Solder ball pump head for laser soldering

A solder ball and laser technology, applied in the direction of tin feeding device, welding equipment, metal processing equipment, etc., can solve problems such as difficult to realize, large frictional resistance, etc., to achieve guaranteed reliability, low manufacturing cost, and reduce random impossibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

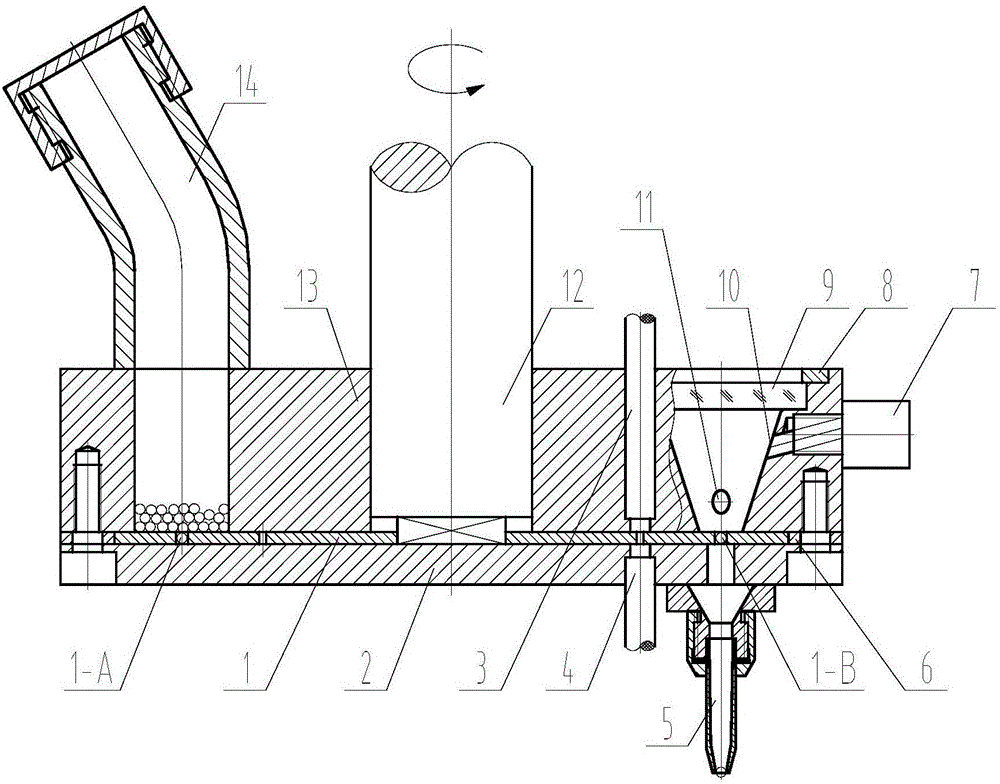

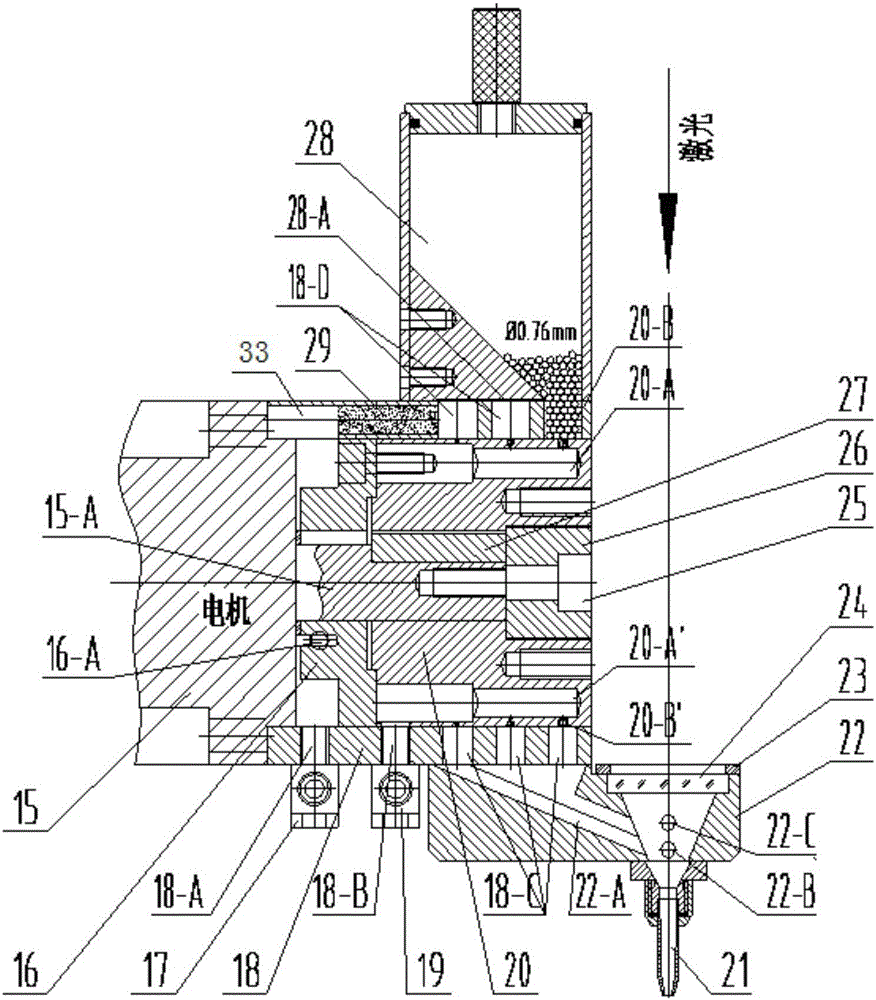

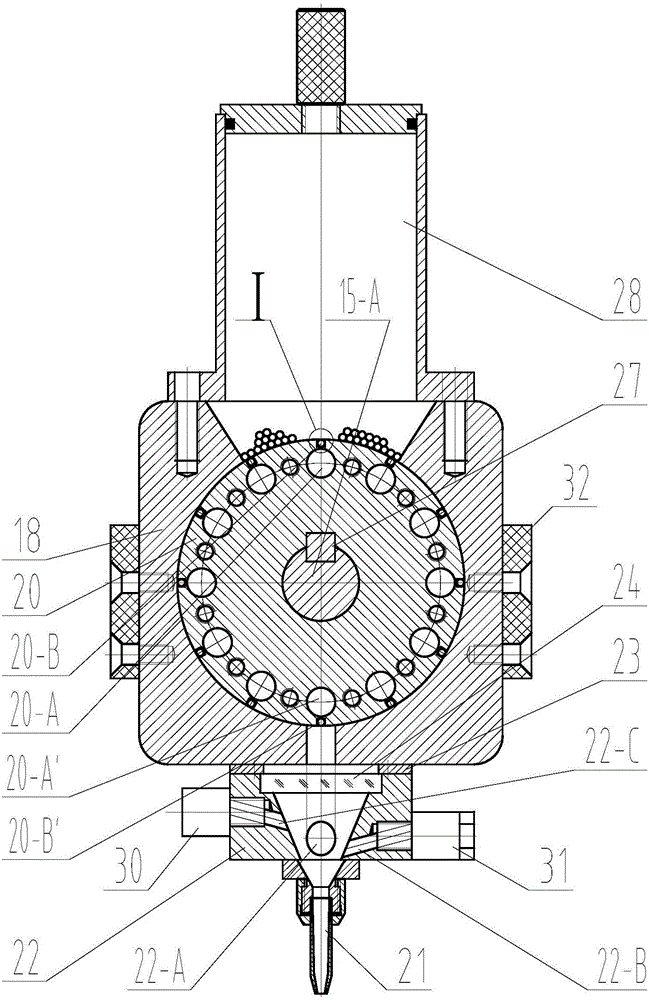

[0040] The technical solutions in the present invention will be clearly and completely described below with reference to the accompanying drawings in the present invention.

[0041] Please refer to Figure 2-4 , the present invention provides a solder ball pump head for laser soldering, the solder ball pump head for laser soldering includes an outer sleeve 18, a solder ball bucket 28 mounted on the outer sleeve 18, The rotor 20 in the sleeve 18 and the motor 15 for driving the rotor 20 to rotate.

[0042] An air gap 28-A whose width is smaller than the diameter of the solder balls and communicates with the inner cavity of the solder ball bucket 28 is provided between the bottom of the solder ball bucket 28 and the outer sleeve 18, and the air gap 28-A is used for introducing protective gas. The air gap 28-A is so arranged to allow the shielding gas to enter the solder ball barrel 28, and to prevent the solder balls in the solder ball barrel 28 from entering the air gap 28-A. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com