Adhesive film for semiconductor, composite sheet, and method for producing semiconductor chip using them

A manufacturing method and semiconductor technology, which can be used in the manufacture of semiconductor/solid-state devices, semiconductor devices, and thin-film/sheet-like adhesives, etc. Fracture and other problems, to achieve the effect of suppressing chip cracks or burrs, excellent moisture resistance and reliability, and realizing processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

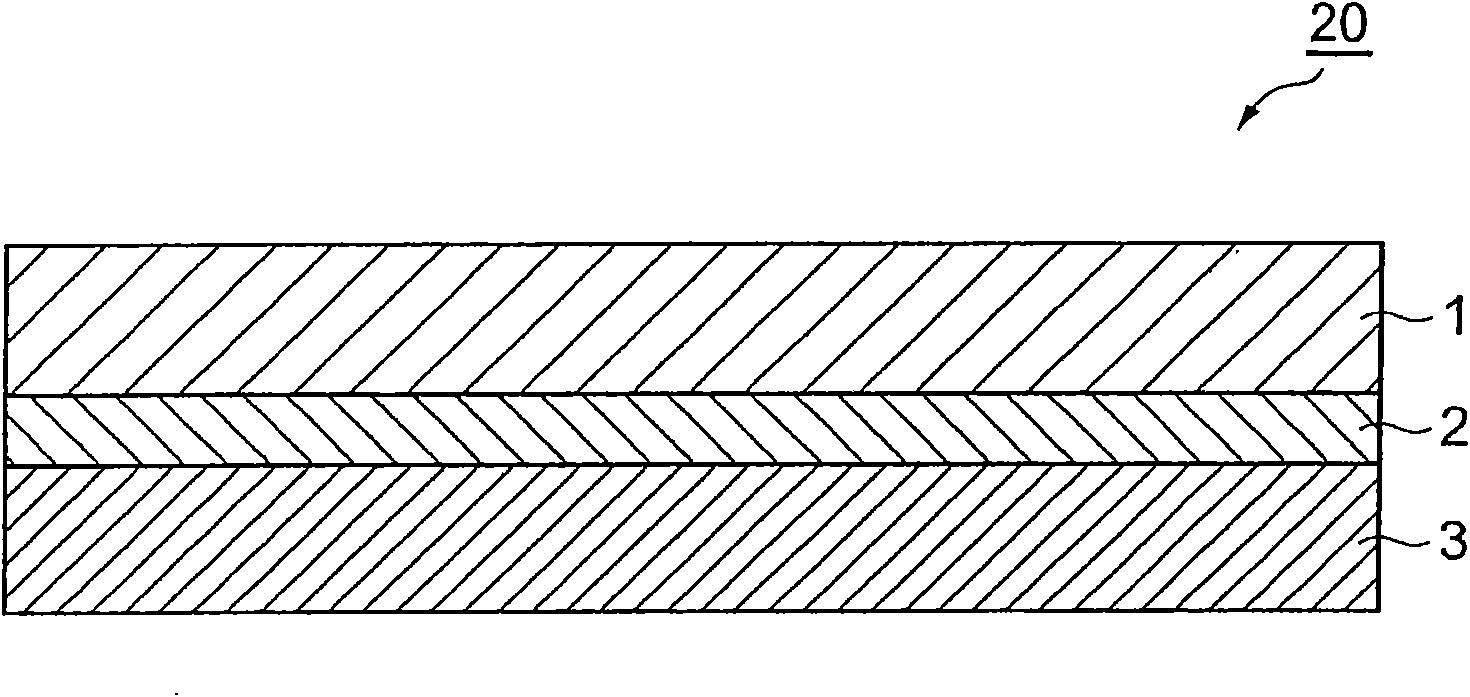

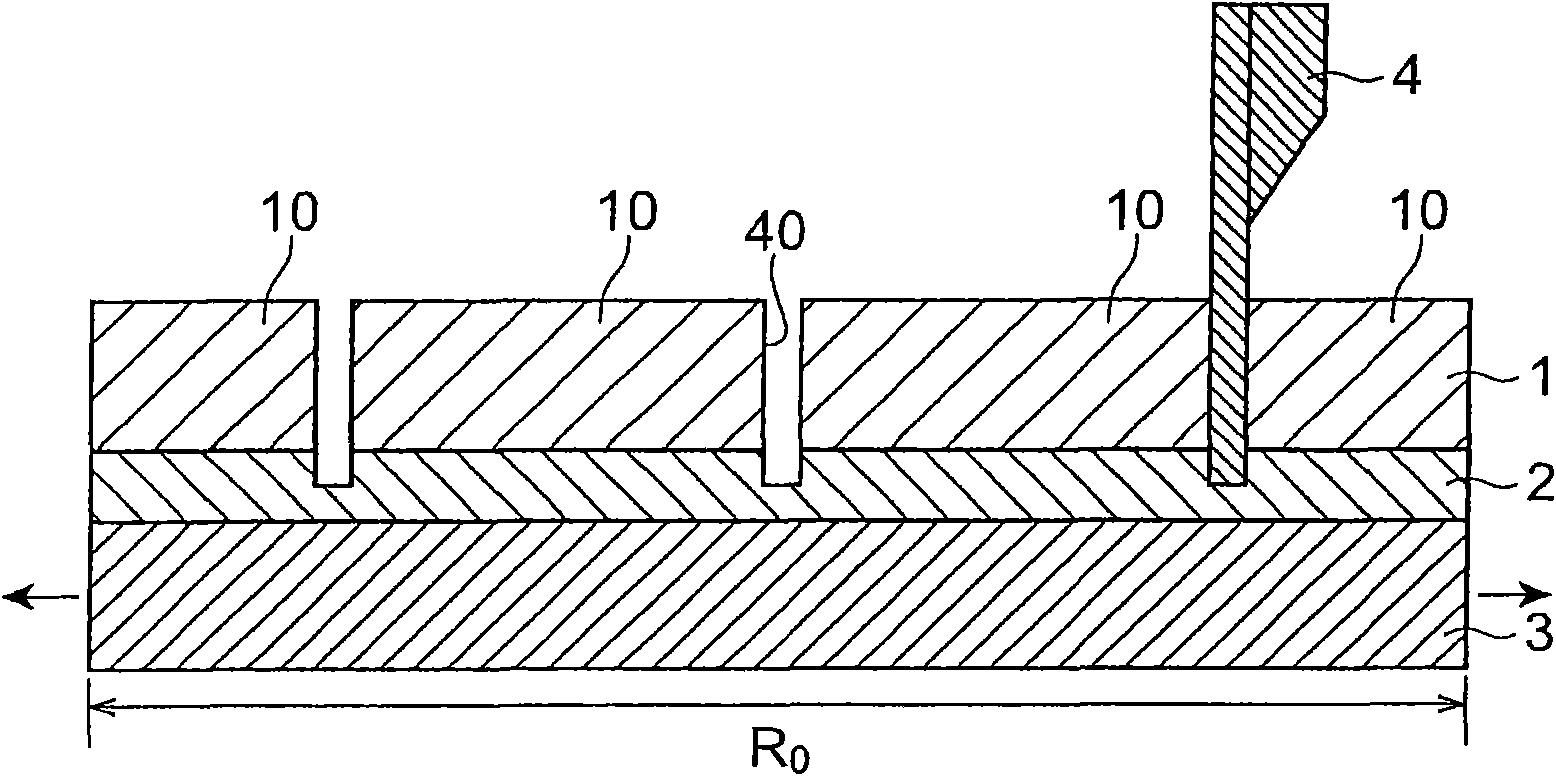

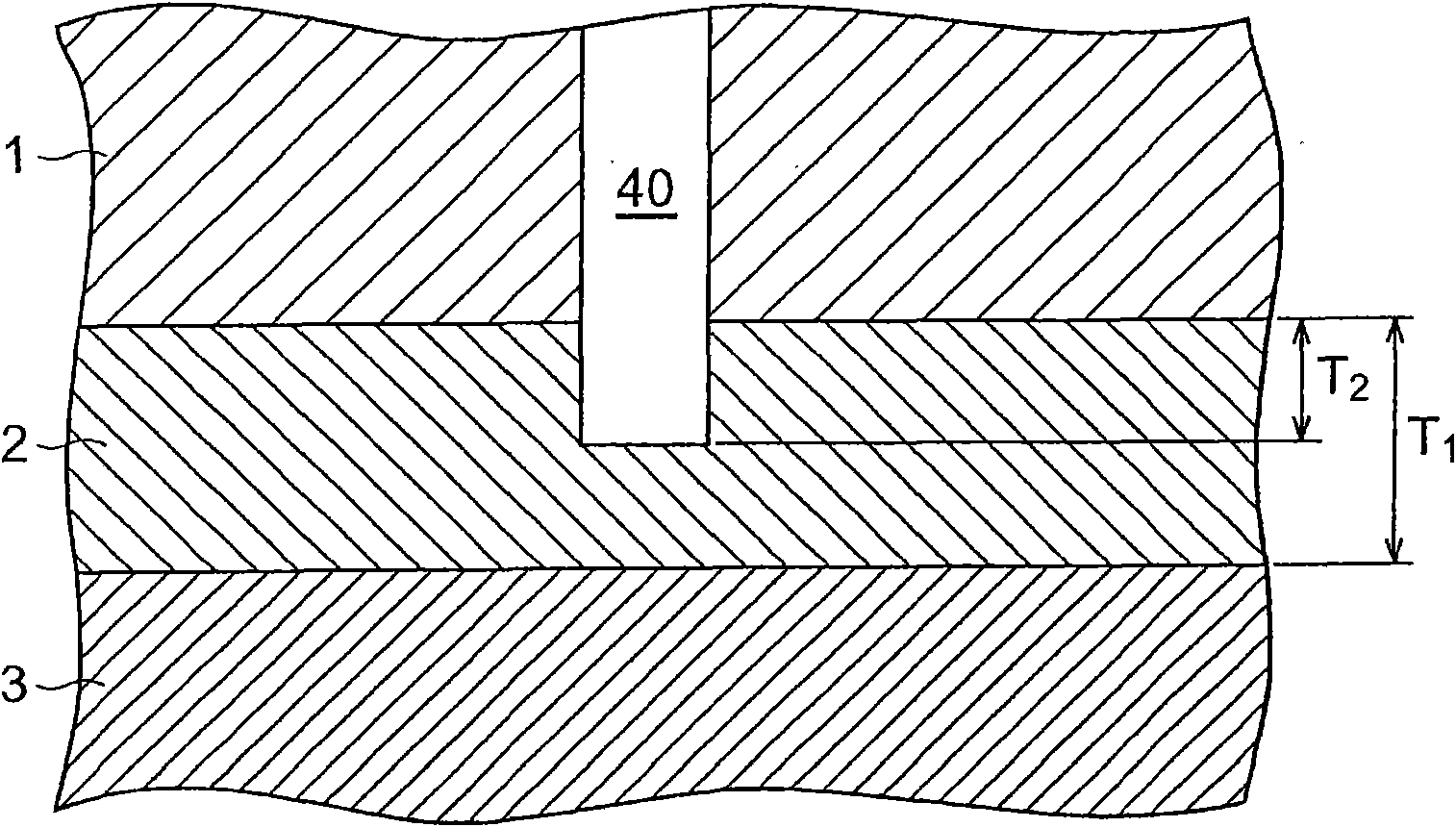

[0103] figure 1 , 2 , 3, 4 and 5 are cross-sectional views showing the method of manufacturing the semiconductor chip according to the first embodiment. The manufacturing method of the semiconductor chip of this embodiment includes: the process of preparing the laminated body 20 which laminated|stacked the semiconductor wafer 1, the adhesive film 2 for semiconductors, and the dicing tape 3 sequentially ( figure 1 ); the process of forming a groove 40 in the stacked body 20 from the semiconductor wafer 1 side ( figure 2 , 3 ); the process of dividing the adhesive film 2 for semiconductors