Non-resonant three-dimensional elliptical diamond fly-cutting optical free curved surface method and special device

A diamond, non-resonant technology, used in metal processing equipment, turning equipment, turning equipment and other directions, can solve the problems of increased cutting speed, crosstalk, difficult adjustment of ellipse plane orientation, etc., to suppress the influence of processing quality and improve the accuracy of reciprocating motion , avoid distorted or distorted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Without loss of generality, the transient position of the workpiece-blade contact point can be written as:

[0027]

[0028] In the formula, x, y and z are the Cartesian coordinates of the tool-workpiece relative position; a x 、a y and a z are the vibration amplitudes in the x, y and z directions, respectively; and are the phase shifts in the x-direction, y-direction and z-direction respectively; ω is the vibration frequency; t is the time variable; x s (t) is the linear feed of the X axis; z s (t) is the reciprocating linear feed motion of the Z axis.

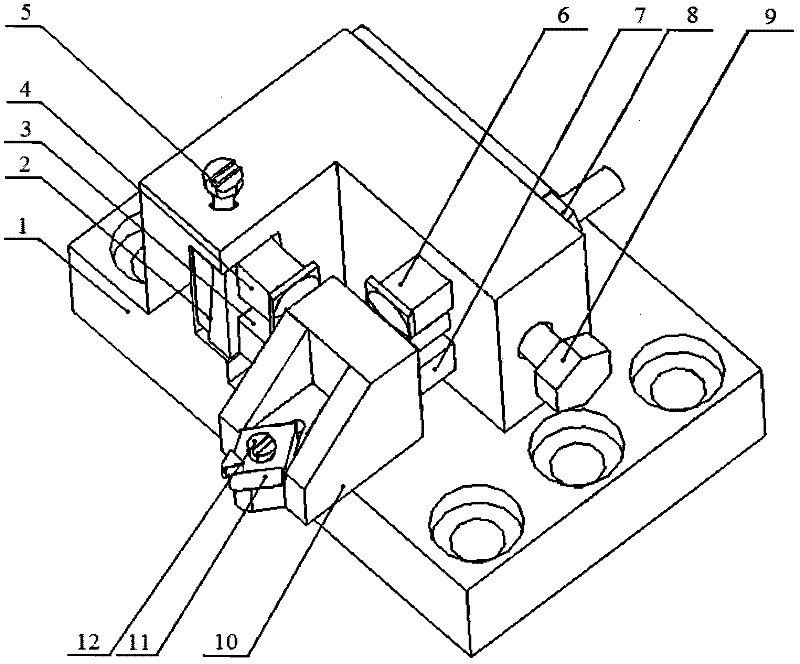

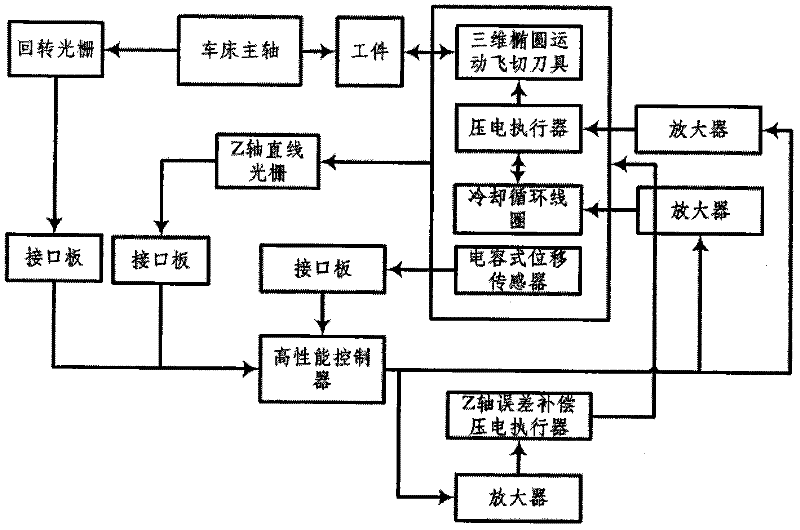

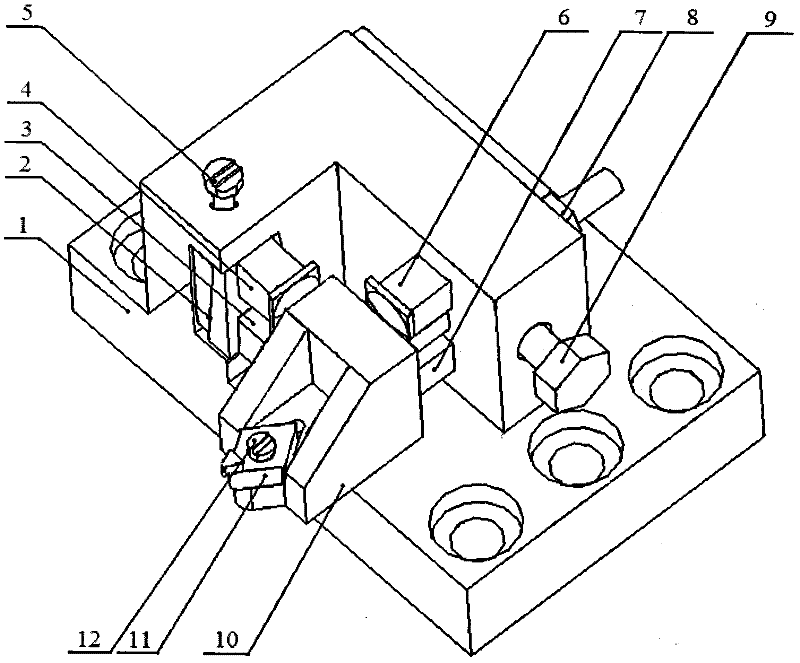

[0029] The transient position (x, y, z) of the workpiece-blade contact point is generated under the joint action of four piezoelectric stacks, each pair of piezoelectric stacks is arranged in parallel, and two pairs of piezoelectric stacks arranged perpendicular to each other. According to formula (1), adjust the initial phases of the drive signals of the four piezoelectric stacks to adjust the phase shift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com