High-efficiency axial flow and screw combined pump for ship

A technology of axial flow pump and screw pump, which is applied in the construction field of marine high-efficiency axial flow and screw optimized combination pump, and can solve the problems of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

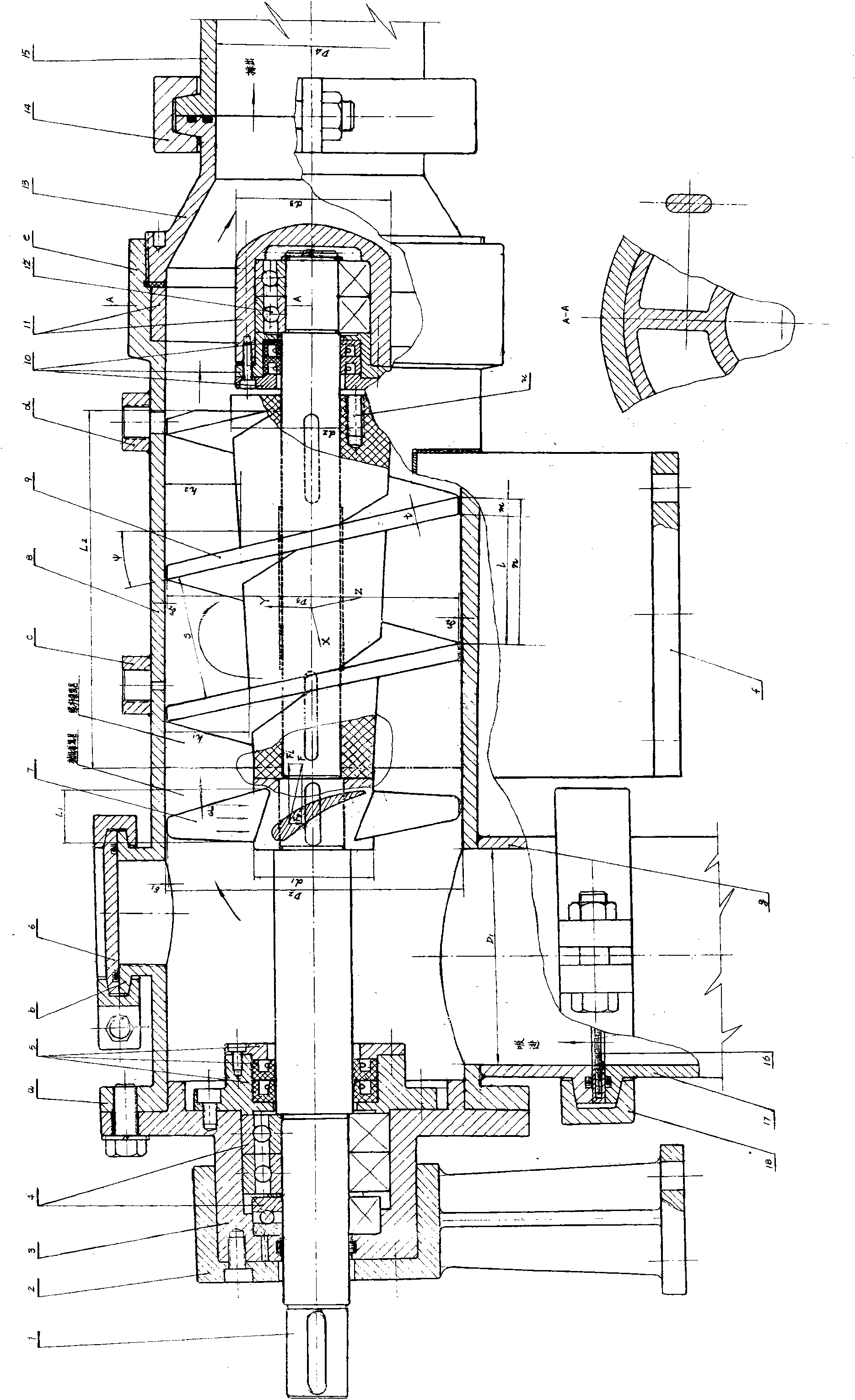

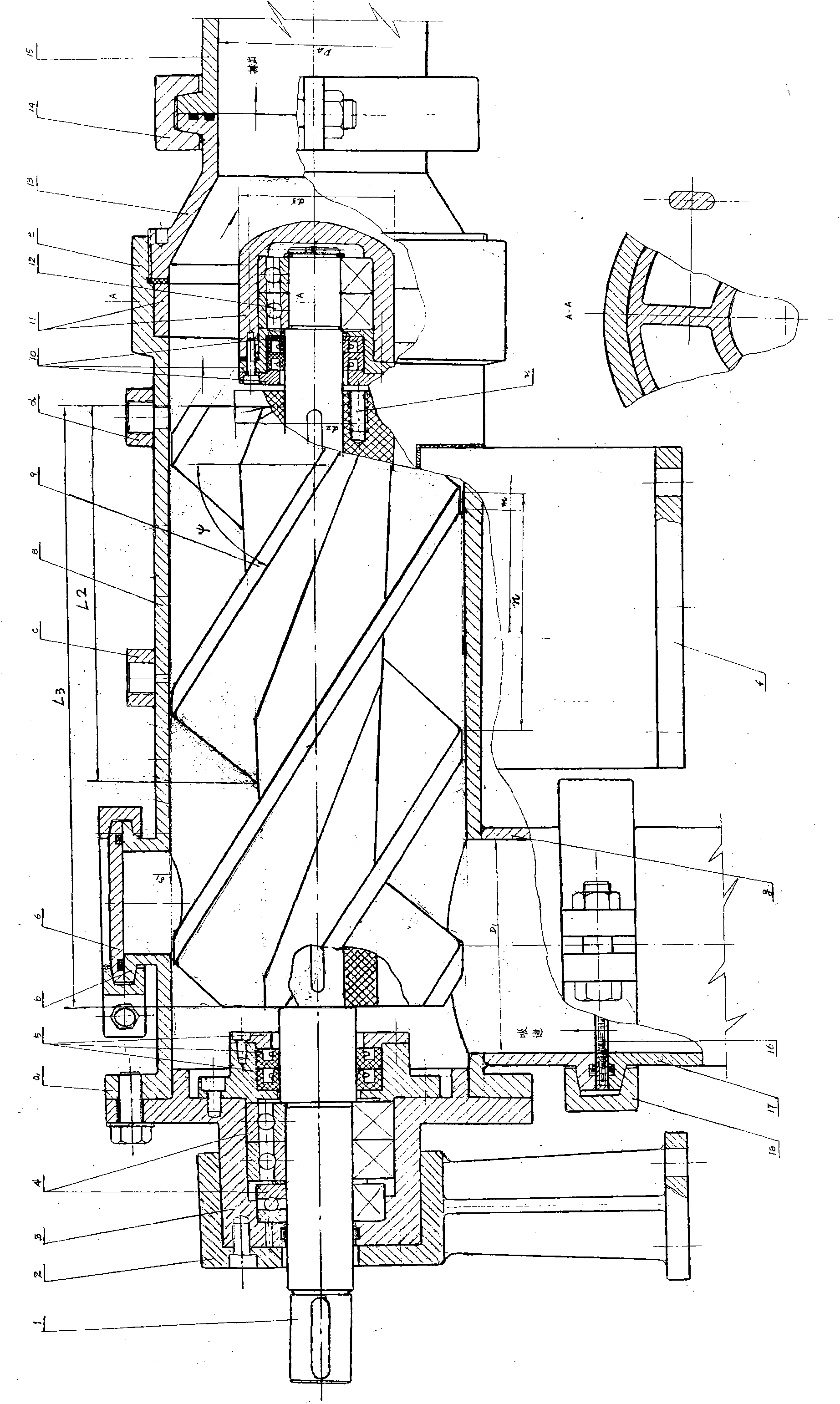

[0032] The optimal combination of two different pumps should be distinguished in the implementation. The screw pump is the main one and the axial flow pump is the second. That is, the working parameters of the screw pump will determine the characteristic parameters of the pump, such as: flow, pressure, power, efficiency, etc.; For the axial flow pump, the flow rate is only required to be slightly larger than that of the screw pump by about 10%, so that the water can obtain initial kinetic energy, and the pressure is not demanding. Because, the screw pump has enough capacity to pressurize. It is not difficult to implement after establishing this leading idea.

[0033] Today's combination figure 1 , to determine the parameters of the screw pump test pump: the thread is selected as a single head, and the outer diameter of the thread is D 3 =160mm, thread lead n=80mm, thread width m=8mm, thread effective working length L 2 =`200mm, the root diameter d at the thread entrance=65m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com