Machining method for graphite blade pump rotor and special clamps thereof

A processing method and technology of special fixtures, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems of high rejection rate and poor rotor accuracy, achieve small precision differences, ensure processing accuracy, and interchangeability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the examples and drawings, but the embodiments of the present invention are not limited thereto.

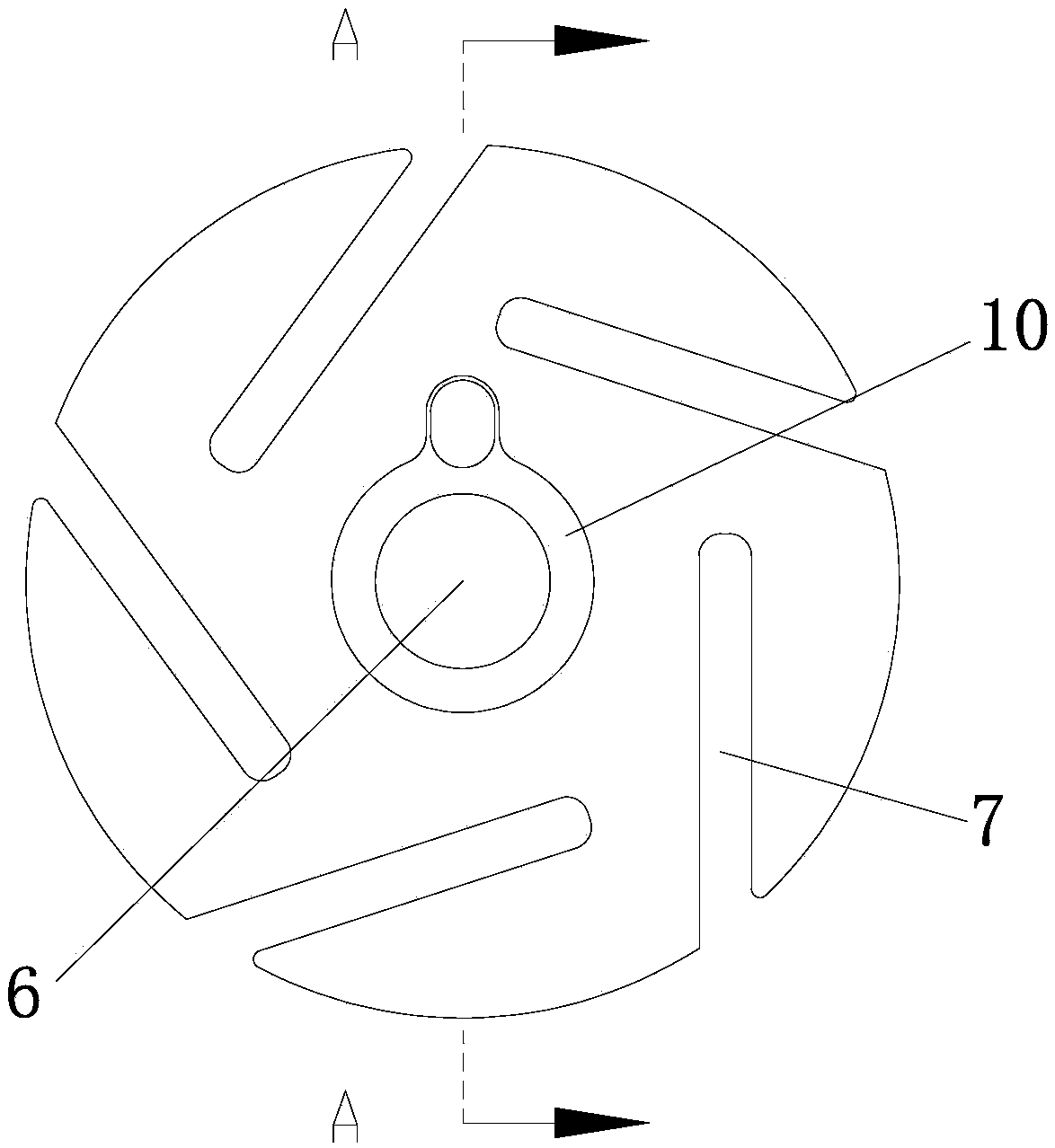

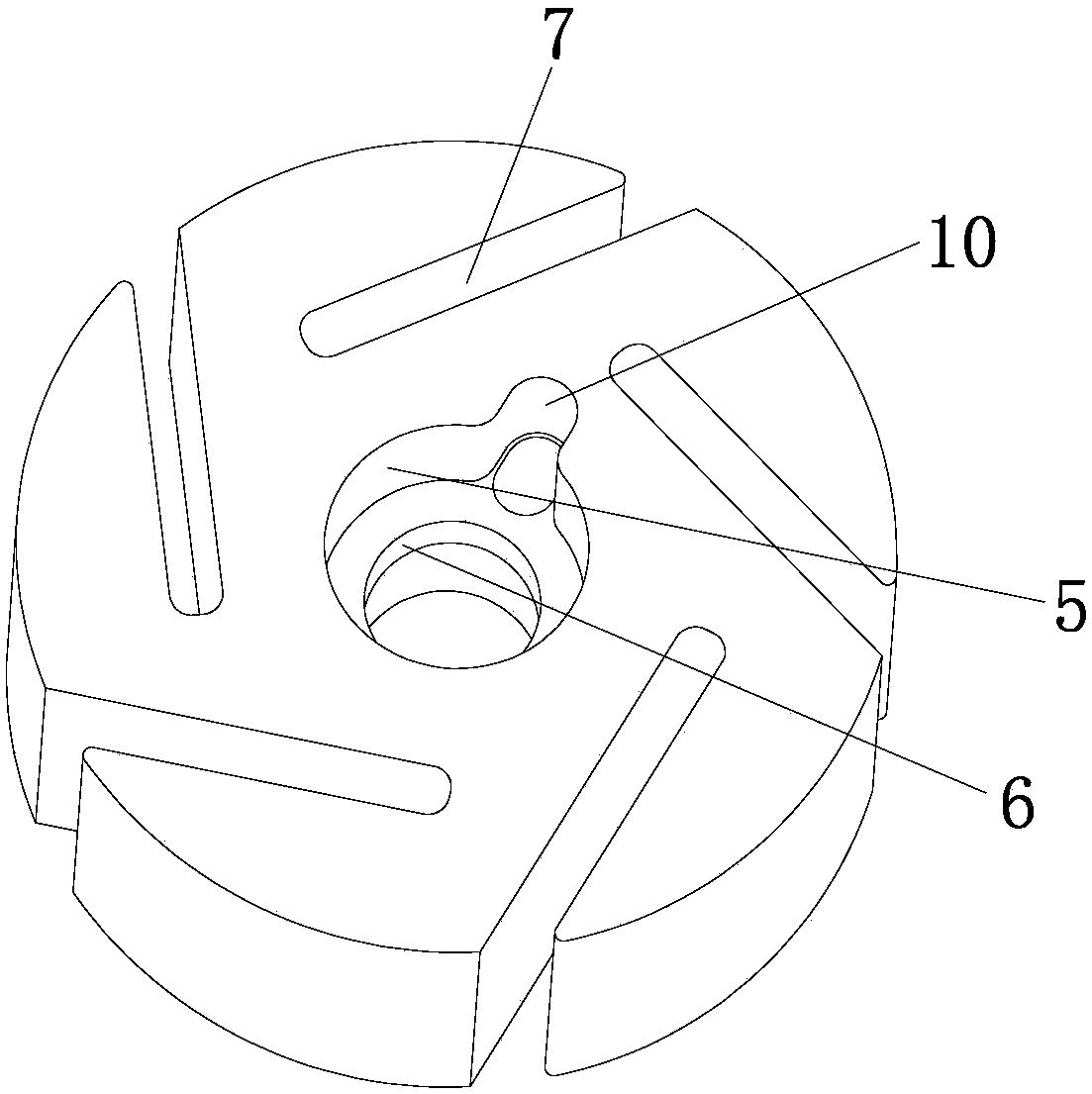

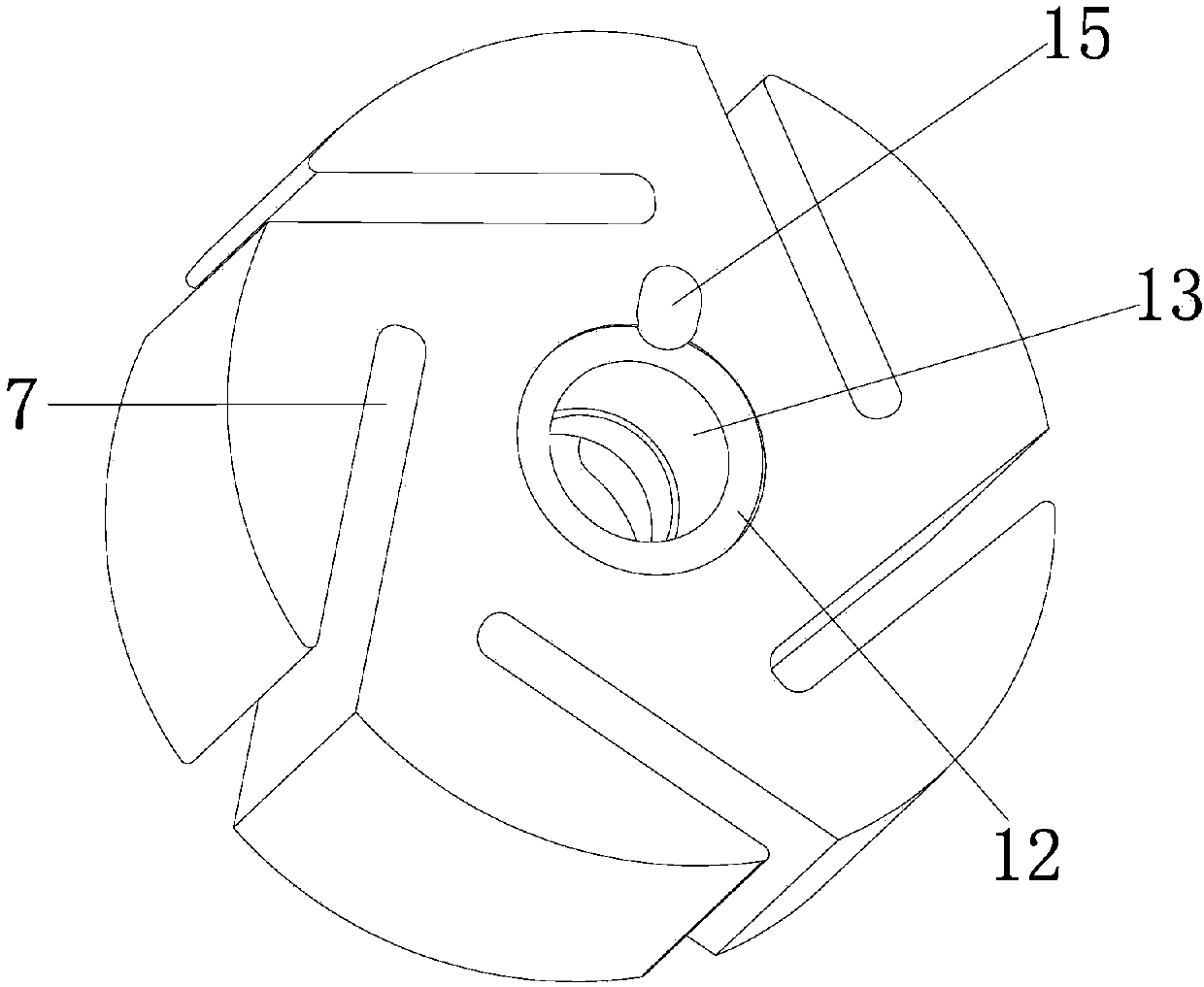

[0056] The processing method of a kind of graphite vane pump rotor in the present embodiment comprises following steps:

[0057] (1) End face milling: Clamp the workpiece on the workbench, first perform rough machining and milling on the first end face 1 of the workpiece, and ensure that the thickness of the workpiece is above 12.2mm, then turn the workpiece over and clamp it, and then Rough milling is carried out on the second end face to ensure that the workpiece is about 12.02 mm in size and ensure the smoothness of the first end face 1 and the second end face 2 . After finishing the rough machining of the milling end face, continue the finishing machining, and carry out finishing milling on the second end face 2, reduce the feed rate during the machining process, and increase the speed of the too...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com