Sealing composition and semiconductor device

A technology of sealing composition and hydrotalcite compound, which is applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve problems such as residues, and achieve the effect of excellent moisture resistance and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0047] The sealing composition of the first embodiment includes an epoxy resin, a curing agent, an inorganic filler, and an unfired resin having a molar ratio of Mg ions to Al ions (Mg / Al, hereinafter also referred to as Mg / Al ratio) of 2.4 or more. Hydrotalcite compound (hereinafter also referred to as a first hydrotalcite compound). The sealing composition of the first embodiment may contain other components such as a curing accelerator.

[0048] The semiconductor device manufactured using the sealing composition of the first embodiment has excellent moisture resistance reliability in a state where a bias voltage is applied. The reason for this is not clear, but it is considered that the reason is that the Mg / Al ratio of the first hydrotalcite compound contained in the sealing composition of the first embodiment is 2.4 or more, and the hydrotalcite compound is sufficiently maintained without firing. In the layer structure of the hydroxide sheet, a sufficient ion trapping ef...

Embodiment 1A~4A

[0192] (Examples 1A to 4A and Comparative Examples 1A to 4A)

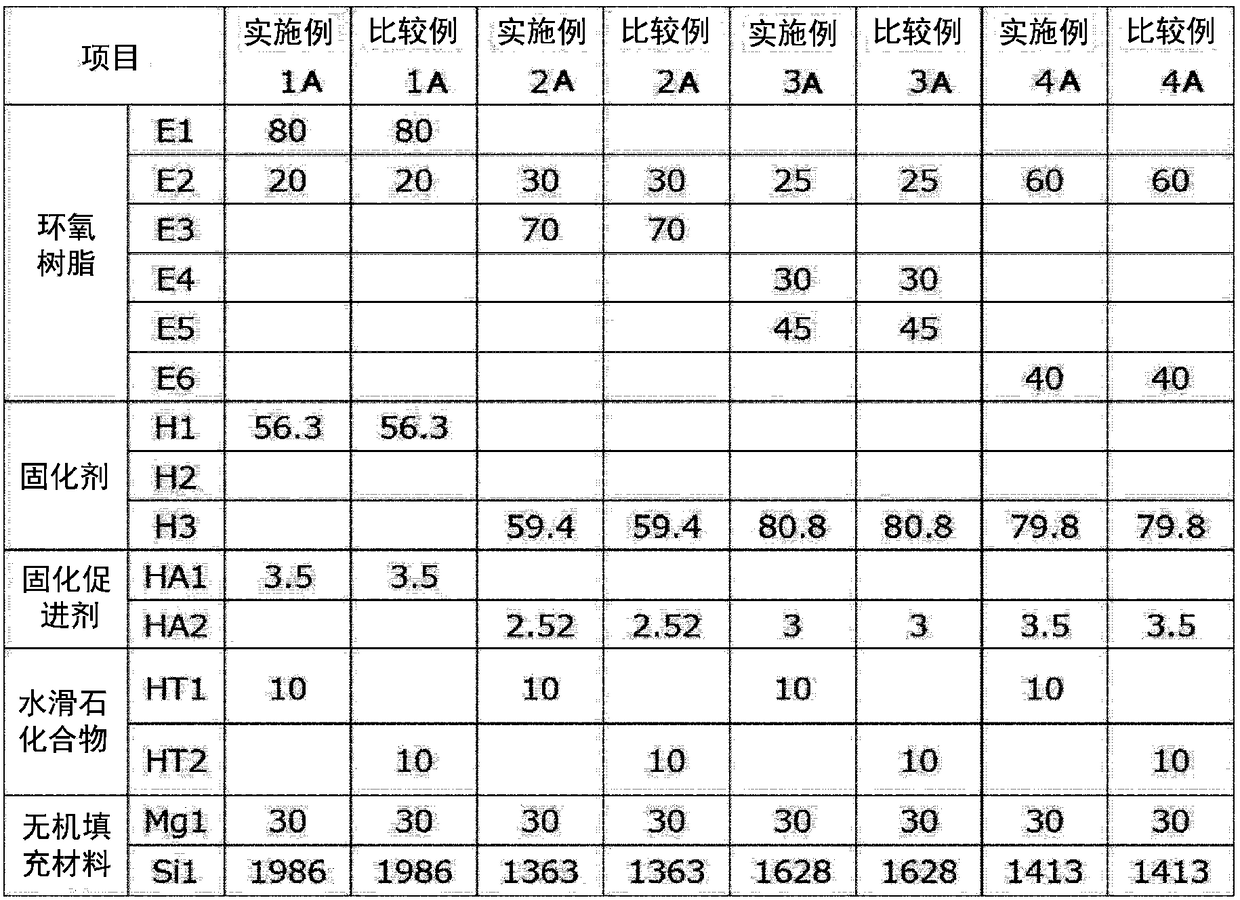

[0193] After pre-mixing (dry blending) the materials shown in Table 1, knead with a twin-axial roller (roller surface temperature: about 80°C) for about 15 minutes, cool and pulverize, and make a powder-like sealing combination thing.

[0194] About Example 1A and Comparative Example 1A, Example 2A and Comparative Example 2A, Example 3A and Comparative Example 3A, and Example 4A and Comparative Example 4A, the composition was the same except that the type of hydrotalcite was changed.

[0195] [Table 1]

[0196]

[0197] The details of the materials in Table 1 are as follows.

[0198] (epoxy resin)

[0199] E1: YSLV-80XY, trade name of Nippon Steel & Sumikin Chemical Co., Ltd.

[0200] E2: YX-4000, oil shell epoxy (Co., Ltd.) trade name

[0201] E3: HP-5000, DIC (Co., Ltd.) trade name

[0202] E4: CER-3000L, trade name of Nippon Kayaku Co., Ltd.

[0203] E5: YSLV-120TE, trade name of Nippon Steel & Sumikin...

Embodiment 5A、6A and comparative example 5-1A~5-3A

[0225] In the same manner as in the above-mentioned examples, a powdery sealing composition and a test piece were prepared using the blended materials shown in Table 3, and a HAST test was performed.

[0226] In Examples 5A and 6A and Comparative Examples 5-1A to 5-3A, unfired hydrotalcite compounds were used. In addition, in Examples 5A and 6A, hydrotalcite compounds having a Mg / Al ratio of 2.4 or more were used, and in Comparative Examples 5-1A to 5-3A, hydrotalcite compounds having a Mg / Al ratio of less than 2.4 were used.

[0227] [table 3]

[0228]

[0229] The details of the materials in Table 3 are as follows.

[0230] E1: YSLV-80XY, trade name of Nippon Steel & Sumikin Chemical Co., Ltd.

[0231] E2: YX-4000, oil shell epoxy (Co., Ltd.) trade name

[0232] H1: HE910, Air water Co., Ltd. product name

[0233] H2: HE200C, Air water Co., Ltd. product name

[0234] HA1: Triphenylphosphine

[0235] HT1: Mg / Al≈3.0, unfired form

[0236] HT3: Mg / Al≈0.6, unfired form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com