Triaxial pressure high-efficient air cooled heat pump unit applicable to large temperature difference

An air-cooled heat pump, large temperature difference technology, applied in refrigerators, compressors, refrigeration components, etc., can solve the problems of high exhaust temperature, large compressor compression ratio, cooling capacity/heating capacity and energy efficiency ratio. Widening application fields, improving reliability, and ingenious effects of unit design optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

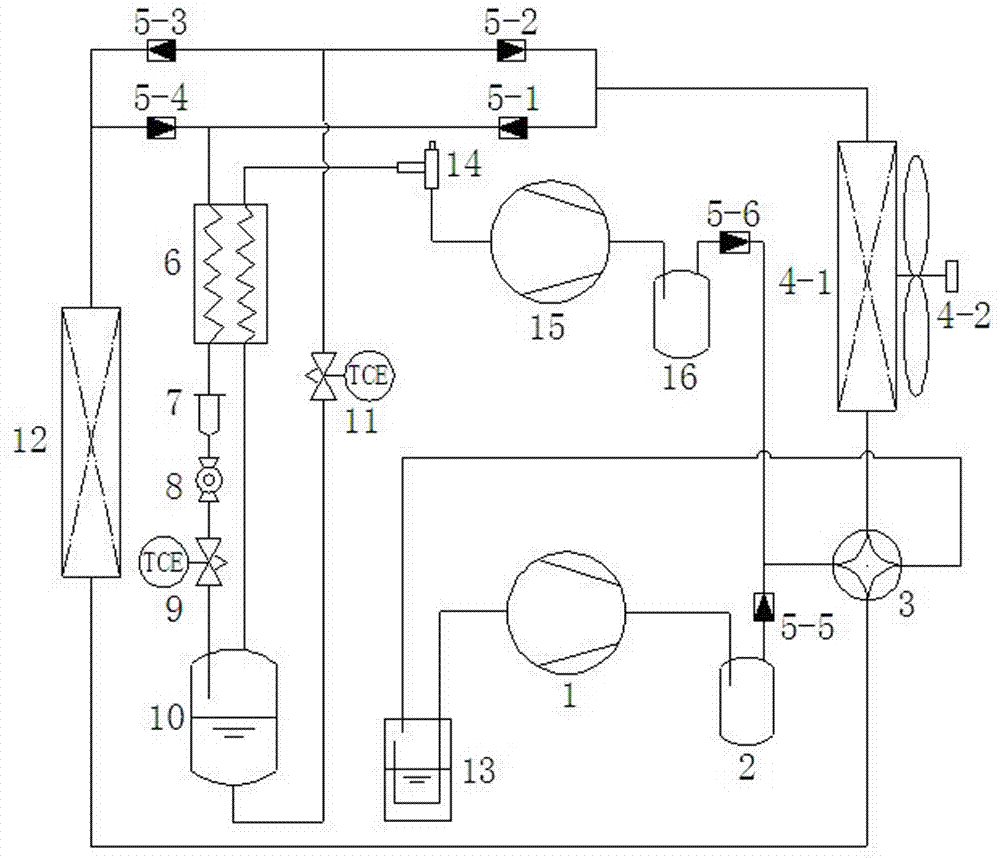

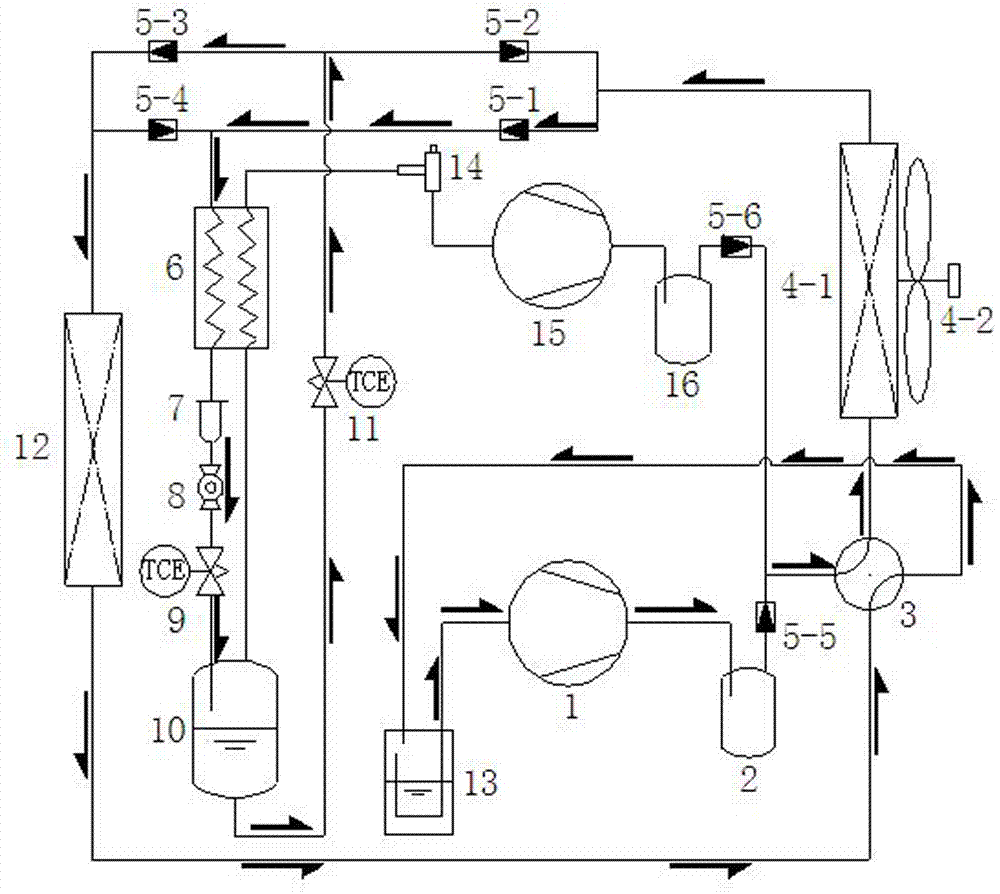

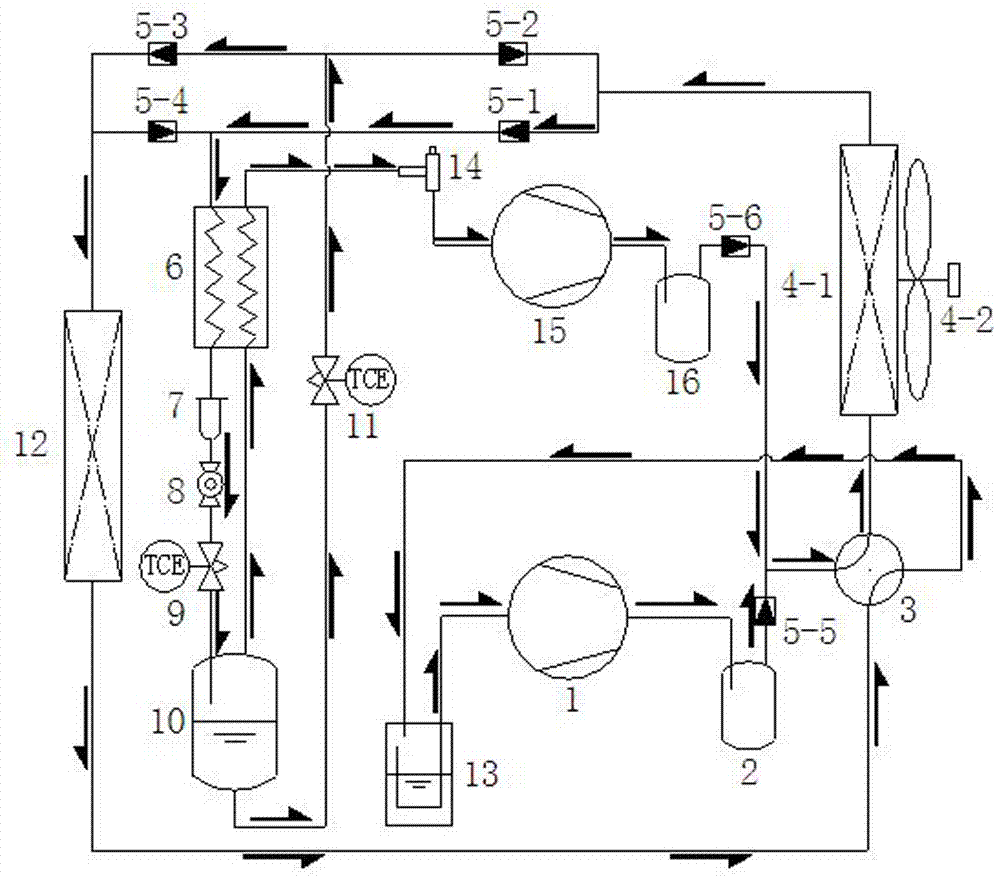

[0023] Such as figure 1 As shown, the present invention provides a three-pressure high-efficiency air-cooled heat pump unit suitable for large temperature differences. Heat exchanger 4-1, outdoor fan 4-2, first check valve 5-1, second check valve 5-2, third check valve 5-3, fourth check valve 5-4, Fifth one-way valve 5-5, sixth one-way valve 5-6, recooler 6, dry filter 7, observation mirror 8, first expansion valve 9, medium pressure gas-liquid separator 10, second expansion valve 11 , Indoor side heat exchanger 12, low-pressure gas-liquid separator 13, evaporation pressure regulator 14, auxiliary circuit compressor 15, auxiliary circuit oil separator 16 and connecting pipelines. The exhaust port of the main road compressor 1 is connected to the inlet of the fifth one-way valve 5-5 through the main road oil separator 2, and the outlet of the fifth one-way valve 5-5 is connected to the sixth one-way valve 5. The outlet of -6 is connected, and the gas outlet after the two are ...

