A Processing Technology of Half-shaft Sleeve

A half-shaft casing and processing technology technology, which is applied in the directions of axles, wheels, transportation and packaging, can solve the problems of low precision, long processing time, and many processing procedures of the half-shaft casing, so as to ensure the coaxiality and consistency. The effect of good strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

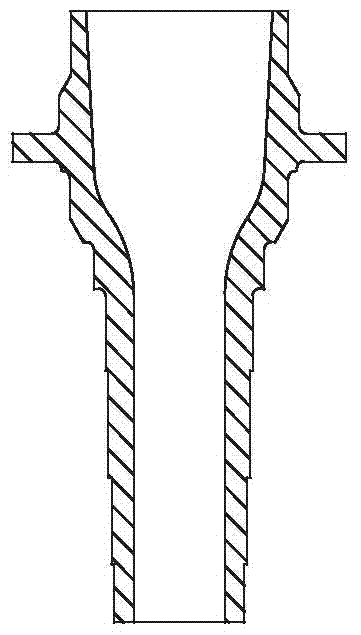

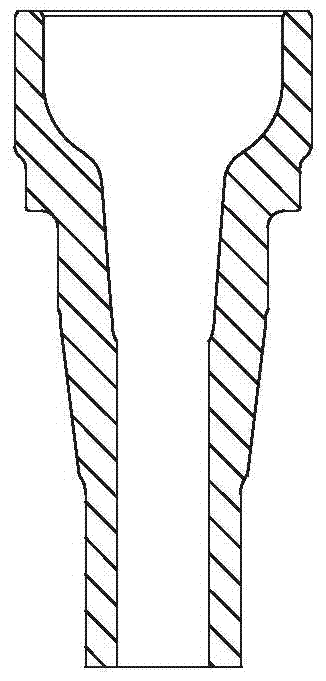

[0048] A kind of processing technology of semi-shaft sleeve, is characterized in that, comprises the following steps:

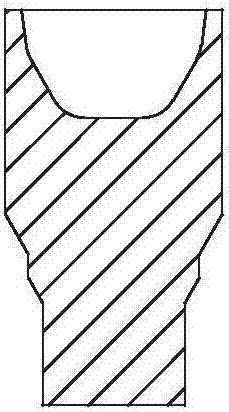

[0049] Step 1. Precision forging of half shaft casing

[0050] 1) Extrusion forming of half shaft sleeve

[0051] ①Material selection process, the extrusion of the half-shaft casing uses hot-rolled round steel made of 45﹟ or 40Cr medium-carbon low-alloy structural steel, and the hot-rolled round steel is selected according to the external dimensions of the half-shaft casing and the requirements of the extrusion forming process. The diameter of the steel, and determine the blanking weight of the process. The diameter of the hot-rolled round steel used for the extrusion of the semi-axle casing of the light truck series is 70 mm to 100 mm, and the blanking weight is 5 kg to 12 kg; The diameter of the hot-rolled round steel used for press forming is 100 mm to 120 mm, and the blanking weight is 12 kg to 20 kg; the hot-rolled round steel that meets the extrusion f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com