along the slit 40 ( Figure 4 ); the process of picking up the semiconductor chip 10 together with the semiconductor adhesive film 2 ( Figure 5 ). The adhesive film for a semiconductor of the embodiment described above is used as the adhesive film 2 for a semiconductor.

[0104] figure 1 The laminated body 20 of the semiconductor wafer 1 is prepared by the following method, that is, t...

no. 2 approach

[0113] Image 6 , 7 , 8 and 9 are cross-sectional views showing the method of manufacturing the semiconductor chip according to the second embodiment. The method of this embodiment has: the process of preparing the laminated body 20 which laminated|stacked the semiconductor wafer 1, the adhesive film 2 for semiconductors, and the dicing tape 3 sequentially ( Figure 6-8 ); the process of dividing the semiconductor wafer 1 into a plurality of semiconductor chips 10 and dividing the adhesive film 2 for semiconductors by stretching the dicing tape 3 in a direction in which the plurality of semiconductor chips 10 are separated from each other ( Figure 9 ); a step of picking up the semiconductor chip 10 together with the adhesive film 2 for a semiconductor.

[0114] The process of preparing the laminated body 20 includes forming the modified portion 1a inside the semiconductor wafer 1 along the line 50 (hereinafter referred to as "planning line for dividing") that divides the se...

Embodiment 1

[0130] In a 500ml four-neck flask with a thermometer, a stirrer and a calcium chloride tube, add 1,3-bis(3-aminopropyl)tetramethyldisiloxane (0.1mol) as a diamine and as a solvent 150 g of N-methyl-2-pyrrolidone was stirred at 60°C. After dissolving the diamine, add 1,10-(decamethylene)bis(trimellitic dianhydride) (0.02mol) and 4,4'-oxydiphthalic anhydride (0.08mol) little by little , reacted at 60°C for 3 hours. Thereafter, after blowing N 2 While heating at 170° C., water in the system was removed together with a part of the solvent by azeotropy over 3 hours. The NMP solution of the polyimide resin obtained by removing water was used for preparation of an adhesive film.

[0131] In the NMP solution (containing 100 parts by weight of polyimide resin) of the polyimide resin obtained by utilizing the above operation, add 4 parts by weight of cresol novolac epoxy resin (made by Tohto Chemical Industry), 4,4'- [1-[4-[1-(4-Hydroxyphenyl)-1-methylethyl]phenyl]ethylene]bisphenol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com