Precise multifunctional incremental pressing die and its making process

A multi-functional stamping die technology, applied in manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems affecting the precision and service life of the die, and achieve the effects of convenient maintenance, adjustment and replacement, simple die structure and short manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

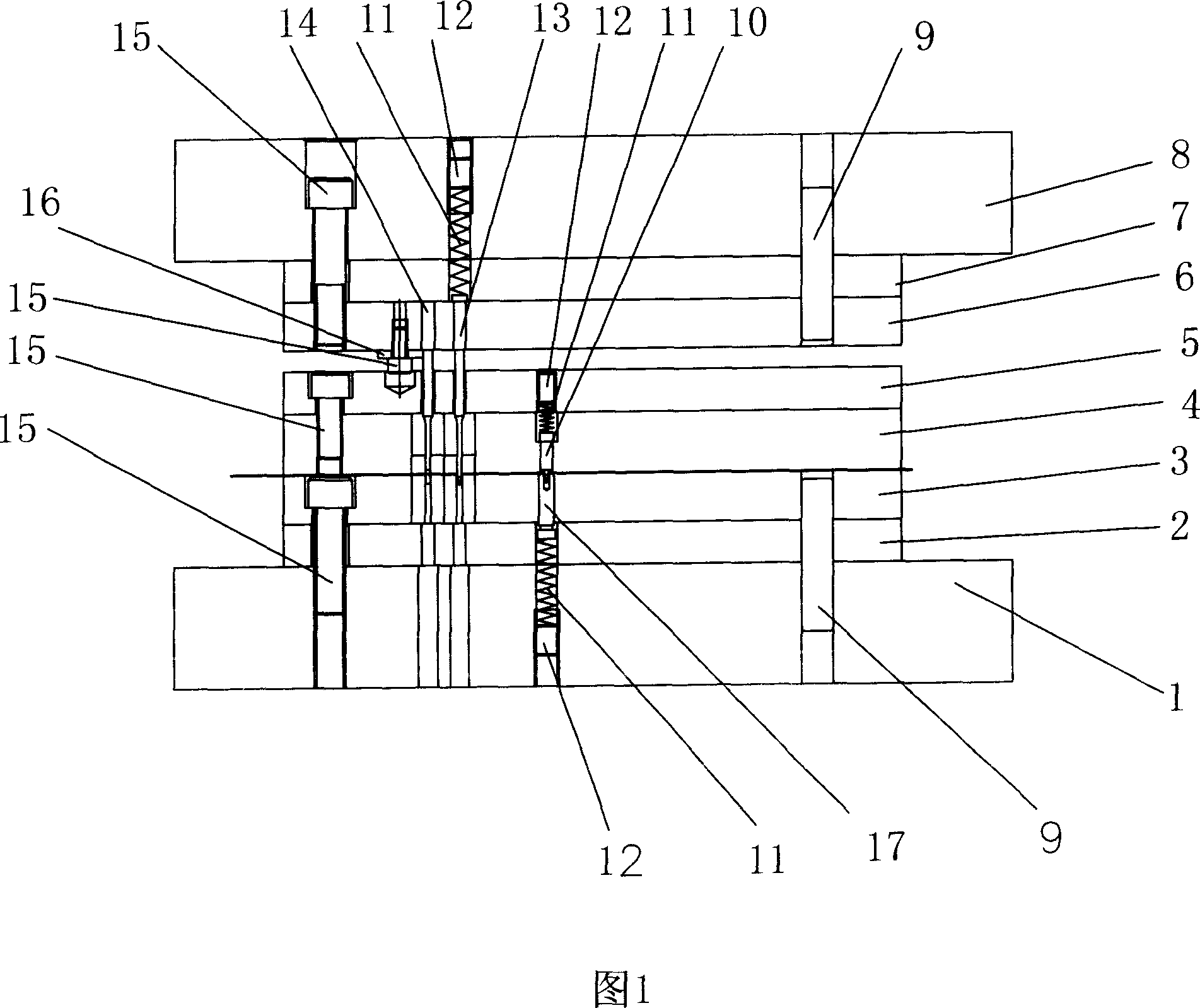

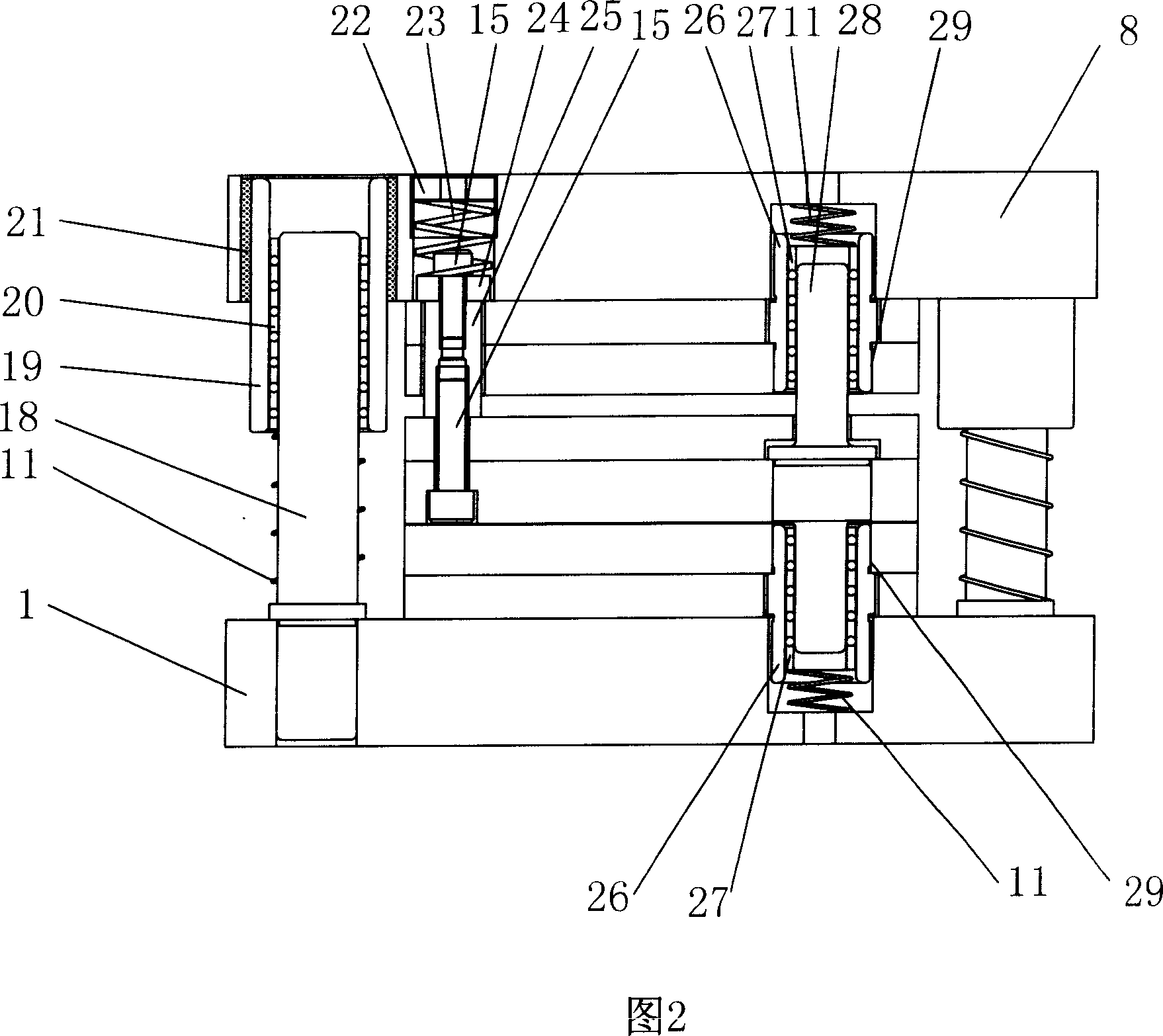

