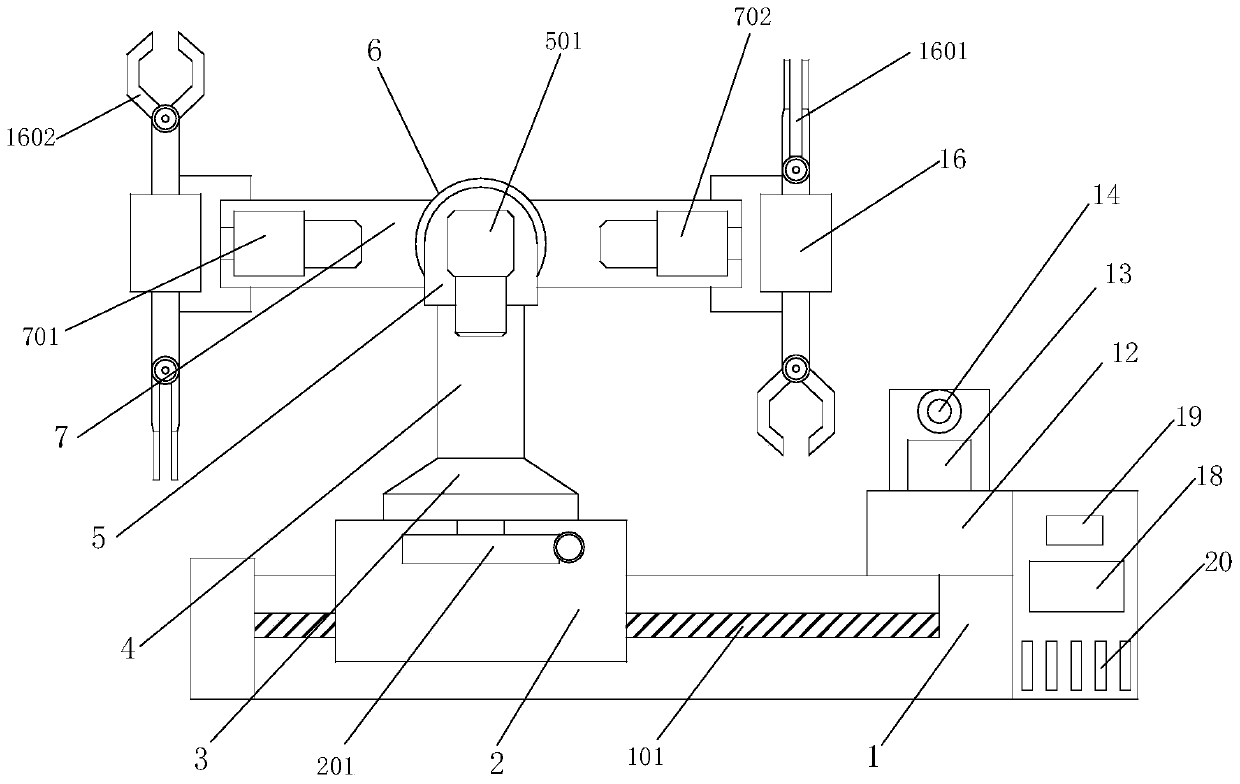

[0037] see Figure 1-5 , the present invention provides the following technical solutions: an industrial robot with its own fault detection function, comprising a fixed base 1 and a horizontal swing arm 7, the top of the fixed base 1 is fitted with a mobile sliding table 2, and the top of the mobile sliding table 2 is fixed A horizontal rotating disc 3 is installed, and the middle part of the top of the horizontal rotating disc 3 is vertically fixed with a column 4, and the top of the column 4 is provided with a grooved support 5, and the grooved support 5 is connected to the horizontal swing arm 7 through the clamping connection plate 6 inside it. In the middle, a first torsion disk 8 and a second torsion disk 9 are symmetrically fixed at both ends of the horizontal swing arm 7, a first working arm 10 is fixed on the first torsion disk 8, and a second working arm 11 is fixed on the second torsion disk 9 One end of the fixed base 1 is the working area, the other end of the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com