A jig for broaching two small holes of a lifting lug

A lifting lug and fixture technology, applied in the direction of clamping, manufacturing tools, clamping devices, etc., can solve the problems affecting the working accuracy, performance and life of automobiles, large coaxiality error of two small holes, low processing yield, etc. problems, to achieve the effect of less error, improved processing yield, and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the content of the present invention easier to understand clearly, the present invention will be described in further detail below according to specific embodiments and in conjunction with the accompanying drawings.

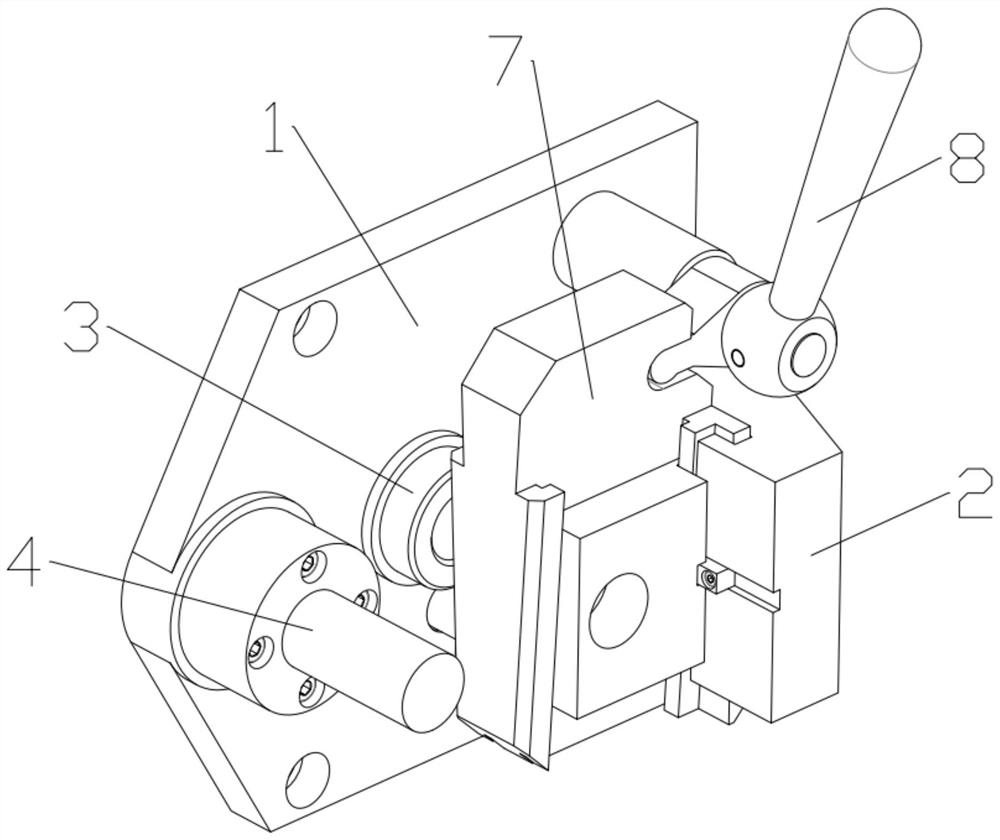

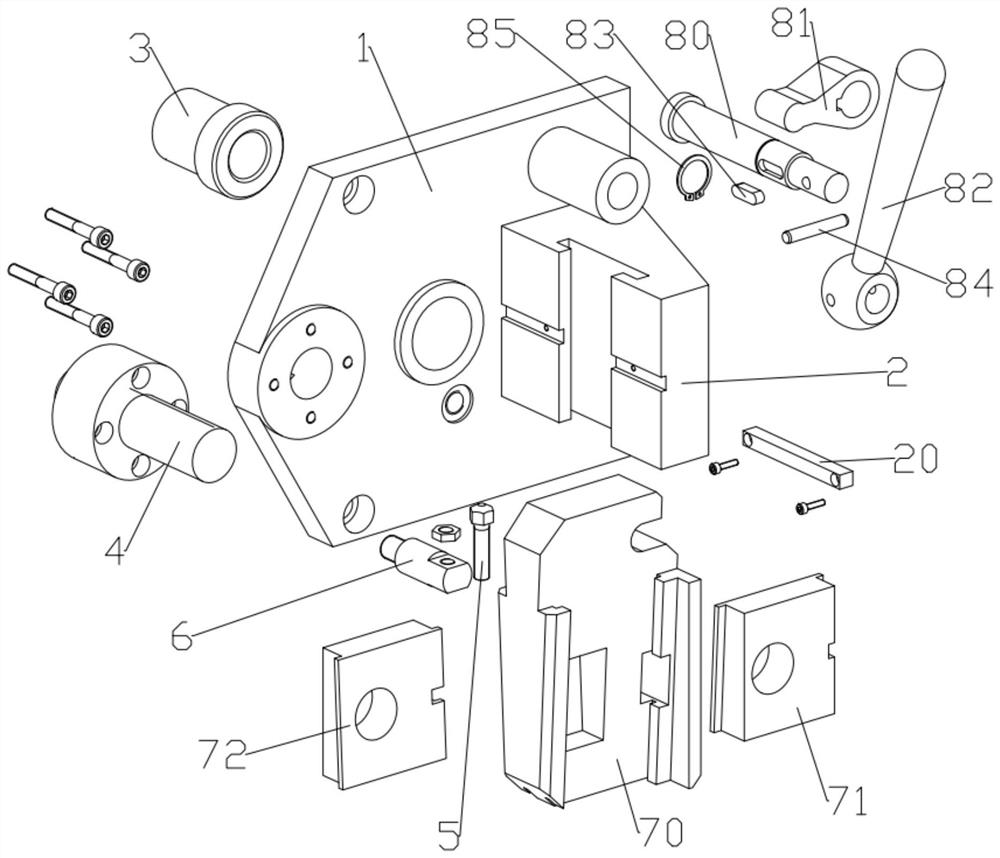

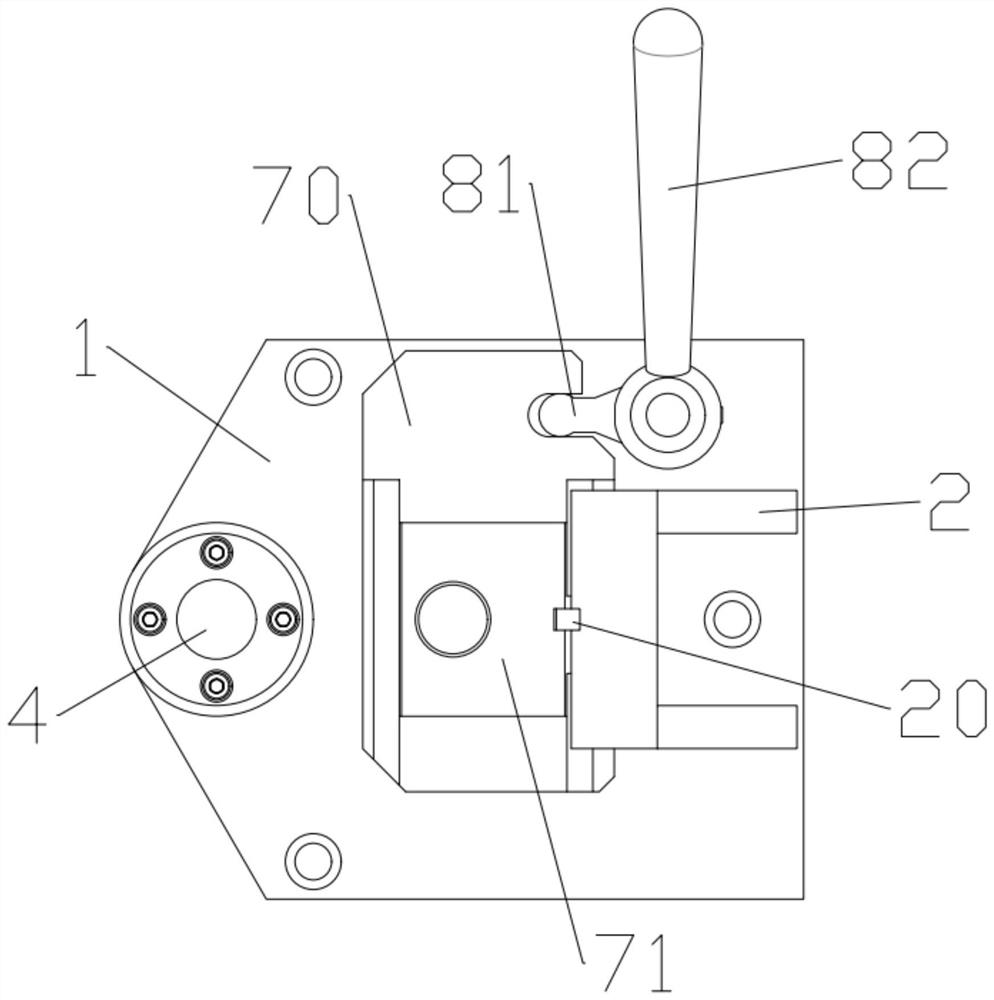

[0031] like Figures 1 to 11 As shown, taking the processing of lifting lug part 1 900 as an example, when broaching the two Φ30mm small holes of the lifting lug part 1 900, the process accuracy requires the dimensional accuracy of the Φ30mm hole to be (0~+0.045mm), and the same The axiality requirement is that the coaxiality tolerance of the two Φ30mm small holes is Φ0.01mm, and the machining error of the existing fixtures is relatively large.

[0032] Therefore, this embodiment provides a clamp for broaching two small holes of a lifting lug, which is composed of a clamp body 1, a trapezoidal support block 2, a positioning sleeve 3, a pre-positioning device, a wedge block combination mechanism 7 and a manual adjustment mechanism 8. The tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com