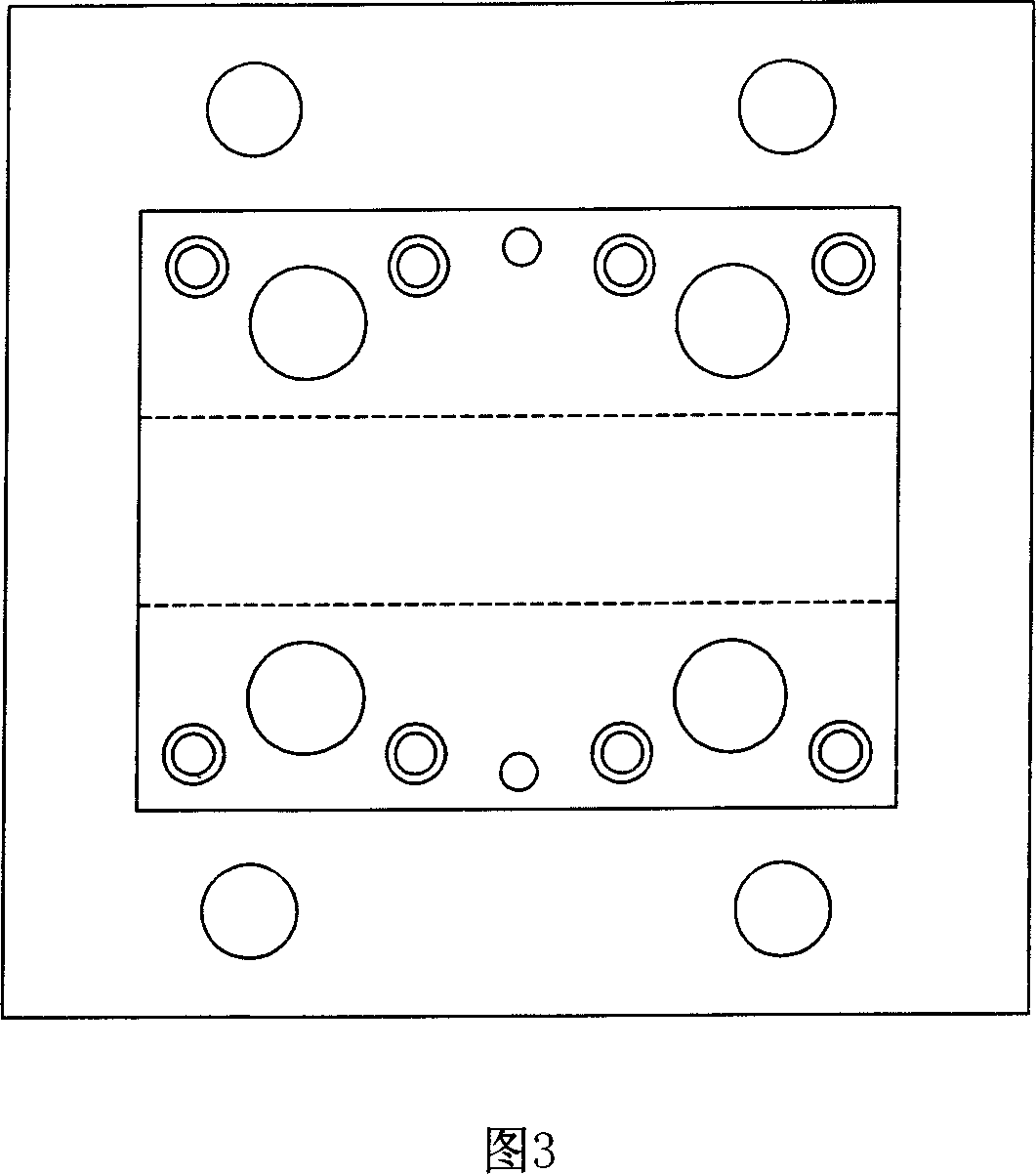

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] As shown in the figure, the main structure of the present invention includes a lower mold base 1, a die backing plate 2, a concave die plate 3, a discharge plate 4, a discharge backing plate 5, a punch fixing plate 6, a punch backing plate 7, an upper Die base 8; In addition, there are inner and outer guide mechanisms, wherein the outer guide mechanism includes a large guide post 18, a large guide sleeve 19, a large ball sleeve 20, and an adhesive 21, and the inner guide mechanism includes a small guide post 28, a small guide sleeve 26, small ball sleeve 27, anaerobic adhesive 29. The connection relationship of the above structure is known.

[0030] Structural features

[0031] 1. The mold is generally composed of eight templates, which are from bottom to top: lower mold base 1, die backing plate 2, concave die plate 3, unloading plate 4, unloading backing plate 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com