Embodiment 2

[0026]The main circuit compressor 1 of the present invention is a fixed-frequency scroll compressor, and the auxiliary circuit compressor 15 is a fixed-frequency rolling rotor compressor; the indoor heat exchanger 12 is an air-cooled heat exchanger; The outdoor side heat exchanger 4-1 is a finned tube heat exchanger; the outdoor side fan 4-2 is a frequency conversion fan; the first expansion valve 9 is a manual expansion valve, and the second expansion valve 11 It is a blocking expansion valve; the evaporating pressure regulator 14 is a proportional regulator controlled by the pre-valve pressure (ie evaporating pressure); the subcooler 6 is a plate heat exchanger. Other structures are the same as in Embodiment 1.

Embodiment 3

[0028] The main circuit compressor 1 described in the present invention is a fixed-frequency rolling rotor compressor, and the auxiliary circuit compressor 15 is a fixed-frequency scroll compressor; the indoor side heat exchanger 12 is an air-cooled heat exchanger; The outdoor side heat exchanger 4-1 is a laminated heat exchanger; the outdoor side fan 4-2 is a frequency conversion fan; the first expansion valve 9 is a float type expansion valve, and the second expansion valve 11 It is a blocking expansion valve; the evaporating pressure regulator 14 is a proportional-integral regulator controlled by the pre-valve pressure (ie evaporating pressure); the subcooler 6 is a casing heat exchanger. Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com