Diamond fly-cutter milling method for micro grooves in ferrous metal material base

A diamond flying knife and milling processing technology, which is applied in the field of mechanical processing, can solve the problems of reduced micro-groove shape accuracy and difficulty in realization, and achieve the effect of suppressing rapid diffusion wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

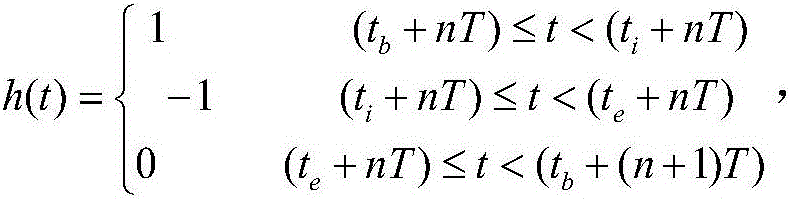

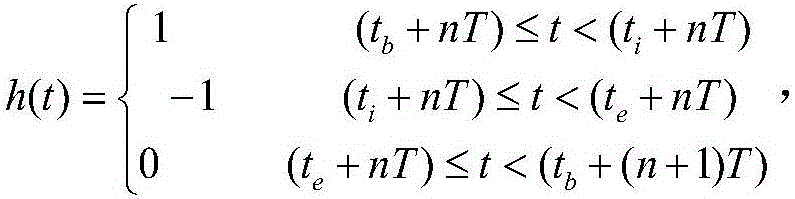

[0032] The concrete steps of the diamond flying cutter milling process method of micro-groove on the black metal material substrate of the present invention are as follows: (1) diamond flying cutter cutter bar is connected to each other with two-dimensional ultrasonic elliptical vibration transducer by screw thread; (2) has A sine wave voltage of 80 volts is applied to the two-dimensional ultrasonic elliptical vibration transducer at the same time, and the two-dimensional ultrasonic elliptical vibration transducer generates ultrasonic vibrations in two directions perpendicular to each other, and synthesizes ultrasonic elliptical vibrations at its output; (3 ) The diamond flying knife holder is designed into a cylindrical stepped shape, so that the two-dimensional elliptical vibration generated by the ultrasonic elliptical vibration transducer can be further increased, reaching a major axis: 10 μm, a minor axis: 5 μm, an included angle: 45°, and a resonance frequency: Ultrasonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com