Grinding wheel guide, production line, and manufacturing method involved in manufacturing central core of secondary battery

A technology for secondary batteries and guides, which is applied in secondary battery manufacturing, manufacturing tools, and final product manufacturing, and can solve problems such as protrusions and breakage of separators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Next, embodiments of the present invention will be described in detail with reference to the drawings as appropriate. However, the present invention is not limited to the following embodiments.

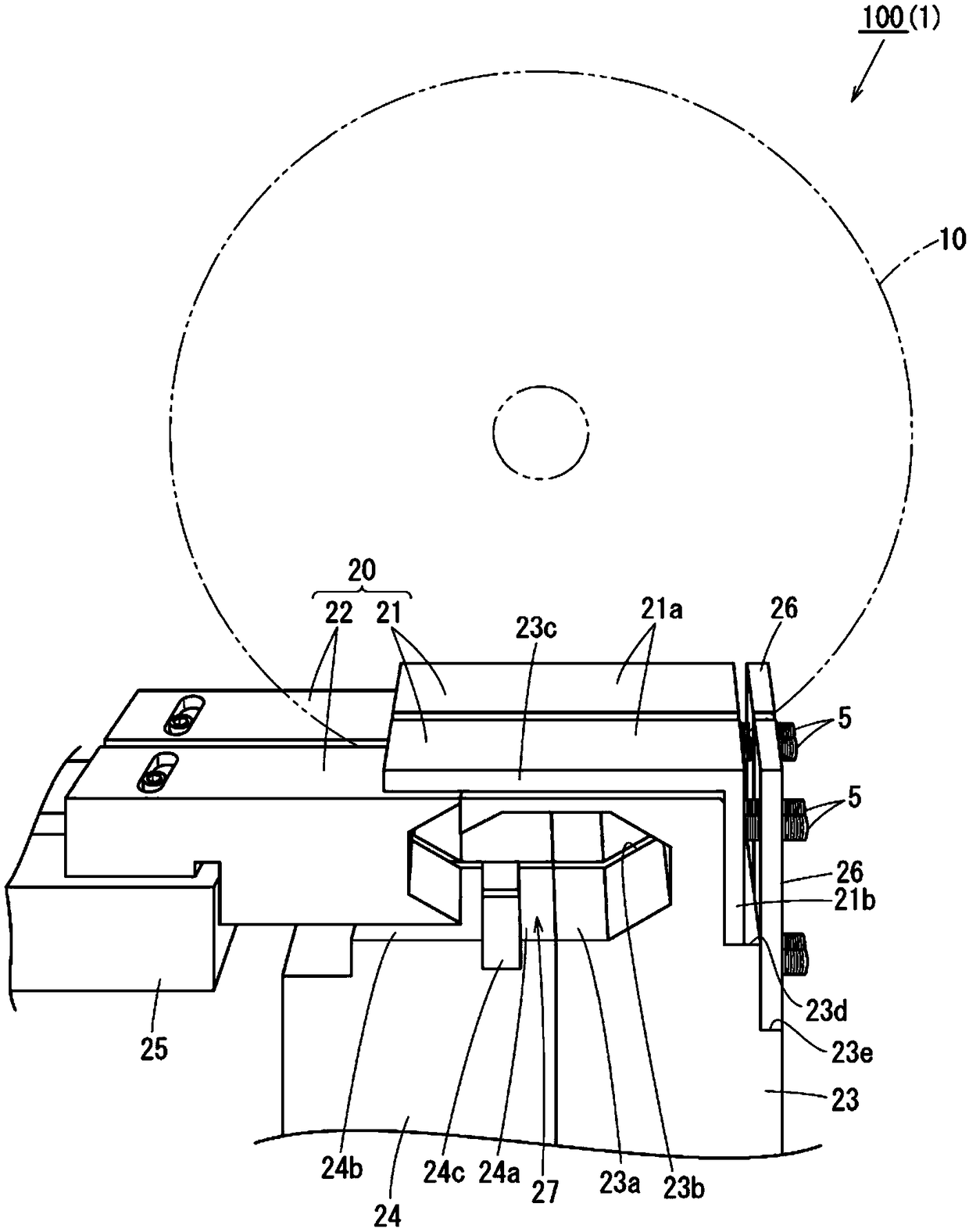

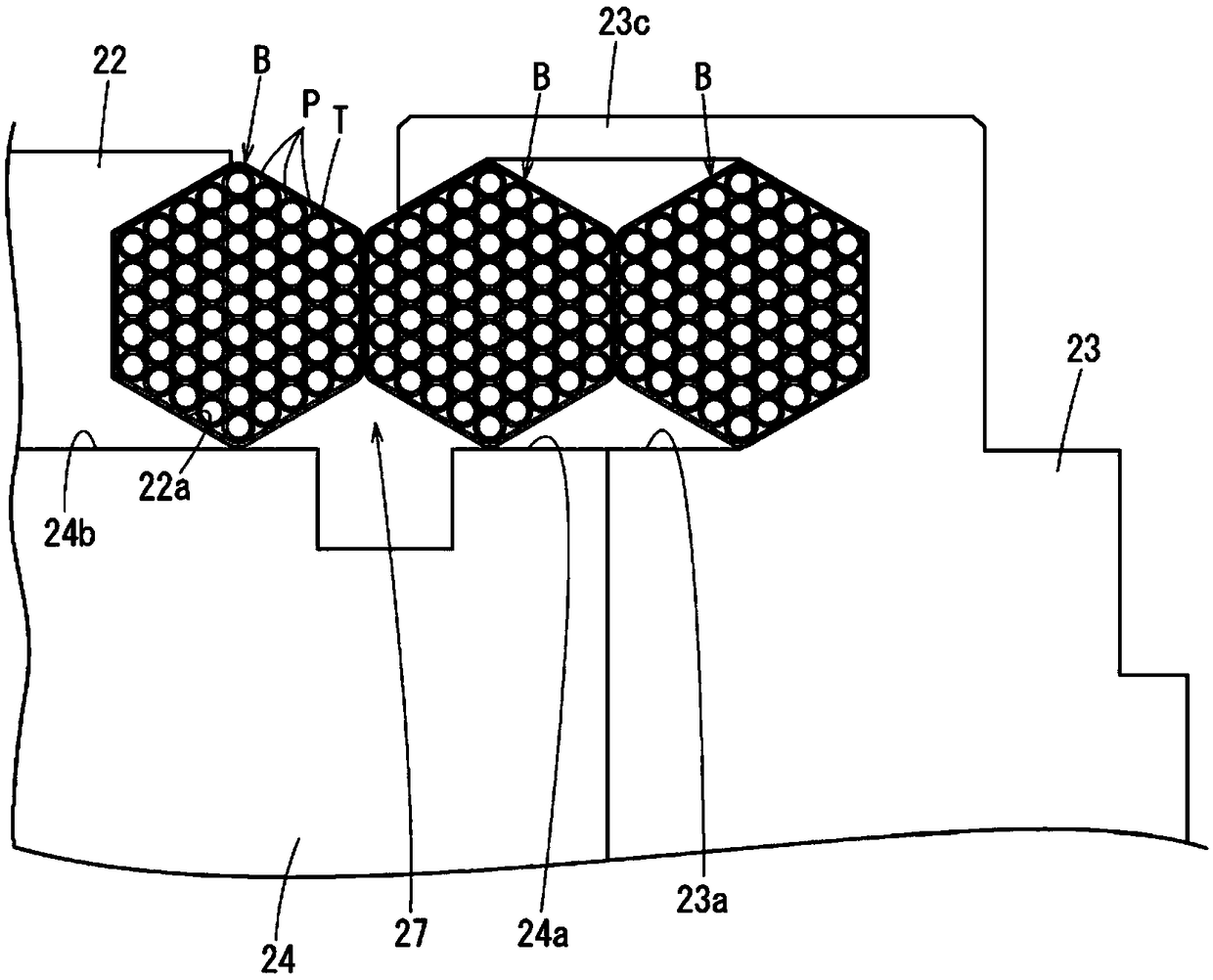

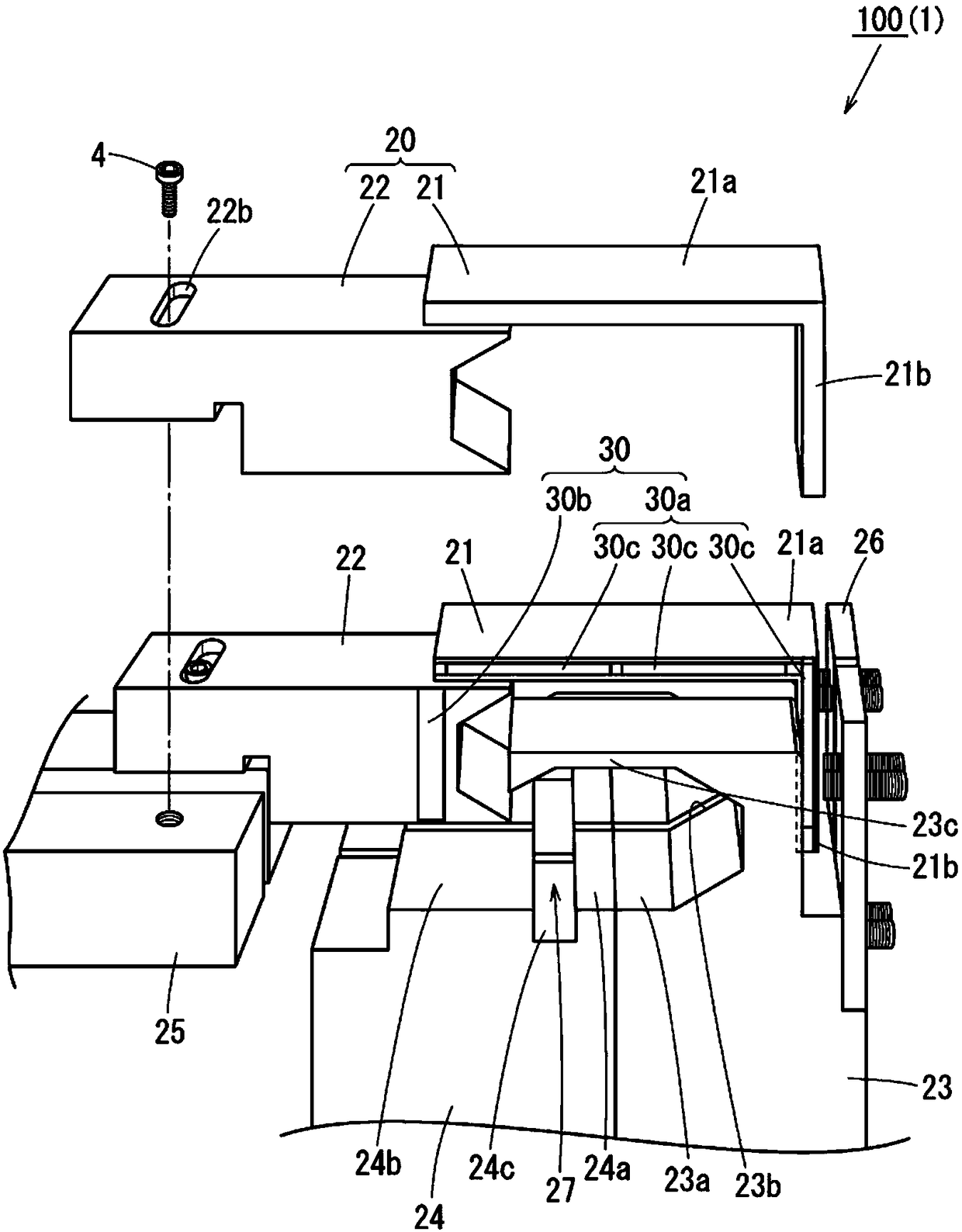

[0038] figure 1 The cutting device 100 of the production line 1 of the central core body C of the lithium ion secondary battery according to one embodiment of the present invention is shown, Figure 9 The noodle beveling device 200 in the production line 1 is shown (the overall view of the production line 1 is not shown). Line 1 is used to manufacture Figure 11 A tubular central core C as shown.

[0039] In addition, in figure 1 , image 3 , Figure 9 In , symbols 100 ( 1 ) and 200 ( 1 ) indicate that both the cutting device 100 and the noodle beveling device 200 are included in the production line 1 .

[0040] Such as figure 2 As shown, the cutting device 100 is used to cut the raw material pipe P to form a workpiece pipe (not shown) A of a predetermined length, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com