Cooling wheel testing device

A test device and wheel technology, applied in wheel testing, etc., can solve problems such as increased tire pressure, tire blowout, and increased cord stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

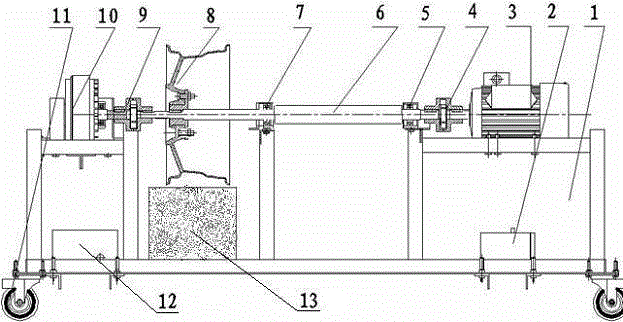

[0030] A cooling wheel test device, comprising a bracket 1, a frequency converter 2, a motor 3, couplings 4, 9, bearings 5, 7, a stepped shaft 6, a torque meter 10, a wheel 11, a load detector 12 and a road condition simulation platform 13;

[0031] The inverter 2 is fixedly installed under the bracket 1;

[0032] The motor 3 and the torque meter 10 are horizontally opposed, fixedly installed on the left and right ends of the bracket 1 respectively, and are on the same axis;

[0033] The stepped shaft 6 includes a small-diameter shaft section and a large-diameter shaft section, supported by two bearings 5 and 7 installed on the bracket 1, and the two ends are respectively connected to the output shaft of the motor 3 and the input shaft of the torque meter 10 through couplings 4 and 9 , the cooling wheel 8 is installed on the small-diameter shaft section for testing;

[0034] The load detector 12 is arranged on the left side of the lower part of the bracket 1; the road cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com